IB-80000A Non Segregated Phase Bus Duct - Powell Industries, Inc.

IB-80000A Non Segregated Phase Bus Duct - Powell Industries, Inc.

IB-80000A Non Segregated Phase Bus Duct - Powell Industries, Inc.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

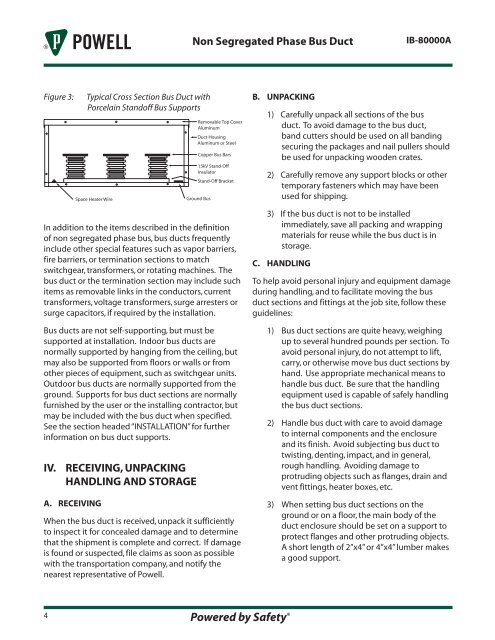

<strong>Non</strong> <strong>Segregated</strong> <strong>Phase</strong> <strong>Bus</strong> <strong>Duct</strong> <strong>IB</strong>-<strong>80000A</strong>Figure 3: Typical Cross Section <strong>Bus</strong> <strong>Duct</strong> withPorcelain Standoff <strong>Bus</strong> SupportsB. UNPACKING1) Carefully unpack all sections of the busRemovable Top CoverAluminum<strong>Duct</strong> HousingAluminum or SteelCopper <strong>Bus</strong> Bars15kV Stand-OffInsulatorStand-Off Bracketduct. To avoid damage to the bus duct,band cutters should be used on all bandingsecuring the packages and nail pullers shouldbe used for unpacking wooden crates.2) Carefully remove any support blocks or othertemporary fasteners which may have beenSpace Heater WireGround <strong>Bus</strong>used for shipping.3) If the bus duct is not to be installedIn addition to the items described in the definitionimmediately, save all packing and wrappingof non segregated phase bus, bus ducts frequentlymaterials for reuse while the bus duct is ininclude other special features such as vapor barriers,storage.fire barriers, or termination sections to matchswitchgear, transformers, or rotating machines. TheC. HANDLINGbus duct or the termination section may include suchitems as removable links in the conductors, currenttransformers, voltage transformers, surge arresters orsurge capacitors, if required by the installation.<strong>Bus</strong> ducts are not self-supporting, but must besupported at installation. Indoor bus ducts arenormally supported by hanging from the ceiling, butmay also be supported from floors or walls or fromother pieces of equipment, such as switchgear units.Outdoor bus ducts are normally supported from theground. Supports for bus duct sections are normallyfurnished by the user or the installing contractor, butTo help avoid personal injury and equipment damageduring handling, and to facilitate moving the busduct sections and fittings at the job site, follow theseguidelines:1) <strong>Bus</strong> duct sections are quite heavy, weighingup to several hundred pounds per section. Toavoid personal injury, do not attempt to lift,carry, or otherwise move bus duct sections byhand. Use appropriate mechanical means tohandle bus duct. Be sure that the handlingequipment used is capable of safely handlingthe bus duct sections.may be included with the bus duct when specified.See the section headed “INSTALLATION” for further2) Handle bus duct with care to avoid damageinformation on bus duct supports.to internal components and the enclosureand its finish. Avoid subjecting bus duct totwisting, denting, impact, and in general,IV. RECEIVING, UNPACKINGrough handling. Avoiding damage toprotruding objects such as flanges, drain andHANDLING AND STORAGEvent fittings, heater boxes, etc.A. RECEIVING3) When setting bus duct sections on theground or on a floor, the main body of theWhen the bus duct is received, unpack it sufficientlyduct enclosure should be set on a support toto inspect it for concealed damage and to determineprotect flanges and other protruding objects.that the shipment is complete and correct. If damageA short length of 2”x4” or 4”x4” lumber makesis found or suspected, file claims as soon as possiblea good support.with the transportation company, and notify thenearest representative of <strong>Powell</strong>.Powered by Safety ®