report-2004-en-rolling-mills (382 KB) - andritz business areas

report-2004-en-rolling-mills (382 KB) - andritz business areas

report-2004-en-rolling-mills (382 KB) - andritz business areas

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

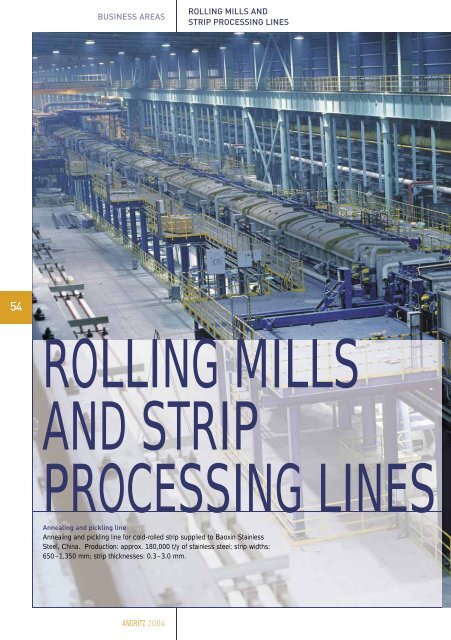

BUSINESS AREASROLLING MILLS ANDSTRIP PROCESSING LINESLEITER DES GESCHÄFTSBEREICHS54ROLLING MILLSAND STRIPPROCESSING LINESAnnealing and pickling lineAnnealing and pickling line for cold-rolled strip supplied to Baoxin StainlessSteel, China. Production: approx. 180,000 t/y of stainless steel; strip widths:650–1,350 mm; strip thicknesses: 0.3–3.0 mm.ANDRITZ <strong>2004</strong>

ROLLING MILLS ANDSTRIP PROCESSING LINESBUSINESS AREASBUSINESS AREA MANAGERPeter GravertVi<strong>en</strong>na, Austria55ANDRITZ <strong>2004</strong>

BUSINESS AREASROLLING MILLS ANDSTRIP PROCESSING LINES56PROFILE> The Rolling Mills and Strip ProcessingLines Business Area designs and buildscomplete lines for the production andfurther processing of cold-rolled stainlesssteel, carbon steel, and non-ferrousmetals. These lines consist of equipm<strong>en</strong>tfor cold-<strong>rolling</strong>, surface treatm<strong>en</strong>t,strip coating and finishing, stamping anddeep drawing, and acid reg<strong>en</strong>eration.The expertise and key equipm<strong>en</strong>t aredeveloped in-house and manufactured atthe Business Area’s own facilities.The Andritz Group is the only singlesourcesupplier capable of providing alltechnologies and processes involvedin the manufacturing of stainless steelstrip (cold <strong>rolling</strong>, annealing, pickling,and finishing) on a compreh<strong>en</strong>sive basis(mechanical, process, and electricalequipm<strong>en</strong>t). This <strong>en</strong>sures minimizedinterfaces and takes the interdep<strong>en</strong>d<strong>en</strong>ciesof the overall process into consideration.The assets of Otto Kaiser GmbH,acquired in <strong>2004</strong> and now called “AndritzKaiser”, <strong>en</strong>able the Business Area toext<strong>en</strong>d its range of equipm<strong>en</strong>t for the“downstream” area of strip finishing.The products and technology portfolioof Andritz Kaiser are a valuable supplem<strong>en</strong>tto the existing product range andstr<strong>en</strong>gth<strong>en</strong> the Business Area’s strategicfocus on value-added steel strip production.Market developm<strong>en</strong>tThe year <strong>2004</strong> was characterized by continuedhigh demand for steel and stainless steel products,mainly as a result of strong demand from China.World consumption of finished steel has ris<strong>en</strong> by7.7% to approximately 950 million tons in <strong>2004</strong>.The stainless steel market developed likewise,with global consumption of stainless steel growingby 7% to approximately 24 million tons in <strong>2004</strong>.China continued to lead the growth of global(stainless) steel consumption and production.Prices for cold-rolled steel and stainless steelproducts increased steadily during the <strong>report</strong>ingperiod and remained at a very high level until the<strong>en</strong>d of the year. Capacity utilization was at a veryhigh level throughout the whole year ev<strong>en</strong> thoughcapacities increased quite steeply.Project activity was almost solely conc<strong>en</strong>tratedon China (including Taiwanese, Korean, andEuropean investm<strong>en</strong>ts in China), where severallarge projects, especially in stainless steel, weredecided. Andritz was able to secure a large shareof orders for stainless steel plants, thus confirmingits leading market position in this area. In NorthAmerica and Europe, only selective investm<strong>en</strong>tswere made.The measures of the Chinese governm<strong>en</strong>t toslow down over-investm<strong>en</strong>t in some industries likecem<strong>en</strong>t or steel led to a delay of some projectsfrom new private companies. However, projectsof established steel producers continued asplanned.Sources: ISSF, IISIThe Rolling Mills and Strip ProcessingLines Business Area operates throughthe following companies: Andritz AG,Austria; Andritz-Ruthner, Inc., USA;Thermtec B.V., Netherlands; SundwigGmbH, Germany; Andritz Selas S.A.S.,France; Andritz Technologies Pvt.Ltd., India; and Andritz Kaiser GmbH,Germany. There are manufacturing andassembly facilities in Graz, Austria, andHemer and Brett<strong>en</strong>, both in Germany.Business developm<strong>en</strong>tSales of the Rolling Mills and Strip ProcessingLines Business Area in <strong>2004</strong> increased significantly.At 235.4 MEUR, Sales surged by 36.0%compared to 2003 (173.1 MEUR). This favorabledevelopm<strong>en</strong>t is mainly due to the execution of therecord Order Backlog as of the <strong>en</strong>d of 2003.EBITA also developed very favorably in <strong>2004</strong>.At 12.1 MEUR, it almost tripled compared to2003 (4.4 MEUR), which was affected by a tem-ANDRITZ <strong>2004</strong>

ROLLING MILLS ANDSTRIP PROCESSING LINESBUSINESS AREASporary capacity under-utilization in one of theBusiness Area’s product segm<strong>en</strong>ts. Profitabilityalso showed a positive developm<strong>en</strong>t, with EBITAmargin increasing to 5.1% in <strong>2004</strong> (2003: 2.5%).The Business Area’s Order Intake in <strong>2004</strong> was266.7 MEUR, a decrease of 7.3% compared tothe record level achieved in 2003 (287.6 MEUR).However, several orders were announced in theThird Quarter <strong>2004</strong> which will become effectivein the First Quarter 2005. The main portion ofthe Order Intake came from China, amounting toapproximately 71% of the Business Area’s totalOrder Intake in <strong>2004</strong>.Major orders• Chinese Taigang Group placed an order to supplythe world´s largest annealing and picklingline for cold-rolled stainless steel strip. Theplant will have an annual capacity of 500,000tons and will be installed at Taiyuan Iron andSteel Co. Ltd., Taiyuan Shanxi, China. With thisorder, Andritz further str<strong>en</strong>gth<strong>en</strong>s its positionas a leading technology supplier for completestainless steel processing lines. In addition,several orders for strip processing lines (t<strong>en</strong>sionlevelers, recoiling lines), including mechanicaland electrical equipm<strong>en</strong>t, were obtained.• SeAH Steel Group, Seoul, South Korea ordereda 6-high cold-<strong>rolling</strong> mill which will be deliveredin spring 2005. This mill will roll carbon steelup to 1,360 mm width at a maximum speed of1,400 m/min. The line is equipped with a POS(Process Optimization System).• The Business Area will supply two sophisticatedinspection lines for steel strip for automotiveapplications to Wuhan Iron & Steel (Group)Corporation, Changqian, Quingshang, Wuhan,China. In addition, Andritz received an orderfrom this customer to supply a very specialhydrochloric acid reg<strong>en</strong>eration plant with a twinreactor design, with a total capacity of 15,000 l/h.• Hunan Valin Iron & Steel Group of the Hunanprovince in China ordered an hydrochloric acidreg<strong>en</strong>eration plant with waste acid purificationand silicon pre-sedim<strong>en</strong>tation. Capacity of thisplant is 10,000 l/h.• The Business Area received an order fromShanghai Krupp Stainless (SKS), a joint v<strong>en</strong>tureof Thyss<strong>en</strong> Krupp Stainless and ShanghaiPudong Iron & Steel Company Ltd. (subsidiaryof Baosteel Group), to supply a hot-stripannealing and pickling line for stainless steel57KEY FIGURES ROLLING MILLS/STRIP PROCESSING LINESMEUR <strong>2004</strong> 2003 2002 2001Sales 235.4 173.1 177.4 167.4Order Intake 266.7 287.6 175.7 196.3Order Backlog as of 31.12. 293.1 265.4 154.0 159.2EBITDA 14.3 6.6 11.1 8.7EBITDA margin 6.1% 3.8% 6.3% 5.2%EBITA 12.1 4.4 8.5 6.1EBITA margin 5.1% 2.5% 4.8% 3.7%Capital investm<strong>en</strong>ts 3.2 1.4 1.6 3.4Employees as of 31.12. 736 533 642 562ANDRITZ <strong>2004</strong>

BUSINESS AREASROLLING MILLS ANDSTRIP PROCESSING LINES58strip. The line will have an annual productioncapacity of approximately 440,000 tons.Equipm<strong>en</strong>t delivery is scheduled for the <strong>en</strong>d of2005 and production of the first strip is plannedfor the summer of 2006.• Andritz also received a large follow-up orderfrom Lianzhong Stainless Steel, a member ofTaiwanese Yieh Group, for the ext<strong>en</strong>sion of th<strong>en</strong>ew stainless steel mill in Guangzhou, China.In 2003, Andritz had received an order to buildthe world’s largest stainless steel hot stripannealing and pickling line for the same customerand that project is curr<strong>en</strong>tly underway.The rec<strong>en</strong>t order relates to a stainless steelcold strip annealing and pickling line with acapacity of approximately 250,000 t/y. Deliveryis scheduled for August 2005, with productionof the first strip expected in July 2006. Inorder to reg<strong>en</strong>erate the waste mixed acids ofthese lines, the customer additionally ordereda Pyromars plant, which will recover nitric acidand fluoric acid.• For the automotive plant joint v<strong>en</strong>ture of Mazdain China on the island of Hainan, Andritzreceived the first cut-to-l<strong>en</strong>gth line which willbe implem<strong>en</strong>ted together with Jier Company, aChinese press manufacturer.• JISCO, a steel company in the northwesternChinese province Gansu, signed a contractwith Andritz for the supply of a complete stainlesssteel strip manufacturing plant, consistingof several <strong>rolling</strong> <strong>mills</strong>, two pickling andannealing lines, and several slitting, cutting andprocessing lines. The contract was split up inan <strong>en</strong>gineering part which came into force inDecember. The supply contract for the equipm<strong>en</strong>twill probably follow in 2005, after receivingall necessary approvals from the Chineseauthorities.Research and Developm<strong>en</strong>tIn <strong>2004</strong>, R&D activities focused on productimprovem<strong>en</strong>ts to further str<strong>en</strong>gth<strong>en</strong> the competitiveadvantage of processes offered to customers.The mixed acid recovery system has be<strong>en</strong> optimizedto increase the nitric-acid recovery rate, aswell as the water balance betwe<strong>en</strong> stainless steelpickling lines and acid recovery plants.A previously started project on alternative corrosion-resistantcoatings has be<strong>en</strong> continued, withspecial focus on zinc/chromium- and zinc/magnesium-coatingsto reduce the zinc-layer thicknessfor improved laser weldability in the automotiveindustry.Implem<strong>en</strong>tation of the IDEAS simulation softwarewas successfully started by creating a static massbalance model of the acid recovery plant.The filter systems for 20-high <strong>rolling</strong> <strong>mills</strong> havebe<strong>en</strong> further improved and are now offered asstandardized product. The roll and strip coolingsystems of 4-high and 6-high <strong>rolling</strong> <strong>mills</strong> havebe<strong>en</strong> optimized for improved flatness of the producedstrip.New advanced coater technology has be<strong>en</strong> successfullyinstalled and commissioned for a line ofthe Austrian steel producer voestalpine. With thistechnology, Andritz once again underscores itsleading position in high-precision color coating.ANDRITZ <strong>2004</strong>

ROLLING MILLS ANDSTRIP PROCESSING LINESBUSINESS AREAS59Annealing and pickling line/FurnaceThis furnace supplied by Andritz affiliate Thermtec is part of the annealing and pickling line for cold-rolled strip deliveredto Shanghai Krupp Stainless Steel, China. Production: approx. 290,000 t/y of stainless steel; strip widths: 800–1,340mm; strip thicknesses: 0.3–3.0 mm.ANDRITZ <strong>2004</strong>