Cast Carbon Steel Valves - Leban Co., Ltd.

Cast Carbon Steel Valves - Leban Co., Ltd.

Cast Carbon Steel Valves - Leban Co., Ltd.

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

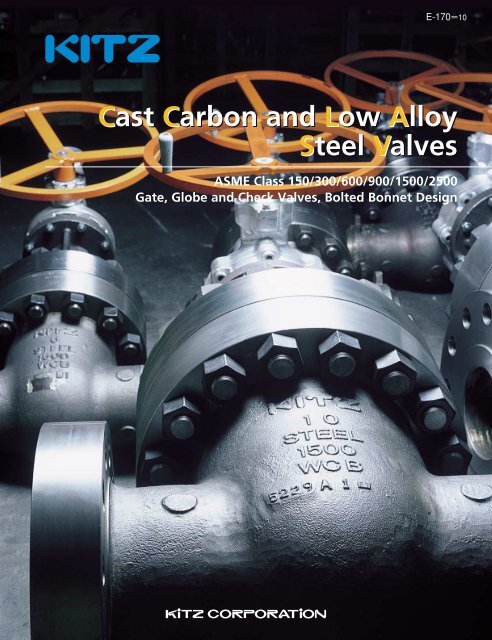

<strong>Cast</strong> <strong>Carbon</strong> and Low Alloy<strong>Steel</strong> <strong>Valves</strong>ASME Class 150/300/600/900/1500/2500Gate, Globe and Check <strong>Valves</strong>, Bolted Bonnet Design

INDEXProfile of KITZ <strong>Cast</strong> <strong>Steel</strong> <strong>Valves</strong>..............................................1Standard Product Range..........................................................2Standard Seat Material and <strong>Co</strong>nstruction ..............................3Product <strong>Co</strong>ding ........................................................................3General Design Specifications .................................................4Valve Shell Materials................................................................4Valve Trim Materials ................................................................5Mounting of Body Seat Rings .................................................6Bonnet Gasket Materials .........................................................6<strong>Co</strong>ntact Face of Flanges...........................................................7NACE <strong>Valves</strong> .............................................................................7Inspection and Warranty Policy of KITZ <strong>Co</strong>rporation ............8Typical KITZ Inspection Flow ...................................................8KITZ Low Emission Service <strong>Valves</strong> ...........................................9Design Features of KITZ Gate Valve Wedges .......................10Valve SpecificationsClass Product <strong>Co</strong>de Valve Type <strong>Co</strong>nstruction Page150300600900150025001503006009001500250015030060090015002500150SCLS300SCLS600SCLS900SCLS1500SCLS2500SCLS150SCJS300SCJS600SCJS900SCJS1500SCJS2500SCJS150SCOS300SCOS600SCOS900SCOS1500SCOS2500SCOSGateGateGateGateGateGateGlobeGlobeGlobeGlobeGlobeGlobeCheckCheckCheckCheckCheckCheckB.B., O.S.&Y.B.B., O.S.&Y.B.B., O.S.&Y.B.B., O.S.&Y.B.B., O.S.&Y.B.B., O.S.&Y.B.B., O.S.&Y.B.B., O.S.&Y.B.B., O.S.&Y.B.B., O.S.&Y.B.B., O.S.&Y.B.B., O.S.&Y.B.C.B.C.B.C.B.C.B.C.B.C.121314151617181920212223242526272829Care for Handling <strong>Valves</strong>.......................................................30Pressure-Temperature Ratings ..............................................31KITZ Ina Plant, Japan (ISO 9001 certified)The products introduced in this catalog are all covered by theISO 9001 certification awarded KITZ <strong>Co</strong>rporation in 1989, theearliest in the valve industry.KITZ <strong>Co</strong>rporation of JIANGSU KUNSHAN

Profile of KITZ <strong>Cast</strong> <strong>Steel</strong> <strong>Valves</strong>KITZ’s wide product range helps customers save onprocurement costs by reducing the number ofsuppliers. It has recently been expanded with theintroduction of low emission service valves thatexceed the US federal environment protectionrequirement of a 500 ppm limit on external leakageof toxic gases and chemicals from valves and otherplant equipment. Every customer is trying hard toimprove their plant life cycle by targeting valvemaintenance problems as an essential managementprogram. KITZ’s low emission service valves offeredin hydrocarbon and chemical industries a realisticand timely solution.To compliment its state-of-the-art production systemand facilities, KITZ has committed itself to qualityassurance management to an extent unparalleled inthe valve industry. Its aggressive employment ofquality management was confirmed by the BureauVeritas Quality International of London when theychose KITZ for their premiere presentation of the ISO9001 certification in 1989, the earliest in the valveindustry.Field applications 1Valve machiningField applications 201

Standard Product RangeKITZ <strong>Cast</strong> carbon <strong>Steel</strong> <strong>Valves</strong>, RF-flanged* (1) , Bolted Bonnet DesignValveTypeASMEClass150Design StandardP-TRatingWallThicknessMaterial* (2)Shell* (3)TrimNominal 1 1 /2 2 2 1 /2 3 4 5 6 8 10 12 14 16 18 20 22 24 26 28 30 32 34 36SizePage<strong>Co</strong>de 40 50 65 80 100 125 150 200 250 300 350 400 450 500 550 600 650 700 750 800 850 900* (4)150SCLS 12300300SCLS12Gate600900API 600BS 1414WCB F6/HF600SCLS900SCLS131315001500SCLS1425002500SCLS14150150SCJS15300300SCJS15Globe600900ASME API 600B16.34 BS 1873WCB F6/HF600SCJS900SCJS161615001500SCJS1725002500SCJS17150150SCOS18300300SCOS18SwingCheck600900API 600BS 1868WCBorA105F6/HF600SCOS900SCOS181915001500SCOS1925002500SCOS19*(1): Butt-welding end available as an option.Refer to ‘‘<strong>Co</strong>ntact Faces of Flanges’’ on Page 7.*(2): For special shell materials, refer to ‘‘Valve Shell Materials’’ on Page 4.*(3): For special trim materials, refer to ‘‘Valve Trim Materials’’ on Page 5.*(4): Nominal size larger than 36 are available for special orders.For KITZ pressure-seal carbon steel valves, <strong>Co</strong>ntact KITZ <strong>Co</strong>rporation.02

Standard Seat Material and <strong>Co</strong>nstructionValveTypeKITZ Product <strong>Co</strong>dePartNominal 1 1 /2Size402502 1 /2653804 5 6 8 10 12 14 16 18 20 22 24 26 28 30 32 34 36100 125 150 200 250 300 350 400 450 500 550 600 650 700 750 800 850 900150SCLS, 300SCLSDiscBody Seat Gate600SCLSDiscBody Seat 900SCLS, 1500SCLS, 2500SCLSDiscBody Seat 150SCJS, 300SCJSDiscBody Seat Globe600SCJSDiscBody Seat 900SCJS, 1500SCJS, 2500SCJSDiscBody Seat 150SCOS, 300SCOSDiscBody Seat SwingCheck600SCOSDiscBody Seat 900SCOS, 1500SCOS, 2500SCOSDiscBody Seat :13Cr Disc :<strong>Cast</strong> <strong>Steel</strong> Disc-13Cr Deposited Seats :<strong>Steel</strong> Seats-Hardfaced and Welded :<strong>Steel</strong> Disc-13Cr Deposited Seats :Directly Deposited HardfacingPRODUCT CODINGG- 150 SC LS6CY3 Other valve specifications:L S 6C Y5 4 1 2 3c Special shell material:No code is required for WCB. Referto “Valve Shell Material” on Page 4,for special shell materials.1 ASME pressure class:150 through 25002 Shell material code:<strong>Carbon</strong> and low alloy steel are alwaysidentified as ‘‘SC’’a b c ba Valve type code:L: Gate valveJ: Globe valveO: Swing check valveb Seat material/mounting:<strong>Co</strong>deDisc SeatMaterialBody SeatMaterialS 13Cr HFS Y HF HF : Special shell material codeType ofMountingRefer toPage 64 Type of end connection:No code is required for RF-flanged endsW: Butt-welding ends.Refer to “<strong>Co</strong>ntact Face of Flanges” onPage 7.5 Type of valve operation:No code is required for manualhandwheel operation.G : Gear operation.E : Electric actuator operation.03

General Design SpecificationsItemsShell wall thickness and general valve designPressure-temperature ratingsFace-to-face dimensionsEnd-to-end dimensionsEnd flange dimensionsGasket contact facingWelding end dimensionsAmerican Std.API 600ASME B16.34ASME B16.10ASME B16.5*ASME B16.25British Std.BS 1414 (Gate valve)BS 1873 (Globe valve)BS 1868 (Check valve)BS 1560BS 2080BS 1560BS 1414 (Gate valve)BS 1873 (Globe valve)BS 1868 (Check valve)*MSS SP-44 for Nominal size 22 and ASME B16.47 Series B for Nominal size 26 and larger, for end flange dimensions.Valve Shell MaterialsBesides ASTM A216 WCB, the standard material, KITZ cast steel valves are optionally available with the materialslisted below:ASTM SpecificationMaterial Designation Working Temperature* °F (°C)KITZ codeA216 WCB<strong>Carbon</strong> steel1000 (538) MaximumA217 WC1C–1/2 Mo1CA217 WC611/4 Cr–1/2 Mo6C1100 (593) MaximumA217 WC921/4 Cr–1Mo9CA217 C55Cr–1/2 Mo5C1200 (649) MaximumA217 C129Cr–1Mo12CA352 LCB<strong>Carbon</strong> steelBL–50 (–46) MinimumA352 LCC<strong>Carbon</strong> steelCLA352 LC1A352 LC2A352 LC3C–1/2 Mo21/2 Ni –10031/2 Ni –150–75 (–59) Minimum–100 (–73) Minimum–150 (–101) Minimum1L2L3LFor ASTM A351 Austenitic Stainless <strong>Steel</strong> <strong>Valves</strong>, refer to KITZ Cat.No.E-150.*Refer to ASME B16.34 for details of ASTM A216, A217 and A352 Pressure-temperature ratings. (See page 31 for A216 and A217)The minimum working temperatures of ASTM A352 are based on ASME B31.3.KITZ Low Temperature Service <strong>Valves</strong>KITZ <strong>Co</strong>rporation offers Class 150, 300 and 600 API 600 design low alloy steel valves for low temperature servicedown to -150°F (-101°C) . Detailed design information is available on request.04

Valve Trim MaterialsAPI 600 and BS 1414/1873/1868 specify the following valve component parts as the valve trim:DescriptionGate ValveGlobe ValveCheck ValveDisc seat surfaceBody seat surfaceBonnet bush (Backseat)StemOthersSpecified byInternal small partsAPI 600BS 1414Lock nutBS 1873Hinge PinBS 1868*Available optionally.Disc seats and body seatsFollowing trims specified in API 600, Table 13, are available from KITZ either as our standard or at your option.<strong>Co</strong>mposition of combination trims which employ different seating surface materials for disc seats and body seats,shall be arranged at the manufacturer’s discretion, unless specified in advance.<strong>Co</strong>mbination number5.8.11.*12.*14.**Available optionally.HF: <strong>Co</strong>-Cr-W Alloy (Stellite No.6) depositMaterial descriptionHF / HF13Cr / HFNi-Cu alloy (Monel) / HF18Cr-8Ni-Mo (316) / HF19Cr-29Ni (Alloy 20) / HFBrinell hardness350HB min.250HB min. / 350HB min.Not specified / 350HB min.Not specified / 350HB min.Not specified / 350HB min.Stems and bonnet bushing (backseat bushing)ASTM A182 (F6a) is our standard material for stems and bonnet bushing. The other materials including ASTMA182 (F304), A182 (F316), Monel and Alloy 20 are available on your specific request.05

Mounting of Body Seat RingsBody seat rings of KITZ cast steel valves are mounted on the valve body by seal welding as shown in the typicalexamples of gate valves illustrated below. Unless specifically requested in advance, mounting of body seat ringsshall be made at the manufacturer's discretion. Specify your own method of mounting, noting your purchaseorders with adequate KITZ product code numbers.SCLS(API Trim8)<strong>Co</strong>-Cr-W Hard FacedSeal WeldingSCLSY(API Trim5)<strong>Co</strong>-Cr-W Hard Faced<strong>Co</strong>-Cr-W Hard FacedSeal WeldingFor KITZ cast steel valves made of ASTM A216 WCB, the standard shell material, disc seats and body seat rings shallbe provided as follows. (Refer to Page 3 for Product <strong>Co</strong>ding)KITZ Product <strong>Co</strong>deStandard Disc SeatStandard Body SeatMounting of Body Seat RingsSCLSSCJSSCOS(Gate)(Globe)(Check)F6a orWCB + 13Cr orA105 + 13Cr orCA15A105 + HF* orA106 Gr. B + HF* orAISI 1022 + HF* orDirect HF**Seal Welded or Direct HF**SCLSY (Gate)SCJSY (Globe)SCOSY(Check)A105 + HF* orWCB + HF* orCA15 + HF*A105 + HF* orA106 Gr. B + HF* orAISI 1022 + HF* orDirect HF**Seal Welded or Direct HF*** <strong>Co</strong>-Cr-W AIloy deposited for hard facing.**<strong>Co</strong>-Cr-W Alloy is directly deposited on valve body for hard facing.KITZ Product <strong>Co</strong>de 900SCJS, 900SCJSY, 1500SCJS, 1500SCJSY, 2500SCJS and 2500SCJSY globe valves employ this hard facing.Bonnet Gasket MaterialsDepending on class ratings and servicing conditions, following gasket materials are available for body/bonnetflange gaskets of KITZ cast steel valves. Specify your gasket material in purchase order.Gasket Material<strong>Co</strong>rrugated metal with flexible graphiteRing joint metalSpiral wound metal, flexible graphite filledStainless steel inserted flexible graphiteClass150 300 600 900 1500 2500 Note: Refer to Page 9 for bonnet gaskets used for KITZ Iow emission service valves.06

<strong>Co</strong>ntact Face of FlangesASME B16.5 specifies several different types of contact face of flanges as illustrated below. Among them, KITZ caststeel valves employ 0.06 RF for Class 150 and 300, and 0.25 RF for higher pressure classes with an optionalemployment of ring-joint contact.Flat Face0.06 RF*0.25 RF*Ring JointSmall M/F**Large M/F**Small T/G***Large T/G***RF*: Raised Face M/F**: Male-Female T/G ***: Tongue & GrooveGasket contact surface finish of end flanges as well as body-bonnet flange very much depends on the materialsselected for flange gaskets.NACE <strong>Valves</strong>For servicing sour gases or other Hydrogen Sulfide bearing hydrocarbon fluids, KITZ offers NACE valves made ofcomponent materials specially heat-treated and hardness-controlled in comformity with NACE MR0103, KITZStandard, or optionally NACE MR0175 Standard.Typical NACE material configuration is shown below for KITZ cast steel gate valves. A note should be taken on thefact that NACE hardness requirement conflicts with the valve trim. KITZ NACE steel valves are available only as aspecified option.Valve PartsBody/bonnetDiscDisc seatGlandStemBonnet bushingBody seat surfaceBonnet boltsBonnet nuts*Double tempered. (Three step process)ASTM SpecificationA216 WCBA216 WCB or AISI Type 410 or A217 CA15*13Cr deposit or AISI Type 410*AISI Type 410HF**A193 B7A193 B7MA194 2HA194 2HM**<strong>Co</strong>-Cr-W Alloy deposited for hard facing.NACE Hardness HRC 22 (237 HB) 350 HB HRC 22 HRC 2207

Inspection and Warranty Policy of KITZ <strong>Co</strong>rporationEvery piece of KITZ cast carbon and low alloy steel valves is subjected to 100% pressure tests, according to API 598requirements. Manufacturer’s material test reports and inspection certificates are available on your request, whileeach valve is guaranteed for 12 months after placement in service, but not exceeding 18 months after shipmentfrom the factories of KITZ <strong>Co</strong>rporation.Various tests and inpections of valves made by KITZ <strong>Co</strong>rporation include the following. Unless otherwise specified,all KITZ cast steel valves shall be subjected to these testing or inspection methods and evaluation criteria.Test/Inspection ItemChemical composition analysisMechanical property testPressure testsRadiographic inspectionWet magnetic particle inspectionLiquid penetrant inspectionLow temperature impact testDimensional inspectionVisual inspectionEmission test**Applicable to low emission service valves.MethodASTM A370API 598ASTM E142 / E49ASTM E138ASTM E165ASTM E23EPA Method 21 and KITZ Std.EvaluationRelevant ASTM Stds.Relevant ASTM Stds.API 598ASME B16.34ASTM A352Relevant Valve Stds.MSS SP-55KITZ Std.Typical KITZ Inspection Flow<strong>Cast</strong>ing Machining Assembly<strong>Co</strong>atingMarkingPackagingMaterialInspectionEveryChargeRandomNon-DestructiveInspection100%DimensionalInspection100%PressureTests100%VisualInspection100%DimensionalInspection100%VisualInspection100%OperationalInspection100%VisualInspectionRandomEmissionTest**Applicable to low emission service valves.08

KITZ Low Emission Service <strong>Valves</strong>In the United States, the Federal Clean Air Act was dramatically amended in 1990, to realize the new environmentalprotection policy of a 95% reduction in fugitive emission or leak levels of toxic gases and chemicals from plantequipment. Promulgated in April, 1994, the new law requires all plants handling the toxic gas specified by theEnvironmental Protection Agency, to periodically monitor their plant equipment for detection of leaks exceeding500 ppm, and repair or replace all defective parts immediately. California has exceeded the Federal law with a stateregulation requiring 100 ppm maximum leak level for an astonishing 99% reduction of such an environmentalpollution for the Northern California Region after 1997.Our low emission valves, the proud fruits of several years of trial and error at our laboratory, are designed,engineered, manufactured and tested to now meet the 100 ppm maximum emission level. This is the standardspecification in North America for KITZ flanged and butt-welding end carbon or low alloy steel valves rated Class150, 300 and 600. In other markets, all these low emission valves are optionally available. Major designconsiderations for having upgraded our standard valves to the low emission performers are introduced below.Gland packingKITZ’s original ‘‘SEALEVER ® ’’ flexible graphite packingset, consisting of 4 dieformed flexible graphite rings*and 2 braided flexible graphite rings, combined with aspacer bush for Class 300 and 600 rated valves.*US Patent No. 5522603 & 5573253. Other patents registered or pending worldwide.Bonnet gaskets (including check valve cover gaskets)Class 150 : Flexible graphite sheet with stainless steelinsert or corrugated metal with flexiblegraphite and permeation protective barrierfor low emission serviceClass 300: Spiral wound (flexible graphite filler andstainless steel hoop) with a stainless steelinner ringClass 600 : Ring joint metal gasketStuffing boxMaximum 125 RMS surface finish. Cylindricity andverticality are precision controlled according to KITZdesign and manufacturing standards.Plug gaskets for check valvesClass 150/300 : Flexible graphite sheet with stainless steelinsert and permeation protective barrier.Class 600 : Spiral wound metal, flexible graphite filledProduct identificationStainless steel ID plates with the letters ‘‘LOWEMISSION’’ in orange are welded on the bonnetflanges.Diametrical interface clearance20 to 32 mils (0.5 to 0.8 mm) : Stem to gland20 to 32 mils (0.5 to 0.8 mm) : Stem to bonnet bushing4 to 12 mils (0.1 to 0.3 mm) : Gland to stuffing boxsStem16 to 32 RMS surface finish. Straightness and roundnessare precision controlled according to KITZ design andmanufacturing standards.YRT Emission Test ResultsIn addition to our in-house lab tests and certifications by Lloyd’s Register of Shipping, a third-party perfomance test was carriedout on a KITZ nominal size 6 Class 300 gate valve at Yarmouth Research and Technology, Maine, USA, according to one user’stesting specifications. The test conditions included an unprecedented 3500 cycle operation of a 99% methane pressurized valvethrough thermal cycles at 350F (177), with the valve stem positioned horizontally to the ground, and the leak level wasmonitored at every 100 cycles, from an aluminum foil housing sealed the valve gland area. In spite of these severe testconditions, the results were in close agreement with findings from the tests made at our laboratory over the last several years.09

Design Features of KITZ Gate Valve Wedges (Discs)Among the four different shapes of wedge gates recognizedby API 600 Paragraph 5.6.1.1 and 5.6.1.2, KITZ hasadopted solid wedges for smaller valves such as nominalsize 2 to 4 of Class 900/1500/2500 gate valves, and flexiblewedges for all other sizes of all pressure classes.H-shaped flexible wedges are featured with mechanicalflexibility to adjust its own shape following the shape ofthe body seats for tightly secured mutual contact. This ispaticularly important when larger gate valves serviceextremely high pressure and temperature, wheretemporary deformation of the valve body always occurs.Operational torque is smaller, seat wear is less and valveclosure is tighter when H-shaped flexible wedges areprovided.Side ViewSolid wedgeFlexible wedgeFront ViewHeavily designed KITZ wedge gates are forged or castsolid, single piece of steel without any welding work.Specially heat-treated wedges are firmly coupled withintegral T-head of the valve stems, which are alsoruggedly designed and specially heat-treated for thehighest possible durability of stem to wedge connection.API 600 Paragraph 5.8.7 particularly emphasizes theimportance of the mechanical strength of thisconnection.As another unique feature, KITZ wedge gates aredesigned for always accurately maintained concentricityand carefully lapped for leakfree contact.Stem-to-Wedge <strong>Co</strong>nnection10

Class150<strong>Cast</strong> <strong>Carbon</strong> <strong>Steel</strong> Gate ValveBolted bonnet, Outside screw-and-yoke, Rising stem, Non-rising handwheel, Flexible wedge.FigEnd <strong>Co</strong>nnections150SCLSRF-flanged ends.DDHW150SCLSPartsButt-welding ends.Standard materials of partsMaterialsBodyASTM A216 Gr.WCBBonnetASTM A216 Gr.WCBH(open)Gear OperationOptionalfor Nominal Size14 to 24 Standardfor 26 & IargerHStemDiscBody seat ringGlandASTM A182 Gr.F6a13Cr/<strong>Carbon</strong> <strong>Steel</strong>+13Cr<strong>Carbon</strong> <strong>Steel</strong>+HF*ASTM A182 Gr.F6aGland packingFlexible GraphiteGland flangeASTM A105/A216 Gr. WCBHandwheelDuctile ironGasketSee Page 6Bonnet bolt/nutASTM A193 Gr.B7/A194 Gr.2HGland bolt/nutASTM A576 Gr.1045/A194 Gr.2HL1L2Buttwelding EndL1Bonnet bushingYoke sleeveGrease nippleASTM A182 Gr.F6aASTM A439 Tp.D2<strong>Carbon</strong> steel150SCLSG-150SCLS*Hard facing with <strong>Co</strong>-Cr-W Alloy.Note:Refer to Page 3&6 for standard seat material andconstruction.DimensionsNominalSize1 1 /2402502 1 /26538041005125615082001025012300143501640018450205002255024600266502870030750328003485036900L1inmm6.501657.001787.501908.002039.0022910.00 10.50 11.50 13.00 14.00 15.00 16.00 17.00 18.00 19.00 20.00 22.00 24.00 24.00 26.00 28.00 28.00254 267 292 330 356 381 406 432 457 483 508 559 610 610 660 711 711L2inmm8.502169.5024111.14 12.00 15.00 15.86 16.50 18.00 19.76 22.50 24.00 26.00 28.00 30.00 32.00 34.00 36.00 36.00 38.00 40.00 40.00283 305 381 403 419 457 502 572 610 660 711 762 813 864 914 914 965 1016 1016Hinmm15.238515.238517.043220.151023.359225.965829.975937.895945.8116353.6136260.0152366.6169174.3188883.6212491.6232698.12492111.6 119.3 124.2 128.6 138.1 149.62835 3030 3154 3267 3507 3801Dinmm7.92007.92007.92009.82509.825011.830011.830013.835015.740017.745019.750023.660023.660026.868026.868029.976019.750023.660023.660023.660023.660023.660012

Class 300<strong>Cast</strong> <strong>Carbon</strong> <strong>Steel</strong> Gate ValveBolted bonnet, Outside screw-and-yoke, Rising stem, Non-rising handwheel, Flexible wedge.FigEnd <strong>Co</strong>nnections300SCLSRF-flanged ends.W300SCLSButt-welding ends.DDHStandard materials of partsPartsMaterialsBodyASTM A216 Gr.WCBH(open)Gear OperationOptionalfor Nominal Size12 to 24Standardfor 26 & IargerHBonnetStemDiscBody seat ringGlandGland packingASTM A216 Gr.WCBASTM A182 Gr.F6a13Cr/<strong>Carbon</strong> <strong>Steel</strong>+13Cr<strong>Carbon</strong> <strong>Steel</strong>+HF*ASTM A182 Gr.F6aFlexible GraphiteGland flangeASTM A105/A216 Gr. WCBHandwheelDuctile ironGasketSee Page 6Bonnet bolt/nutASTM A193 Gr.B7/A194 Gr.2HGland bolt/nutASTM A576 Gr.1045/A194 Gr.2HL1L2Buttwelding EndL1Bonnet bushingYoke sleeveGrease nippleASTM A182 Gr.F6aASTM A439 Tp.D2<strong>Carbon</strong> steel300SCLSG-300SCLS*Hard facing with <strong>Co</strong>-Cr-W Alloy.Note:Refer to Page 3&6 for standard seat material andconstruction.DimensionsNominalSize1 1 /2402502 1 /26538041005125615082001025012300143501640018450205002255024600266502870030750328003485036900L1inmm7.501908.502169.5024111.14 12.00 15.00 15.86 16.50 18.00 19.76 30.00 33.00 36.00 39.00 43.00 45.00 49.00 53.00 55.00 60.00 64.00 68.00283 305 381 403 419 457 502 762 838 914 991 1092 1143 1245 1346 1397 1524 1626 1727L2inmm8.502169.5024111.14 12.00 15.00 15.86 16.50 18.00 19.76 30.00 33.00 36.00 39.00 43.00 45.00 49.00 53.00 55.00 60.00 64.00 68.00283 305 381 403 419 457 502 762 838 914 991 1092 1143 1245 1346 1397 1524 1626 1727Hinmm16.241116.241117.945420.852824.161327.269231.179039.9101347.8121556.6143761.5156168.1172976.0193184.1213793.123641002540112.1 124.1 131.5 137.8 150.6 154.62848 3151 3341 3500 3826 3926Dinmm7.92007.92007.92009.82509.825011.830013.835015.740017.745019.750023.660023.660026.868029.976029.976035.891023.660023.660023.660023.660023.660023.660013

Class 600<strong>Cast</strong> <strong>Carbon</strong> <strong>Steel</strong> Gate ValveBolted bonnet, Outside screw-and-yoke, Rising stem, Non-rising handwheel, Flexible wedge.FigEnd <strong>Co</strong>nnections600SCLSRF-flanged ends.DDHW600SCLSPartsButt-welding ends.Standard materials of partsMaterialsBodyASTM A216 Gr.WCBH(open)Gear OperationOptionalfor Nominal Size8 to 18Standardfor 20 & IargerHBonnetStemDiscBody seat ringGlandGland packingASTM A216 Gr.WCBASTM A182 Gr.F6a13Cr/<strong>Carbon</strong> <strong>Steel</strong>+13Cr<strong>Carbon</strong> <strong>Steel</strong>+HF*ASTM A182 Gr.F6aFlexible GraphiteGland flangeASTM A105/A216 Gr. WCBHandwheelDuctile ironGasketSee Page 6Bonnet bolt/nutASTM A193 Gr.B7/A194 Gr.2HGland bolt/nutASTM A576 Gr.1045/A194 Gr.2HL1L2Buttwelding EndL1Bonnet bushingYoke sleeveGrease nippleASTM A182 Gr.F6aASTM A439 Tp.D2<strong>Carbon</strong> steel600SCLSG-600SCLS*Hard facing with <strong>Co</strong>-Cr-W Alloy.Note:Refer to Page 3&6 for standard seat material andconstruction.DimensionsNominalSize2502 1 /2 3 4 5 6 8 10 12 14 16 18 20 22 2465 80 100 125 150 200 250 300 350 400 450 500 550 600L1inmm11.5029213.0033014.0035617.0043220.0050822.0055926.0066031.0078733.0083835.0088939.0099143.00109247.00119451.00129555.001397L2inmm11.5029213.0033014.0035617.0043220.0050822.0055926.0066031.0078733.0083835.0088939.0099143.00109247.00119451.00129555.001397Hinmm17.644719.649921.454426.266630.377035.189241.9106549.5125757.6146462.7159370.0177981.5207188.8225698.42500107.52730Dinmm7.92009.82509.825011.830015.740017.745019.750023.660026.868029.976029.976035.891023.660023.660024.061014

Class 900<strong>Cast</strong> <strong>Carbon</strong> <strong>Steel</strong> Gate ValveBolted bonnet, Outside screw-and-yoke, Rising stem, Non-rising handwheel,Solid wedge (Nominal Size 2 to 4) or Flexible wedge (Nominal Size 6& larger).FigEnd <strong>Co</strong>nnectionsD900SCLSW900SCLSRF-flanged ends.Butt-welding ends.DHStandard materials of partsPartsMaterialsBodyASTM A216 Gr.WCBBonnetASTM A216 Gr.WCBH(open)Gear OperationOptionalfor Nominal Size6 to 12Standardfor 14 & IargerHStemDiscBody seat ringGlandGland packingASTM A182 Gr.F6a13Cr/<strong>Carbon</strong> <strong>Steel</strong>+13Cr<strong>Carbon</strong> <strong>Steel</strong>+HF*ASTM A182 Gr.F6aFlexible GraphiteGland flangeASTM A105/A216 Gr. WCBHandwheelDuctile ironGasketSee Page 6Bonnet bolt/nutASTM A193 Gr.B7/A194 Gr.2HGland bolt/nutASTM A576 Gr.1045/A194 Gr.2HL1L2Buttwelding EndL1Bonnet bushingYoke sleeveGrease nippleASTM A182 Gr.F6aASTM A439 Tp.D2<strong>Carbon</strong> steel900SCLSG-900SCLS*Hard facing with <strong>Co</strong>-Cr-W Alloy.Note:Refer to Page 3&6 for standard seat material andconstruction.DimensionsNominalSize2350 8041006150820010250123001435016400184502050024600L1inmm14.5036815.0038118.0045724.0061029.0073733.0083838.0096540.50102944.50113048.00121952.00132161.001549L2inmm14.5036815.0038118.0045724.0061029.0073733.0083838.0096540.50102944.50113048.00121952.00132161.001549Hinmm20.552124.462027.569835.590142.8108750.6128659.0149862.2158169.5176685.8218094.52400105.52680Dinmm9.825011.830013.835019.750023.660026.868029.976023.660023.660023.660024.061024.061015

Class1500<strong>Cast</strong> <strong>Carbon</strong> <strong>Steel</strong> Gate ValveBolted bonnet, Outside screw-and-yoke, Rising stem, Non-rising handwheel,Solid wedge (Nominal Size 2 to 4) or Flexible wedge (Nominal Size 6& larger).FigEnd <strong>Co</strong>nnectionsDDH1500SCLSW1500SCLSRF-flanged ends.Butt-welding ends.Standard materials of partsPartsMaterialsH(open)Gear OperationOptionalfor Nominal Size6 to 12Standardfor 14 & IargerHBodyBonnetStemDiscBody seat ringASTM A216 Gr.WCBASTM A216 Gr.WCBASTM A182 Gr.F6a13Cr/<strong>Carbon</strong> <strong>Steel</strong>+13Cr<strong>Carbon</strong> <strong>Steel</strong>+HF*GlandASTM A182 Gr.F6aGland packingFlexible GraphiteGland flangeASTM A105/A216 Gr. WCBHandwheelDuctile ironGasketSee Page 6Bonnet bolt/nutASTM A193 Gr.B7/A194 Gr.2HGland bolt/nutASTM A576 Gr.1045/A194 Gr.2HL1L2Buttwelding EndL1Bonnet bushingYoke sleeveGrease nippleASTM A182 Gr.F6aASTM A439 Tp.D2<strong>Carbon</strong> steel1500SCLSG-1500SCLS*Hard facing with <strong>Co</strong>-Cr-W Alloy.Note:Refer to Page 3&6 for standard seat material andconstruction.DimensionsNominalSize2502 1 /25038041006150820010250123001435016400L1inmm14.5036816.5041918.5047021.5054627.7570532.7583239.0099144.50113049.50125754.501384L2inmm14.5036816.5041918.5047021.5054627.7570532.7583239.0099144.50113049.50125754.501384Hinmm20.552124.963327.068630.477241.3105049.2125058.1147765.3165869.0175051.12060Dinmm9.825011.830013.835015.740023.660026.868035.891035.891023.660024.061016

Class 2500<strong>Cast</strong> <strong>Carbon</strong> <strong>Steel</strong> Gate ValveBolted bonnet, Outside screw-and-yoke, Rising stem, Non-rising handwheel,Solid wedge (Nominal Size 2 to 4) or Flexible wedge (Size 6& larger).FigEnd <strong>Co</strong>nnectionsDDH2500SCLSW2500SCLSRF-flanged ends.Butt-welding ends.Standard materials of partsPartsMaterialsGear OperationStandardfor Nominal Size 6BodyBonnetStemASTM A216 Gr.WCBASTM A216 Gr.WCBASTM A182 Gr.F6aH(open)HDiscBody seat ring13Cr/<strong>Carbon</strong> <strong>Steel</strong>+13Cr<strong>Carbon</strong> <strong>Steel</strong>+HF*GlandASTM A182 Gr.F6aGland packingFlexible GraphiteGland flangeASTM A105/A216 Gr. WCBHandwheelDuctile ironGasketSee Page 6Bonnet bolt/nutASTM A193 Gr.B7/A194 Gr.2HGland bolt/nutASTM A576 Gr.1045/A194 Gr.2HL1L2Buttwelding EndL1Bonnet bushingYoke sleeveGrease nippleASTM A182 Gr.F6aASTM A439 Tp.D2<strong>Carbon</strong> steel2500SCLSG-2500SCLS*Hard facing with <strong>Co</strong>-Cr-W Alloy.Note:Refer to Page 3&6 for standard seat material andconstruction.DimensionsNominalSize2502 1 /26538041006150L1inmm17.7545120.0050822.7557826.5067336.00914L2inmm17.7545120.0050822.7557826.5067336.00914Hinmm24.963329.073730.076234.888548.91243Dinmm9.825011.830013.835015.740019.750017

Class150<strong>Cast</strong> <strong>Carbon</strong> <strong>Steel</strong> Globe ValveBolted bonnet, Outside screw-and-yoke, Rising stem handwheel, Swivel disc.DFig150SCJSW150SCJSEnd <strong>Co</strong>nnectionsRF-flanged ends.Butt-welding ends.DDHStandard materials of partsPartsBodyMaterialsASTM A216 Gr.WCBBonnetASTM A216 Gr.WCBH(open)Gear OperationStandard forNominal Size 10larger Hammer-blowType Handwheelfor 6 & 8HStemDiscLock nutBody seat ringGlandASTM A276 Tp.40313Cr/<strong>Carbon</strong> <strong>Steel</strong>+13CrASTM A182 Gr.F6a<strong>Carbon</strong> <strong>Steel</strong>+HF*ASTM A182 Gr.F6aGland packingFlexible GraphiteGland flangeASTM A105/A216 Gr. WCBHandwheelDuctile ironGasketSee Page 6Bonnet bolt/nutASTM A193 Gr.B7/A194 Gr.2HL1L2Buttwelding EndL1Gland bolt/nutBonnet bushingYoke sleeveASTM A576 Gr.1045/A194 Gr.2HASTM A182 Gr.F6aASTM A439 Tp.D2150SCJSG-150SCJS*Hard facing with <strong>Co</strong>-Cr-W Alloy.Note:Refer to Page 3&6 for standard seat material andconstruction.DimensionsNominalSize1 1 /2402502 1 /26538041005125615082001025012300143501640018450L1inmm6.501658.002038.502169.5024111.5029214.0035616.0040619.5049524.5062227.5069831.0078736.0091438.50978L2inmm8.002038.502169.5024111.5029214.0035616.0040619.5049524.5062237.5069831.0078736.0091438.50978Hinmm13.133213.133214.937915.439018.146019.146420.251324.863038.597941.3104943.5110648.2122449.81264Dinmm7.92007.92009.82509.82509.825011.830013.835015.740019.750019.750019.750023.660023.660018

Class 300<strong>Cast</strong> <strong>Carbon</strong> <strong>Steel</strong> Globe ValveBolted bonnet, Outside screw-and-yoke, Rising stem handwheel, Swivel disc.DFig300SCJSW300SCJSEnd <strong>Co</strong>nnectionsRF-flanged ends.Butt-welding ends.DDHStandard materials of partsPartsMaterialsBodyASTM A216 Gr.WCBH(open)Gear OperationStandard forNominal Size 8 largerHammer-blowType Handwheelfor 5 & 6HBonnetStemDiscLock nutBody seat ringASTM A216 Gr.WCBASTM A276 Tp.40313Cr/<strong>Carbon</strong> <strong>Steel</strong>+13CrASTM A182 Gr.F6a<strong>Carbon</strong> <strong>Steel</strong>+HF*GlandASTM A182 Gr.F6aGland packingFlexible GraphiteGland flangeASTM A105/A216 Gr. WCBHandwheelDuctile ironGasketSee Page 6Bonnet bolt/nutASTM A193 Gr.B7/A194 Gr.2HL1L2Buttwelding EndL1Gland bolt/nutBonnet bushingYoke sleeveASTM A576 Gr.1045/A194 Gr.2HASTM A182 Gr.F6aASTM A439 Tp.D2300SCJSG-300SCJS*Hard facing with <strong>Co</strong>-Cr-W Alloy.Note:Refer to Page 3&6 for standard seat material andconstruction.DimensionsNominalSize1 1 /2240 502 1 /265380410051256150820010250123001435016400L1inmm9.0022910.5026711.5029212.5031814.0035615.7540017.5044422.0055924.5062228.0071133.0083834.00864L2inmm10.5026711.5029212.5031814.0035615.7540017.5044422.0055924.5062228.0071133.0083834.00864Hinmm14.336214.336217.043317.243620.151024.061027.068541.8106245.0114346.8118857.1145055.51410Dinmm7.92007.92009.82509.825013.835015.740017.745019.750023.660023.660023.660023.660019

Class 600<strong>Cast</strong> <strong>Carbon</strong> <strong>Steel</strong> Globe ValveBolted bonnet, Outside screw-and-yoke, Rising stem handwheel, Swivel disc.DDFig600SCJSW600SCJSEnd <strong>Co</strong>nnectionsRF-flanged ends.Butt-welding ends.Standard materials of partsDHPartsBodyMaterialsASTM A216 Gr.WCBBonnetASTM A216 Gr.WCBH(Open)Gear OperationStandard for Nominal Size4 to 12Hammer-blowType Handwheel for 3HStemDiscLock nutBody seat ringASTM A276 Tp.40313Cr/<strong>Carbon</strong> <strong>Steel</strong>+13CrASTM A182 Gr.F6a<strong>Carbon</strong> <strong>Steel</strong>+HF*GlandASTM A182 Gr.F6aGland packingFlexible GraphiteGland flangeASTM A105/A216 Gr. WCBHandwheelDuctile ironGasketSee Page 6Bonnet bolt/nutASTM A193 Gr.B7/A194 Gr.2HL1L2Buttwelding EndL1Gland bolt/nutBonnet bushingYokeASTM A576 Gr.1045/A194 Gr.2HASTM A182 Gr.F6aASTM A216 Gr.WCB600SCJSG-600SCJS*Hard facing with <strong>Co</strong>-Cr-W Alloy.Note:Refer to Page 3&6 for standard seat material andconstruction.DimensionsNominalSize2502 1 /26538041005125615082001025012300L1inmm11.5029213.0033014.0035617.0043220.0050822.0055926.0066031.0078733.00838L2inmm11.5029213.0033014.0035617.0043220.0050822.0055926.0066031.0078733.00838Hinmm15.740018.747519.950635.389736.693039.099145.9116752.0132062.21580Dinmm9.825011.830013.835019.750019.750019.750023.660023.660024.061020

Class 900<strong>Cast</strong> <strong>Carbon</strong> <strong>Steel</strong> Globe ValveBolted bonnet, Outside screw-and-yoke, Rising stem, Swivel disc.DFig900SCJSW900SCJSEnd <strong>Co</strong>nnectionsRF-flanged ends.Butt-welding ends.Standard materials of partsPartsMaterialsHAll GearOperationBodyBonnetASTM A216 Gr.WCB+HF*ASTM A216 Gr.WCBStemASTM A276 Tp.403Disc13Cr/<strong>Carbon</strong> <strong>Steel</strong>+13CrLock nutASTM A182 Gr.F6aGlandASTM A182 Gr.F6aGland packingFlexible GraphiteGland flangeASTM A105/A216 Gr. WCBGasketSee Page 6Bonnet bolt/nutASTM A193 Gr.B7/A194 Gr.2HL1L2Buttwelding EndGland bolt/nutBonnet bushingYokeASTM A576 Gr.1045/A194 Gr.2HASTM A182 Gr.F6aASTM A216 Gr.WCB900SCJS*Hard facing with <strong>Co</strong>-Cr-W Alloy.Note:Refer to Page 3&6 for standard seat material andconstruction.DimensionsNominalSize380410061508200L1inmm15.0038118.0045724.0061029.00737L2inmm15.0038118.0045724.0061029.00737Hinmm35.490037.795746.2117354.41381Dinmm19.750019.750023.660023.660021

Class1500<strong>Cast</strong> <strong>Carbon</strong> <strong>Steel</strong> Globe ValveBolted bonnet, Outside screw-and-yoke, Rising stem handwheel, Swivel disc.DDHFig1500SCJSW1500SCJSEnd <strong>Co</strong>nnectionsRF-flanged ends.Butt-welding ends.Standard materials of partsH(open)Gear Operation forStandard NominalSize 2 1 /2 and largeHammer-blow TypeHandwheel for 2HPartsBodyBonnetStemDiscMaterialsASTM A216 Gr.WCB+HF*ASTM A216 Gr.WCBASTM A276 Tp.40313Cr/<strong>Carbon</strong> <strong>Steel</strong>+13CrLock nutASTM A182 Gr.F6aGlandASTM A182 Gr.F6aGland packingFlexible GraphiteGland flangeASTM A105/A216 Gr. WCBHandwheelDuctile ironGasketSee Page 6Bonnet bolt/nutASTM A193 Gr.B7/A194 Gr.2HL1L2Buttwelding EndL1Gland bolt/nutBonnet bushingYokeASTM A576 Gr.1045/A194 Gr.2HASTM A182 Gr.F6aASTM A216 Gr.WCB1500SCJSG-1500SCJS*Hard facing with <strong>Co</strong>-Cr-W Alloy.Note:Refer to Page 3&6 for standard seat material andconstruction.DimensionsNominalSize2502 1 /265380410061508200L1inmm14.5036816.5041918.5047021.5054627.7570532.75832L2inmm14.5036816.5041918.5047021.5054627.7570532.75832Hinmm21.354036.292038.096443.4110253.8136655.11400Dinmm13.835019.750019.750023.660023.660024.061022

Class 2500<strong>Cast</strong> <strong>Carbon</strong> <strong>Steel</strong> Globe ValveBolted bonnet, Outside screw-and-yoke, Rising stem handwheel, Swivel disc.DDHFig2500SCJSW2500SCJSEnd <strong>Co</strong>nnectionsRF-flanged ends.Butt-welding ends.Standard materials of partsH(open)Gear OperationStandard for NominalSize 3 & 4Hammer-blowType Handwheelfor 2 & 2 1 /2HPartsBodyBonnetStemDiscMaterialsASTM A216 Gr.WCB+HF*ASTM A216 Gr.WCBASTM A276 Tp.403ASTM A182 Gr.F6aLock nutASTM A182 Gr.F6aGlandASTM A182 Gr.F6aGland packingFlexible GraphiteGland flangeASTM A105HandwheelDuctile ironGasketSee Page 6Bonnet bolt/nutASTM A193 Gr.B7/A194 Gr.2HL1L2Buttwelding EndL1Gland bolt/nutBonnet bushingYokeASTM A576 Gr.1045/A194 Gr.2HASTM A182 Gr.F6aASTM A216 Gr.WCB2500SCJSG-2500SCJS*Hard facing with <strong>Co</strong>-Cr-W Alloy.Note:Refer to Page 3&6 for standard seat material andconstruction.DimensionsNominalSize2502 1 /2653804100L1inmm17.7545120.0050822.7557826.50673L2inmm17.7545120.0050822.7557826.50673Hinmm25.564827.670240.0101650.31278Dinmm15.740019.750023.660023.660023

Class150<strong>Cast</strong> <strong>Carbon</strong> <strong>Steel</strong> Check ValveBolted cover, Swing type disc.Nominal Size 6 & largerFig150SCOSW150SCOSEnd <strong>Co</strong>nnectionsRF-flanged ends.Butt-welding ends.Standard materials of partsPartsMaterialsHBody<strong>Co</strong>verASTM A216 Gr.WCBASTM A105/A216 Gr.WCBDisc13Cr/<strong>Carbon</strong> <strong>Steel</strong>+13CrDisc nutASTM A194 Gr.8Body seat ring<strong>Carbon</strong> <strong>Steel</strong>+HF*<strong>Co</strong>ver bolt/nutASTM A193 Gr.B7/A194 Gr.2HL1L2Buttwelding EndArmGasketPlugASTM A105 (1 1 /214)ASTM A216 Gr.WCB (16and larger)See Page 6ASTM A576 Gr.1045150SCOS*Hard facing with <strong>Co</strong>-Cr-W Alloy.Note:Refer to Page 3&6 for standard seat material andconstruction.DimensionsNominalSize1 1 /2402502 1 /26538041005125615082001025012300143501640018450205002255024600266502870030750L1inmm6.501658.002038.502169.5024111.5029213.0033014.0035619.5049524.5062227.5069831.0078734.0086438.5097838.5097842.00106751.00129551.00129557.00144860.001524L2inmm8.002038.502169.5024111.5029213.0033014.0035619.5049524.5062227.5069831.0078734.0086438.5097838.5097842.00106751.00129551.00129557.00144860.001524Hinmm5.31356.01526.71707.11807.92009.252359.825011.629513.233414.536816.341518.146020.151023.058323.058524.863026.868028.271629.976024

Class 300<strong>Cast</strong> <strong>Carbon</strong> <strong>Steel</strong> Check ValveBolted cover, Swing type disc.Nominal Size 4 & largerFig300SCOSW300SCOSEnd <strong>Co</strong>nnectionsRF-flanged ends.Butt-welding ends.Standard materials of partsPartsMaterialsHBody<strong>Co</strong>verASTM A216 Gr.WCBASTM A105/A216 Gr. WCBDisc13Cr/<strong>Carbon</strong> <strong>Steel</strong>+13CrDisc nutASTM A194 Gr.8Body seat ring<strong>Carbon</strong> <strong>Steel</strong>+HF*<strong>Co</strong>ver bolt/nutASTM A193 Gr.B7/A194 Gr.2HL1L2Buttwelding EndArmGasketPlugASTM A105 (1 1 /212)ASTM A216 Gr.WCB (14 and larger)See Page 6ASTM A576 Gr.1045300SCOS*Hard facing with <strong>Co</strong>-Cr-W Alloy.Note:Refer to Page 3&6 for standard seat material andconstruction.DimensionsNominalSize1 1 /2402502 1 /2653804100512561508200102501230014350164001845020500246002870030750L1inmm9.5024110.5026711.5029212.5031814.0035615.7540017.5044421.0053324.5062228.0071133.0083834.0086438.5097840.00101653.00134659.00149962.751594L2inmm10.5026711.5029212.5031814.0035615.7540017.5044421.0053324.5062228.0071133.0083834.0086438.5097840.00101653.00134659.00149962.751594Hinmm5.51406.51657.51908.12058.92259.825010.727213.033014.236016.040618.948021.153522.657524.863031.780536.693038.497525

Class 600<strong>Cast</strong> <strong>Carbon</strong> <strong>Steel</strong> Check ValveBolted cover, Swing type disc.Nominal Size 4 & largerFig600SCOSW600SCOSEnd <strong>Co</strong>nnectionsRF-flanged ends.Butt-welding ends.Standard materials of partsPartsMaterialsHBody<strong>Co</strong>verASTM A216 Gr.WCBASTM A216 Gr.WCBDisc13Cr/<strong>Carbon</strong> <strong>Steel</strong>+13CrDisc nutASTM A194 Gr.8Body seat ring<strong>Carbon</strong> <strong>Steel</strong>+HF*<strong>Co</strong>ver bolt/nutASTM A193 Gr.B7/A194 Gr.2HL1L2Buttwelding EndArmGasketPlugASTM A105 (1 1 /212)ASTM A216 Gr.WCB (14 and larger)See page 6ASTM A576 Gr.1045600SCOS*Hard facing with <strong>Co</strong>-Cr-W Alloy.Note:Refer to Page 3&6 for standard seat material andconstruction.DimensionsNominalSize2502 1 /265380410051256150820010250123001435016400184502050024600L1inmm11.5029213.0033014.0035617.0043220.0050822.0055926.0066031.0078733.0083835.0088939.0099143.00109247.00119455.001397L2inmm11.5029213.0033014.0035617.0043220.0050822.0055926.0066031.0078733.0083835.0088939.0099143.00109247.00119455.001397Hinmm7.11807.81978.722010.125611.529212.531814.035616.341517.745021.955623.760125.063527.870733.785626

Class 900<strong>Cast</strong> <strong>Carbon</strong> <strong>Steel</strong> Check ValveBolted cover, Swing type disc.Fig900SCOSW900SCOSEnd <strong>Co</strong>nnectionsRF-flanged ends.Butt-welding ends.Standard materials of partsHPartsMaterialsBodyASTM A216 Gr.WCB<strong>Co</strong>verASTM A216 Gr.WCBDiscASTM A216 Gr.WCB+13CrDisc nutASTM A194 Gr.8Body seat ring<strong>Carbon</strong> <strong>Steel</strong>+HF*<strong>Co</strong>ver bolt/nutASTM A193 Gr.B7/A194 Gr.2HL1L2Buttwelding EndArmGasketPlugASTM A216 Gr.WCBSee Page 6ASTM A576 Gr.1045900SCOS*Hard facing with <strong>Co</strong>-Cr-W Alloy.Note:Refer to Page 3&6 for standard seat material andconstruction.DimensionsNominalSize380410061508200102501230014350164001845020500L1inmm15.0038118.0045724.0061029.0073733.0083838.0096540.50102944.50113048.00121952.001321L2inmm15.0038118.0045724.0061029.0073733.0083838.0096540.50102944.50113048.00121952.001321Hinmm11.529213.634617.544420.752624.462028.372031.379434.688037.595241.0104227

Class1500<strong>Cast</strong> <strong>Carbon</strong> <strong>Steel</strong> Check ValveBolted cover, Swing type disc.Fig1500SCOSW1500SCOSEnd <strong>Co</strong>nnectionsRF-flanged ends.Butt-welding ends.Standard materials of partsHPartsMaterialsBodyASTM A216 Gr.WCB<strong>Co</strong>verASTM A216 Gr.WCBDiscASTM A216 Gr.WCB+13CrDisc nutASTM A194 Gr.8Body seat ring<strong>Carbon</strong> <strong>Steel</strong>+HF*<strong>Co</strong>ver bolt/nutASTM A193 Gr.B7/A194 Gr.2HL1L2Buttwelding EndArmGasketPlugASTM A216 Gr.WCBSee Page 6ASTM A576 Gr.10451500SCOS*Hard facing with <strong>Co</strong>-Cr-W Alloy.Note:Refer to Page 3&6 for standard seat material andconstruction.DimensionsNominalSize2502 1 /26538041006150820010250123001435016400L1inmm14.5036816.5041918.5047021.5054627.7570532.7583239.0099144.50113049.50125754.501384L2inmm14.5036816.5041918.5047021.5054627.7570532.7583239.0099144.50113049.50125754.501384Hinmm11.429012.431613.734715.439120.351525.665029.073734.487537.695542.6108228

Class 2500<strong>Cast</strong> <strong>Carbon</strong> <strong>Steel</strong> Check ValveBolted cover, Swing type disc.Fig2500SCOSW2500SCOSEnd <strong>Co</strong>nnectionsRF-flanged ends.Butt-welding ends.Standard materials of partsHPartsMaterialsBodyASTM A216 Gr.WCB<strong>Co</strong>verASTM A216 Gr.WCBDiscASTM A216 Gr.WCB+13CrDisc nutASTM A194 Gr.8Body seat ring<strong>Carbon</strong> <strong>Steel</strong>+HF*<strong>Co</strong>ver bolt/nutASTM A193 Gr.B7/A194 Gr.2HL1L2Buttwelding EndArmGasketPlugASTM A216 Gr.WCBSee Page 6ASTM A576 Gr.10452500SCOS*Hard facing with <strong>Co</strong>-Cr-W Alloy.Note:Refer to Page 3&6 for standard seat material andconstruction.DimensionsNominalSize2502 1 /26538041006150L1inmm17.7545120.0050822.7557826.5067336.00914L2inmm17.7545120.0050822.7557826.5067336.00914Hinmm13.233515.238515.740017.745022.858029

Care for Handling <strong>Valves</strong>1. Before mounting valves:Before mounting valves, be sure that adequate valveshave been prepared to exactly meet the serviceconditions including the maximum design pressuresand temperatures. Foreign objects such as sand orscale may be left in the pipes, and care should betaken to remove all of them by filters or strainers toprotect valve seat surfaces during subsequent valvecommissioning.2. Mounting valves:On mounting valves, clean the inside of pipes again sothat no welding spatter, chips, scale or sand are left.For installation of flanged end valves, flange boltsshould be tightened alternately in a star pattern.Where extraordinary external forces such as pipingstress may be applied to the flanges of valves beingmounted, provide valve supports or any otheradequate protective measures.Check body/bonnet bolting during installation, stressrelaxation of fasteners can occur during transit andstorage.Lubricate stem and yoke sleeve prior to valve operation.KITZ valves are shipped from the factory withonly a light lubricant which facilitates assembly.3. Retightening valves glands:When leakage is detected from the gland area whilethe valve is being in service, the gland nuts should beimmediately retightened. Tighten the gland slowlyand gradually until the leakage stops, while rotatingthe valve handwheel. In case the valve operatingtorque has been found considerably increased afterthese procedures, it is recommended to replace allpacking rings at the time of valve maintenance.4. Replacing packing rings:It is recommended to replace packing rings duringvalve maintenance operation, but never while thevalve is being pressurized in service, except when theline pressure is reduced to the atmospheric level. KITZcast carbon and low alloy steel valves are providedwith the backseats on the bonnet bushing. If leakagefrom the gland area cannot be stopped byretightening the gland nuts, operate the valve to itsfull open position and add a few packing rings orreplace packing rings utilizing sealing function ofthese backseats.Sealing function of backseats is sometimes disturbeddue to rust or other foreign objects trapped inside. Itshould be carefully checked before adding orreplacing packing rings that backseats functionproperly. When the valve is highly pressurized, itsometimes causes danger to replace all of packingrings. In this case, adding a few new rings or replacinga few rings on top of the packing chamber isrecommended as a first aid solution.For replacement of packing rings, first remove thegland nuts and then packing rings. Clean the packingchamber and the valve stem. After checking that allsliding parts are in good condition, securely installnew packing rings. Press new packing rings lightly afew times with the gland and then evenly tighten thegland nuts.30

Pressure - Temperature Ratings <strong>Valves</strong> - Flanged and Welding End : Standard ClassASTM Material Standard-to ASME B16.34 2004TemperatureWorking Pressures by Class, psigClass 150 Class 300 Class 600FCWCB(a)WC6(b)C5(c)C12(c)LCC(d)WCB(a)WC6(b)C5(c)C12(c)LCC(d)WCB(a)WC6(b)C5(c)C12(c)LCC(d)-20 to 10020030040050060065070075080085090095010001050110011501200-29 to 38931492042603163433713994274544825105385665936216492852602302001701401251109580655035202902602302001701401251109580655035202020201529026023020017014012511095806550352020202015290260230200170140125110958065503520202020202902602302001701401251109580655035207406806556356055705505305054103202301358575075072069566560559057053051048545032021514595654075075073070566560559057053051048537527520014510060357507507307056656055905705305104854503752551701157550750750730705665605590555505410320225135851,4801,3601,3101,2651,2051,1351,1001,0601,0158256404602751701,5001,5001,4451,3851,3301,2101,1751,1351,0651,015975900640430290190130801,5001,5001,4551,4101,3301,2101,1751.1351,0651,015975745550400290200125701,5001,5001,4551,4101,3301,2101,1751.1351,0651,0159759007555053452251501051,5001,5001,4551,4051,3301,2101,1751,1101,015825640445275170TemperatureWorking Pressures by Class, psigClass 900 Class 1500 Class 2500FCWCB(a)WC6(b)C5(c)C12(c)LCC(d)WCB(a)WC6(b)C5(c)C12(c)LCC(d)WCB(a)WC6(b)C5(c)C12(c)LCC(d)-20 to 10020030040050060065070075080085090095010001050110011501200-29 to 38931492042603163433713994274544825105385665936216492,2202,0351,9651,9001,8101,7051,6501,5901,5201,2359556904102552,2502,2502,1652,0801,9951,8151,7651,7051,5951,5251,4601,3509556504302901951252,2502,2502,1852,1151,9951,8151,7651,7051,5951,5251,4601,1208255954303001851052,2502,2502,1852,1151,9951,8151,7651,7051,5951,5251,4601,3501,1307605153402251552,2502,2502,1852,1101,9951,8151,7651,6651,5201,2359556704102553,7053,3953,2703,1703,0152,8402,7452,6652,5352,0551,5951,1506854303,7503,7503,6403,5303,3253,0252,9402,8402,6602,5402,4352,2451,5951,0807204803252053,7503,7503,6403,5303,3253,0252,9402,8402,6602,5402,4351,8701,3709957204953101703,7503,7503,6403,5303,3253,0252,9402,8402,6602,5402,4352,2451,8851,2708555653752553,7503,7503,6403,5303,3253,0252,9402,7752,5352,0551,5951,1156854306,1705,6555,4505,2805,0254,7304,5754,4254,2303,4302,6551,9151,1457156,2506,2506,0155,7755,5405,0404,9054,7304,4304,2304,0603,7452,6551,8001,2008005453456,2506,2506,0705,8805,5405,0404,9054,7304,4304,2304,0603,1152,2851,6551,2008305152856,2506,2506,0705,8805,5405,0404,9054,7304,4304,2304,0603,7453,1452,1151,4309456304306,2506,2506,0705,8805,5405,0404,9054,6304,2303,4302,6551,8551,145715(a) Upon prolonged exposure to temperatures above 800F, the carbide phase of steel may be converted to graphite.Permissible, but not recommended for prolonged use above 800F(b) Use normalized and tempered material only. Permissible, but not recommended for prolonged use above 1100F(c) Use normalized and tempered material only.(d) Not to be used over 650F.31

CAUTION NOTICE