771D Quarry Truck

771D Quarry Truck

771D Quarry Truck

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

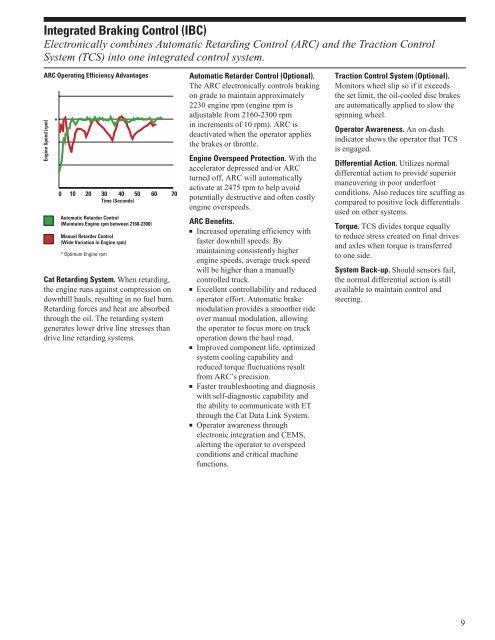

Integrated Braking Control (IBC)Electronically combines Automatic Retarding Control (ARC) and the Traction ControlSystem (TCS) into one integrated control system.ARC Operating Efficiency AdvantagesEngine Speed (rpm)*01020 30 40 50 60Time (Seconds)Automatic Retarder Control(Maintains Engine rpm between 2160-2300)Manual Retarder Control(Wide Variation in Engine rpm)* Optimum Engine rpmCat Retarding System. When retarding,the engine runs against compression ondownhill hauls, resulting in no fuel burn.Retarding forces and heat are absorbedthrough the oil. The retarding systemgenerates lower drive line stresses thandrive line retarding systems.70Automatic Retarder Control (Optional).The ARC electronically controls brakingon grade to maintain approximately2230 engine rpm (engine rpm isadjustable from 2160-2300 rpmin increments of 10 rpm). ARC isdeactivated when the operator appliesthe brakes or throttle.Engine Overspeed Protection. With theaccelerator depressed and/or ARCturned off, ARC will automaticallyactivate at 2475 rpm to help avoidpotentially destructive and often costlyengine overspeeds.ARC Benefits.■ Increased operating efficiency withfaster downhill speeds. Bymaintaining consistently higherengine speeds, average truck speedwill be higher than a manuallycontrolled truck.■ Excellent controllability and reducedoperator effort. Automatic brakemodulation provides a smoother rideover manual modulation, allowingthe operator to focus more on truckoperation down the haul road.■ Improved component life, optimizedsystem cooling capability andreduced torque fluctuations resultfrom ARC’s precision.■ Faster troubleshooting and diagnosiswith self-diagnostic capability andthe ability to communicate with ETthrough the Cat Data Link System.■ Operator awareness throughelectronic integration and CEMS,alerting the operator to overspeedconditions and critical machinefunctions.Traction Control System (Optional).Monitors wheel slip so if it exceedsthe set limit, the oil-cooled disc brakesare automatically applied to slow thespinning wheel.Operator Awareness. An on-dashindicator shows the operator that TCSis engaged.Differential Action. Utilizes normaldifferential action to provide superiormaneuvering in poor underfootconditions. Also reduces tire scuffing ascompared to positive lock differentialsused on other systems.Torque. TCS divides torque equallyto reduce stress created on final drivesand axles when torque is transferredto one side.System Back-up. Should sensors fail,the normal differential action is stillavailable to maintain control andsteering.9