Sound & Communications February 2009 Issue

Sound & Communications February 2009 Issue

Sound & Communications February 2009 Issue

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

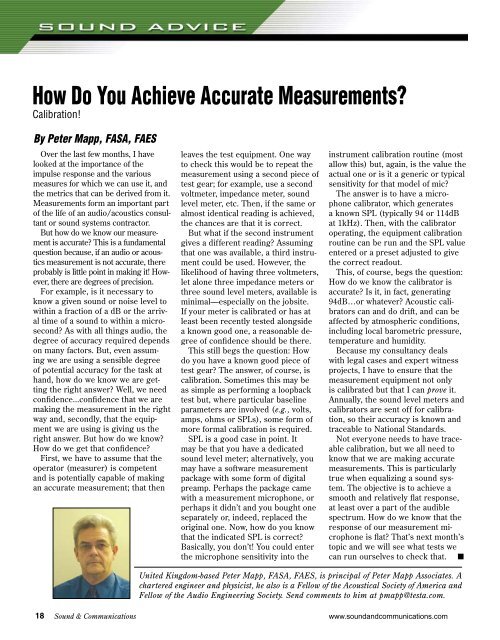

How Do You Achieve Accurate Measurements?Calibration!By Peter Mapp, FASA, FAESOver the last few months, I havelooked at the importance of theimpulse response and the variousmeasures for which we can use it, andthe metrics that can be derived from it.Measurements form an important partof the life of an audio/acoustics consultantor sound systems contractor.But how do we know our measurementis accurate? This is a fundamentalquestion because, if an audio or acousticsmeasurement is not accurate, thereprobably is little point in making it! However,there are degrees of precision.For example, is it necessary toknow a given sound or noise level towithin a fraction of a dB or the arrivaltime of a sound to within a microsecond?As with all things audio, thedegree of accuracy required dependson many factors. But, even assumingwe are using a sensible degreeof potential accuracy for the task athand, how do we know we are gettingthe right answer? Well, we needconfidence...confidence that we aremaking the measurement in the rightway and, secondly, that the equipmentwe are using is giving us theright answer. But how do we know?How do we get that confidence?First, we have to assume that theoperator (measurer) is competentand is potentially capable of makingan accurate measurement; that thenleaves the test equipment. One wayto check this would be to repeat themeasurement using a second piece oftest gear; for example, use a secondvoltmeter, impedance meter, soundlevel meter, etc. Then, if the same oralmost identical reading is achieved,the chances are that it is correct.But what if the second instrumentgives a different reading? Assumingthat one was available, a third instrumentcould be used. However, thelikelihood of having three voltmeters,let alone three impedance meters orthree sound level meters, available isminimal—especially on the jobsite.If your meter is calibrated or has atleast been recently tested alongsidea known good one, a reasonable degreeof confidence should be there.This still begs the question: Howdo you have a known good piece oftest gear? The answer, of course, iscalibration. Sometimes this may beas simple as performing a loopbacktest but, where particular baselineparameters are involved (e.g., volts,amps, ohms or SPLs), some form ofmore formal calibration is required.SPL is a good case in point. Itmay be that you have a dedicatedsound level meter; alternatively, youmay have a software measurementpackage with some form of digitalpreamp. Perhaps the package camewith a measurement microphone, orperhaps it didn’t and you bought oneseparately or, indeed, replaced theoriginal one. Now, how do you knowthat the indicated SPL is correct?Basically, you don’t! You could enterthe microphone sensitivity into theinstrument calibration routine (mostallow this) but, again, is the value theactual one or is it a generic or typicalsensitivity for that model of mic?The answer is to have a microphonecalibrator, which generatesa known SPL (typically 94 or 114dBat 1kHz). Then, with the calibratoroperating, the equipment calibrationroutine can be run and the SPL valueentered or a preset adjusted to givethe correct readout.This, of course, begs the question:How do we know the calibrator isaccurate? Is it, in fact, generating94dB…or whatever? Acoustic calibratorscan and do drift, and can beaffected by atmospheric conditions,including local barometric pressure,temperature and humidity.Because my consultancy dealswith legal cases and expert witnessprojects, I have to ensure that themeasurement equipment not onlyis calibrated but that I can prove it.Annually, the sound level meters andcalibrators are sent off for calibration,so their accuracy is known andtraceable to National Standards.Not everyone needs to have traceablecalibration, but we all need toknow that we are making accuratemeasurements. This is particularlytrue when equalizing a sound system.The objective is to achieve asmooth and relatively flat response,at least over a part of the audiblespectrum. How do we know that theresponse of our measurement microphoneis flat? That’s next month’stopic and we will see what tests wecan run ourselves to check that. nUnited Kingdom-based Peter Mapp, FASA, FAES, is principal of Peter Mapp Associates. Achartered engineer and physicist, he also is a Fellow of the Acoustical Society of America andFellow of the Audio Engineering Society. Send comments to him at pmapp@testa.com.18 <strong>Sound</strong> & <strong>Communications</strong>www.soundandcommunications.com