ERIKS nv - O-ring Technical Handbook

ERIKS nv - O-ring Technical Handbook

ERIKS nv - O-ring Technical Handbook

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

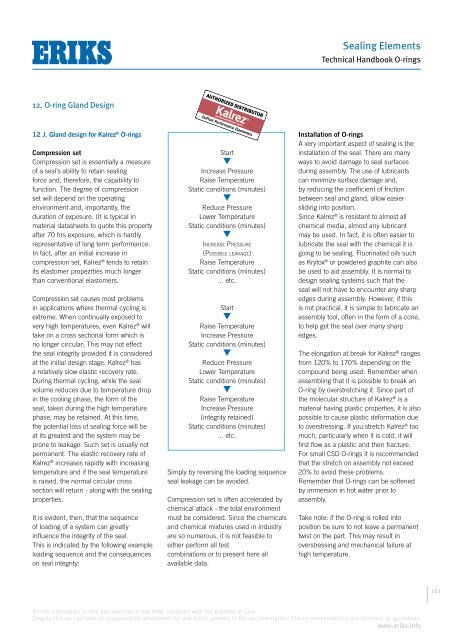

Sealing Elements<strong>Technical</strong> <strong>Handbook</strong> O-<strong>ring</strong>s12. O-<strong>ring</strong> Gland Design12 J. Gland design for Kalrez ® O-<strong>ring</strong>sCompression setCompression set is essentially a measureof a seal’s ability to retain sealingforce and, therefore, the capability tofunction. The degree of compressionset will depend on the operatinge<strong>nv</strong>ironment and, importantly, theduration of exposure. (It is typical inmaterial datasheets to quote this propertyafter 70 hrs exposure, which is hardlyrepresentative of long term performance.In fact, after an initial increase incompression set, Kalrez ® tends to retainits elastomer propezrties much longerthan co<strong>nv</strong>entional elastomers.Compression set causes most problemsin applications where thermal cycling isextreme. When continually exposed tovery high temperatures, even Kalrez ® willtake on a cross sectional form which isno longer circular; This may not effectthe seal integrity provided it is consideredat the initial design stage. Kalrez ® hasa relatively slow elastic recovery rate.Du<strong>ring</strong> thermal cycling, while the sealvolume reduces due to temperature dropin the cooling phase, the form of theseal, taken du<strong>ring</strong> the high temperaturephase, may be retained. At this time,the potential loss of sealing force will beat its greatest and the system may beprone to leakage. Such set is usually notpermanent. The elastic recovery rate ofKalrez ® increases rapidly with increasingtemperature and if the seal temperatureis raised, the normal circular crosssection will return - along with the sealingproperties.It is evident, then, that the sequenceof loading of a system can greatlyinfluence the integrity of the seal.This is indicated by the following exampleloading sequence and the consequenceson seal integrity:Start▼Increase PressureRaise TemperatureStatic conditions (minutes)▼Reduce PressureLower TemperatureStatic conditions (minutes)▼In c r e a s e Pressure(Po s s i b l e l e a k a g e)Raise TemperatureStatic conditions (minutes)... etc.Start▼Raise TemperatureIncrease PressureStatic conditions (minutes)▼Reduce PressureLower TemperatureStatic conditions (minutes)▼Raise TemperatureIncrease Pressure(integrity retained)Static conditions (minutes)... etc.Simply by reversing the loading sequenceseal leakage can be avoided.Compression set is often accelerated bychemical attack - the total e<strong>nv</strong>ironmentmust be considered. Since the chemicalsand chemical mixtures used in industryare so numerous, it is not feasible toeither perform all testcombinations or to present here allavailable data.Installation of O-<strong>ring</strong>sA very important aspect of sealing is theinstallation of the seal. There are manyways to avoid damage to seal surfacesdu<strong>ring</strong> assembly. The use of lubricantscan minimize surface damage and,by reducing the coefficient of frictionbetween seal and gland, allow easiersliding into position.Since Kalrez ® is resistant to almost allchemical media, almost any lubricantmay be used. In fact, it is often easier tolubricate the seal with the chemical it isgoing to be sealing. Fluorinated oils suchas Krytox ® or powdered graphite can alsobe used to aid assembly. It is normal todesign sealing systems such that theseal will not have to encounter any sharpedges du<strong>ring</strong> assembly. However, if thisis not practical, it is simple to fabricate anassembly tool, often in the form of a cone,to help get the seal over many sharpedges.The elongation at break for Kalrez ® rangesfrom 120% to 170% depending on thecompound being used. Remember whenassembling that it is possible to break anO-<strong>ring</strong> by overstretching it. Since part ofthe molecular structure of Kalrez ® is amaterial having plastic properties, it is alsopossible to cause plastic deformation dueto overstressing. If you stretch Kalrez ® toomuch, particularly when it is cold, it willfirst flow as a plastic and then fracture.For small CSD O-<strong>ring</strong>s it is recommendedthat the stretch on assembly not exceed20% to avoid these problems.Remember that O-<strong>ring</strong>s can be softenedby immersion in hot water prior toassembly.Take note: if the O-<strong>ring</strong> is rolled intoposition be sure to not leave a permanenttwist on the part. This may result inoverstressing and mechanical failure athigh temperature.161All the information in this documentation has been compiled with the greatest of care.Despite this we can bear no responsibility whatsoever for any errors present in the documentation. The recommendations are intended as guidelines.www.eriks.info