Valve and Valve Actuator Selection Guide - Staefa Control System

Valve and Valve Actuator Selection Guide - Staefa Control System

Valve and Valve Actuator Selection Guide - Staefa Control System

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

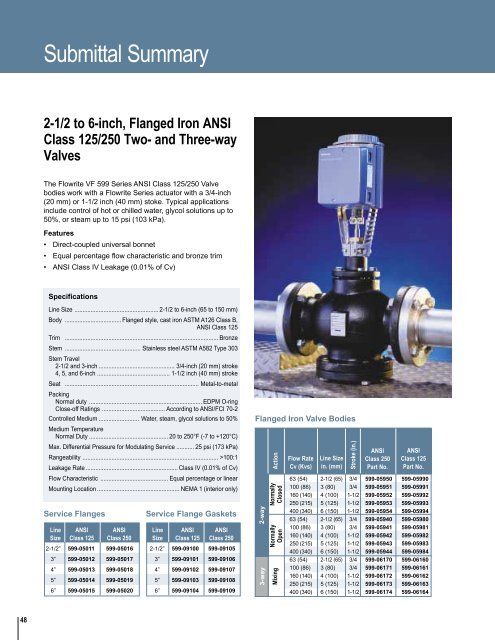

Submittal Summary2-1/2 to 6-inch, Flanged Iron ANSIClass 125/250 Two- <strong>and</strong> Three-way<strong>Valve</strong>sThe Flowrite VF 599 Series ANSI Class 125/250 <strong>Valve</strong>bodies work with a Flowrite Series actuator with a 3/4-inch(20 mm) or 1-1/2 inch (40 mm) stoke. Typical applicationsinclude control of hot or chilled water, glycol solutions up to50%, or steam up to 15 psi (103 kPa).Features• Direct-coupled universal bonnet• Equal percentage flow characteristic <strong>and</strong> bronze trim• ANSI Class IV Leakage (0.01% of Cv)SpecificationsLine Size .................................................... 2-1/2 to 6-inch (65 to 150 mm)Body ................................... Flanged style, cast iron ASTM A126 Class B,ANSI Class 125Trim ............................................................................................... BronzeStem ............................................... Stainless steel ASTM A582 Type 303Stem Travel2-1/2 <strong>and</strong> 3-inch............................................... 3/4-inch (20 mm) stroke4, 5, <strong>and</strong> 6-inch............................................. 1-1/2 inch(40 mm) strokeSeat ................................................................................... Metal-to-metalPackingNormal duty ...................................................................... EDPM O-ringClose-off Ratings ....................................... According to ANSI/FCI 70-2<strong>Control</strong>led Medium ......................... Water, steam, glycol solutions to 50%Medium TemperatureNormal Duty ................................................. 20 to 250°F (-7 to +120°C)Max. Differential Pressure for Modulating Service ........... 25 psi (173 kPa)Rangeability .................................................................................... >100:1Leakage Rate ......................................................... Class IV (0.01% of Cv)Flow Characteristic .......................................... Equal percentage or linearMounting Location ................................................... NEMA 1 (interior only)Service FlangesLine ANSI ANSISize Class 125 Class 2502-1/2” 599-05011 599-050163” 599-05012 599-050174” 599-05013 599-050185” 599-05014 599-050196” 599-05015 599-05020Service Flange GasketsLine ANSI ANSISize Class 125 Class 2502-1/2” 599-09100 599-091053” 599-09101 599-091064” 599-09102 599-091075” 599-09103 599-091086” 599-09104 599-09109Flanged Iron <strong>Valve</strong> Bodies2-way3-wayActionNormallyClosedNormallyOpenMixingFlow RateCv (Kvs)Line Sizein. (mm)Stroke (in.)ANSIClass 250Part No.ANSIClass 125Part No.63 (54) 2-1/2 (65) 3/4 599-05950 599-05990100 (86) 3 (80) 3/4 599-05951 599-05991160 (140) 4 (100) 1-1/2 599-05952 599-05992250 (215) 5 (125) 1-1/2 599-05953 599-05993400 (340) 6 (150) 1-1/2 599-05954 599-0599463 (54) 2-1/2 (65) 3/4 599-05940 599-05980100 (86) 3 (80) 3/4 599-05941 599-05981160 (140) 4 (100) 1-1/2 599-05942 599-05982250 (215) 5 (125) 1-1/2 599-05943 599-05983400 (340) 6 (150) 1-1/2 599-05944 599-0598463 (54) 2-1/2 (65) 3/4 599-06170 599-06160100 (86) 3 (80) 3/4 599-06171 599-06161160 (140) 4 (100) 1-1/2 599-06172 599-06162250 (215) 5 (125) 1-1/2 599-06173 599-06163400 (340) 6 (150) 1-1/2 599-06174 599-0616448