The Most Complete Subframe System - Chris Alston's Chassisworks

The Most Complete Subframe System - Chris Alston's Chassisworks

The Most Complete Subframe System - Chris Alston's Chassisworks

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

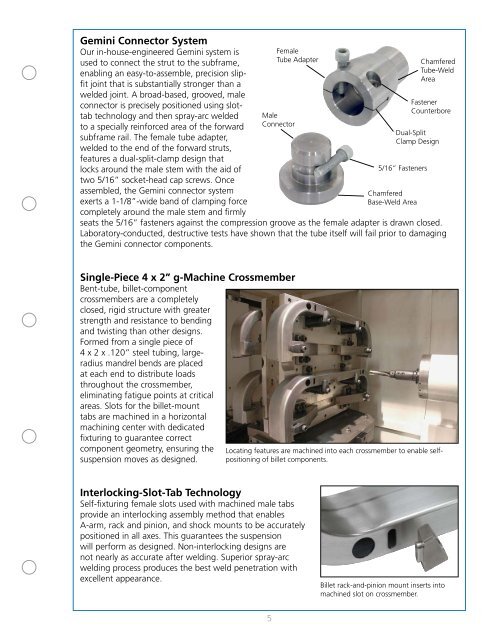

Gemini Connector <strong>System</strong>Our in-house-engineered Gemini system isused to connect the strut to the subframe,enabling an easy-to-assemble, precision slipfitjoint that is substantially stronger than awelded joint. A broad-based, grooved, maleconnector is precisely positioned using slottabtechnology and then spray-arc weldedto a specially reinforced area of the forwardsubframe rail. <strong>The</strong> female tube adapter,welded to the end of the forward struts,features a dual-split-clamp design thatlocks around the male stem with the aid oftwo 5/16” socket-head cap screws. Onceassembled, the Gemini connector systemexerts a 1-1/8”-wide band of clamping forcecompletely around the male stem and firmlyFemaleTube AdapterMaleConnectorFastenerCounterboreDual-SplitClamp Design5/16” FastenersChamferedBase-Weld AreaChamferedTube-WeldAreaseats the 5/16” fasteners against the compression groove as the female adapter is drawn closed.Laboratory-conducted, destructive tests have shown that the tube itself will fail prior to damagingthe Gemini connector components.Single-Piece 4 x 2” g-Machine CrossmemberBent-tube, billet-componentcrossmembers are a completelyclosed, rigid structure with greaterstrength and resistance to bendingand twisting than other designs.Formed from a single piece of4 x 2 x .120” steel tubing, largeradiusmandrel bends are placedat each end to distribute loadsthroughout the crossmember,eliminating fatigue points at criticalareas. Slots for the billet-mounttabs are machined in a horizontalmachining center with dedicatedfixturing to guarantee correctcomponent geometry, ensuring thesuspension moves as designed.Locating features are machined into each crossmember to enable selfpositioningof billet components.Interlocking-Slot-Tab TechnologySelf-fixturing female slots used with machined male tabsprovide an interlocking assembly method that enablesA-arm, rack and pinion, and shock mounts to be accuratelypositioned in all axes. This guarantees the suspensionwill perform as designed. Non-interlocking designs arenot nearly as accurate after welding. Superior spray-arcwelding process produces the best weld penetration withexcellent appearance.Billet rack-and-pinion mount inserts intomachined slot on crossmember.5