Lecture 5 - GUC - Faculty of Information Engineering & Technology

Lecture 5 - GUC - Faculty of Information Engineering & Technology

Lecture 5 - GUC - Faculty of Information Engineering & Technology

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

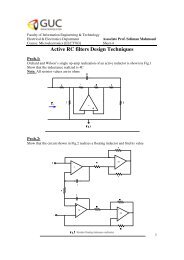

Crystal growth, Wafer fabrication andBasic Properties <strong>of</strong> Silicon WafersCrystal structure (silicon) and defectsAtomic Packing Factor (APF)Miller IndicesCzochralski single crystal growth.Growth rate and dopant incorporation for CZ method.Float zone single crystal growth and doping.Dopant incorporation for FZ method.Wafer fabricationMeasurement methods

Float-Zone (FZ) ProcessA seed crystal is brought into contact with the top end <strong>of</strong>the rod.The seed crystal determines the crystal orientation <strong>of</strong> theboule.A small RF coil provides power, which generates largecurrents in the silicon and locally melts it.The "floating" melt zone is about 2 cm wide.Surface tension and levitation due to RF field keep thesystem stable.RFCoilPolysiliconIngotSingleCrystallineSiSeedAtoms from the liquid phase bond to the single-crystalsolid material plane by atomic plane (As in the CZ process).No crucible is used, which reduces impurity levels.Single

Dopant Incorporation during Crystal GrowthDoping is required in CMOS process with specified type (P or N) and concentration.Dopants are incorporated into the crystal during growth simply by adding dopantsto the melt.It is very important to be able to predict the dopant concentration in the pulledcrystal. This is not as straightforward as might be because <strong>of</strong> segregation.The impurities segregate between the liquid and solid phase at the interfacebetween them.The concentrations <strong>of</strong> the impurity are C S in the solid and C L in the liquid, Asegregation coefficient k O is defined as:kOSegregation occurs due to different solubilities <strong>of</strong> impurity in two phases.CCSL

Segregation Coefficients for Sik O values are normally experimentally measured for a particular impurity in aparticular system at a particular temperature.For most impurities in silicon CZ growth, k O 1. This means that these impuritiesprefer to be in the liquid phase.Both C L and C S are functions <strong>of</strong> time during the growth and will increase if k O 1.

Modeling Dopant Behavior During CZ CrystalGrowthWe define V O , I O and C O to be, respectively, the initial volume, number <strong>of</strong>impurities and impurity concentration in melt, V L , I L and C L to be, respectively, thevolume, number, and concentration <strong>of</strong> impurities in the melt during growth.While, V S and C S to be the corresponding quantities in the solid crystal.Note that V L , I L , C L ,V S and C S will all be functions <strong>of</strong> time if k O 1.V S , C SV O , I O , C OV L , I L , C L

Dopant Behavior During CZ Crystal GrowthFor dopants like antimony where k O 1, the doping concentration increasesdramatically along the length <strong>of</strong> the pulled crystal.The common P-type dopant boron, produces a much flatter pr<strong>of</strong>ile because iscloser to 1.BoronPhosphorus, ArsenicCSCOkO V1 VSOkO1AntimonyC OV S /V 0impurity concentration in melt and C S impurity concentration in solid crystal.

Segregation in FZ ProcessIf the molten zone (L) moves upwards by a distance dx, the number <strong>of</strong> impuritiesin the liquid zone (I) will change since some will be dissolved into the meltingliquid (K O C L dx) at the top and some will be lost to the freezing solid (C O dx) onthe bottom. ThusdI ( CO kOCL)dxwhere I is the number <strong>of</strong> impurities in the liquid. But C L = I/L. Substituting andintegrating, we find thatx0dxIIOCOdIkOILwhere I o is the number <strong>of</strong> impurities in the zone whenit is first formed at the bottom. Noting that I O = C O Land C S = k O I/L,IC Lk CLk0 0 I0e0k00xLCS( x) CO1 (1 kO)ekOx L

Segregation in FZ ProcessIn the float zone process, dopants andother impurities tend to stay in theliquid.Suitable for crystal purificationreduction <strong>of</strong> impurities after eachpass. Suitable for crystal purification

Oxygen Contamination in SiliconDuring CZ Growth Process

Oxygen Contamination in SiliconOxygen is the most important impurity found in silicon.It is incorporated in silicon during the CZ growth process as a result <strong>of</strong> dissolution<strong>of</strong> the quartz crucible in which the molten silicon is contained.Oxygen in silicon is always present at concentrations <strong>of</strong> ~10-20 ppm (5x10 17 -10 18 /cm 3 ) in CZ silicon.Oxygen has three principal effects in the silicon crystal.1. The oxygen is incorporated primarily asdispersed single atoms O I occupying interstitialpositions in the silicon lattice. The oxygen atomsthus replace one <strong>of</strong> the normal Si-Si covalentbonds with a Si-O-Si structure. Oxygen atomsimprove the yield strength <strong>of</strong> silicon by as muchas 25%, making silicon wafers more robust in amanufacturing facility.

Oxygen Contamination in SiliconOxygen is the most important impurity found in silicon.It is incorporated in silicon during the CZ growth process as a result <strong>of</strong> dissolution<strong>of</strong> the quartz crucible in which the molten silicon is contained.Oxygen in silicon is always present at concentrations <strong>of</strong> ~10-20 ppm (5x10 17 -10 18 /cm 3 ) in CZ silicon.Oxygen has three principal effects in the silicon crystal.2. The formation <strong>of</strong> oxygen donors. A small amount<strong>of</strong> the oxygen in the crystal forms SiO 4complexes which act as donors. As many as10 16 /cm 3 donors can be formed, which issufficient to significantly increase theresistivity <strong>of</strong> lightly doped P-type wafers.

Oxygen Contamination in SiliconOxygen is the most important impurity found in silicon.It is incorporated in silicon during the CZ growth process as a result <strong>of</strong> dissolution<strong>of</strong> the quartz crucible in which the molten silicon is contained.Oxygen in silicon is always present at concentrations <strong>of</strong> ~10-20 ppm (5x10 17 -10 18 /cm 3 ) in CZ silicon.Oxygen has three principal effects in the silicon crystal.3. The tendency <strong>of</strong> the oxygen to precipitateunder normal device processing conditions,forming SiO 2 regions inside the wafer. Theprecipitation arises because the oxygen wasincorporated at the melt temperature and istherefore supersaturated in the silicon atprocess temperatures.

Oxygen PrecipitationThe solubilityby*C O<strong>of</strong> oxygen in silicon increases at higher temperatures and is given* 20 0. 89 5.5 10exp kTeV cm3C O1Oxygen’s diffusivity in silicon is given byD O0.13exp 2.53eVkT cm2 secThere is an optimum temperature at which SiO 2 precipitates can be nucleated at700 o C.At lower temperatures the diffusivity <strong>of</strong> oxygen is too low to provide anappreciable probability <strong>of</strong> nuclei forming.Once the nuclei are formed, they continue to grow as long as the wafer is atprocess temperature; optimum growth temperature is 1000 o C .

Future Trends in TechnologiesMagnetic field during CZ growth process help in controlling oxygen concentrations.Surrounding the crucible containing the molten silicon with magnetic field resultsin suppression <strong>of</strong> the thermal convection currents in the melt.The direction <strong>of</strong> the magnetic force tends to reduce the currents flowing in thesilicon conductor due to thermal convection.This produces a more uniform ingot diameter and resistivity because thetemperature fluctuations are smaller, and it produces lower and more uniformoxygen concentrations.Vacuum systemoperating atabove 1400 °C<strong>of</strong>fersThe application <strong>of</strong> DC magneticfield in CZ Si growth.

Crystal growth, Wafer fabrication andBasic Properties <strong>of</strong> Silicon WafersCrystal structure (silicon) and defectsAtomic Packing Factor (APF)Miller IndicesCzochralski single crystal growth.Growth rate and dopant incorporation for CZ method.Float zone single crystal growth and doping.Dopant incorporation for FZ method.Wafer fabricationMeasurement methods

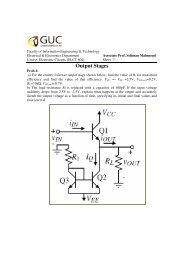

Hot Point ProbeThe hot probe technique is used to determine the type <strong>of</strong> dopant in a waferN or P.A voltmeter placed across the probes will measure a potential differencewhose polarity indicates whether the material is N or P type.For N-type sampleAt the hot probe, the thermal energy <strong>of</strong> the electrons is higher than at thecold probe so the electrons will tend to diffuse away from hot probe.As the electrons diffuse away from the hotprobe, they leave behind the positively charged,while, the cold probe will be negatively charged.Vm-25 -100 o ChotterThe current that flows due to the majoritycarrier is given byJqnn npndTdxP n is thermoelectric power, negative forelectrons, positive for holes.Coldn-type wafere-Hot

Sheet ResistanceThe four point probe method measures the resistance/resistivity <strong>of</strong> a wafer.Using values <strong>of</strong> carrier mobility, one can calculates the carrier concentration.Use four points (rather than two) to eliminate the effect <strong>of</strong> contact resistance.r 1cmqn qpnIf we assume that the semiconductor dimensions are large compared to theprobe spacing, then the resistivity r is simplyVr 2s cmIpIVwhere I is the current driven throughthe two outer probes and V is thepotential difference measuredbetween the inner two.tSd

Hall Effect MeasurementsThis technique can determine the material type, carrier concentration and carriermobility separately. Silicon is placed inside a magnetic field (B z ).The Hall coefficient R H is defined asRHtVB IZHXThe sign <strong>of</strong> R H gives (n or P).The Hall mobility is given asfactor.HRH re,hwhere r is the Hall scatteringThe carrier concentration is given asp, n 1qR H