Melting of lead - Studsvik

Melting of lead - Studsvik

Melting of lead - Studsvik

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

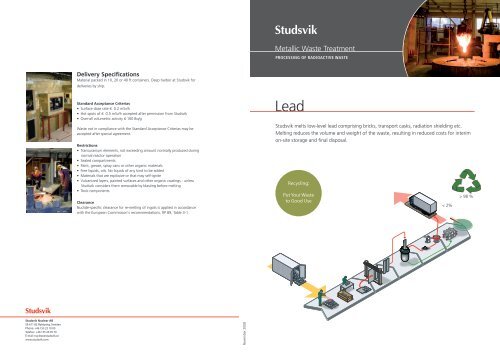

Metallic Waste Treatmentprocessing <strong>of</strong> radioactive wasteDelivery SpecificationsMaterial packed in 10, 20 or 40 ft containers. Deep harbor at <strong>Studsvik</strong> fordeliveries by ship.Standard Acceptance Criterias• Surface dose rate ≤ 0.2 mSv/h• Hot spots <strong>of</strong> ≤ 0.5 mSv/h accepted after permission from <strong>Studsvik</strong>• Over-all volumetric activity ≤ 100 Bq/gWaste not in compliance with the Standard Acceptance Criterias may beaccepted after special agreement.Restrictions• Transuranium elements, not exceeding amount normally produced duringnormal reactor operation• Sealed compartments• Paint, grease, spray cans or other organic materials• Free liquids, oils. No liquids <strong>of</strong> any kind to be added• Materials that are explosive or that may self-ignite• Vulcanized layers, painted surfaces and other organic coatings - unless<strong>Studsvik</strong> considers them removable by blasting before melting• Toxic componentsClearanceNuclide-specific clearance for re-melting <strong>of</strong> ingots is applied in accordancewith the European Commission’s recommendations, RP 89, Table 3-1.Lead<strong>Studsvik</strong> melts low-level <strong>lead</strong> comprising bricks, transport casks, radiation shielding etc.<strong>Melting</strong> reduces the volume and weight <strong>of</strong> the waste, resulting in reduced costs for interimon-site storage and final disposal.Recycling:Put Your Wasteto Good Use< 2%> 98 %<strong>Studsvik</strong> Nuclear ABSE-611 82 Nyköping, SwedenPhone: +46 155 22 10 00Telefax: +46 155 26 30 70E-mail: nuclear@studsvik.sewww.studsvik.comNovember 2008

Lead<strong>Studsvik</strong> melts low-level <strong>lead</strong> comprisingbricks, transport casks, radiation shieldingetc. <strong>Melting</strong> reduces the volume and weight<strong>of</strong> the waste, resulting in reduced costs forinterim on-site storage and final disposal.The end-product is <strong>lead</strong> ingots, which canusually be immediately free-released andsold as conventional scrap metal. Residualproducts (slag, sorted material, cutting residuesand dust from the ventilation filters)and ingots that cannot be free-released arereturned to the customer no later than 2years after delivery.Volume Reduction and RecyclingProviding that the waste is delivered inaccordance with the Delivery Specifications(see last page), we expect to free-release atleast 98 % <strong>of</strong> incoming weight and returna maximum <strong>of</strong> 2 % <strong>of</strong> residual secondarywaste.Logistics<strong>Studsvik</strong> can provide transport co-ordinationand on-site assistance.6.The secondary waste (slag, sortedmaterial, cutting residues and dust from theventilation filters) is packed and measuredaccording to the customer’s requirementsand returned.< 2%> 98 %Slagging agents are added to the molten<strong>lead</strong> to bind the radioactive isotopes to theslag.1.Containerized scrap is normally deliveredin 20 ft containers. The scrap can be deliveredin either drums or boxes or in larger parts.5.The end-product is ingots forfree-release and recycling. Normallymore than 98 % <strong>of</strong> incoming weight isfree-released.4.During melting slagging agentsare added to bind the isotopes to theslag. The melting will homogenize theactivity and allow for reliable sampling.3.If required, additional segmentation isperformed.2.Upon arrival all scrap is inspected andsorted.