LaserFOCUS VLF-250 Product Guide - Pertronic Industries Ltd

LaserFOCUS VLF-250 Product Guide - Pertronic Industries Ltd

LaserFOCUS VLF-250 Product Guide - Pertronic Industries Ltd

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

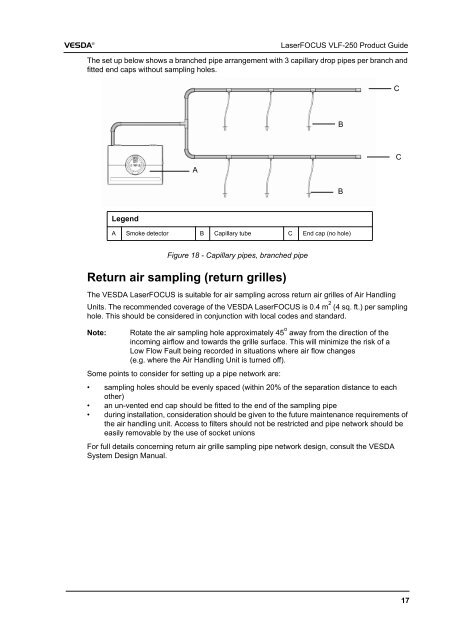

VESDA ®<strong>LaserFOCUS</strong> <strong>VLF</strong>-<strong>250</strong> <strong>Product</strong> <strong>Guide</strong>The set up below shows a branched pipe arrangement with 3 capillary drop pipes per branch andfitted end caps without sampling holes.CBACBLegendA Smoke detector B Capillary tube C End cap (no hole)Figure 18 - Capillary pipes, branched pipeReturn air sampling (return grilles)The VESDA <strong>LaserFOCUS</strong> is suitable for air sampling across return air grilles of Air HandlingUnits. The recommended coverage of the VESDA <strong>LaserFOCUS</strong> is 0.4 m 2 (4 sq. ft.) per samplinghole. This should be considered in conjunction with local codes and standard.Note: Rotate the air sampling hole approximately 45 o away from the direction of theincoming airflow and towards the grille surface. This will minimize the risk of aLow Flow Fault being recorded in situations where air flow changes(e.g. where the Air Handling Unit is turned off).Some points to consider for setting up a pipe network are:• sampling holes should be evenly spaced (within 20% of the separation distance to eachother)• an un-vented end cap should be fitted to the end of the sampling pipe• during installation, consideration should be given to the future maintenance requirements ofthe air handling unit. Access to filters should not be restricted and pipe network should beeasily removable by the use of socket unionsFor full details concerning return air grille sampling pipe network design, consult the VESDASystem Design Manual.17