Britflex BEJ Expansion Joints - StonCor Africa

Britflex BEJ Expansion Joints - StonCor Africa

Britflex BEJ Expansion Joints - StonCor Africa

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

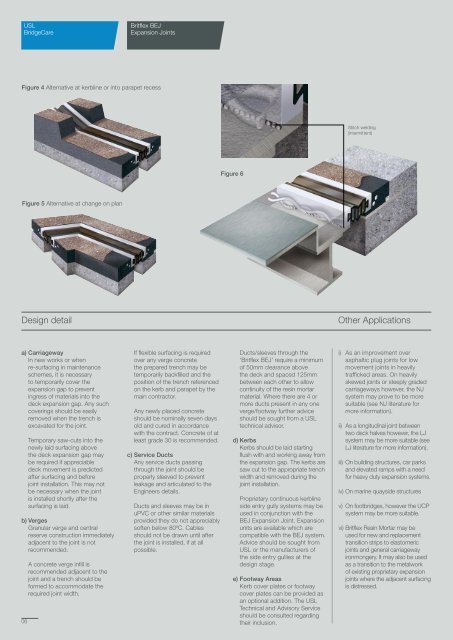

USLBridgeCare<strong>Britflex</strong> <strong>BEJ</strong><strong>Expansion</strong> <strong>Joints</strong>Figure 4 Alternative at kerbline or into parapet recessStitch welding(intermittent)Figure 6Figure 5 Alternative at change on planDesign detailOther Applicationsa) CarriagewayIn new works or whenre-surfacing in maintenanceschemes, it is necessaryto temporarily cover theexpansion gap to preventingress of materials into thedeck expansion gap. Any suchcoverings should be easilyremoved when the trench isexcavated for the joint.Temporary saw-cuts into thenewly laid surfacing abovethe deck expansion gap maybe required if appreciabledeck movement is predictedafter surfacing and beforejoint installation. This may notbe necessary when the jointis installed shortly after thesurfacing is laid.b) VergesGranular verge and centralreserve construction immediatelyadjacent to the joint is notrecommended.06A concrete verge infill isrecommended adjacent to thejoint and a trench should beformed to accommodate therequired joint width.If flexible surfacing is requiredover any verge concretethe prepared trench may betemporarily backfilled and theposition of the trench referencedon the kerb and parapet by themain contractor.Any newly placed concreteshould be nominally seven daysold and cured in accordancewith the contract. Concrete of atleast grade 30 is recommended.c) Service DuctsAny service ducts passingthrough the joint should beproperly sleeved to preventleakage and articulated to theEngineers details.Ducts and sleeves may be inuPVC or other similar materialsprovided they do not appreciablysoften below 80ºC. Cablesshould not be drawn until afterthe joint is installed, if at allpossible.Ducts/sleeves through the‘<strong>Britflex</strong> <strong>BEJ</strong>’ require a minimumof 50mm clearance abovethe deck and spaced 125mmbetween each other to allowcontinuity of the resin mortarmaterial. Where there are 4 ormore ducts present in any oneverge/footway further adviceshould be sought from a USLtechnical advisor.d) KerbsKerbs should be laid startingflush with and working away fromthe expansion gap. The kerbs aresaw cut to the appropriate trenchwidth and removed during thejoint installation.Proprietary continuous kerblineside entry gully systems may beused in conjunction with the<strong>BEJ</strong> <strong>Expansion</strong> Joint. <strong>Expansion</strong>units are available which arecompatible with the <strong>BEJ</strong> system.Advice should be sought fromUSL or the manufacturers ofthe side entry gullies at thedesign stage.e) Footway AreasKerb cover plates or footwaycover plates can be provided asan optional addition. The USLTechnical and Advisory Serviceshould be consulted regardingtheir inclusion.i) As an improvement overasphaltic plug joints for lowmovement joints in heavilytrafficked areas. On heavilyskewed joints or steeply gradedcarriageways however, the NJsystem may prove to be moresuitable (see NJ literature formore information).ii) As a longitudinal joint betweentwo deck halves however, the LJsystem may be more suitable (seeLJ literature for more information).iii) On building structures, car parksand elevated ramps with a needfor heavy duty expansion systems.iv) On marine quayside structuresv) On footbridges, however the UCPsystem may be more suitable.vi) <strong>Britflex</strong> Resin Mortar may beused for new and replacementtransition strips to elastomericjoints and general carriagewayironmongery. It may also be usedas a transition to the metalworkof existing proprietary expansionjoints where the adjacent surfacingis distressed.