Adsorption isotherms of chicory inulin powder ... - Deag.ufcg.edu.br

Adsorption isotherms of chicory inulin powder ... - Deag.ufcg.edu.br

Adsorption isotherms of chicory inulin powder ... - Deag.ufcg.edu.br

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

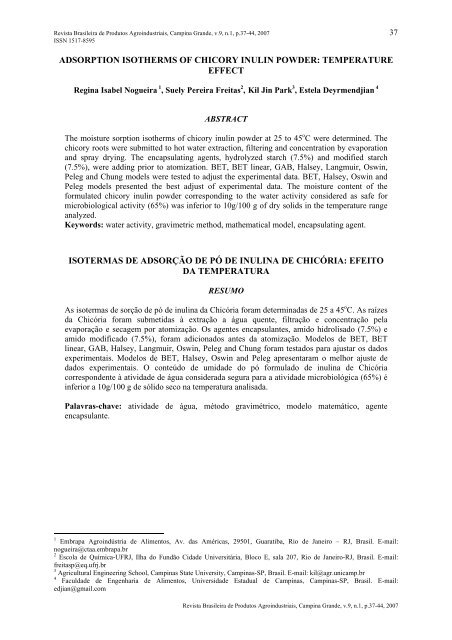

Revista Brasileira de Produtos Agroindustriais, Campina Grande, v.9, n.1, p.37-44, 2007 37ISSN 1517-8595ADSORPTION ISOTHERMS OF CHICORY INULIN POWDER: TEMPERATUREEFFECTRegina Isabel Nogueira 1 , Suely Pereira Freitas 2 , Kil Jin Park 3 , Estela Deyrmendjian 4ABSTRACTThe moisture sorption <strong>isotherms</strong> <strong>of</strong> <strong>chicory</strong> <strong>inulin</strong> <strong>powder</strong> at 25 to 45 o C were determined. The<strong>chicory</strong> roots were submitted to hot water extraction, filtering and concentration by evaporationand spray drying. The encapsulating agents, hydrolyzed starch (7.5%) and modified starch(7.5%), were adding prior to atomization. BET, BET linear, GAB, Halsey, Langmuir, Oswin,Peleg and Chung models were tested to adjust the experimental data. BET, Halsey, Oswin andPeleg models presented the best adjust <strong>of</strong> experimental data. The moisture content <strong>of</strong> theformulated <strong>chicory</strong> <strong>inulin</strong> <strong>powder</strong> corresponding to the water activity considered as safe formicrobiological activity (65%) was inferior to 10g/100 g <strong>of</strong> dry solids in the temperature rangeanalyzed.Keywords: water activity, gravimetric method, mathematical model, encapsulating agent.ISOTERMAS DE ADSORÇÃO DE PÓ DE INULINA DE CHICÓRIA: EFEITODA TEMPERATURARESUMOAs isotermas de sorção de pó de <strong>inulin</strong>a da Chicória foram determinadas de 25 a 45 o C. As raízesda Chicória foram submetidas à extração a água quente, filtração e concentração pelaevaporação e secagem por atomização. Os agentes encapsulantes, amido hidrolisado (7.5%) eamido modificado (7.5%), foram adicionados antes da atomização. Modelos de BET, BETlinear, GAB, Halsey, Langmuir, Oswin, Peleg and Chung foram testados para ajustar os dadosexperimentais. Modelos de BET, Halsey, Oswin and Peleg apresentaram o melhor ajuste dedados experimentais. O conteúdo de umidade do pó formulado de <strong>inulin</strong>a de Chicóriacorrespondente à atividade de água considerada segura para a atividade microbiológica (65%) éinferior a 10g/100 g de sólido seco na temperatura analisada.Palavras-chave: atividade de água, método gravimétrico, modelo matemático, agenteencapsulante.1 Em<strong>br</strong>apa Agroindústria de Alimentos, Av. das Américas, 29501, Guaratiba, Rio de Janeiro – RJ, Brasil. E-mail:nogueira@ctaa.em<strong>br</strong>apa.<strong>br</strong>2 Escola de Química-UFRJ, Ilha do Fundão Cidade Universitária, Bloco E, sala 207, Rio de Janeiro-RJ, Brasil. E-mail:freitasp@eq.ufrj.<strong>br</strong>3 Agricultural Engineering School, Campinas State University, Campinas-SP, Brasil. E-mail: kil@agr.unicamp.<strong>br</strong>4Faculdade de Engenharia de Alimentos, Universidade Estadual de Campinas, Campinas-SP, Brasil. E-mail:edjian@gmail.comRevista Brasileira de Produtos Agroindustriais, Campina Grande, v.9, n.1, p.37-44, 2007

38 <strong>Adsorption</strong> <strong>isotherms</strong> <strong>of</strong> <strong>chicory</strong> <strong>inulin</strong> <strong>powder</strong>: temperature effect Nogueira et al.INTRODUCTIONThe Cichorium intybus L is a seasonalfood material, native <strong>of</strong> Europe, west andcentral Asia, north <strong>of</strong> Africa and South Americaand its tuberous roots store <strong>inulin</strong> (superiot to20%). Inulin is a reserve carbohydrate, whichconsists <strong>of</strong> a chain <strong>of</strong> fructose molecules with aterminal glucose molecule. The application <strong>of</strong><strong>inulin</strong> as a substitute for sugar or fat in foodsindustries has been increased recently due to itsuses to low caloric foods formulations. The<strong>inulin</strong> also presents some functional properties.It acts on the organism in a similar way todietary fibers and have found applications in theproduction <strong>of</strong> functional foods and nutritionalcomposites and medicines (Figueira et al.,2004).The most stable form <strong>of</strong>commercialization <strong>of</strong> <strong>inulin</strong> is the <strong>powder</strong>edextract due to its better facility <strong>of</strong> manipulation.Conventionally, the <strong>chicory</strong> <strong>powder</strong> <strong>inulin</strong> isobtained by dehydration <strong>of</strong> the aqueous extract<strong>of</strong> <strong>chicory</strong> roots (Cichorium intybus L.) in aspray dryer (Nogueira, 2002).The relationship between moisturecontent and other constituents <strong>of</strong> foods affectthe hygroscopic properties <strong>of</strong> these materials.Moisture adsorption <strong>isotherms</strong> exhibitequili<strong>br</strong>ium relation between the moisturecontent <strong>of</strong> food and water activity at a giventemperature and pressure (Gustafson and Hall,1974). Knowledge <strong>of</strong> adsorption <strong>isotherms</strong> <strong>of</strong> afood product is essential to very importantapplications in food science and technology asprocessing, transport, storage and consumption.The deteriorative mechanism in food systems isvery dependent on water activity. In order toinhibit microbial growth and enhanced the shelflife <strong>of</strong> dry food, the water activity is <strong>of</strong>tenr<strong>edu</strong>ced (Labuza, 1986). The knowledge <strong>of</strong>moisture sorption characteristics for theseproducts would allow correctly specifying theconditions <strong>of</strong> storage and packaging.The moisture sorption curves aremathematically expressed as equili<strong>br</strong>ium<strong>isotherms</strong> equations. These equations predictthe effect <strong>of</strong> temperature and pressure in thequantity <strong>of</strong> adsorbed or desorbed water by agiven product. The just determination <strong>of</strong>equili<strong>br</strong>ium moisture in dry products isimportant to optimization <strong>of</strong> dehydrationprocess (Erbas et al, 2004). Model <strong>of</strong>experimental sorption <strong>isotherms</strong> are <strong>of</strong> great usefor predicting thermodynamic tools fordetermining interactions between water and thefood matrix. Several empirical, semi-empiricaland theoretical models have been used fordescribing moisture sorption <strong>isotherms</strong> <strong>of</strong> foods(Labuza, 1985, Chirife & Iglesias, 1978;Valentini et al., 1997). Park and Nogueira(1992); Zhang et al. (1996); Kiranoudis et al.(1993); Lomauro, Baski & Labuza (1985),reported that the three-parameter BET and GABpolynomial models are the more appropriate fordescribing most food <strong>isotherms</strong> (fruits,vegetables, c<strong>of</strong>fee, milk, condiments andothers) over a wide water activity range.Figueira et al, 2004 conclude that sorptioncurves <strong>of</strong> <strong>chicory</strong> roots at 60, 70 and 80 o C,fitted better to the GAB and Peleg models. Inthis case, the equili<strong>br</strong>ium moisture contentdecreased as temperature increased for constantvalue <strong>of</strong> water activity.No significant data is available in theliterature on water sorption <strong>isotherms</strong> <strong>of</strong>formulated <strong>inulin</strong> products. Considering thedevelopment a shelf stable <strong>inulin</strong> product, theobjective <strong>of</strong> the present study was to determine,at different temperatures, the adsorption<strong>isotherms</strong> <strong>of</strong> formulated <strong>inulin</strong> <strong>powder</strong> and soas to adjust them different modelsrecommended in the literature.MATERIAL AND METHODSPreparation <strong>of</strong> <strong>inulin</strong> <strong>powder</strong>Formulated <strong>inulin</strong> <strong>powder</strong> was preparedaccording Nogueira (2000). The <strong>chicory</strong> rootswere submitted to following steps: hot waterextraction, filtering and concentration byevaporation and spray drying. Theencapsulating agents, hydrolyzed starch (7.5%)and modified starch (7.5%), were adding priorto atomization. The inlet and outlet dryingtemperature in spray dryer were 190ºC and95ºC, respectively.Chemical analysisProximate composition <strong>of</strong> <strong>inulin</strong> <strong>powder</strong>was determined by standard methods indicatedin AOAC (2000).Sorption equili<strong>br</strong>ium measurementThe standard gravimetric technique (Bell& Labuza, 2000) was used for equili<strong>br</strong>iumstudies at different temperatures (25 o C, 35 o Cand 45 o C). It consisted <strong>of</strong> sorption measurementusing nine saturated salt solutions (LiCl,KCH 3 COO, KF, MgCl 2 , K 2 CO 3 , NaBr, KI,NaCl, KCl) for a range <strong>of</strong> relative humidityRevista Brasileira de Produtos Agroindustriais, Campina Grande, v.9, n.1, p.37-44, 2007

<strong>Adsorption</strong> <strong>isotherms</strong> <strong>of</strong> <strong>chicory</strong> <strong>inulin</strong> <strong>powder</strong>: temperature effect Nogueira et al. 39from de 0.1116 to 0.8434 according Greenspan(1977). These salts were recommended tomaintain the relative humidity inside thedesiccators (Bizou, Riou & Molton, 1987). Thedesiccators were immersed in an oven (OlidefCZ) adjusted to a fixed temperature to maintainthe salt solutions at a constant temperature.For the sorption experiments the samples<strong>of</strong> <strong>inulin</strong> <strong>powder</strong> were weighted (1g 0.001g)in polystyrene dishes and placed into the sealeddesiccators for adsorption data acquisition. Theweight recording period was two days until aconstant weight determined in an analyticalbalance (Scientech). The difference betweentwo consecutives measurements was less than0.001 g. The dry solid <strong>of</strong> samples wasdetermined by drying at 105 o C in an ovenaccording to standard method (AOAC, 2000).Each experiment was carried out in triplicate.The equili<strong>br</strong>ium moisture in dry basis wasdetermined according to Eq. 1.Xemeq− ms=ms[Eq. 1]where:X e – equili<strong>br</strong>ium moisture content [gH 2 O/g drymass]m eq – weight <strong>of</strong> sample at equili<strong>br</strong>ium [g]m s – dry mass <strong>of</strong> sample [g]Data analysisLeast square regression analysis wasused to adjust the experimental data by BET,BET linear, GAB, Halsey, Langmuir, Oswin,Peleg Henderson and Chung mathematicalmodels (Table 1). The “STATISTICA”program was used to estimate the equili<strong>br</strong>iumparameters from experimental data <strong>of</strong> sorption<strong>isotherms</strong> at constant temperature. The criteriato select the best fitted model was thecorrelation coefficient (r 2 ) and percent averagerelative deviation (ARD) as recommended byChen & Morey (1989). To practical purposes,ARD bellows 10% indicate the goodness <strong>of</strong>adjust. The water content <strong>of</strong> the monolayer wasdetermined from the BET equation.Table 1. Mathematical models applied to the sorption <strong>isotherms</strong> <strong>of</strong> formulated <strong>inulin</strong> <strong>powder</strong>Model Mathematical expressionBET nn+1( Xm⋅ CBET⋅ aw) ⋅ ( 1−( n + 1) ⋅ aw+ n ⋅ aw)Xe=n+11−a ⋅ 1+( C −1)⋅ a − C ⋅ aBET linearX =( ) ( )wBET( 1−a )[ 1−( C −1)a ]wXmCBETGABXm ⋅CGAB⋅ KGAB⋅ awXe=( 1−KGAB⋅ aw) ⋅ (1 − K ⋅ aw+ CGAB⋅ KGAB⋅ aw)Halsey⎛ ⎞⎜ − Aa⎟w= exp⎜ BX ⎟e⎝ ⎠Langmuir XeCLAN+ aw=Xm 1 + CLAN+ awOswinD'⎛ aw⎞Xe= C ⋅⎜1 a⎟⎝ −w ⎠Peleg n1n2Xe= k1⋅ aw+ k2⋅ aw(n 1 1)ChungAln aw= − exp[ −BXe]R ⋅ TaBETwwwBETwRevista Brasileira de Produtos Agroindustriais, Campina Grande, v.9, n.1, p.37-44, 2007

40 <strong>Adsorption</strong> <strong>isotherms</strong> <strong>of</strong> <strong>chicory</strong> <strong>inulin</strong> <strong>powder</strong>: temperature effect Nogueira et al.RESULTS AND DISCUSSIONThe equili<strong>br</strong>ium moisture contents for<strong>powder</strong> <strong>inulin</strong> are found in the range 0.0197 to0.8444 g/g in dry basis (Table 2). It can beobserved a significant effect <strong>of</strong> temperature inthe moisture equili<strong>br</strong>ium for aw between 0.5757and 0.8434. In general it can be observed thatX eq decrease as temperature increase (Table 3).The effect <strong>of</strong> temperature is more significant forwater activity superior to 0.60. The sorption<strong>isotherms</strong> <strong>of</strong> formulated <strong>inulin</strong> <strong>powder</strong> can berepresented by Type III curve (non-sigmoidal),typical <strong>of</strong> many sorption <strong>isotherms</strong> <strong>of</strong> foodmaterial (Fig. 1). According Samaniego-Esguerra, Boag & Robertson (1990), food withhigh sugar content adsorbed low quantity <strong>of</strong>water at low relative humidity and very highquantity <strong>of</strong> water at high relative humidity. Italso can be observed in Fig 1 the interception <strong>of</strong>experimental curves as temperature varies. Thiscomportment is too typical <strong>of</strong> materials withhigh sugar content (Saravacos, Tsiourvas &Tsami (1986); Maroulis, Tsami & Marinos-Kouris, 1988). The same comportment wasobserved by Iglesias & Chirife (1978) fordifferent fruits with high sugar content. It canbe observed that the adsorption increases asrelative humidity increases promoting the sugardissolution. At higher temperatures theequili<strong>br</strong>ium moisture is lower, at a given wateractivity, indicating less hygroscopic capacity.The estimated parameters, the regressioncoefficients and average relative deviation forthe BET, BET linear, GAB, Halsey, Langmuir,Oswin, Peleg, Henderson and Chung modelsare presented in Table 3. According to criteriaadopted, it can be concluded that BET, Halsey,Oswin and Peleg models presented the bestfitted to experimental data with regressioncoefficients superior to 0.9816 and averagerelative deviation in the range <strong>of</strong> 2.54% a9.79%. The experimental and adjusted curves toBET models are presented in the Figure 1.Table 2 – Equili<strong>br</strong>ium moisture (Xe for.) data <strong>of</strong> <strong>chicory</strong> <strong>powder</strong> <strong>inulin</strong> obtained by sorption atdifferent relative humidity at 25ºC, 35ºC and 45ºC.25 o C 35 o C 45 o Ca w X e a w X e a w X e0.1130 0.0434 0.1125 0.0441 0.1116 0.04320.2251 0.0626 0.2459 0.0677 0.2146 0.05740.3278 0.0699 0.3205 0.0697 0.311 0.06530.4316 0.0910 0.4316 nd 0.4316 0.08990.5757 0.1261 0.5455 0.0902 0.5195 0.09770.6886 0.1581 0.6696 0.1551 0.6526 0.11860.7529 0.1830 0.7487 0.1800 0.7452 0.13580.8434 0.2508 0.8295 0.1854 0.8174 0.1616nd- no determined.Revista Brasileira de Produtos Agroindustriais, Campina Grande, v.9, n.1, p.37-44, 2007

<strong>Adsorption</strong> <strong>isotherms</strong> <strong>of</strong> <strong>chicory</strong> <strong>inulin</strong> <strong>powder</strong>: temperature effect Nogueira et al. 41e0.3000Equili<strong>br</strong>ium moisture (g/g)0.25000.20000.15000.10000.05000.00000 0.2 0.4 0.6 0.8 1.0Water activityE25P25E35P35E45P45Figure 1 – Sorption Isotherms fitted by BET model at 25ºC, 35ºC and 45ºC.E – experimental values P – predicted valuesMonolayer moisture content values (X m ),that is a important parameter in food storageand deterioration, are found 0.0522, 0.0528 and0.0505 g/g in dry basis at 25ºC, 35ºC and 45º,respectively (table 3). X m values indicates thatformulated <strong>inulin</strong> <strong>powder</strong> presented lowhygroscopic characteristics, similar to valueobtained to starchy products, between 0.0323and 0.1297, according to experimental datareported by Lomauro, Bakshi & Labuza (1985).Different to equili<strong>br</strong>ium moisture content, theeffect <strong>of</strong> temperature on the X m value can beconsidered neglected. Similar to data reportedby Schar & Rueg (1985), it can be consideredthat water molecules, surrounding the sample,presented the same kinetic energy astemperature change in the range evaluated. TheX m values obtained by the GAB model werehigher than those by the BET model. Thesimilar results were reported by the otherinvestigators (Sandoval & Bareiro, 2005).The X m values <strong>of</strong> foods change withcomposition and processing. Cadden (1988),reported that the processing <strong>of</strong> wheat flourcause a slight r<strong>edu</strong>ction in the X m values(0.0636 in the natural fiber to 0.0595 aftermilling). It was reported by He<strong>br</strong>ard et al(2003) that proteins <strong>of</strong> wheat flour have aboutfive times higher hydration capacity than nativestarch.The BET constant (C BET ) was foundbetween 23.78 and 27.5. In the literature,reported value <strong>of</strong> C BET for wheat is 21.7(Timmerman et al 2001). This constant isrelated logarithmically to the differencebetween the chemical potential <strong>of</strong> the sorbatemolecules in the pure liquid state and in the firstsorption layer. So, these results are consideredas indicative <strong>of</strong> intermolecular attractive forcesbetween adsorption sites and water vapor.Revista Brasileira de Produtos Agroindustriais, Campina Grande, v.9, n.1, p.37-44, 2007

42 <strong>Adsorption</strong> <strong>isotherms</strong> <strong>of</strong> <strong>chicory</strong> <strong>inulin</strong> <strong>powder</strong>: temperature effect Nogueira et al.Table 3. Estimated parameters for all models selected <strong>of</strong> sorption <strong>isotherms</strong> for <strong>chicory</strong> <strong>inulin</strong> <strong>powder</strong>at at 25ºC, 35ºC and 45ºC.Model Parameters 25ºC 35ºC 45ºCX m 0,0522 0,0528 0,0505BETBET - linearGABHalseyLangmuirOswinPelegHendersonChungC BET 27,5005 23,7812 27,2331n 12,9135 8,7170 6,7035R 2 0,9977 0,9793 0,9950ARD (%) 0,0364 0,0779 0,0303X m 0,0436 0,0391 0,0354C BET 6,51E05 2,67E06 2,64E06R 2 0,9712 0,8901 0,9967ARD (%) 0,1139 0,1526 0,1781X m 0,0630 0,0727 0,0653C GAB 13,4816 10,3989 15,7780K GAB 0,4444 0,7820 0,0284R 2 0,9765 0,9719 0,9970ARD (%) 0,1494 0,1687 0,0284A 0,0203 0,0105 0,0053B 1,5523 1,8090 2,0261R 2 0,9979 0,9616 0,9906ARD (%) 0,0401 0,1144 0,0643X m 2,9072 0,6282 0,5153C LAN 0,0916 0,4666 0,4974R 2 0,9532 0,9468 0,1725ARD (%) 0,1551 0,1583 0,1037C 0,1070 0,1028 0,9340D 0,4987 0,4181 0,3650R 2 0,9985 0,9689 0,9973ERM (%) 0,0423 0,0940 0,0254K 1 0,1365 0,0630 0,1353K 2 0,2874 0,2044 0,1296n 1 0,5415 0,1492 0,5508n 2 4,9160 2,2365 5,8805R 2 0,9985 0,9781 0,9972ARD (%) 0,0291 0,0881 0,0308K HEND 0,0646 * *n’ 1,4897 * *R 2 0,9650 * *ARD (%) 0,1288 * *a 9,66E03 * *b 14,2362 * *R 2 0,7423 * *ARD (%) 0,2791 * *CONCLUSIONSThe moisture sorption <strong>isotherms</strong> <strong>of</strong><strong>chicory</strong> <strong>inulin</strong> <strong>powder</strong> at 25 to 45 o C werecharacteristic <strong>of</strong> the type III isotherm (nonsigmoidalcurve). Formulated <strong>chicory</strong> <strong>inulin</strong><strong>powder</strong> presented low hygroscopiccharacteristics in the temperature range <strong>of</strong> 25 to45 o C. BET, Halsey, Oswin and Peleg modelspresented the best adjust <strong>of</strong> experimental dataRevista Brasileira de Produtos Agroindustriais, Campina Grande, v.9, n.1, p.37-44, 2007

<strong>Adsorption</strong> <strong>isotherms</strong> <strong>of</strong> <strong>chicory</strong> <strong>inulin</strong> <strong>powder</strong>: temperature effect Nogueira et al. 43with regression coefficients superior to 0,98 andaverage relative deviation in the range <strong>of</strong> 2.54%to 9.79%. The moisture content <strong>of</strong> theformulated <strong>chicory</strong> <strong>inulin</strong> <strong>powder</strong>corresponding to the water activity consideredas safe for microbiological activity (65%) wasinferior to 10g/100 g <strong>of</strong> dry solids in thetemperature range analyzed. If storage in thehigh relative humidity and temperature, typical<strong>of</strong> tropical ambient air, the moisture content <strong>of</strong>the formulated <strong>chicory</strong> <strong>inulin</strong> <strong>powder</strong> wassuperior to 15 g/100g <strong>of</strong> dry solids.BIBLIOGRAPHY REFERENCEAssociation <strong>of</strong> Official Analytical Chemists.Official methods <strong>of</strong> analysis <strong>of</strong> A.O.A.C.international. 17 ed. Arlington, Virgínia,2000.Bell. L.N.; Labuza, T.P. Moistur sorption<strong>isotherms</strong>: practical aspects <strong>of</strong> <strong>isotherms</strong>measurement and use. Apud In: Moreira,R.; Chenlo, F. Vasquez, M.J.; Cameán, P.Sorption <strong>isotherms</strong> <strong>of</strong> turnip top leave andstems in the temperature range from 298 to328 K. Journal <strong>of</strong> Food Engineering ,v.71, p.193-199, 2005.Bizot, H, Riou, N.; Molton, J.L. Guide pratiquepour la determination des <strong>isotherms</strong> et del’activité de l’eau. Sciences dês aliments:numéro hors série, 1987.Cadden, A. Moisture Sorption Characteristics<strong>of</strong> Several Food Fibers. Journal <strong>of</strong> FoodScience, Chicago, v.53, n.4, p.1150-1155,1988.Chen, C.C.; Morey R.V. Comparison <strong>of</strong> fourEMC/ERH equations. Transaction <strong>of</strong> theASAE, v.32, p. 983-989, 1989.Chirife, J.; Iglesias, H. A. Equations for fittingwater sorption <strong>isotherms</strong> <strong>of</strong> foods: part 1 – areview. Journal <strong>of</strong> Food Technology,London, v. 13, p.159-174, 1978.Erbas, M.; Ertugay, M.F.; Certel, M. Moistureadsortion behaviour <strong>of</strong> semolina and farina.Journal <strong>of</strong> Food engineering, v.69, p. 191-198, 2005.Figueira, G.M.; Park, K.J.; Brod, F.P.R.;Honório, S.L. Evaluation <strong>of</strong> desorption<strong>isotherms</strong>, drying rates and <strong>inulin</strong>concentration <strong>of</strong> <strong>chicory</strong> roots (Chichoriumintybus, L) with and without enzymaticinactivation. Journal <strong>of</strong> Food Engineering,v.63, p. 273-280, 2004.Greenspan, L. Humidity fixed point <strong>of</strong> binarysaturated aqueous solutions. Journal <strong>of</strong>Reserch <strong>of</strong> National Bureau <strong>of</strong> Standards,v. 81, p. 89-96, 1977.Gustafson, R. J.; Hall, G. .Equili<strong>br</strong>ium moisturecontent <strong>of</strong> shelled corn from 50 to 155 o F.Transaction <strong>of</strong> the ASAE, v.17, n.1, p.120-124, 1974.He<strong>br</strong>ard, A. Oulahna, D. Galet, L.; Cuq, B.Abecassis, J.; Fages, J. Hydration properties<strong>of</strong> durum wheat semolina: Influence <strong>of</strong>particle size and temperature. Powdertechnology, v. 130, p. 211-218, 2003.Kiranoudis, C. T.; Maroulis, Z. B.; Tssami, E.;Marinos-Kouris, D. Equili<strong>br</strong>ium moisturecontent <strong>of</strong> some vegetables. Journal <strong>of</strong>Food Engineering, oxford, v.20, n.1, p. 55-74, 1993.Labuza, T. P. Sorption phenomena in foods.Food Technology, Chicago, v.22, n.3,p.263-272, 1968.Labuza, T.P.; Kaanane, A.; Chen, J.Y. effect <strong>of</strong>temperature on the moisture sorption<strong>isotherms</strong> and water activity shift <strong>of</strong> twodehydrated foods. Journal <strong>of</strong> Food Science,v. 50, n.2, p. 385, 1985.Lomauro C. J.; Bakshi, A.S.; Labuza, T.P.Moisture transfer properties <strong>of</strong> dry and semimoistfoods. Journal <strong>of</strong> Food Science,Chicago, v.50, n. 2 p.397-400, 1985.Marchetti, G. Inulina e fruttani. IndustrieAlimentari, Pinerolo, v.32, n.319, p.945-949, 1993.Maroulis, Z. B.; Tsami, E.; Marinos-Kouris, D.Aplicattion <strong>of</strong> the GAB Model to moisturesorption <strong>isotherms</strong> for dried foods. Journal<strong>of</strong> Food Engineering, Oxford, v.7, n.1,p.93, 1988.Nogueira, R. I. Processo de obtenção de<strong>inulin</strong>a de chicória (Cichorium intybus)em pó, Campinas, 2002. 151p. Tese(Doutorado em Engenharia Agrícola)-Faculdade de Engenharia Agrícola,Universidade Estadual de Campinas,Campinas.Nogueira, R. I.; Park, K. J.; Deyrmendjian, E.Flow properties <strong>of</strong> <strong>chicory</strong> (Chicoriumintybus L) extract. In: INTERNATIONALCONGRESS ON ENGINEERING ANDFOOD, 8, 2000, Puebla. Proceedings….Lancaster: Technomic Publishing Co. Inc.,2001. p.425-429.Samaniego-Esguerra, C. M.; Boag, I.F.;Robertson, G.L. Comparison <strong>of</strong> RegressionMethods for fitting the GAB model to themoisture <strong>isotherms</strong> <strong>of</strong> some died fruits andvegetables. Journal <strong>of</strong> Food Engineering,Oxford, v.13, p. 115-133. 1990.Revista Brasileira de Produtos Agroindustriais, Campina Grande, v.9, n.1, p.37-44, 2007

44 <strong>Adsorption</strong> <strong>isotherms</strong> <strong>of</strong> <strong>chicory</strong> <strong>inulin</strong> <strong>powder</strong>: temperature effect Nogueira et al.Sandoval; A.J.; Bareiro, J.A. water sorption<strong>isotherms</strong> <strong>of</strong> non-fermented cocoa beans(theo<strong>br</strong>oma cacao). Journal <strong>of</strong> FoodEngineering, v.51, p. 119-123, 2002.Saravacos, G. D.; Tsiouvars, D. A.; TSAMI, E.Effect <strong>of</strong> temperature on the water sorption<strong>of</strong> sultana raisins. Journal <strong>of</strong> Food Science,Chicago, v. 51, n.2, p. 381-394, 1986.Schar, W.; Ruegg, M. The Evaluation <strong>of</strong> G. A.B. Constants from Water Vapour SorptionData. Lebensmittel-wissenschaft u.Technologie. London, v.18, n.4, p.225-229,1985.Timmerman, E.O.; Chirife, J.; Iglesias, H.A.Water sorption <strong>isotherms</strong> <strong>of</strong> foods andfoodstufss: BET and GAB parameters.Journal <strong>of</strong> Food Engineering, v. 48, p.19-31, 2001.Valentini, S. R. T.; Park, K.J.; Gomes, R. A. R.;Toro, L. F. A. Ventrucci, G. Determinaçãodas isotermas de sorção e propriedadesfísicas de canola (Brassica napus).Coletânea do Instituto de Tecnologia deAlimentos, Campinas, v.27, n.1-2, p.101-109, 1997.Zhang, X. W.; Liu, X; Gu, D. X.; Zhou, W.;Wang, R.L.; Liu, P. Desorption <strong>isotherms</strong> <strong>of</strong>some vegetables. Journal <strong>of</strong> Science andAgriculture, W. Sussex, v. 70, n.3, p. 303-306, 1996.Revista Brasileira de Produtos Agroindustriais, Campina Grande, v.9, n.1, p.37-44, 2007