Quality Control & Six Sigma - ESD

Quality Control & Six Sigma - ESD

Quality Control & Six Sigma - ESD

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

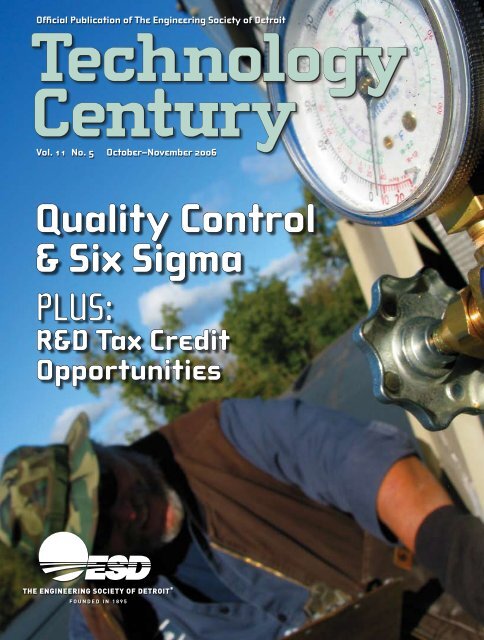

OCT–NOV 200620Official Publication of The Engineering Society of DetroitTechnologyCenturyVol. 11 No. 5 October–November 2006Departments02 PUBLICATION NOTES03 President’s Message04 LETTERS05 IN THE NEWS08 <strong>ESD</strong> Membership10 SUSTAINING & Corporate MEMBERS12 In Memoriam14 <strong>ESD</strong> EVENT HIGHLIGHTS14 <strong>ESD</strong> Upcoming Events18 <strong>ESD</strong> AFFILIATE COUNCIL19 Volunteer Opportunity44 Column: Working World 101SpeciaLS20 What’s Happening at Michigan UniversitiesFeatures23 by Kai Yang<strong>Six</strong> <strong>Sigma</strong> in a Nutshell25 By Antje Lembcke and Hans-Juergen KiesowSustaining Success28 BY Maria StaabDoes <strong>Six</strong> <strong>Sigma</strong> Apply toNonmanufacturing Enterprises?33 BY Norma S. SimonsCustomized Solutions forPerformance Improvement37 BY Judson B. EstesBlack Belt Development at DCX40 BY Andy WalkerR&D Tax Credit Opportunitieswww.esd.org | The Engineering Society of Detroit |

Technology CenturyVol. 11 No. 5 October–November 20062000 Town Center, Suite 2610 • Southfield, MI 48075-1307248–353–0735 • 248–353–0736 fax • esd@esd.org • www.esd.org<strong>ESD</strong> Publications CommitteeChair: Ralph H. Kummler, PhD, F<strong>ESD</strong>, Wayne State UniversityMichael F. Cooper, PE, Harley Ellis DevereauxUtpal Dutta, PhD, University of Detroit–MercyChristopher D. Dyrda, DaimlerChrysler CorporationWilliam A. Moylan, PhD, PMP, F<strong>ESD</strong>, Eastern Michigan UniversityJohn G. Petty, F<strong>ESD</strong>, General DynamicsCharles L. Wu, PhD, F<strong>ESD</strong>, Ford Motor CompanyYang Zhao, PhD, Wayne State UniversityStaff Liaison: Dale Thomas, The Engineering Society of Detroit<strong>ESD</strong> Board of DirectorsPresident: David S. Meynell, Dürr Systems, Inc.PRESIDENT-ELECT: Richard J. Haller, Walbridge Aldinger Co.Vice President: David A. Skiven, PE, General Motors CorporationTreasurer: Steven E. Kurmas, PE, Detroit EdisonSecretary: Darlene Trudell, CAE, The Engineering Society of DetroitPast President: Donald E. Goodwin, DaimlerChrysler CorporationMembers at large: Katherine Banicki, Testing Engineers and ConsultantsDennis M. King, FAIA, F<strong>ESD</strong>, Harley Ellis DevereauxMary Kramer, Crain’s Detroit BusinessThomas H. Landry, Jonna Construction CompanyMichael Morrison, Perot SystemsDavid C. Munson, Jr., PhD, University of MichiganDouglas Patton, DENSO International America, Inc.Richard F. Pearson, National Center for Manufacturing SciencesYogendra N. Rahangdale, American Axle and ManufacturingWilliam P. Russo, Ford Motor CompanyPaul T. Sgriccia, PE, Golder Associates Inc.Rebecca M. Spearot, PhD, PEMumtaz A. Usmen, PhD, PE, F<strong>ESD</strong>, Wayne State UniversityLewis N. Walker, PhD, PE, Lawrence Technological UniversityTechnology Century StaffPublisher: Darlene Trudell, CAE, <strong>ESD</strong> Executive Vice PresidentPub. Coordinator: Dale Thomas, <strong>ESD</strong> Managing Director of Marketing and CommunicationCreative DirECTOR: Nick Mason, <strong>ESD</strong> Creative Director and IT Systems DirectorEDITOR: Susan C. McCravenSTAFF: CeAnne LeonardTechnology Century (ISSN 1091-4153 USPS 155-460) is published six times per year by The Engineering Society of Detroit (<strong>ESD</strong>),2000 Town Center, Suite 2610, Southfield, MI 48075. Subscriptions are free to <strong>ESD</strong> members. Nonmembers may subscribe for$175 per year by contacting <strong>ESD</strong> at 248–353–0735. Periodical postage paid at Southfield, MI, and at additional mailing offices.POSTMASTER: Send address changes to <strong>ESD</strong>, 2000 Town Center, Suite 2610, Southfield, MI 48075.The authors, editors and publisher will not accept any legal responsibility for any errors or omissions that may be madein this publication. The publisher makes no warranty, express or implied, with respect to the material contained herein.Advertisements in Technology Century for products, services, courses and symposia are published with a caveat emptor (buyerbeware) understanding. The authors, editors and publisher do not imply endorsement of products, nor quality, validity orapproval of the educational material offered by such advertisements. ©2006 The Engineering Society of DetroitPublicationNOT<strong>ESD</strong>r. Ralph H.Kummler, F<strong>ESD</strong><strong>ESD</strong> PublicationsCommittee Chair;Dean, College ofEngineering, WayneState UniversityIt has been a source of pride for theengineering profession of Michigan to seethe quality ratings of our United Statesautomotive products climb into the toptier once again. Our companies have madequality a top priority and it shows. Hencewe felt that the theme of this issue should bequality management and one of the primarytools of that trade, <strong>Six</strong> <strong>Sigma</strong>. In the pages tofollow, we go from pedagogical strategy toreal-world examples.We begin with the fundamentals, called<strong>Six</strong> <strong>Sigma</strong> in a Nutshell, by Professor ofIndustrial and Manufacturing EngineeringKai Yang, from Wayne State University, whohas written two books on the subject. Then,we have articles from Simons-White, a <strong>Six</strong><strong>Sigma</strong> Training and Consulting Company,the Ford Motor Company and Siemens, alllooking at the application of <strong>Six</strong> <strong>Sigma</strong> in theirquality management efforts, so that you cangain an appreciation for how <strong>Six</strong> <strong>Sigma</strong> can beused to improve our manufacturing quality.Next, we have a historical perspectiveof the Black Belt development at theDaimlerChrysler Corporation, and then,in a continuing effort to let you know whatyour local universities are doing in the themearea, we have a spread giving each universitythe opportunity to brag a bit about what itprovides in quality management.In case quality management is not yourthing (don’t admit this publicly), we includean article on R&D tax credits by Monetek,a tax credit consulting company, and MikeCooper’s column giving advice to ouryounger members. This is a jam-packed issueillustrating the talent in <strong>ESD</strong>, so enjoy! | Technology Century | OCTOBER–NOVEMBER 2006

<strong>ESD</strong> PRESIDENT’s MESSAGE | October–November 2006Importance of Mentoring Young Engineershen successfulpeople are interviewedabouttheir careers, theyare usually asked,“Who has been themost influentialperson in your life?”Besides the obligatory mention of one’sfamily, successful professional peopleusually respond by naming an influentialmentor who helped shape their earlycareer and helped them over rough spots.How valuable is mentoring for a recentengineering graduate just beginningworking life?In a new upcoming feature onyoung engineers in Technology Century,recipients of <strong>ESD</strong>’s Outstanding YoungEngineer Award verify the importanceof mentoring in their careers. Mentoringcan mean the difference between successand mediocrity, or even the loss of apotentially talented engineer fromthe profession. It is the responsibilityof all of us to take mentoring of newengineering and technical employeesvery seriously. Experience has shownthat placing a young engineer underthe wing of an experienced and encouragingmentor results in the acceleratedprogress and development of newtechnical employees.Those of us with many years ofprofessional experience can easilyremember how much we felt we knewat the completion of four rigorous yearsof engineering classes—and how littlewe realized we knew once we steppedinto the realities of the working world.The outstanding engineering curriculaat our state universities (see “What’sHappening at Michigan Universities”on page 20) provides studentswith excellent knowledge in variousengineering disciplines and of othersubjects through elective courses, butwhat course covers a sensible scenarioin how to deal with a contentiouspersonal situation on a constructionsite or in an industrial plant? Right outof college, most engineering graduateshave little experience in the practicalimportance of company culture, turfwarfare, chain-of-command, managementdemands, office politics and the“Dilbert” view of “how things arereally done around here.”<strong>ESD</strong> offers a wonderful opportunityto inspire students by becominginvolved as an engineering mentorand technical advisor in its MichiganRegional Future City Competition heldin January. In this very successful teambasedprogram consisting of 7th and 8thgrade students, a teacher, and an engineermentor, the competition challengesstudents to design a fully functioningcity. You, too, can join <strong>ESD</strong> and otherengineers in helping students learnfirsthand how engineers turn ideas intoreality. More important, as a mentor,you can have a real impact in fostering ayoung person’s interest in math, scienceand engineering.I believe that newly hired youngengineers should be introduced to adesignated company mentor as a matterof corporate policy. Moreover, a recentissue of The Business Journal indicatedthat minority groups are unlikely toreach success at the corporate levelwithout significant mentoring at thebeginning, and consistently throughout,their careers.Experts generally agree thatmentoring has been found to be atwo-way street, where the young engineergains confidence and a sense ofbelonging, and the company mentorfinds his or her supporting role offersprofound personal and professionalsatisfaction in helping a young personfind success.Take a few minutes to reflect on yourown career, and recall those individualswho have guided you along the way…you’ll be surprised.Sincerely,David S. MeynellPresident, <strong>ESD</strong> Board of DirectorsPresident and CEO, DÜrr Systems, Inc.www.esd.org | The Engineering Society of Detroit |

LETTERSWhat’s Happening atMichigan UniversitiesI am a graduate of Michigan Technological University,and I am disappointed that MTU was notincluded in the summary of “What’s Happening atMichigan Universities” (August-September 2006issue of Technology Century).I hope that there is little debate that MichiganTech is an excellent engineering school, and thatMTU is working to maintain its reputation foreducating many successful engineers. This is accomplisheddespite many challenges that come from thelocation of this school with respect to “the businessside” of the state of Michigan (meaning approximatelythe lower third of the Lower Peninsula). Butif there is debate, we need to remember that thereare numerous examples of very successful engineerswho have graduated from Michigan Tech and technologies,which were identified at the university.I apologize for writing this because the articlepresents information that can be useful to the engineeringcommunity or those considering joiningour profession. I know that many decisions arebased on space constraints for the publication, andthere is significant effort in putting this excellentpublication together.Thank You.Stan StachelskiDailmlerChrysler Corporation<strong>ESD</strong> MemberThe editor welcomes discussion of articles and features published inTechnology Century. Comments must be confined to the scope of thearticle being discussed. Letters regarding this issue of the magazinemust be received by January 1, 2007. Please e-mail esd@esd.org andput “Technology Century” in the subject line. | Technology Century | OCTOBER–NOVEMBER 2006

IN THE NEWSCischkeHakim Pease Doran PhillionPitcherSue Cischke, F<strong>ESD</strong>, Vice President, Environmental and SafetyEngineering, Ford Motor Company, was selected as a Womanof Distinction by Girl Scouts of the Huron Valley Council.The Women of Distinction Award is given annually to womenwho exemplify excellence in their professional and/or theircommunity service work by giving their time and experienceto enrich the lives of others. Ms. Cischke was the recipient ofthe Horace H. Rackham Award for Outstanding Achievementin 1997 and has been an <strong>ESD</strong> Fellow since 2002. Throughouther career, she has been a strong advocate for women workingin historically male positions by breaking down gender barriersand helping other women along the trail she has paved.George N. Hakim, PE, an <strong>ESD</strong> member since 1980, has beennamed director of Facilities Administration for the MichiganDepartment of Management and Budget. Mr. Hakim’s newposition will be to lead an extensive facilities operation thatprovides building operations, design, construction, securityand real estate services for state government and relatedservices for public institutions. Mr. Hakim earned a bachelor’sdegree in civil engineering from the University of Detroit andcontinued post-graduate study at Wayne State University.NextEnergy, along with the United States Army Tank-Automotive and Armament Command’s NationalAutomotive Center and several Michigan alternativeenergy technology industry partners, are developing anAdvanced Mobile Microgrid Power System that will allow thedeployment of mobile power of up to 1.5 megawatts, anywherein the world in 48 hours or less. The system has projecteduses in the wake of a natural disaster, in the aftermath of ahomeland security incident and to support military operations.Turner Construction announced the following new hires:Jerry Moses, as Senior Project Manager; Mel Pease, asSuperintendent; Matt Bort, as Superintendent; DwightHooks, as lead estimator; and Eric Fairbanks, as SafetyCoordinator. Turner Construction is the leading generalbuilder in the United States and has completed more than$4 Billion worth of work in the state of Michigan.Altair Engineering, Inc. donated computer-aided engineeringsoftware to Western Michigan University estimated to beworth $1.5 million over the next five years. The program, AltairHyperWorks, is a suite of tools used by most of the world’sleading manufacturers, especially in the automotive industry.Altair Engineering is a leading global provider of technology andservices that strengthen client innovation and decision making.Thomas Doran, PE, was elected to the Board of Directors asVice President/Partner, for Hubbell, Roth & Clark (HRC),Inc. Mr. Doran will strengthen and expand HRC’s industrialand municipal offerings. HRC provides consulting engineeringand architectural services to municipal, industrial and privateclients throughout southeastern Michigan.DeMaria Building Company announced the following newhires: Todd Ackermann, as Project Superintendent; AnthonyPedrosi, as Project Engineer; and Carolyn Phillion, as ProjectBookkeeper. DeMaria also announced that they promoted JeffPitcher to Project Engineer and that they obtained the contractfor the renovation of City Hall for the City of Inskter.CTI & Associates is developing a bioreactor at a St. ClairCounty landfill that will speed up the decomposition oforganic garbage by injecting it with septic-tank waste. CTI’ssystem can be used to retrofit current lined landfills or buildinto new ones, thereby offering communities alternativesto dumping the sludge at wastewater treatment plants or onfarm fields, the two approved methods in Michigan. CTI is aconsulting firm that specializes in land development, landfilldesign and environmental engineering.The Bosch Group celebrated its 100th anniversary in theUnited States on August 31, 2006. What began with a salesoffice for magneto ignition devices in New York City inSeptember 1906 is now the Bosch Group’s largest marketoutside Germany. Bosch has also acquired both Mann &Hummel and Telex Communications Holdings since thebeginning of the year in an effort to achieve greater marketposition in the United States.www.esd.org | The Engineering Society of Detroit |

IN THE NEWSRuby & Associates won top honors in two categoriesin the Pinnacle Awards sponsored by the Society forMarketing Professional Services–Michigan. Ruby &Associates’ corporate brochure and annual calendar werenamed best in their categories by a panel of judges from thecommunications industry. Ruby & Associates is a structuralengineering firm based in Farmington Hills.Lear Corporation announced that Wendy Foss waspromoted to position of Vice President, Finance andAdministration and Deputy Corporate Secretary andEd Lowenfeld was promoted to Assistant Treasurer, CapitalMarkets and Director of Investor Relations. Ms. Foss joinedLear as Accounting Director in 1999 and Mr. Lowenfeldjoined the Lear Treasury team in 2004.SKF announced that the 2006 Cadillac STS-V will use itsX-Tracker high-performance hub bearing units. The X-Tracker system reduces brake caliper piston knock back,allowing the driver to brake later, creating faster corneringspeeds and reducing lap times. SKF won the Premier AutomotiveSuppliers’ Contribution to Excellence (PACE) Awardfor product innovation for its X-Tracker in April 2006.<strong>ESD</strong> Executive Vice President Darlene J. Trudell, CAE, (right) withJohn Puvogel, Benefit Specialist, Hartland InsuranceGroup, at theMichigan Society of Association Executives Diamond Award banquet.Mr. Puvogel is <strong>ESD</strong>’s representative for our Blue Cross/Blue Shieldand Blue Care Network insurance programs for <strong>ESD</strong> members. Pleasecontact <strong>ESD</strong> at 248-353-0735 or esd@esd.org for more informationabout insurance programs for <strong>ESD</strong> members.Innovation in the MakingLawrence Tech’s graduate programs strive to give you the tools andthe practical experience you’ll need to realize your dreams and beone of the minds behind tomorrow’s great innovations.• Automotive EngineeringLawrence Tech offers• Civil Engineeringover 60 undergraduate and• Computer Sciencegraduate programs in• Construction Engineering Management Colleges of Architecture• Electrical and Computer Engineeringand Design, Arts andSciences, Engineering,• Energy and Environmental Managementand Management.• Engineering in Manufacturing Systems• Engineering Management• Mechanical Engineering• Mechatronic Systems Engineering NEW!Your Future in the MakingOffice of Admissions21000 West Ten Mile Road, Southfield, MI 48075-1058800.CALL.LTU • admissions@ltu.eduwww.ltu.edu/engineering | Technology Century | OCTOBER–NOVEMBER 2006

IN THE NEWSAssociation ExecutivesHonor <strong>ESD</strong> with <strong>Six</strong> AwardsThe Michigan Society of Association Executives (MSAE)honored <strong>ESD</strong> with three Diamond Awards, two Gold Awardsand one Silver Award at the 5th Annual Diamond AwardsBanquet on September 21, 2006. <strong>ESD</strong> President David S.Meynell and Past President Charles M. Ayers, F<strong>ESD</strong> joinedthe <strong>ESD</strong> staff in attending the banquet.For the second year in a row, in the $500,000–$2 MillionBudget category, <strong>ESD</strong> won first-place Diamond Awards forWeb Site (www.esd.org), Electronic Newsletter (<strong>ESD</strong> E-News)and Membership Development (the <strong>ESD</strong> Engineering andTechnology Job Fair). The Job Fair is hosted by the <strong>ESD</strong> YoungEngineers Council and generated over 400 new <strong>ESD</strong> studentmembers last year.<strong>ESD</strong> took a second-place Gold Award for Technology Centurymagazine in the Magazine Publishing category. In the Meetings& Expositions category, <strong>ESD</strong> received both the Gold andthird-place Silver awards for the Energy Conference and Exhibitionhosted by DTE Energy and <strong>ESD</strong> and the 2006 EconomicForecast for Design and Construction, respectively.Thank you to the hard-working volunteer members whosecommitment and service earned these recognitions. If you areinterested in joining committees such as those working withthe above events or publications, please contact Laura Govan at248-353-0735, ext. 4120 or lgovan@esd.org.Board Member Retires,Replacement NamedAugust Olivier has stepped downfrom his position as a memberof the <strong>ESD</strong> Board of Directors,effective September 1, 2006, simultaneouswith his retirement fromGeneral Motors Corporation,where he served as Director ofCapital Projects. We congratulateMr. Olivier on his retirementOlivierand thank him for his service toour Society.As his replacement, the <strong>ESD</strong>Board unanimously approvedthe recommendation of theNominating Committee andappointed David C. Munson,Jr., PhD, Robert J. Vlasic Deanof Engineering, University ofMunsonMichigan, to fill the vacancy untilJune 30, 2008.Before assuming his role as Dean of the U-MCollege of Engineering, Dr. Munson served as aprofessor and chair of U-M’s Electrical Engineering &Computer Science Department. Dr. Munson is highlyregarded for his research in digital signal and imageprocessing. He has spent much of his career workingon imaging systems, especially synthetic apertureradar. He earned his bachelor’s degree in electricalengineering from the University of Delaware. Heearned his MS, MA and PhD in electrical engineeringfrom Princeton University.We welcome Dr. Munson to our Board andcongratulate him on his new deanship.Accepting the Diamond Award for Best Electronic Newsletter are(from left) Dale Thomas, <strong>ESD</strong> Managing Director of Communications;Shelly Smith, <strong>ESD</strong> Manager of Communications and MemberBenefits; Leslie Smith, <strong>ESD</strong> Director of Programs; and SusanShanaman, <strong>ESD</strong> Future City Coordinator.Harley Ellis Devereaux andGreenWorks Studio celebratedGreenWeek 2006 in September.This five-day informationalseries was devoted to spreadingthe good works of going green.Information from each sessionis available to you by contactingChris Meter at 248-233-0200 orcmeter@hedev.comwww.esd.org | The Engineering Society of Detroit |

<strong>ESD</strong> MEMBERSHIP<strong>ESD</strong>’s Newest Individual MembersTim AdamsPrincipalManer, Costerisan & Ellis, P.C.John AdamsonDirector of Business DevelopmentPatrick Engineering Inc.Carlos AgudeloEngineering ManagerLink Engineering Co.Faris AlamiDirector of MarketingEngineering Laboratories, Inc.Shani J. AllisonProduct Development Engineer -Climate <strong>Control</strong>Ford Motor CompanyJose A. AlmanzaElectrical EngineerHarley Ellis DevereauxIbraheem AlshunnarVice PresidentNTH Consultants, Ltd.Rebecca M. BakerCivil EngineerWade-TrimAnthony BangoVice PresidentSkanska USA Building Inc.Judi A. BennettProject ScientistShaw Environmental, Inc.Danny B. BerrySupv, Mech EngineeringFord Motor CompanyKurt A. BinderDesign ServicesGeneral Dynamics Land SystemsDan BirchmeierDirector, Sales & MarketingDesign Systems, Inc.Thomas BlazerFord Motor CompanyRao L. BoggavaraouSenior Staff EngineerGeneral DynamicsDavid P. BourgeoisVice President, BusinessDevelopmentWalbridge Aldinger Co.Skiles BoydVice PresidentDTE EnergyDan BrooksWade-TrimThomas W. BullinerManager, Wheeled VehiclesSystems EngineeringGeneral DynamicsStacy BurganDirector Human ResourcesNTH Consultants, Ltd.Mark ButtaVice President BusinessDevelopmentDetroit Thermal, LLCDave CaldwellPrincipalManer, Costerisan & Ellis, P.C.Larry CampbellAccount ManagerModern Engineering, Inc.John CarnagoRecruiterKelly ServicesMichael W. Carroll, CPASecretary/Treasurer CFOGeorge W. Auch CompanyPeter J. ChatelVice President, New MarketDevelopmentPerceptron, Inc.Vinod C. ChauhanIndustrial EngineerFord Motor CompanyChingchen ChuFord Motor CompanyJames W. ClawsonEngineering SpecialistGeneral DynamicsJohn M. CzarneckiVice PresidentSkanska USA Building Inc.James S. DaceFacility Energy CoordinatorFord Motor CompanyDona DavisFord Motor CompanyVincent DeLeonardisVice President, Project DirectorGeorge W. Auch CompanyRichard DeMariaCEODeMaria Building Company, Inc.Tim DuncanVice President Test OperationsLink Engineering Co.Bruce DunnPresidentManer, Costerisan & Ellis, P.C.Ryan DunningPrincipalCivil & Environmental ConsultantsJohn DwyerSenior Software EngineeringSpecialistGeneral Dynamics Land SystemsRodney ElgieWhite ConstructionJeffrey S. Elliott, PEVice PresidentTTL Associates, Inc.Alan EricksonAssociateNTH Consultants, Inc,Dan FahrerManagerDTE EnergyKen FayRecruiterOn AssignmentKedzie FernholzResearch EngineerFord Motor CompanyRick Flynn<strong>Control</strong>ler/<strong>Quality</strong> ManagerDeMaria Building Company, Inc.Kevin FoyeProject EngineerCTI & Associates, Inc.Kirk FrownfelterEVP-Area General ManagerSkanska USA Building Inc.Tyrone GallagherSection ManagerGeneral DynamicsVerne GarrardSales ManagerLimbach Company, LLCAric Geda, PEVice PresidentCivil & Environmental ConsultantsTom GibbonsDirector of Business DevelopmentPower Process PipingLisa R. GirardinManager, Marketing ServicesWalbridge AldingerTimothy GorenchanWade-TrimJohn GossiauxElectrical EngineerLink Engineering Co.Leah GroyaWade-TrimAmy B. GrundmanManager, Public RelationsKelly ServicesGenci GurabardhiKelly ServicesJosephine GustiloSenior Engineer, Tracked VehicleSystems Eng.General DynamicsRichard H. HagforsAutomotive Account ManagerINCOE CorporationDavid L. HamiltonPresidentGeorge W. Auch CompanyJeffrey HamiltonDirector, Project ManagerGeorge W. Auch CompanyEric HarrisWade-TrimGuy HarrisDirectorDTE EnergyDavid HarwoodDirectorDTE EnergyPaul HebelAuditorUHY AdvisorsCharles W. Heil, Jr., PESupervisorFord Motor CompanyAnil K. HingweVice President of <strong>Quality</strong>Metaldyne Corp.Mark HottaChief EngineerFord Motor CompanyEdward JakubiakDirectorDTE EnergyJoan JasinskiAccount ManagerModern Engineering, Inc.Jeffrey JelcinKelly ServicesDavid L. JohnsonMgr. Undergraduate DegreeProgramsCentral Michigan UniversityYvette P. JohnsonPrincipal Account ManagerDTE EnergyRobert M. JustinVice PresidentQ·Quest CorporationKevin M. KalinowskiSenior Engineering Specialist C4IGeneral DynamicsNesreen KhouriBenjamin W. Kiehl, Jr.Plant DirectorDTE EnergyJohn KingmanAccount ManagerModern Engineering, Inc.Donna KinseyKelly ServicesFritz KlinglerVice PresidentNTH Consultants, Ltd.Paul G. KnutsonDirectorDTE EnergySharad KumarSenior Director, SystemsEngineeringGeneral DynamicsDennis La PortePrincipalUHY Advisors - MI, Inc.E S D L e g a c y S o c i e t yThe Engineering Society of Detroit is committed toserving this generation of engineers and fostering thenext. To ensure that we achieve our mission, we havecreated the <strong>ESD</strong> Legacy Society. As leaders who knowfirsthand what it takes to meet life’s challenges, weinvite you to become a member of this program. To join,you need only pledge a gift in any amount to <strong>ESD</strong> fromyour estate. For more information, contact Dale Thomasat dthomas@esd.org or 248–353–0735, ext. 4123. | Technology Century | OCTOBER–NOVEMBER 2006

<strong>ESD</strong> MEMBERSHIPJohn LaRosaBrandon MuscottSenior Project ManagerAccount ManagerDeMaria Building Company, Inc. Modern Engineering, Inc.Larry K. Larson Cindy NorlinSenior Engineer,VetronicsDirerctorSubsystemsDTE EnergyGeneral Dynamics Land SystemsRon NoyesLamonte LatorManager Electrical EngineeringTreasurerLink Engineering Co.Maner, Costerisan & Ellis, P.C.Jim NyquistTrevor F. LauerDirectorVice President Retail Marketing Maner, Costerisan & Ellis, P.C.DTE EnergyJohn J. O’Donnell, Jr.,Bill LaurainPE,PMPProject DirectorManagerSkanska USA Building Inc.DTE EnergyDeborah Lazowski Tim OlexEngineerVP EngineeringFord Motor CompanyLink Engineering Co.Oddie Leopando David OlsonVice President & Gen. Mgr.Business Devepopment Mgr.Metaldyne Corp.NTH ConsultantsSandra LusarsTim OriansOffice ManagerPrincipalParagon Forensic EngineeringManer, Costerisan & Ellis, P.C.Rob ManganShawn PattersonSales EngineerDirectorLink Engineering Co.DTE EnergyAaron MarksBrian PaulSales EngineerSenior EngineerLink Engineering Co.General Dynamics Land SystemsPatrick M. Martin Scott PerkinsDirector of SalesUS Manufacturing Corp.Q·Quest CorporationTom MathieuDeborah PetersonOffice ManagerDirector of AdministrationWashington Group InternationalManer, Costerisan & Ellis, P.C.Gerry McClellandSharon PfeufferPlant DirectorEstimatorDTE EnergyGeorge W. Auch CompanyAndrew McCuneCindy PhillipsKelly ServicesSenior Vice PresidentWade-TrimCharles Poat, AIA,Dann McDonaldLEED APMarketing ManagerEngineering ManagerDeMaria Building Company, Inc. Walbridge AldingerRichard T. McGlew, Jr. Patricia PoppePresidentPlant DirectorQ·Quest CorporationDTE EnergyJonathan Means Frank V. PurczynskiVice PresidentDirector, Logistics Engineering andKelly ServicesProduct TestGeneral DynamicsStephen G. MeinscheinEngineering Spec, Structural Systems Dave Raeck& AnalysisDirectorGeneral DynamicsManer, Costerisan & Ellis, P.C.Ken MickBill ReaderSenior Director, SubsystemDirector Corporate MarketingEngineeringNTH Consultants, LtdGeneral DynamicsDavid ReeceBob MillerVice PresidentDirectorSkanska USA Building, Inc.Maner, Costerisan & Ellis, P.C.Wallace RiaseJohn MillerUS Manufacturing Corp.Manager Software EngineeringLink Engineering Co.Marc RichDirectorKaren MitchellDTE EnergyManagerDTE EnergyRobert RichardSenior VPAmanda MooreDTE EnergyAccount ManagerModern Engineering, Inc.Heather D. RivardDirectorSteve MorseDTE EnergyTraining DirectorWalbridge AldingerSteve RobbinsSecretaryManer, Costerisan & Ellis, P.C.Don RogersProject ExecutiveSkanska USA Building Inc.Paulette RossmannSales EngineerLink Engineering Co.Jim RumaSenior Director, Project EngineeringManagementGeneral DynamicsJudith RushlowDirector of AdministrationQ·Quest CorporationLinda A. RussoDirector Org. DevelopmentMetaldyne Corp.Henry A. SadaConsultantMetaldyne Corp.Mike SchlenkeProject ExecutiveSkanska USA Building Inc.Glenn SchultzContollerWhite ConstructionSteve ScottPrincipalManer, Costerisan & Ellis, P.C.Gordon ShutekDirector, Structures & MechanicalSystemsGeneral DynamicsBrian A. SimonPresidentU.S. Manufacturing CorporationKaramvir (Kevin)SinghPatrick Engineering Inc.Brian R. Smith, Ph.DHuman Factors EngineeringSpecialistGeneral Dynamics Land SystemsDarin SmithSpecial Projects ManagerLimbach Company, LLCBrian M. SnyderMechanical EngineerHarley Ellis DevereauxTe-Yang Soong, PEDirectorCTI & Associates, Inc.James SorensonService RepresentativeKelly Automotive Services GroupMaria Cecylia Staab<strong>Six</strong>-<strong>Sigma</strong> Integration DirectorFord LandJohn StadnicarVice PresidentNTH ConsultantsJeff StevensVice PresidentManer, Costerisan & Ellis, P.C.Michael StromayerJob Locator Developer CoordinatorOakland UniversityMorgan Subbarayan,PEPresidentCTI & Associates, Inc.Christine SuminskiEngineering SpecialistGeneral Dynamics Land SystemsRobert SwopeVice PresidentMetaldyne Corp.Dennis TheisPrincipalManer, Costerisan & Ellis, P.C.Kris ThorneOperations ManagerLimbach Company, LLCDan TitusConstruction ManagerCTI & Associates, Inc.Erin TorroneProject ScientistCTI & Associates, Inc.Yan TranApplications EngineerLink Engineering Co.James P. TurissiniVP Business DevelopmentSkanska USA BuildingBradley C. VenmanAssociateNTH ConsultantsRose Vinuya, PEEnvironmental EngineerTucker, Young, Jackson,Tull, Inc.Kim VisintineAccount ManagerModern Engineering, Inc.Erik R. WaldronEngineerMetaldyne Corp.Franklin WarrenPlant ManagerDTE EnergyDon WhitakerAccount ManagerModern EngineeringPaul D. WhitmanManagerDTE EnergyMichael P. WickCapital Projects-EngineeringServicesGeneral Motors Corp.Karen M. WilhelmResearcher/EditorKaren M. Wilhelm LLCTrey WilliamsPrincipalManer, Costerisan & Ellis, P.C.Steve WintheiserDirectorCTI & Associates, Inc.Vicky YarbroughVariant Requirements SectionManagerGeneral DynamicsLaura YousifEngineerWade-TrimXianda ZhaoSenior Project ManagerCTI & Associates, Inc.Terri ZickDirectorCTI & Associates, Inc.Chad ZielinskiParagon Forensic EngineeringJohn A. ZielkeDirector of TechnologyQ·Quest Corporation<strong>ESD</strong>’s NewestCorporate MembersManer, Costerisan & Ellis, P.C.Rep: James R. DeDyne, PrincipalMacomb Community CollegeRep: Linda O.Wells, Vice President forStudent and Community RelationsQ·Quest CorporationRep: Judith Rushlow, Director ofAdministrationCivil & Environmental ConsultantsRep: Ryan Dunning, PrincipalGeorge W. Auch CompanyRep: Vincent DeLeonardis, Vice PresidentParagon Forensic EngineeringRep: Sandra Lusars, Office ManagerSouthwest Research InstituteRep: Scott Hotz, Group Leader<strong>ESD</strong>’s NewestAffiliate SocietyCertified Hazardous MaterialsManagers of MichiganRep: Kevin BateFor information on <strong>ESD</strong> Affiliate Societies orindividual or corporate membership, pleasecontact Laura Govan at lgovan@esd.org or248–353–0735, ext. 4120.<strong>ESD</strong> Corporate Members receive Crain’s Detroit Businessfree with membership, compliments of <strong>ESD</strong>.<strong>ESD</strong> Professional Members can subscribe for only$15/year—75% off a regular subscription! Membersof <strong>ESD</strong> Affiliate societies can subscribe for only $35per year—a 40% discount! Contact Laura Govan at248-353-0735, ext. 4120, or lgovan@esd.org.www.esd.org | The Engineering Society of Detroit |

<strong>ESD</strong> Thanks Our Sustaining and Corporate Members, the Foundation of Our SuccessFord Motor CompanyAerotek, Inc.Albert Kahn Associates, Inc.American Axle & ManufacturingAmerican Iron & Steel InstituteAmerican Society of EmployersARKEMA Inc.BEI Associates Inc.Boyden Executive SearchBruel & Kjaer Instruments, Inc.Building Industry Association ofSoutheast MichiganC. Ayers LimitedCentral Michigan UniversityCeramicTech Dental Lab, Inc.Chrysan IndustriesCivil & Environmental Consultants, Inc.Climatek Engineering Inc.CompuwareConstruction Association of MichiganCornerstone <strong>Control</strong>sCTI & Associates, Inc.DaimlerChrysler CorporationThe Dako GroupDeMaria Building Company, Inc.DENSO International America, Inc.The Dragun CorporationDTE EnergyDTE Energy Gas OperationsDürr Systems, Inc.Eastern Michigan UniversityElectrical Resources CompanyElevator, Inc.Elsas Engineering, P.C.EMC² Inc.Engineering Laboratories, Inc.Financial One, Inc.Ford Motor CompanyFori AutomationGannett Fleming of Michigan, Inc.Gas Recovery Systems, Inc.Gates CorporationGeneral DynamicsGeneral Motors Corporation–WorldwideFacilities GroupGenslerGeorge W. Auch CompanyGHAFARI Associates, LLCGlenn E. Wash & Associates, Inc.Golder Associates, Inc.GZA GeoEnvironmental, Inc.Harley-Davidson Motor CompanyHarley Ellis DevereauxHartland Insurance Group, Inc.Henry Ford Health SystemHinshon Environmental Consulting, Inc.HNTB Michigan, Inc.Horiba Automotive Test Systems, Inc.Hubbell, Roth & Clark, Inc.Jacobs SverdrupJervis B. WebbKelly ServicesKettering UniversityKFORCE Professional StaffingKitch Drutchas Wagner Valitutti &Sherbrook, P.C.Kolene CorporationL3 Communications-CombatPropulsion SystemsLawrence Technological UniversityLear CorporationLimbach Company, Inc.Link Engineering Co.LTI Information TechnologyMacomb Community CollegeManer, Costerisan & Ellis, P.C.Metaldyne CorporationMichigan State UniversityMichigan Technological UniversityMidwest Steel Inc.Midwestern Consulting, LLCModern Engineering, Inc.Monetek, LLCMyron Zucker, Inc.National Center for Mfg. SciencesNewman Consulting Group, LLCNextEnergyNorthern Industrial ManufacturingCorporationNTH Consultants, Ltd.Oakland UniversityOn AssignmentOriginal Equipment Suppliers Assn.Paragon Forensic EngineeringParsons BrinckerhoffPatrick Engineering Inc.Perceptron, Inc.Perot Systems CorporationProfessional Concepts Insurance AgencyProfessional Underwriters, Inc.Q·Quest CorporationR.L. Coolsaet Construction Co.The Rains Group, A Division ofGallagher Benefit ServicesRemy, Inc.Results Systems Corp.Robert Bosch CorporationRuby & Associates, P.C.Shaw Environmental, Inc.Simons-White Associates, Inc.Skanska USA Building Inc.Southwest Research InstituteTech-Line Engineering CompanyTechnip USATesting Engineers & Consultants, Inc.Trammell Crow CompanyTranSystems CorporationTurner Construction Co.U.S. Manufacturing Corp.Universal Weatherstrip and BuildingSupplyUniversity of Detroit MercyUniversity of MichiganUniversity of Michigan–DearbornVeolia Water North AmericaW.K. Krill & Associates, Inc.Wade-TrimWalbridge Aldinger Co.Washington Group InternationalWayne State UniversityWestern Michigan UniversityWhite Construction Co.Worley Parsons10 | Technology Century | OCTOBER–NOVEMBER 2006

<strong>ESD</strong> Corporate Members ReceiveFree Subscriptions to~ Includes an subscription for each corporate representative—2 to 25 subscriptions, based on the level of your membership~ A $1500.00 value for a Level 5 Corporate Member—$60 for each corporate representative’s subscription~ 52 information-packed issues of the newspaper—with more than50 business lists including top architects, general contractors, largestdevelopers and technology-based companies, to name a few.~ Full access to crainsdetroit.com—with industry specific pages coveringautomotive, economic development, manufacturing and much more!~ Subscriptions renew with <strong>ESD</strong> corporate membershipsAs an engineer, you know how important it is to keepup on the issues facing your industry. But that is justone part of the big picture that shapes the businesscommunity you live in. For this reason, <strong>ESD</strong> is partneringwith Crain’s Detroit Business—to help you complete theentire picture of metro Detroit’s business landscapeby offering <strong>ESD</strong> corporate members complimentarysubscriptions to the leading weekly business publicationin metro Detroit. Crain’s Detroit Business is the bestplace to answer these and other questions:% What’s next in the ever-changing economicenvironment in Michigan?% What are your competitors up to?% Where does your company stand compared to othersin our region?% What is happening in Michigan that will affect yourbottom line?For corporate membership information, please contactLaura Govan at 248–353–0735, ext. 4120, or lgovan@esd.org.More information is online at www.esd.org.www.esd.org | The Engineering Society of Detroit | 11

<strong>ESD</strong> MembershipIn MemoriamWith deep gratitude for their membership andservice, The Engineering Society of Detroitacknowledges the deaths of the following members:Howard A. CollinsRetired/President, Collins AssociatesMember since 1970John A. Pylat, Jr.Consulting EngineerAssociated Manufacturing Systems EngineeringMember since 1985Lawrence J. RadzieckiSenior Project ManagerPinnacle Contracting, Inc. and Ruscilli ConstructionCompany, Inc.Member since 1981Collis James SimpsonRetired/ Manufacturing ConsultantMember since 1982TESTING ENGINEERS & CONSULTANTS, INC.Engineering Client Success• Geotechnical Services• Indoor Air <strong>Quality</strong>• Environmental Services• Asbestos/Mold/Lead• Building Envelope Services• Construction Materials Testing• Property Condition Assessments• Automotive Component Testing1-800-835-2654email: tec@tectest.com www.testingengineers.comOffices in: Ann Arbor,Detroit & TroyA Certified WBE/DBB12 | Technology Century | OCTOBER–NOVEMBER 2006

<strong>ESD</strong> HolidayNetworking Eventat The Parade Company Dec. 6, 2006sPONSORED BYBring the whole family.See details on page 15.www.esd.org | The Engineering Society of Detroit | 13

<strong>ESD</strong> Event HighlightsA Living lab of sustainabledesign: ltu’s Taubmanstudent services center<strong>ESD</strong>’s September 26, 2006, Networking Eventand Technical Tour of LTU’s Taubman StudentServices Center drew over 100 people.<strong>ESD</strong> Upcoming EventsWant to Get Ahead?Get LicensedAre you thinking about taking the NCEES FE or PE exam in April 2007? If so,then mark your calendar for <strong>ESD</strong>’s PE and FE Review courses—the best preparationtools available. Since 1940, <strong>ESD</strong> has successfully prepared thousands ofcandidates for both exams.In all of our courses, you will:• study from past exam questions;• learn from instructors who have firsthand knowledge of the course material;• be provided with a comprehensive binder of course notes to aid you duringyour exam;• learn from and meet your peers who are also studying for the State Exam; and• receive a certificate of completion from <strong>ESD</strong>.Free information sessions on earning your Pe licenseFind out from experts why you should become a PE andthe steps to take to get there. To learn more about theexams and how they can help your career, attend a FreeInformation Session on Earning Your PE License.We have various dates and locations between now andJanuary 2007. For more information and to register, visit www.esd.org orcontact Fran Mahoney at 248–353–0735, ext. 4116, or fmahoney@esd.org.Lewis N. Walker, PhD, PE, President of LTU,welcomes attendees at the Taubman StudentServices Center. The event and tour weresponsored by Harley Ellis Devereaux andWalbridge Aldinger Co.Fundamentals of Engineering (FE) Part IDates: January 30–April 5, 2007Times: 6–9 p.m., Tuesdays and ThursdaysLocation: Offered in both East Lansing and SouthfieldState Exam Date: April 21, 2007Principles & Practice of Engineering (PE) part IIDisciplines: Civil, Electrical, Environmental, MechanicalDates: February 17–March 31, 2007Times—Electrical & Civil: 8:30 a.m.–12:30 p.m., SaturdaysTimes—Mechanical & Environmental: 1–5 p.m., SaturdaysLocation: Southfield, MichiganState Exam Date: April 20, 2007Samuel R. Bayne, FAIA, of Harley EllisDevereaux (HED), explains various elementsof the HED-designed Taubman Center thatwas built according to the U.S. Green BuildingCouncil’s Leadership in Energy and Environmental(LEED) specifications.For information and to register for courses, visit www.esd.org or contactFran Mahoney at 248–353–0735, ext. 4116, or fmahoney@esd.org.Register by January 5, 2007, and save $25, plus you will receive ExamCafé, an online timed practice exam—for a total savings of $50.00!14 | Technology Century | OCTOBER–NOVEMBER 2006

<strong>ESD</strong> UPCOMING EVENTS3rd Thursdays Networking Events3rd thursdays, through januaryJoin us for fun and networking in some of Southfield’s bestrestaurants. These free networking events are hosted by <strong>ESD</strong>,the City of Southfield, and the Southfield Area Chamberof Commerce.Take advantage of this opportunity to network with engineersand business leaders throughout Southeast Michigan. Wewill meet from 4–6 p.m. on the third Thursday of every monthat various restaurants in Southfield. Hors d’oeuvres will beserved, and there will be a cash bar.Full details are on the Web, but the upcoming dates andvenues are:• November 16 — Tangos Restaurant• December 21 — Beans & Cornbread• January 18 — Fishbones2006 <strong>ESD</strong> Holiday Networking Eventat The Parade CompanyWednesday, December 6, 2006You will be blown away by the location we’ve found for ourannual Holiday Networking Event. Bring your family to the2006 <strong>ESD</strong> Holiday Networking Event at The Parade Companyon Wednesday, December 6, 2006, from 5:30 to 8:00 p.m. Kids12 and under attend for free!There is no cost to attend. Please show up and registeron site. For more information, please contact Tim Walker at248-353-0735 ext. 4115, or twalker@esd.org.<strong>ESD</strong> Safety SeriesElectrical Safety Is Not ShockingTuesday, November 14, 2006, <strong>ESD</strong> HeadquartersThis seminar will discuss MIOSHA ElectricalStandard Part 40 for General Industry, andPart 17 Construction and the best practicesneeded to avoid injury by qualified and unqualified persons.They will discuss arc flash injuries and how to prevent them,personal protective equipment training requirements,grounding, handheld electrical tools, guarding, flexible cords,GFCI’s, most cited MIOSHA violations and common hazards.For more information, visit www.esd.org, contact FranMahoney at 248-353-0735, ext. 4116, or fmahoney@esd.org.Next in series: MIOSHA Construction Excavation,Wednesday, January 24, 2007The Parade Company produces the America’s ThanksgivingParade and The International Freedom Festival. Our eveningof cocktails and conversation will be held in the Parade Studio,with its unique atmosphere of parade floats and costumes.This former Chrysler facility is truly the most unusual use of aretired auto plant in the world!For questions and to register for this event, please contactTim Walker at 248-353-0735, ext. 4115, or twalker@esd.org.Engineering & Technology Job FairThursday, February 13, 2007If you are looking for a job, you won’t want to miss <strong>ESD</strong>’s2007 Engineering & Technology Job Fair, presented by the<strong>ESD</strong> Young Engineers Council. The fair will showcase someof Michigan’s largest engineering, energy, technology andmanagement corporations. Companies will be recruiting inall disciplines including: chemical; civil; computers; design;electrical; energy: architects; environmental; manufacturing;mechanical; technical and other technology-related fields. Ifyou’re looking for a job in any engineering or technology discipline,this is the job fair for you!Registration for this event is only $12 for students, and thatincludes a 1-year student membership in The EngineeringSociety of Detroit. The event takes place from 2 p.m. to 7 p.m.in the 2000 Building atrium of the Southfield Town Center.For more information, contact Shelly Smith at 248-353-0735, ext. 4112, or ssmith@esd.org.www.esd.org | The Engineering Society of Detroit | 15

<strong>ESD</strong> Upcoming EventsRegional Development ConferenceTuesday, February 27, 2007The Engineering Society of Detroit has established aRegional Development Committee to encourage growth inDetroit and Southeastern Michigan. The group’s first eventwill define issues from the viewpoint of some of the region’smajor stakeholders. The program will focus on mappingthe present situation, the impediments to developmentand the opportunities for growth. Attendees will leave withsuggested strategies and tactics for economic progress inthe region.This half-day event will kick off with a keynotepresentation by Mike Duggan, President and ChiefExecutive Officer of the Detroit Medical Center (DMC).Other featured speakers include Vince Nystrom, Directorof Technology–Business Development from the MichiganEconomic Development Corporation (MEDC).For additional information or to register, contact LeslieSmith at 248-353-0735, ext 4152, or lsmith@esd.org.16 | Technology Century | OCTOBER–NOVEMBER 2006

<strong>ESD</strong> UPCOMING EVENTS & DeadlinesThe Future of Alternative DisputeResolution: Construction PractitionersResolving Construction DisputesFebruary 1, 2007When a dispute cannot be settled outside of the legal system,it is important to know what your legal options are and howto stay in control of the dispute. Alternative Dispute Resolution(ADR) is a viable alternative to the court system. It enablesyou to resolve disputes more efficiently and save money aswell as time. In order to protect your best interests, you needto become knowledgeable and be involved in the AlternativeDispute Resolution process.This conference will include dialogue about constructiondispute resolution in general, using trained constructionprofessionals as neutrals, and ways that you can take control ofthe resolution of disputes.• Keynote: James J. Giachino, President, James J. Giachino, Inc.• Overview of ADR: Michael T. Lynch, Esq., Associate, CorporateCounsel, Harley Ellis Devereaux• Panel Discussion: Experiences of Construction Practitionersas ADR NeutralsJanice Holdinski (Moderator), Vice President, AmericanArbitration AssociationJeff Roth, Roth, Inc.Linda Haith, RA, American Arbitration AssociationJohn Spittler, PMA Consultants• Insurance Industry Perspective:Michael Cosgrove, Senior Vice President, ProfessionalConcepts Insurance AgencyTonya L O’Hern, Claim Consultant, XL DesignProfessional• Panel Discussion: The Advocate’s Perspective on ConstructionPractitioners as ADR NeutralsJohn V. Tocco, Esq. (Moderator), Consultant, ToccoConstruction ConsultingRonald A. Deneweth, Esq., Managing Partner, Deneweth,Duggan & ParfittJim Case, Esq., Kerr, Russell & WeberEd Hartfield, Executive Director, National Center forDispute Settlementand Construction Arbitration ServicesJohn Sier, Esq., Principal, Kitch Drutchas Wagner Valitutti& SherbrookFor additional information or to register, visit www.esd.orgor contact Leslie Smith at 248-353-0735, ext 4152, orlsmith@esd.org. Sponsorship opportunities are available.<strong>ESD</strong> Construction & Design AwardsENTRy DEADLINE: February 2, 2007The <strong>ESD</strong> Construction &Design Awards are uniquein that they honor thethree primary members ofthe building team-owners,designers and constructors—and recognize outstandingteam achievement and innovativeuse of technology. Theawards were conceived 32 yearsago to encourage elevation ofthe standards of practice in theconstruction industry.Eligibility requirements: Submissions are accepted fromproject teams of owner, designer and contractor. At least oneof the primary members of the project team must be a memberof <strong>ESD</strong>. All projects must have been completed after January1, 2005, to qualify for nomination. Entries may be submittedfor: new buildings or significant construction; renovations andadditions; significant engineered systems; significant restoration,redesign and renovation of historical structures and engineeredsystems in Michigan. All original structures must be atleast 50 years old at the time of submission.Awards are presented at a gala on June 21, 2007, at theDetroit Science Center. For more details, visit www.esd.org.<strong>ESD</strong> Alpha Awards for Innovation inEngineering and TechnologyEntry DeadlinE: February 28, 2007The <strong>ESD</strong> Alpha Awards for Innovation in Engineering andTechnology recognize and celebrate the creative and originalideas of men and women in the engineering and technologyprofessions that develop innovative solutions to the needs of thegeneral public, business or academia.Eligibility requirements: Any product, material, system,structure, process or methodology that is innovative in applicationor use, including inventions, is eligible. The innovationmust have become commercially available, introducedinto general, active practical use, or demonstrated new, uniqueapplications within the last three years (since January 2004).The submission must be endorsed by a member of <strong>ESD</strong>, or youmay become an <strong>ESD</strong> member when you apply by enclosingmembership dues with your entry form.Awards are presented at a gala on June 21, 2007, at theDetroit Science Center. For more details, visit www.esd.org.www.esd.org | The Engineering Society of Detroit | 17

VOLUNTEER OPPORTUNITY<strong>ESD</strong> Director of Education, Ron Smith (center), shows attendees a Future City model at the Sally Ride Festival at Macomb Community College.Become a Future City Judge<strong>ESD</strong> is looking for engineers and architects to act as judges forthe <strong>ESD</strong> Michigan Regional Future City Competition. Theprogram helps prepare 7th and 8th grade students for life inthe real world and has a positive impact on the future of engineeringas a profession.The role of the judges is to draw on their expertise andresources to fairly judge a team’s efforts. Judges will be neededat each of the three stages of the competition.1. By November 22, teams must submit the city plan thatthey designed using SimCity software. The SimCity designswould be e-mailed to you for judging in December and earlyJanuary.2. Next students write a 300–500 word abstract about thehighlights of their city and a 500–700 word essay on fuelcelltechnology. Essays and abstracts would be e-mailed forjudging in early January.3. The final part of the competition will take place onJanuary 17, 2007, at Rock Financial Showplace in Novi. Atthat time, schools display a scale model of their futuristiccity constructed of recycled materials. Three representativesfrom each school give a five to seven minute presentation toa panel of judges. The winning Michigan team goes to thenational Future City Competition during NationalEngineers week in February.To volunteer or for more information, contact SusanShanaman at 248-353-0735, ext. 4117 or sshanaman@esd.org.Additional information is also available at www.esd.org.Helen Keller Middle School team members make final adjustments totheir model prior to judging of the <strong>ESD</strong> 2006 Michigan Regional FutureCity Competition.www.esd.org | The Engineering Society of Detroit | 19

What’s Happening atMichigan UniversitiesQC and <strong>Six</strong> <strong>Sigma</strong>Master of Science in <strong>Quality</strong> Managementat Eastern Michigan UniversityAre you a mid-career individual with quality-related responsibilitieslooking to:• Increase your salary?• Enhance your marketability?• Earn a master’s degree at yourconvenience?Look to EMU’s <strong>Quality</strong>Management online or livedegree program, developedusing the American Society for<strong>Quality</strong> body of knowledge.You’ll benefit from coursework in customersatisfaction, statistical process control, human factors, designof experiments, reliability, problem solving, quality planning,quality auditing, lean practices, cost of quality and <strong>Six</strong> <strong>Sigma</strong>.For more information, go to http://cot.emich.edu/quality ore-mail Dr. Thomas Soyster at tsoyster@emich.edu.If hands-on, real-world workshop-based programs will suityour needs, the ISO 9001:2000 Certified Center for <strong>Quality</strong>at Eastern Michigan University offers over 50 quality assuranceseminars, including <strong>Six</strong> <strong>Sigma</strong> Green, Black and MasterBlack Belt along with five other certificate programs. For information,please contact: www.centerforquality.org or ElenaO’Connor at 734-487-4926 or eoconnor@emich.eduMaster Black Belts at Lawrence Tech<strong>Quality</strong> control and<strong>Six</strong> <strong>Sigma</strong> principlespermeate the engineeringand managementcurricula atLawrence TechnologicalUniversity,and the educationalopportunities rangefrom short courses toa doctorate program.The ProfessionalDevelopment Centeroffers a variety ofProfessor Khalil Taraman discussesresearch with two candidates in theDoctorate of Engineering in ManufacturingSystems (DEMS) program at LTU.quality control and <strong>Six</strong> <strong>Sigma</strong> programs on campus, on-site andthrough e-learning. Participants can be tested and certified in<strong>Six</strong> <strong>Sigma</strong> courses all the way to Master Black Belt. Programcontent can be customized or can be taken with the originalmanufacturing/engineering focus. The Doctorate of Engineeringin Manufacturing Systems (DEMS) program seamlesslyintegrates the essential knowledge of quality control and<strong>Six</strong> <strong>Sigma</strong> with many manufacturing disciplines. For moreinformation, please contact: Professional Development Center248-204-4053, www.ltu.edu/pdc or DEMS Director, KhalilTaraman at 248-204-2565 or taraman@ltu.edu or visitwww.ltu.edu/engineering/mechanical/doctora.asp.20 | Technology Century | OCTOBER–NOVEMBER 2006

At the University of Michigan, cutting-edge research leads to cutting-edge professional programs. Photo by Richard Hirneisen.University of Michigan = <strong>Quality</strong>U of M’s Center for Professional Development offers professionaleducation programs that enable engineers, managersand technical professionals to be more effective, productiveand competitive through the use of leading technologies andprocesses. Participants gain a working knowledge of proventools from highly regarded faculty. Offerings include:• Online <strong>Six</strong> <strong>Sigma</strong>—Green & Black Belts:· Transactional-Service Focus· Manufacturing Focus· Healthcare Focus (Green Belt only)• Lean Certifications in:· Manufacturing· Product-Process Development· Office· Logistics· Healthcare· Pharma• Lean/<strong>Six</strong> <strong>Sigma</strong> CertificatePrograms can be customized and delivered at your site.Online programs include master’s degrees in AutomotiveEngineering, Manufacturing, Integrated Microsystems,Global Product Development and Manufacturing.Visit our Web site for more information: http://cpd.engin.umich.edu or contact Becky Erskine, Marketing & ProgramDevelopment, at 734-615-5698 or berskine@umich.edu.Lean Management at UD≠ MercyIn the current competitivebusiness environment,industries arestriving to improve efficienciesby increasingproductivity, enhancingproducts and serviceswhile reducing cost.Lean Manufacturing,<strong>Six</strong> <strong>Sigma</strong> and LeastTotal Cost Scheduling development and deployment haveemerged as the leading initiatives that have enabled manyorganizations to achieve all these goals. The techniques arewidely implemented at a variety of industries (medical,banking, insurance, pharmaceutical, automotive, aerospaceand others). This course (<strong>Quality</strong> Management/<strong>Six</strong> <strong>Sigma</strong> IEM 546) is intended for industry professionals who seek anunderstanding of such tools and techniques. It will introducethe participants to the principals of Lean Manufacturing, <strong>Six</strong><strong>Sigma</strong>, Least Total Cost Scheduling and integration of thoseto approach product and process improvement opportunities.The course is offered as part of the Master of EngineeringManagement (MEM) Program and is open to participantsoutside the MEM Program. For more information, pleasecontact Hriday Prasad, Director, MPD and MEM Programs, at313-993-3378, fax 313-993-1955 or prasadh@udmercy.edu.www.esd.org | The Engineering Society of Detroit | 21

Dr. Sheryl Sorby heads up the new MTU curriculum program designed forprivate sector industries, including training in <strong>Six</strong> <strong>Sigma</strong> methodologies.WSU Offers MS and PhD Degrees in<strong>Quality</strong> Management/EngineeringStudents interested in quality management and quality engineeringcareers can pursue master’s and doctoral degreespecializations through Wayne State University’s highlyrespected Department of Industrial and Manufacturing EngineeringDepartment. Learn <strong>Six</strong> <strong>Sigma</strong> principles and design,quality management systems, quality assurance and control,reliability estimation, robust design, advanced quality engineeringand value engineering from top experts in their areas.<strong>Six</strong> <strong>Sigma</strong> courses are taught by Professor Kai Yang, author of<strong>Six</strong> <strong>Sigma</strong> textbooks and a world-reknown expert (see articlepage 23). Hands-on learning, industrial partnerships, facultyexperts: three good reasons why students at WSU’s College ofEngineering receive a world-class education in the real world.For more information, please contact: http://mie.eng.wayne.edu/ or Ratna Babu Chinnam r_chinnam@wayne.edu or KaiYang kyang1@wayne.edu.Wayne State University’s Manufacturing Engineering buildingMTU New Curriculum: Engineeringfor the Service IndustryEngineering students are generally taught how to design andbuild products—better machines, instruments and other devicesor manufacturing processes—rather than services. However, theservice sector accounts for nearly 80% of all economic activity inthe United States. An interdisciplinary team at Michigan Techhas developed a new undergraduate engineering curriculumespecially for industries within the service sector. “If engineeringknow-how can be used to reduce health care costs, imagine theresulting savings in the cost of producing manufactured goods,”notes Dr. Sheryl Sorby, Associate Dean of the College of Engineering.Sorby received a $500,000 NSF grant to develop theprogram, which will launch in fall 2007. <strong>Six</strong> <strong>Sigma</strong> concepts willbe included in the new curriculum. In addition, Michigan Techoffers a number of excellent courses on <strong>Quality</strong> Engineering andDesigned Experiments, including an online course, Advanced<strong>Quality</strong> Engineering, through ME-EM Distance Learning.For more information, please contact: Dr. Sheryl Sorby,Michigan Technological University College of Engineering,906-487-2005, sheryl@mtu.edu or www.doe.mtu.edu.Kettering’s IME Program 1st in NationKettering University’s undergraduateIndustrial andManufacturing Engineering(IME) program has beenranked first in the nationseven years in a row by theU.S. News and World Report—America’s Best Colleges Edition.One of the concentrations inthe IME curriculum is <strong>Quality</strong>Assurance; it combinestheory, hands-on laboratoryexperience and integratedinter-disciplinary projects toenhance learning. ExtensiveStudents at work in KetteringUniversity <strong>Quality</strong> Assurancelab are, from left to right: NandaNeethimangala, Kathleen Monforeand Andrew Liddell.use of statistical computer software in every course allows ourstudents to solve real world problems. The <strong>Quality</strong> Assuranceconcentration courses sequence includes:• IME 332 Engineering Statistics II• IME 333 Design of Experiments• IME 471 <strong>Quality</strong> Assurance• IME 572 Introduction to Reliability and Maintainability• IME 573 Advanced <strong>Quality</strong> AssuranceFor more information, please contact Dr. Tony Lin atKettering University, Flint, MI 48504, 810-762-7948, tlin@kettering.edu.22 | Technology Century | OCTOBER–NOVEMBER 2006

<strong>Six</strong> <strong>Sigma</strong>Fig.in a NutshellFundamentalBeliefs1. <strong>Six</strong> <strong>Sigma</strong>as a BusinessStrategyBY Kai YangOrganizationalInfrastructureProjectExecutionix <strong>Sigma</strong> is one of the most successful businessmanagement systems ever developed. MotorolaCorp. developed the first <strong>Six</strong> <strong>Sigma</strong> initiative inthe mid-1980s. In 1995, the <strong>Six</strong> <strong>Sigma</strong> systemgained publicity after Jack Welch, former CEO ofGeneral Electric (GE), made this system a centralfocus of his business strategy and used it to transformGE into one of America’s flagship companies.GE’s remarkable success was contagious, and over thelast ten years, thousands of companies all over the world haveimplemented their own <strong>Six</strong> <strong>Sigma</strong> programs. The <strong>Six</strong> <strong>Sigma</strong>movement is credited with generating greatly improved operationalefficiencies and billions of dollars in savings.What is <strong>Six</strong> <strong>Sigma</strong>?The name ‘<strong>Six</strong> <strong>Sigma</strong>’ comes from statistical terminology: TheGreek symbol sigma (σ) represents standard deviation. For anormal statistical distribution, the probability of falling within± 6 sigma range of the statistical mean is 0.9999966, or almost100%. In production and manufacturing processes, the “<strong>Six</strong><strong>Sigma</strong> Standard” means that a process will produce defectiveproducts at the rate of 3.4 defects per million units. Therefore,<strong>Six</strong> <strong>Sigma</strong> quality is a valid indicator of an extremely lowdefective rate in a very high-quality process. <strong>Six</strong> <strong>Sigma</strong> is notjust statistical jargon; it is a proven, comprehensive businessstrategy with multiple aspects, or components (Fig. 1).<strong>Six</strong> <strong>Sigma</strong> Fundamental Beliefs1. Do the right things and do things right.“Doing the right thing” means that we have to designabsolutely the best product or service in terms of customervalues. ‘Doing things right’ means not only having a gooddesign, but also that we will make all our products, servicesor processesperform consistentlyso allcustomers will besatisfied at all times.2. Process is everything.TrainingMethods andTools<strong>Six</strong> <strong>Sigma</strong> is a process-focused approach tobusiness improvement, with the key feature of improvingone process at a time. The process here could be a productionsystem, a business process or a product-usage process.Compared with other quality initiatives, the <strong>Six</strong> <strong>Sigma</strong>system applies not only to product quality, but also to allaspects of business operation by improving key processes.For example, <strong>Six</strong> <strong>Sigma</strong> may help create well-designed,highly reliable and consistent customer billing systems, costcontrol systems and project management systems.Organizational InfrastructureIn order to achieve perfect products and processes in abusiness enterprise, <strong>Six</strong> <strong>Sigma</strong> needs to build an organizationalinfrastructure to manage and execute <strong>Six</strong> <strong>Sigma</strong> improvementactivities (Fig. 2).<strong>Six</strong> <strong>Sigma</strong> Terminology• Champion: Champion is a person responsible for coordinatinga business roadmap to achieve <strong>Six</strong> <strong>Sigma</strong> qualitygoals. A champion selects <strong>Six</strong> <strong>Sigma</strong> projects, executescontrol and alleviates roadblocks for the <strong>Six</strong> <strong>Sigma</strong> projectsin a given area of responsibility.• Master Black Belt: Master Black Belt is a mentor, trainerand coach of Black Belts and others in the organization. AMaster Black Belt brings the broad organization up to therequired <strong>Six</strong> <strong>Sigma</strong> professional competency level.www.esd.org | The Engineering Society of Detroit | 23

• Black Belt: Black Belt is a team leader implementing the<strong>Six</strong> <strong>Sigma</strong> methodology on projects. A Black Belt introducesthe methodology and tools to team members and to thebroader organization.• Green Belt: Green Belt is an important team member thathelps a Black Belt or leads successful, small and focuseddepartmental projects.• Project Team Members: Project team members willparticipate on the project teams and support the goals ofthe project—typically in the context of his or her existingresponsibilities.Black Belt TrainingAll <strong>Six</strong> <strong>Sigma</strong> professionals undergo various trainings dependon their duties. For example, Black Belt training usually takesfour weeks. Black Belt candidates will learn some basics ofbusiness processes, project management, team leadership skills,process maps and many statistical methods. In order to obtaina Black Belt certificate, the Black Belt candidate needsto complete one to several projects that deliver verifiablefinancial benefits to the company.<strong>Six</strong> <strong>Sigma</strong> Projects<strong>Six</strong> <strong>Sigma</strong> activities are characterized by the completion of projects—manyprojects. The goal for each project is to improveone process at a time. Each <strong>Six</strong> <strong>Sigma</strong> project is typically ahigh-impact project that brings verifiable monetary benefit tothe company’s bottom line. In the United States, the averagesavings of a <strong>Six</strong> <strong>Sigma</strong> project is over $200,000.A typical <strong>Six</strong> <strong>Sigma</strong> process improvement project usuallyfollows a DMAIC project flowchart. DMAIC stands for thefollowing five project steps: define, measure, analyze, improveand control. Specifically, these steps are:1. Define the problem and customer requirements.2. Measure the defects and process operation.3. Analyze the data and discover causes of the problem.4. Improve the process to remove causes of defects.5. <strong>Control</strong> the process to make sure defects don’t reoccur.<strong>Six</strong> <strong>Sigma</strong> Methods and ToolsMany methods and tools are used in <strong>Six</strong> <strong>Sigma</strong> activities. <strong>Six</strong><strong>Sigma</strong> Green Belts and Black Belts go through rigorous trainingsto learn the system’s methods and tools and effective applicationof these tools in projects. Commonly used methods andtools include project management, teamwork, leadership andapplied statistical methods.From Fig.1, we can see that <strong>Six</strong> <strong>Sigma</strong> is quite flexible interms of using different methods and tools, because as soonas the organizational infrastructure and project managementsystem is established, <strong>Six</strong> <strong>Sigma</strong> professionals learn and applyLeader/ChampionMaster Black Belt(MBB)Black Belts (BB)Green Belts (GB)Project Team MembersFig. 2. <strong>Six</strong> <strong>Sigma</strong> Organizational Infrastructurenew tools to solve new problems. Recently, two trends in <strong>Six</strong><strong>Sigma</strong> have emerged. One trend is Lean <strong>Six</strong> <strong>Sigma</strong>, whichfeatures lean manufacturing methods both to streamlinebusiness processes and improve efficiency.The second trend is Design for <strong>Six</strong> <strong>Sigma</strong> (DFSS), whichfeatures using creative, statistical design methods, such as QFD,TRIZ and Axiomatic Design, as well as robust design methodsto greatly improve the product development process and bringcustomer values into product offerings. One of the extremelysuccessful instances of DFSS application is the Samsung Corp.story: In only five years of using rigorous DFSS methods,Samsung surpassed its major competitor, Sony Corp., in termsof both revenue and profit.Information on Dr. Yang’s books, Design for <strong>Six</strong> <strong>Sigma</strong>: ARoadmap for Product Development, Design for <strong>Six</strong> <strong>Sigma</strong> for Service,and Multivariate Statistical Methods in <strong>Quality</strong> Management,may be obtained by contacting: kyang1@wayne.edu or calling313-577-3858.Kai Yang, PhD, is a professor in theindustrial and manufacturing engineeringdepartment at Wayne State University,Detroit, Michigan. With a PhD and MS inindustrial engineering from the Universityof Michigan in Ann Arbor, Dr. Yang isa leading expert in the area of quality,reliability and <strong>Six</strong> <strong>Sigma</strong>, and hasadministered over $2.5 million in research projects from theNational Science Foundation, General Motors, Ford Motor Co.,DaimlerChrysler and Siemens Corp.24 | Technology Century | OCTOBER–NOVEMBER 2006

Sustaining Success:Evolution of the <strong>Six</strong> <strong>Sigma</strong> Program atSiemens Gas Turbine Engineering DivisionHow Siemens Overcame Challengesto <strong>Six</strong> <strong>Sigma</strong> ImplementationBY Antje Lembcke and Hans-Juergen Kiesowbout six years ago, <strong>Six</strong> <strong>Sigma</strong> was introduced toSiemens Power Generation as part of the Siemensimprovement initiative “Top+”. Siemens PowerGeneration is a business of Siemens, a globaltechnology company.Gas turbine engineering is a major divisionof Siemens Power Generation, and its engineersoperate in a highly technical environment. Inthis article, the authors present the quality-control challengesfaced by Siemens engineering and how these hurdles were overcometo establish and maintain successful <strong>Six</strong> <strong>Sigma</strong> methodologiesin this complex industrial environment.Investigation of Initial Rejection RateTwo years after initiating <strong>Six</strong> <strong>Sigma</strong> methods at Siemens PowerGeneration, data revealed—besides large business benefits—anumber of problems. In particular, several <strong>Six</strong> <strong>Sigma</strong> projectsrelated to turbine engineering processes had been cancelledduring different phases of the DMAIC process (Define, Measure,Analyze, Improve and <strong>Control</strong>). This costly cancellationtriggered an investigation to help understand potential programissues and to develop specific mitigation measures.A detailed investigation at Siemens Gas Turbine EngineeringDivision (GT) was launched to uncover general program issuesand to understand the underlying reasons for the high <strong>Six</strong> <strong>Sigma</strong>project rejection rate of about 30%. Usually, the start-to-finishduration of a <strong>Six</strong> <strong>Sigma</strong> project in the engineering environmentis about six months to one year. At GT, 70% of the programrejections occurred in the Define Phase of <strong>Six</strong> <strong>Sigma</strong>’s DMAICprocess and 80% of all projects were rejected after 70 days afterinitiation. Cost of rejected <strong>Six</strong> <strong>Sigma</strong> projects was estimated at$1M per year, based on non-value-added work only (omittingthe intangible costs of frustrated <strong>Six</strong> <strong>Sigma</strong> Black Belt leadersand lost process opportunities).At GT, questionnaires were given to engineering managers,<strong>Six</strong> <strong>Sigma</strong> Black Belt leaders (certified experts in <strong>Six</strong> <strong>Sigma</strong>methodologies, also called “Belts”) and GT process owners. Thequestionnaire included questions about: <strong>Six</strong> <strong>Sigma</strong> program focus;Black Belt candidate selection process; business impact of <strong>Six</strong><strong>Sigma</strong> projects; importance of selected <strong>Six</strong> <strong>Sigma</strong> projects relativeto non-<strong>Six</strong> <strong>Sigma</strong> projects; quality of <strong>Six</strong> <strong>Sigma</strong> training; andorganizational support for Black Belt project work. During theone-on-one interview sessions, procedures ensured that questionswere interpreted in the same way. Several important <strong>Six</strong> <strong>Sigma</strong>Program findings were identified. In general, results showedthe following:1. Knowledgeable contact for questions relative to <strong>Six</strong> <strong>Sigma</strong> isnot available.2. <strong>Six</strong> <strong>Sigma</strong> project selections seem more arbitrary than systematic.3. Knowledge of the purpose of <strong>Six</strong> <strong>Sigma</strong> is lacking.4. Methods for validating and capturing <strong>Six</strong> <strong>Sigma</strong> projectideas are not clear.5. GT projects with <strong>Six</strong> <strong>Sigma</strong> program potential are notselected (because <strong>Six</strong> <strong>Sigma</strong> projects tend to have highvisibility to top management, responsible managers werehesitant to identify potential process weaknesses through awww.esd.org | The Engineering Society of Detroit | 25

<strong>Six</strong> <strong>Sigma</strong> analysis—a reaction often described as “protectingone’s own turf”).6. An adequate business case needs to be made for <strong>Six</strong> <strong>Sigma</strong>application at the start.7. There is no process-owner involvement and buy-in upfront(at project onset).8. Management shows insufficient recognition of <strong>Six</strong> <strong>Sigma</strong>process success.9. No charge number established for <strong>Six</strong> <strong>Sigma</strong> billing costs;insufficient program funding.After carefully weighing of all issues brought to light fromthe investigation, three main areas for improvement wereidentified: project selection, resource allocation and generalprogram support.Modification SolutionsTop+ <strong>Six</strong> <strong>Sigma</strong> TeamIssues identified by the investigation led to an overhaul of the<strong>Six</strong> <strong>Sigma</strong> process with several enhancements. The first majorimprovement was establishing a small group called the Top+<strong>Six</strong> <strong>Sigma</strong> Team, composed of engineers with a strong <strong>Six</strong><strong>Sigma</strong> background. Within GT, this team is charged with <strong>Six</strong><strong>Sigma</strong> program management and is identified as the directcontact for all Belts within engineering. Monthly metrics(process scorecards) identify targets, such as measuring:Fig. 1. Improved product selection processFig. 2. Improved project implementation26 | Technology Century | OCTOBER–NOVEMBER 2006