Reaction Mechanisms of Charcoal and Coke in the ... - Pyro.co.za

Reaction Mechanisms of Charcoal and Coke in the ... - Pyro.co.za

Reaction Mechanisms of Charcoal and Coke in the ... - Pyro.co.za

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

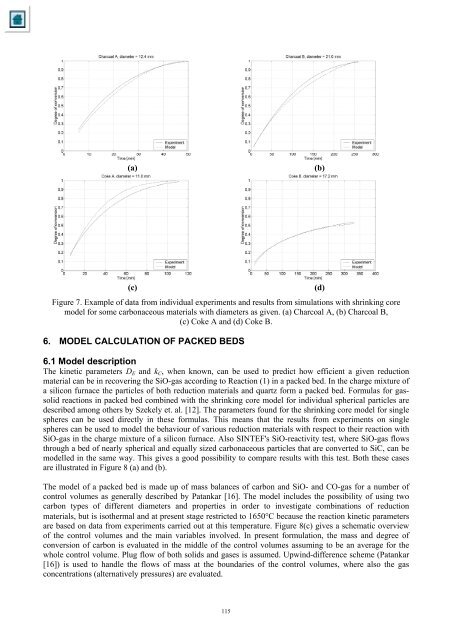

(a)(b)(c)Figure 7. Example <strong>of</strong> data from <strong>in</strong>dividual experiments <strong>and</strong> results from simulations with shr<strong>in</strong>k<strong>in</strong>g <strong>co</strong>remodel for some carbonaceous materials with diameters as given. (a) <strong>Char<strong>co</strong>al</strong> A, (b) <strong>Char<strong>co</strong>al</strong> B,(c) <strong>Coke</strong> A <strong>and</strong> (d) <strong>Coke</strong> B.6. MODEL CALCULATION OF PACKED BEDS6.1 Model descriptionThe k<strong>in</strong>etic parameters D E <strong>and</strong> k C , when known, can be used to predict how efficient a given reductionmaterial can be <strong>in</strong> re<strong>co</strong>ver<strong>in</strong>g <strong>the</strong> SiO-gas ac<strong>co</strong>rd<strong>in</strong>g to <strong>Reaction</strong> (1) <strong>in</strong> a packed bed. In <strong>the</strong> charge mixture <strong>of</strong>a sili<strong>co</strong>n furnace <strong>the</strong> particles <strong>of</strong> both reduction materials <strong>and</strong> quartz form a packed bed. Formulas for gassolidreactions <strong>in</strong> packed bed <strong>co</strong>mb<strong>in</strong>ed with <strong>the</strong> shr<strong>in</strong>k<strong>in</strong>g <strong>co</strong>re model for <strong>in</strong>dividual spherical particles aredescribed among o<strong>the</strong>rs by Szekely et. al. [12]. The parameters found for <strong>the</strong> shr<strong>in</strong>k<strong>in</strong>g <strong>co</strong>re model for s<strong>in</strong>glespheres can be used directly <strong>in</strong> <strong>the</strong>se formulas. This means that <strong>the</strong> results from experiments on s<strong>in</strong>glespheres can be used to model <strong>the</strong> behaviour <strong>of</strong> various reduction materials with respect to <strong>the</strong>ir reaction withSiO-gas <strong>in</strong> <strong>the</strong> charge mixture <strong>of</strong> a sili<strong>co</strong>n furnace. Also SINTEF's SiO-reactivity test, where SiO-gas flowsthrough a bed <strong>of</strong> nearly spherical <strong>and</strong> equally sized carbonaceous particles that are <strong>co</strong>nverted to SiC, can bemodelled <strong>in</strong> <strong>the</strong> same way. This gives a good possibility to <strong>co</strong>mpare results with this test. Both <strong>the</strong>se casesare illustrated <strong>in</strong> Figure 8 (a) <strong>and</strong> (b).The model <strong>of</strong> a packed bed is made up <strong>of</strong> mass balances <strong>of</strong> carbon <strong>and</strong> SiO- <strong>and</strong> CO-gas for a number <strong>of</strong><strong>co</strong>ntrol volumes as generally described by Patankar [16]. The model <strong>in</strong>cludes <strong>the</strong> possibility <strong>of</strong> us<strong>in</strong>g twocarbon types <strong>of</strong> different diameters <strong>and</strong> properties <strong>in</strong> order to <strong>in</strong>vestigate <strong>co</strong>mb<strong>in</strong>ations <strong>of</strong> reductionmaterials, but is iso<strong>the</strong>rmal <strong>and</strong> at present stage restricted to 1650°C because <strong>the</strong> reaction k<strong>in</strong>etic parametersare based on data from experiments carried out at this temperature. Figure 8(c) gives a schematic overview<strong>of</strong> <strong>the</strong> <strong>co</strong>ntrol volumes <strong>and</strong> <strong>the</strong> ma<strong>in</strong> variables <strong>in</strong>volved. In present formulation, <strong>the</strong> mass <strong>and</strong> degree <strong>of</strong><strong>co</strong>nversion <strong>of</strong> carbon is evaluated <strong>in</strong> <strong>the</strong> middle <strong>of</strong> <strong>the</strong> <strong>co</strong>ntrol volumes assum<strong>in</strong>g to be an average for <strong>the</strong>whole <strong>co</strong>ntrol volume. Plug flow <strong>of</strong> both solids <strong>and</strong> gases is assumed. Upw<strong>in</strong>d-difference scheme (Patankar[16]) is used to h<strong>and</strong>le <strong>the</strong> flows <strong>of</strong> mass at <strong>the</strong> boundaries <strong>of</strong> <strong>the</strong> <strong>co</strong>ntrol volumes, where also <strong>the</strong> gas<strong>co</strong>ncentrations (alternatively pressures) are evaluated.(d)