download - andritz business areas

download - andritz business areas

download - andritz business areas

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

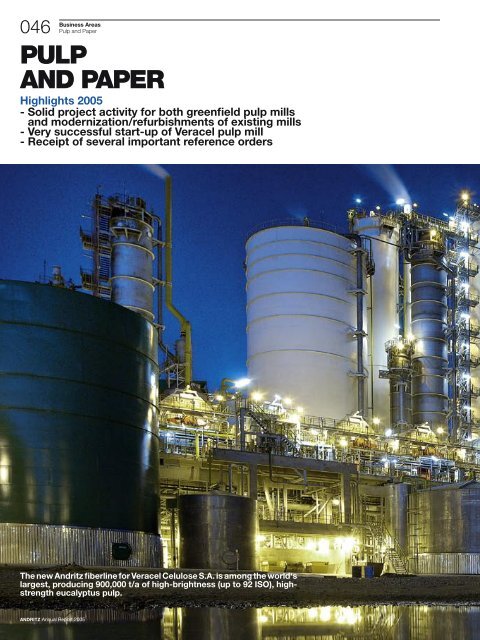

046Business AreasPulp and PaperPULPAND PAPERHighlights 2005- Solid project activity for both greenfield pulp millsand modernization/refurbishments of existing mills- Very successful start-up of Veracel pulp mill- Receipt of several important reference ordersThe new Andritz fiberline for Veracel Celulose S.A. is among the world‘slargest, producing 900,000 t/a of high-brightness (up to 92 ISO), highstrengtheucalyptus pulp.ANDRITZ Annual Report 2005

052Business AreasPulp and PaperAspen trees are the raw material for the Estonian Cell pulp mill.All state-owned forests in Estonia have been certified by the ForestryStewardship Council (FSC) since 2002.Andritz supplied the technology and process equipment for themechanical pulp mill of Estonian Cell. The photo shows the 90 m chipconveyor bridge from the chip silo to the process building.ANDRITZ Annual Report 2005

054Business AreasPulp and PaperResearchand DevelopmentThe Divisions have focused their R&D programs primarilyon improving fiber quality while lowering investment, operatingand maintenance costs, and also reducing environmentalimpact of the equipment and processes.The trend today is towards large, single-line mills, sinceredundant or repetitive smaller systems increase bothcapital and operating costs. This places extreme demandson the equipment in terms of scale, reliability, andavailability. All Andritz Divisions are actively developinglarger scale equipment.The Divisions’ R&D programsin detail are as follows:Wood ProcessingThe main focus was on large-scale field-testing new developmentsat customer locations. The new chip samplingsystem was started up and automatically producedrepresentative chip samples for the analyzer. This provideschip quality information for use by pulp mill operators.Full-scale tests of debarking behavior of tropical hardwoodswere carried out in southern Europe. The testsgenerated important information about the correct debarkingparameters. Tests of a new method for removingloose bark from hardwoods were successful. In NorthAmerica, a new monitoring and diagnostics package forportal cranes, which will improve the overall efficiency ofthe equipment, was developed.FiberlineDevelopments are continuing in the program to reducecustomers’ overall costs while maintaining equipmentperformance and availability. The adaptation and improvementof process and equipment solutions forsouthern hemisphere applications are also progressing.These developments are not only related to scale-up ofthe production capacity for extremely large mills, butalso to the development of cost-competitive solutionsfor small and medium-size mills.New developments of the Drum Displacer (DD)Washer show remarkable progress with regard to washingefficiency and capacity. The best proof for these improvementsis visible in the start-up curves and chemicalconsumption figures of recent deliveries. The next generationof MC equipment is under intensive developmentwith the goal of system simplification and energysavings.In the area of modeling and simulation development,the first Advanced Control Systems (ACS) were sold toVCP in Brazil and CMPC in Chile to optimize the digesteroperations. Development work continues to include theremaining fiberline process <strong>areas</strong>.RecoveryFurther development of black liquor crystallizing technologyis underway to extend the time between concentratorwashouts and to improve evaporator availability.The first Ash Re-Crystallization (ARC) system for chlorideand potassium removal was successfully commissionedat the Portucel Soporcel Group mill in Portugal. Duringthe start-up, a new computer model for simulating theARC process and leaching processes was tested.Research has been conducted on evaporator materials.Electro-chemical testing of the corrosion resistance ofdifferent materials has been performed in a mill environment.In addition, through heat transfer material research,the Division has found more cost-effective materials forevaporators. Development of manufacturing and weldingprocedures for lamellas is an important part of theresearch. The study is being conducted in cooperationwith technical universities and material producers.Developments for recovery boilers are focused onproducing more power from biofuel (black liquor), whichalso eliminates the release of greenhouse gases intothe atmosphere. A new arrangement of heat transfersurfaces in the upper furnace of the recovery boiler isimplemented in three new recovery boilers now underconstruction. This will enable more effective utilizationof flue gas heat to produce higher pressure steam inthe boiler.Chemical SystemsA new lime kiln burner has been developed, and is nowsuccessfully operating at a mill in Finland. The burnerproduces lower nitrogen oxide levels than existing technology.A centrifuge for green liquor dregs handling is beingmarketed. It offers advantages for mills which carefullymanage non-process element removal in the lime circulation.A new concept for lime mud drying has been developedand a patent has been applied for. The new technologyshould enable customers to increase the capacity of existingkilns with lime mud dryers or reduce the size of anew lime kiln for a given capacity.The first LMD-Filter TM for lime mud dewatering and washinghas exceeded performance expectations. Two unitsare in operation and seven units were sold. Developmentsare continuing to design larger sizes of all majorequipment in the white liquor plant (4,000 t/d pulp productionand 14,000 m 3 /d white liquor production).Pulp Mill ServicesLife cycle management and optimization have been theDivision’s focus <strong>areas</strong> during the last few years.For the woodyard, a service has been developed to optimizechipping operations efficiency and control. The offeringis a combination of equipment (HQ-Plus chipperknife system), service, and automation (Acutest ® conditionmonitoring and the new chip sampler/analyzer).In the chemical recovery area, cast air nozzles, minihoods,and smelt shattering systems in the recoveryboiler improve equipment availability and extend thetime between shutdowns.A new product group, Automation & Diagnostics, isresponsible for developing and managing automationtechnology – including condition monitoring, simulation,process control, and optimization.ANDRITZ Annual Report 2005

Business AreasPulp and Paper055Fiber Preparation SystemsIn the Fiber Preparation Systems Division, Andritz cannow perform full-line production trials and testing forrecycled fiber applications in its Graz pilot plant. Theplant is capable of receiving customer raw materials,processing the fibers (including deinking if necessary),and producing the final pulp. Future research work willconcentrate on different aspects of residuals (sludge/rejects)and water handling technologies to further reduceenvironmental impact.Mechanical PulpingTechnologies and equipment to process alternative rawmaterials (different species of pine, a variety of hardwoods,and annual plants) have been developed.In chemi-mechanical pulping, development has concentratedon mill-scale optimization of the advancedP-RC APMP process. Results that had been achievedin pilot plant work were confirmed or surpassed in actualmill operation.New pre-treatment and high-consistency refining technologieswere developed to allow for the use of alternativewood species in the RTS TMP process. Pulps ofvery high quality have been produced with these processesand specific energy consumption has been reducedby 20–30% compared to standard TMP.Major drivers in equipment development are productivityimprovements and increased production capacities.Following these requirements, new machine sizes withlarger capacities were introduced to the market. Availabilityand ease of maintenance for refiners and dewateringmachines have been improved. New methodsto increase replacement intervals of refiner plates havebeen successfully introduced.Customer requirements include sophisticated processcontrol. The new Andritz Bleach Commander usesmodeling and predictive control strategies to better controlthe bleaching process – minimizing quality deviationsand maximizing the production of “on-grade” pulp.Chemical consumption is optimized to the target brightness,which reduces bleaching costs.Pulp DryingTechnology development in the Pulp Drying Division continuesto focus on lowering the investment cost per tonof pulp produced. The main R&D thrust is to producea single drying line with production of 4,000 t/d basedupon successful Twin Wire Former technology. The relatedspecific design capacity was reached on the Division’sfull-scale pilot machine. In addition, developmentis underway to continually improve the machinery’s uptimethrough easy/fast sheet threading and process conditionmonitoring.A highly sophisticated process simulator for the entiresheet drying line has been developed. This is used foroperator training and DCS checkout prior to start-up.This simulation approach ensures fast production rampupsafter the line is started. The simulator also contributesto continuous optimization of the plant.Work on the new slab press was completed, givingAndritz full-line capabilities for mechanical market pulpmills. The first commercial installations of this press wereat Estonian Cell, Estonia and Phuong Nam, Vietnam.Tissue MachinesFor optimum “hands-on” operator training, the TissueMachines Division developed a tool to provide dynamicsimulation of all mass and energy flows in a tissue orTAD plant. Operators can virtually run the future paperproduction line and change settings in a safe, virtualenvironment.The shoe press technology has been proven in 13 tissuemachine installations around the world. One of its latestfeatures is “machine direction” shoe movement. Thisadditional functionality results in gaining more bulk orachieving higher post-press dryness, giving the operatormore flexibility. Record speeds of over 1,900 m/minhave been achieved with a shoe press.A further development of the reel concentrated on the improvementof the centerwind. A centerwind reel is mainlyused in TAD machines to retain the volume and waterabsorption properties for bulky heavyweight tissue andtowel grades. The new PrimeReel Centerwind controlsvery low nip loads sufficient for crease-free winding.Furthermore, it allows winding of larger diameter rolls toincrease productivity.A stable sheet transfer in the area between the crepingdoctor at the Yankee cylinder and the reel is criticalto runability. The PrimeRun system of sheet transfercomponents ensures better runability, especially withlightweight tissue at high machine speeds.Paper Mill ServicesA new wedge wire basket with the brand name Bar-Tec was successfully introduced, with a focus on optimizationof the screen basket production process andthe application of new profile types and wires to ensurehighest quality and maximum stability.Building on the LemaxX Spiral TM success in Andritz/Durametal’s core Double-Disc refiner plate <strong>business</strong>, thelow consistency product line is now pursuing growthin the conical refiner plate market. The first field trialsof LemaxX Spiral C TM , the latest development for thehigh performance, value-added conical market, haveproved very successful; product launch is expected during2006.Development programs were designed for Bauer DoubleDisc Refiners in order to address the seal and bearingproblems of those machines. They are a guideless andtrammable rebuild kit for the Twin 60 to ensure parallelplate gap over the service life, and a Keraloy hard facingproduct to increase service life of compression plugscrews (MSD, chip press, etc.).The modern Refiner Protection System (RPS) developedfrom Andritz was upgraded with additional security functions.Furthermore, it was improved in a way to enablethe condition monitoring with this system.New SCP wear shoes for both the high pressure andthe low pressure zones were developed, targeting increasedlifetime and thus reducing maintenance costson screw presses. The new wear shoes are available forall Andritz and competition screw presses.ANDRITZ Annual Report 2005