316 Stainless Steel, Bronze and Cast Iron Models - SHURflo Industrial

316 Stainless Steel, Bronze and Cast Iron Models - SHURflo Industrial

316 Stainless Steel, Bronze and Cast Iron Models - SHURflo Industrial

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

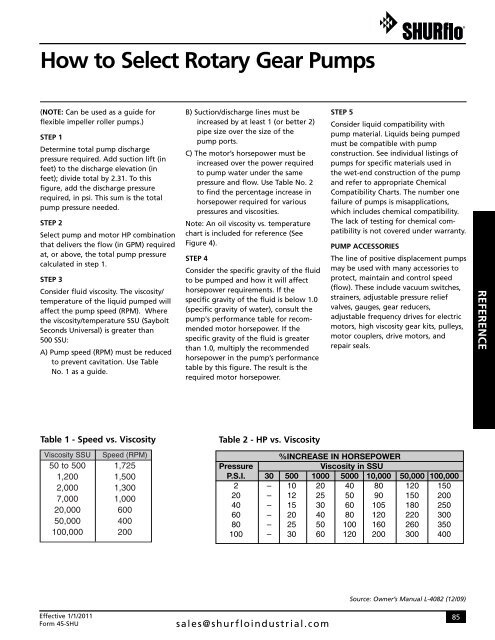

How to Select Rotary Gear Pumps(NOTE: Can be used as a guide forflexible impeller roller pumps.)STEP 1Determine total pump dischargepressure required. Add suction lift (infeet) to the discharge elevation (infeet); divide total by 2.31. To thisfigure, add the discharge pressurerequired, in psi. This sum is the totalpump pressure needed.STEP 2Select pump <strong>and</strong> motor HP combinationthat delivers the flow (in GPM) requiredat, or above, the total pump pressurecalculated in step 1.STEP 3Consider fluid viscosity. The viscosity/temperature of the liquid pumped willaffect the pump speed (RPM). Wherethe viscosity/temperature SSU (SayboltSeconds Universal) is greater than500 SSU:A) Pump speed (RPM) must be reducedto prevent cavitation. Use TableNo. 1 as a guide.B) Suction/discharge lines must beincreased by at least 1 (or better 2)pipe size over the size of thepump ports.C) The motor’s horsepower must beincreased over the power requiredto pump water under the samepressure <strong>and</strong> flow. Use Table No. 2to find the percentage increase inhorsepower required for variouspressures <strong>and</strong> viscosities.Note: An oil viscosity vs. temperaturechart is included for reference (SeeFigure 4).STEP 4Consider the specific gravity of the fluidto be pumped <strong>and</strong> how it will affecthorsepower requirements. If thespecific gravity of the fluid is below 1.0(specific gravity of water), consult thepump's performance table for recommendedmotor horsepower. If thespecific gravity of the fluid is greaterthan 1.0, multiply the recommendedhorsepower in the pump’s performancetable by this figure. The result is therequired motor horsepower.STEP 5Consider liquid compatibility withpump material. Liquids being pumpedmust be compatible with pumpconstruction. See individual listings ofpumps for specific materials used inthe wet-end construction of the pump<strong>and</strong> refer to appropriate ChemicalCompatibility Charts. The number onefailure of pumps is misapplications,which includes chemical compatibility.The lack of testing for chemical compatibilityis not covered under warranty.PUMP ACCESSORIESThe line of positive displacement pumpsmay be used with many accessories toprotect, maintain <strong>and</strong> control speed(flow). These include vacuum switches,strainers, adjustable pressure reliefvalves, gauges, gear reducers,adjustable frequency drives for electricmotors, high viscosity gear kits, pulleys,motor couplers, drive motors, <strong>and</strong>repair seals.REFERENCETable 1 - Speed vs. ViscosityTable 2 - HP vs. Viscosity%INCREASE IN HORSEPOWERPressureViscosity in SSUP.S.I. 30 500 1000 5000 10,000 50,000 100,0002 – 10 20 40 80 120 15020 – 12 25 50 90 150 20040 – 15 30 60 105 180 25060 – 20 40 80 120 220 30080 – 25 50 100 160 260 350100 – 30 60 120 200 300 400Source: Owner’s Manual L-4082 (12/09)Effective 1/1/2011Form 45-SHUsales@shurfloindustrial.com85