ERIKS nv - O-ring Technical Handbook

ERIKS nv - O-ring Technical Handbook

ERIKS nv - O-ring Technical Handbook

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

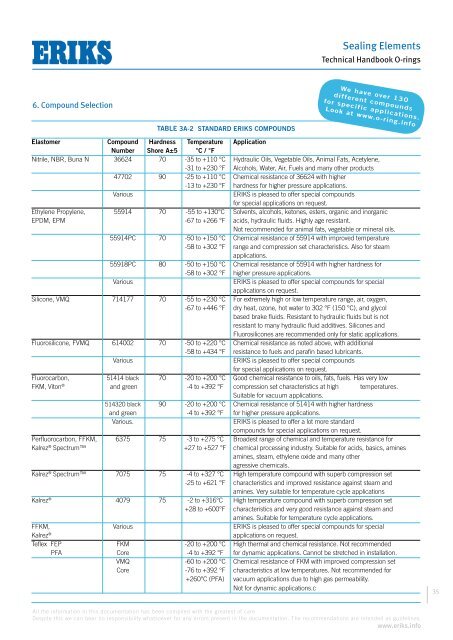

Sealing Elements<strong>Technical</strong> <strong>Handbook</strong> O-<strong>ring</strong>s6. Compound SelectionWe have over 130different compoundsfor specific applications.Look at www.o-<strong>ring</strong>.infoTable 3A-2 Standard <strong>ERIKS</strong> CompoundsElastomer Compound Hardness Temperature ApplicationNumber Shore A±5 °C / °FNitrile, NBR, Buna N 36624 70 -35 to +110 °C Hydraulic Oils, Vegetable Oils, Animal Fats, Acetylene,-31 to +230 °F Alcohols, Water, Air, Fuels and many other products47702 90 -25 to +110 °C Chemical resistance of 36624 with higher-13 to +230 °F hardness for higher pressure applications.Various<strong>ERIKS</strong> is pleased to offer special compoundsfor special applications on request.Ethylene Propylene, 55914 70 -55 to +130°C Solvents, alcohols, ketones, esters, organic and inorganicEPDM, EPM -67 to +266 °F acids, hydraulic fluids. Highly age resistant.Not recommended for animal fats, vegetable or mineral oils.55914PC 70 -50 to +150 °C Chemical resistance of 55914 with improved temperature-58 to +302 °F range and compression set characteristics. Also for steamapplications.55918PC 80 -50 to +150 °C Chemical resistance of 55914 with higher hardness for-58 to +302 °F higher pressure applications.Various<strong>ERIKS</strong> is pleased to offer special compounds for specialapplications on request.Silicone, VMQ 714177 70 -55 to +230 °C For extremely high or low temperature range, air, oxygen,-67 to +446 °F dry heat, ozone, hot water to 302 °F (150 °C), and glycolbased brake fluids. Resistant to hydraulic fluids but is notresistant to many hydraulic fluid additives. Silicones andFluorosilicones are recommended only for static applications.Fluorosilicone, FVMQ 614002 70 -50 to +220 °C Chemical resistance as noted above, with additional-58 to +434 °F resistance to fuels and parafin based lubricants.Various<strong>ERIKS</strong> is pleased to offer special compoundsfor special applications on request.Fluorocarbon, 51414 black 70 -20 to +200 °C Good chemical resistance to oils, fats, fuels. Has very lowFKM, Viton ® and green -4 to +392 °F compression set characteristics at high temperatures.Suitable for vacuum applications.514320 black 90 -20 to +200 °C Chemical resistance of 51414 with higher hardnessand green -4 to +392 °F for higher pressure applications.Various.<strong>ERIKS</strong> is pleased to offer a lot more standardcompounds for special applications on request.Perfluorocarbon, FFKM, 6375 75 -3 to +275 °C Broadest range of chemical and temperature resistance forKalrez ® Spectrum +27 to +527 °F chemical processing industry. Suitable for acids, basics, aminesamines, steam, ethylene oxide and many otheragressive chemicals.Kalrez ® Spectrum 7075 75 -4 to +327 °C High temperature compound with superb compression set-25 to +621 °F characteristics and improved resistance against steam andamines. Very suitable for temperature cycle applicationsKalrez ® 4079 75 -2 to +316°C High temperature compound with superb compression set+28 to +600°F characteristics and very good resistance against steam andamines. Suitable for temperature cycle applications.FFKM, Various <strong>ERIKS</strong> is pleased to offer special compounds for specialKalrez ®applications on request.Teflex FEP FKM -20 to +200 °C High thermal and chemical resistance. Not recommendedPFA Core -4 to +392 °F for dynamic applications. Cannot be stretched in installation.VMQ -60 to +200 °C Chemical resistance of FKM with improved compression setCore -76 to +392 °F characteristics at low temperatures. Not recommended for+260°C (PFA) vacuum applications due to high gas permeability.Not for dynamic applications.c35All the information in this documentation has been compiled with the greatest of care.Despite this we can bear no responsibility whatsoever for any errors present in the documentation. The recommendations are intended as guidelines.www.eriks.info