2010 - Putzmeister

2010 - Putzmeister

2010 - Putzmeister

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

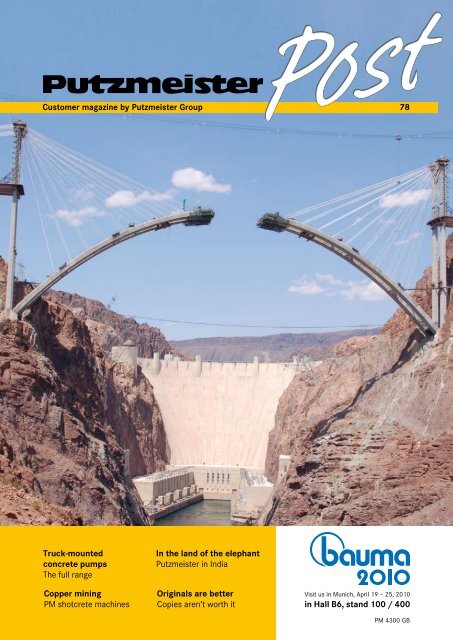

Customer magazine by <strong>Putzmeister</strong> Group 78<br />

Truck-mounted<br />

concrete pumps<br />

The full range<br />

Copper mining<br />

PM shotcrete machines<br />

In the land of the elephant<br />

<strong>Putzmeister</strong> in India<br />

Originals are better<br />

Copies aren‘t worth it<br />

Visit us in Munich, April 19 – 25, <strong>2010</strong><br />

in Hall B6, stand 100 / 400<br />

PM 4300 GB

Foreword<br />

Truck-mounted concrete pumps<br />

New solutions in practice and<br />

the full range at Bauma<br />

M 49-5 – With 4 axles in the fast lane<br />

Technology<br />

Important PUMI functions significantly improved<br />

Telebelt –<br />

From specialist to attractive allrounder<br />

Increased profitability for the prefabricated parts industry<br />

The P 13 piston pump –<br />

the “offroad plastering machine”<br />

Bauma partner country India<br />

“Our core competences remain<br />

product, quality and service”<br />

Not just for India –<br />

robust and cost-effective trailer concrete pump<br />

Mining and tunneling<br />

New high-performance pump<br />

for mining tailings and fly ash<br />

The new SPM 4207 – concrete spraying<br />

specially for small tunnel cross-sections<br />

Services<br />

Fleet management with the i-DAISY<br />

international web application<br />

Economic concrete placement beyond<br />

the reach of truck-mounted concrete pumps<br />

Beware of cheap parts and dumping offers!<br />

<strong>Putzmeister</strong> used machines –<br />

first class from second hand<br />

3<br />

4<br />

6<br />

9<br />

12<br />

13<br />

22<br />

14<br />

16<br />

17<br />

19<br />

8<br />

10<br />

20<br />

23<br />

Imprint<br />

Titel<br />

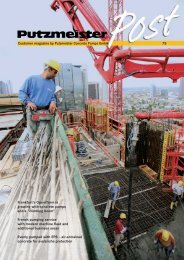

Title picture: The Colorado River Bridge<br />

on the Hoover Dam crosses the river at a<br />

height of approx. 294m.<br />

The main contractor for the project was an<br />

Obyashi/PSM Joint Venture. The sub-contractor<br />

for concrete pumping was Quinn<br />

Concrete Pumping. From the outset, <strong>Putzmeister</strong><br />

was involved in this project in an<br />

advisory capacity. In the end, a wide range<br />

of PM machines was used: the stationary<br />

concrete pumps BSA 2107 HP-E and BSA<br />

2109 H-E, the stationary booms MX 32/36 Z<br />

and MX 36/40 Z, and the truck-mounted<br />

concrete pumps M 42 and M 58.<br />

Due to the heat and to avoid blockages,<br />

pumping was carried out predominantly<br />

at night.<br />

Publisher:<br />

<strong>Putzmeister</strong> Concrete Pumps GmbH,<br />

Max-Eyth-Straße 10,<br />

72631 Aichtal / Germany<br />

Editorial department: Volker Wehner<br />

<strong>Putzmeister</strong> Concrete Pumps GmbH<br />

Layout/DTP: GleisNeun GmbH,<br />

Gerbergasse 16,<br />

97877 Wertheim / Germany<br />

Print: Offizin Scheufele GmbH + Co. KG,<br />

Tränkestraße 17,<br />

70597 Stuttgart / Germany<br />

1<br />

2<br />

Welcome to Bauma, welcome to<br />

<strong>Putzmeister</strong> in hall B6.<br />

The last two years have been marked by<br />

dramatic changes in the global economy<br />

and almost every company has been<br />

affected by this. And in many meetings, we<br />

have learnt from you, our customers, how<br />

you are adjusting to this in your business.<br />

We have based our trade fair appearance<br />

on this: with new machines and plant solutions,<br />

which can also open up opportunities<br />

in the difficult market environment.<br />

These include the M 49-5 truck-mounted<br />

concrete pump on 4 axles, a new shotcrete<br />

machine for small tunnel diameters and<br />

the Telebelt TBS 130, which can be a new<br />

business approach for service providers,<br />

as a semi-trailer. Consistent further development<br />

and staggered services aim to<br />

optimise applications and reduce your operating<br />

costs.<br />

India is the partner country of this year‘s<br />

Bauma. That‘s why this issue includes<br />

a brief insight into the activities of our<br />

Indian subsidiary, which has made a good<br />

name for itself there in just a short time.<br />

Our trade fair stand for <strong>2010</strong>, as always, is<br />

in hall B6. This should give you an outward<br />

sign that we, the new company management,<br />

stand for continuity in accordance<br />

with our motto “Serve, Improve, Create<br />

value”.<br />

We look forward to your visit.<br />

Norbert Scheuch<br />

Managing Director<br />

<strong>Putzmeister</strong> Holding GmbH (Chairman) and<br />

<strong>Putzmeister</strong> Concrete Pumps GmbH (CEO)<br />

Foreword<br />

3 4<br />

Dr. Robert Abel<br />

Managing Director<br />

<strong>Putzmeister</strong> Concrete Pumps GmbH (CCO)<br />

2 PM 4300 GB PM 4300 GB 3

Truck-mounted concrete pumps<br />

M 42-4 in use in Emirate Scharjah (UAE)<br />

Truck-mounted concrete pumps – new<br />

solutions in practice and the full range<br />

At the trade fair stand, <strong>Putzmeister</strong> will<br />

exhibit many models, from the smallest to<br />

the biggest truck-mounted concrete pump.<br />

The machines, with vertical boom reaches<br />

of approximately 20 to 70 m are, as shown<br />

in the following overview, very specifical-<br />

ly tailored to the needs or requirements of<br />

individual countries and applications.<br />

With various models, <strong>Putzmeister</strong> shows<br />

its wide range of innovative technology<br />

such as Follow-me, EBC (Ergonic Boom<br />

The large boom for India<br />

Not exhibited at Bauma in Munich:<br />

The BSS 46-5 truck-mounted<br />

concrete pump exhibited for the<br />

first time at the Indian Excon last<br />

November.<br />

This large boom trailer is specially<br />

tailored to the specific requirements<br />

of the Indian market. Above<br />

all, the Indian conditions for approval<br />

for road use had to be met. Since<br />

4-axle vehicles are limited to a maximum<br />

gross weight of 31 tons, 46 m<br />

vertical reaches are not so feasible.<br />

The answer is a 3-axle tractor unit with<br />

3-axle trailer, which is significantly under<br />

the permissible gross weight of 44 tons.<br />

6<br />

Control) or the patented TRDV variable<br />

position support system. There is also<br />

practice-oriented equipment and options,<br />

such as the Sanima kit, radio remote control<br />

with display, solutions for the extension<br />

of end hoses, etc. n<br />

Another important argument, in addition<br />

to the enormous reach with the<br />

flexible 5-arm boom, is the efficient<br />

independent power unit. In addition,<br />

it is possible to pump without a tractor<br />

unit. This means the tractor unit is<br />

free to be used for other tasks. n<br />

BSS 46-5 –<br />

the 5-arm large boom<br />

specially designed for<br />

the Indian market<br />

4 PM 4300 GB<br />

5<br />

Maximum reach of 20 to 70 m<br />

7<br />

8<br />

9<br />

10<br />

11<br />

12<br />

Truck-mounted concrete pumps<br />

M 20-4<br />

Ideal for halls, under bridges, etc. with<br />

3.9 m minimum unfolding and working<br />

height. It also has the smallest<br />

support area and is extremely manoeuvrable<br />

on the road.<br />

M 36-4<br />

The bestseller in the 30 m class: Versatile<br />

thanks to the flexible Z fold<br />

system and small support area..<br />

Bauma tip: At the trade fair, we will<br />

be performing a live demonstration<br />

of the latest version of the Follow Me<br />

technology on the M 36-4.<br />

M 42-5<br />

Allrounder on 4 axles with flexible<br />

5-arm RZ fold system.<br />

Practical detail: The container on the<br />

support leg gives additional storage<br />

space.<br />

M 49-5<br />

Maximum reach and optimal priceperformance<br />

ratio: Available either on<br />

4 or 5 axles. On the Chinese market, a<br />

special version of the M 49-5 is available<br />

(see next page).<br />

M 58-5<br />

The large boom on 5 axles with spacesaving,<br />

variable position TRDV support.<br />

This means the machine doesn‘t<br />

take up any more space than is absolutely<br />

necessary.<br />

M 70-5<br />

The world‘s longest 5-arm boom in<br />

actual construction site use. Full utilisation<br />

of the reach without<br />

limiting pump torque. The<br />

innovative IRS support technology<br />

ensures minimum space<br />

requirements.<br />

PM 4300 GB 5

Truck-mounted concrete pumps<br />

M 49-5 – with 4 axles in the fast lane<br />

The request for maximum reach on 4 axles<br />

first came from the Chinese market. <strong>Putzmeister</strong><br />

exhibited its new M 49-5 truckmounted<br />

concrete pump for the first time<br />

at the last Bauma Shanghai. The innovation<br />

was an immediate success there.<br />

This was due to the right balance between<br />

reaching the permissible gross weight for<br />

the 4-axle chassis (HINO) established on<br />

the market there and the minimum support<br />

area with a flexible 5-arm boom. In<br />

addition, the price for the M 49-5 should<br />

be significantly lower than the M 52-5 with<br />

the highly flexible, variable position TRDV<br />

support. These advantages will be presented<br />

by <strong>Putzmeister</strong> in Europe for the first<br />

time at the Bauma fair.<br />

The gross weight of this machine on 4<br />

axles is approx. 40 tons. It is therefore of<br />

interest wherever a large boom is required<br />

on a low-priced chassis with a maximum<br />

reach of 50 m. The RZ fold system offers<br />

crucial advantages in certain application<br />

situations in high-rise construction<br />

(see box). n<br />

Here, the 5-arm boom of the M 49-5 shows an enormous horizontal reach.<br />

The additional 5th arm and its hinge increase flexibility, possible uses and<br />

net reach of a truck-mounted concrete pump (top). Due to a lack of manoeuvrability,<br />

a 4-arm boom is much more difficult to slip into buildings. It<br />

may have to give up on attaining its net reach, depending on how great the<br />

distance is.<br />

13<br />

14<br />

Practical<br />

training is<br />

worth it<br />

<strong>Putzmeister</strong> offers its customers a wide range<br />

of possibilities for training and further<br />

training. In theory courses, with learning<br />

modules developed in-house by <strong>Putzmeister</strong>,<br />

and in practical courses, users of <strong>Putzmeister</strong><br />

machines can learn the best way to<br />

use their PM products. n<br />

Please contact us at:<br />

www.pm-akademie.de<br />

Improper handling can be prevented<br />

through competent training.<br />

The range of <strong>Putzmeister</strong> collector‘s<br />

models is certainly not as wide as<br />

the range of actual 1:1 models. But<br />

in terms of quality and attention to<br />

detail, <strong>Putzmeister</strong> is uncompromising<br />

here too. All available models are<br />

“Made in Germany“ and come from<br />

the famous model maker Conrad.<br />

At this year‘s Bauma, you can purchase<br />

these concrete pumps, PUMIs and<br />

mortar machines in the <strong>Putzmeister</strong><br />

advertising gift shop at trade fair prices.<br />

Moreover, they are available to<br />

collectors via the <strong>Putzmeister</strong> web<br />

shop the whole year through. n<br />

You can find our shop at:<br />

www.mycybershop.de/shopPM<br />

With our qualified personnel, you can learn in practical situations, thereby avoiding<br />

later operating errors. This increases safety for man and machine.<br />

16 17 18<br />

The worldwide local training courses<br />

ensure increased competence and<br />

efficiency.<br />

Training significantly reduces maintenance<br />

requirements and costs.<br />

Concrete pump models for collectors<br />

Beside numerous models true to the original like the Pumi you will find our<br />

exclusive anniversary model of the 1972 truck-mounted concrete pump in<br />

our webshop.<br />

6 PM 4300 GB PM 4300 GB 7<br />

Services<br />

15<br />

19

Fleet management system<br />

Fleet management with the<br />

i-DAISY international web application<br />

With i-DAISY, <strong>Putzmeister</strong> offers simplified,<br />

Internet-based scheduling of the<br />

machine fleet with machine location,<br />

especially for customers abroad.<br />

The connection between the vehicles and<br />

the concrete pump headquarters is established<br />

via GPRS (General Packet Radio<br />

Service). Access via the Internet means the<br />

system is available internationally. To this<br />

end, certain technical, personnel and linguistic<br />

conditions are required on site.<br />

With i-DAISY, the company‘s entire vehicle<br />

fleet including truck mixers, silo trains,<br />

etc. can be scheduled. Likewise, an economically<br />

viable cooperation is possible for<br />

operators with widespread sites and partners.<br />

These are the experiences of the Reno<br />

Pumbeton AG concrete pumping service in<br />

Maienfeld, Switzerland, for example.<br />

Reno Pumpbeton AG is a joint venture of<br />

4 local concrete plants. They joined forces<br />

in order to offer their customers a pumping<br />

service. Each pump is stationed at<br />

a different site and pump scheduling is<br />

performed locally at the respective concrete<br />

plants. Mr Tobler (technical manager)<br />

reports that in the past this meant<br />

that several calls were often required bet-<br />

Entry of customer order<br />

Telephone reception of<br />

customer order<br />

Scheduling diagram –<br />

order progress<br />

automatically<br />

Display of<br />

geographical location<br />

ween the plants and the customer in order<br />

to reserve a site use. This system was very<br />

time-consuming and inefficient for the<br />

customer and for the schedulers. With the<br />

introduction of i-DAISY at the end of 2007,<br />

the situation improved instantly.<br />

Complete overview for schedulers.<br />

At any time.<br />

Although scheduling is still decentralised,<br />

each scheduler has a full overview of the<br />

availability of the concrete pumps and the<br />

status of the current orders. He can therefore<br />

book a site use for a customer or, if the<br />

desired pump type is not available, offer<br />

alternatives immediately.<br />

This clear plus point in service is rated<br />

highly by the customers and the schedulers,<br />

after initial scepticism, can no longer<br />

imagine working without i-DAISY. In<br />

the opinion of Reno Pumpbeton AG, experience<br />

with i-DAISY has shown the following<br />

advantages: Easy operation, minimum<br />

training effort, low investment costs (PC<br />

with Internet connection), improved customer<br />

service and increased efficiency, optimal<br />

planability and utilisation of the fleet.<br />

A further advantage is that i-DAISY increases<br />

transparency, resulting in a more<br />

visible site status of the vehicle, time recor-<br />

Delivery note<br />

administration –<br />

semi-automatic<br />

Time recording<br />

Order processing<br />

GPS location<br />

ding by clocking in and off in the vehicle,<br />

GPS localisation of the vehicle and display<br />

of the vehicle and site of use on the map.<br />

In addition, fully automatic construction<br />

site processing is possible with i-DAISY.<br />

In other words, the construction site status,<br />

the arrival and departure from the<br />

construction site, as well as the start and<br />

end of pumping operations are determined<br />

and transmitted by the vehicle equipment,<br />

BCL on-board computer, without intervention<br />

by the driver.<br />

i-DAISY can also be combined with the reduced<br />

and more cost-effective functions of<br />

the standalone module i-GOT-U. There, as<br />

in i-DAISY, the current vehicle positions<br />

and, retrospectively, the routes driven,<br />

are displayed. In addition, the system can<br />

send e-mails or text messages to defined<br />

addressees, for example if a vehicle leaves<br />

a geographically defined region or interventions<br />

are made on the BCT on-board<br />

computer. n<br />

Order data/<br />

GPS data<br />

Internet<br />

Central internet server<br />

Communication /<br />

radio data<br />

transmission<br />

GPRS (TCP/IP)<br />

20<br />

Important PUMI functions<br />

significantly improved<br />

The PUMI 31.89 S exhibited at the trade fair stand is also available in a version with<br />

a vertical reach of nearly 28 m.<br />

Seven years ago, we introduced the<br />

Ergonic control for the PUMI. This tried<br />

and tested technology allows us to realise<br />

further application-oriented functions<br />

easily. Some of these are new at BAUMA.<br />

We spoke with Frank Riderer, the head<br />

of the PUMI Business Sector, on this<br />

subject.<br />

PM: What are the innovations in the im-<br />

proved PUMI?<br />

FR: We have several interesting new options.<br />

These include, for example, a radio<br />

remote control with display.<br />

PM: This will primarily help the machine<br />

operator. Are there other new functions to<br />

help the operator?<br />

FR: Yes, with the software controlled Ergonic,<br />

it is possible to realise even complex<br />

processes, such as an automatic draining<br />

function. This is difficult or impossible<br />

to accomplish with purely hydraulic controls.<br />

PM: What does “automatic draining function”<br />

mean?<br />

FR: With this patent-pending function, the<br />

speed of the mixer is adapted to the delivery<br />

rate of the pump. That is, with a low<br />

delivery rate, the mixer also turns slowly.<br />

Jerky start-up and braking of the mixer, as<br />

was the case before, is therefore resolved.<br />

PM: You are exhibiting a mixer cleaning<br />

function. What‘s behind this?<br />

FR: If this function is activated during<br />

pumping, for example, the mixer drum<br />

automatically rotates briefly to the right<br />

and then to the left, without any intervention<br />

by the operator. This causes the water<br />

in the drum to slosh to and fro so that any<br />

concrete stuck in the mixing spirals near<br />

the outlet can be continuously rinsed and<br />

washed away with very little water.<br />

PM: What option do you consider to be particularly<br />

interesting?<br />

FR: The request by a Swiss customer,<br />

who wants to add water to the mixer drum<br />

metered via the radio remote control.<br />

PM: What is the advantage of this?<br />

FR: Often, after starting to pump, the<br />

placement team complains that the concrete<br />

is too stiff. The machine operator<br />

must then go from the site of concrete<br />

placement to the machine to add water to<br />

the concrete and then mix it through again.<br />

In future, this will be possible directly from<br />

the radio remote control.<br />

PM: Is it actually permissible to add water to<br />

the concrete mixer?<br />

FR: It is permissible to add water to the<br />

concrete if it is scheduled, there is a metering<br />

device and the added water volume is<br />

noted on the delivery note. n<br />

21<br />

Die PUMI 31.89 S in operation<br />

Frank Riderer<br />

Business Sector<br />

Manager<br />

Email:<br />

RidererF@pmw.de<br />

The Ergonic radio remote control<br />

with display<br />

8 PM 4300 GB PM 4300 GB 9<br />

Pumi<br />

22<br />

23<br />

24

Concrete Project Division (CPD) project consultation<br />

Solutions “off the shelf” do not meet all requirements. In special projects in particular, intelligent and economic individual<br />

concepts are required.<br />

Economical concrete conveying beyond<br />

the reach of truck-mounted concrete pumps<br />

Just like in sports, <strong>Putzmeister</strong> had to<br />

work hard for the many, worldwide pump<br />

records in its history in concrete high-rise<br />

and long-distance placement.<br />

Essentially, these records were achieved<br />

by the right solutions to engineering<br />

requests or, in other words, the successful<br />

implementation of customer requirements.<br />

This decade-long development of concrete<br />

placement concepts is today the foundation<br />

of machine technology and, above all, the<br />

knowledge to which the <strong>Putzmeister</strong> engineers<br />

from the Concrete Project Division<br />

(CPD) refer in their engineering services.<br />

The field of application here ranges from<br />

high-rise, power plant, water, dam and<br />

bridge construction to tunnelling, longdistance<br />

concrete placement and excavation.<br />

The CPD contacts will be at Bauma, in hall<br />

6 or outside, ready to answer your questions<br />

or discuss your individual Projects.<br />

Wie present you the following machines<br />

and aspects of stationary concrete placement<br />

technology at Bauma:<br />

• Concrete placement climbing system<br />

RS 850 with the new boom MX 30(33)-3<br />

• Stationary pumps from various service<br />

classes in electric and diesel versions<br />

• System parts from the <strong>Putzmeister</strong><br />

concrete delivery line, coupling and gate<br />

valve systems, designed for concrete<br />

pressures of 85 bar to over 200 bar.<br />

The <strong>Putzmeister</strong> Concrete Project Division<br />

(CPD) is your partner for:<br />

• Demanding concrete delivery tasks<br />

in construction engineering<br />

• Consultation in the fields of concreting<br />

logistics, concrete technology with the<br />

focus on „pumpability of concretes“ and<br />

concreting processes<br />

25<br />

The aim: Increased profitability through<br />

timely planning of the correct machine<br />

technology and the right concrete placement<br />

processes. n<br />

Special cases require individual<br />

solutions: For example, the “Dubai<br />

gate valve”, which was responsible for<br />

enabling the record-breaking delivery<br />

heights of over 600 metres during the<br />

construction of the Burj Khalifa.<br />

26<br />

Concrete work on Block 3 of the Finnish KKW Olkiluoto<br />

Concreting of the huge cavern of the Austrian pump accumulator power plant KOPS II<br />

Super high-pressure pumps BSA 14,000 SMPD in use for<br />

high-rise pumping at the Burj Khalifa (formerly Burj Dubai).<br />

Concrete Project Division (CPD) project consultation<br />

27<br />

28<br />

29<br />

Sample applications of <strong>Putzmeister</strong><br />

concrete delivery line systems and<br />

concrete gate valve systems<br />

Concrete pressure < 130 bar<br />

High, deep and long-distance placement<br />

• Economical solution for common<br />

applications with stationary concrete<br />

pumps<br />

• Low material weight, short assembly<br />

times, easy handling<br />

Concrete pressure 130 – 200 bar<br />

High-rise construction up to<br />

approx. 450 m, far and deep placement<br />

• Economical solution for large outputs at<br />

high pressures<br />

• Very good line stability and flexibility<br />

• High wear-resistance and long<br />

service life<br />

Concrete pressure > 200 bar<br />

Extremely high and long-distance<br />

concrete placement<br />

• Very good stability in the event of load<br />

shifting during concrete pump switchover<br />

at very high pump pressures<br />

• Very good line stability and assembly<br />

High wear-resistance and long<br />

service life<br />

10 PM 4300 GB PM 4300 GB 11

Telebelt<br />

The tried and tested <strong>Putzmeister</strong> Telebelt will in future also be available in a new version as a semi-trailer.<br />

This will turn the material transport specialist into an unbeatably versatile multi-talent.<br />

From specialist to<br />

attractive allrounder<br />

The <strong>Putzmeister</strong> Telebelt (Telescopic<br />

Belt Conveyor) is a versatile construction<br />

machine for placing concrete and a<br />

range of other materials up to a diameter<br />

of 300 mm. The constant pulsation<br />

and pressure-free material transport on<br />

the belt allows for high placement (up to<br />

450 m 3 /h) with low operating costs.<br />

The world‘s biggest population of Telebelt<br />

machines is in the USA. There, the Telebelt<br />

is used by service providers as an addition<br />

to the truck-mounted concrete pump and<br />

places not only concrete, but also hardcore,<br />

gravel, sand and other materials on<br />

construction sites.<br />

Outside the USA, the Telebelt has previously<br />

been used predominantly in dam<br />

construction. The reason for this is its<br />

strength in delivering standard concretes<br />

and non-pumpable concretes, such as coarse<br />

concrete, earth-moist concrete or roller<br />

compacted concrete. The Telebelt is also<br />

excellently suited to special placement<br />

tasks in gardening and landscaping. There,<br />

materials like sand, earth and mulch<br />

can be conveyed.<br />

With the new semi-trailer version TBS 130,<br />

it was possible to change the fields of use<br />

world-wide quickly from specialist to allrounder.<br />

The semi-trailer now enables operation<br />

of a wide range of tractor units<br />

as a Telebelt with just minimal adaptation<br />

effort. The country-specific approval<br />

for road use must be checked, however,<br />

a special chassis is no longer required in<br />

Europe. n<br />

31<br />

What does this mean for the operator<br />

or investor?<br />

• significantly lower investment<br />

• almost every make can be used as the<br />

tractor unit, even a used machine or<br />

a machine from an existing fleet<br />

• onward sale is subject to hardly<br />

any restrictions in terms of approval<br />

for road use and the exhaust gas<br />

standard of the chassis. This makes<br />

financing easier.<br />

• lower fuel consumption through<br />

the use of the independent power<br />

unit belonging to the semi-trailer<br />

• significantly lower wear costs<br />

per m 3 than with truck-mounted<br />

concrete pumps<br />

The Telebelt is therefore worth it not<br />

only for the high placement volumes<br />

of large projects. This is reason<br />

enough to see a familiar subject<br />

in a new light.<br />

30<br />

More profitability for the<br />

prefabricated parts industry<br />

Autocor is the name <strong>Putzmeister</strong> gives<br />

to systems for the prefabricated parts<br />

industry, in which concrete pumps and<br />

placement systems are used to place<br />

the concrete particularly efficiently and<br />

economically in the formworks.<br />

When identifying a solution, for example,<br />

the elimination of bottlenecks, the reduction<br />

in maintenance times or less followup<br />

work due to improved surface quality<br />

all play a major role. And depending on<br />

the annual capacity, end product, available<br />

hall, investment framework, etc. customer-specific<br />

answers have to be developed<br />

using modular components. Previously,<br />

such systems were predominantly used<br />

for the production of prestressed concrete<br />

towers for wind energy generation, noise<br />

protection walls, prestressed concrete pipe,<br />

manholes, bridge elements or 2-dimensional<br />

structural concrete components.<br />

To represent this pumping technology,<br />

<strong>Putzmeister</strong> is exhibiting the rotor<br />

pump Autocor BQ 06 at Bauma.<br />

This is just as suitable for a stationary<br />

installation as for mobile jobs, for which it<br />

is transported from hall to hall to the formworks.<br />

As another alternative, the machine<br />

can be set up on a carrier frame and thereby<br />

used flexibly in different production<br />

halls (see photo).<br />

The BQ 06 fills formwork with concrete<br />

quickly and economically. At the same<br />

time, there is little concrete residue and<br />

cleaning is quick and easy. The Bauma<br />

machine shows an attached crane, as special<br />

equipment, with which the delivery<br />

line can be easily guided. Other advantages<br />

of the rotor system: Only one individual,<br />

quick-change wear part and low<br />

noise emissions.<br />

For prefabricated parts plants, <strong>Putzmeister</strong><br />

offers not only machines and equipment,<br />

but also competent advice for the operator,<br />

so that the system can meet his individual<br />

requirements. n<br />

Autocor ® benefits at a glance:<br />

Solutions for the prefabricated part industry<br />

This application case shows the filling of large structural parts. The Autocor BQ 06,<br />

secured to a carrier frame, moves along the formwork.<br />

33 34<br />

• ideal for prefabricated concrete parts plants which produce medium or large<br />

structural prefabricated parts and use pumpable normal concrete or self-compressing<br />

concrete<br />

• increases the production volume by up to 60%<br />

• high quality of parts thanks to continuous concrete placement<br />

• cleaner process thanks to closed system<br />

• no expensive and time-consuming lining of the formwork thanks to<br />

flexible boom<br />

• formwork can be filled from top or bottom<br />

• separation of crane operation and concreting process<br />

12 PM 4300 GB PM 4300 GB 13<br />

32

Bauma partner country India<br />

“Our core competences remain<br />

product, quality and service”<br />

Extracts from an interview with Mr.<br />

M. Schmid-Lindenmayer on the successful<br />

<strong>Putzmeister</strong> presence on the India<br />

subcontinent.<br />

PM: For around 3 years, <strong>Putzmeister</strong> has<br />

been present on the Indian market with its<br />

own plant. What were the reasons for this?<br />

SL: We have invested in our own team and<br />

production here in India because we are<br />

convinced of the big future for this market<br />

and wanted to be able to meet demand for<br />

marketable products quickly and more efficiently.<br />

PM: Have you as OEM now got a different<br />

strategy?<br />

SL: Our strategy rests on two pillars. On<br />

the one hand, we want to develop products<br />

that the market really needs in a short time<br />

and bring them onto the market. And on<br />

the other hand, we are increasingly expanding<br />

our service network. This is a critical<br />

success factor in this business, which<br />

<strong>Putzmeister</strong> is pursuing worldwide.<br />

PM: How far have you come in this<br />

short time?<br />

SL: In our modern plant in Goa, with<br />

an area of 100,000 m 2 , we now produce<br />

13 machine types for the Indian market<br />

with 250 employees. These are the stationary<br />

pumps BSA 1404, 1407, the Moli 1404,<br />

Moli 1407 in diesel and electric versions<br />

and the truck-mounted concrete pump models<br />

BSF 32.09, BSF 36.07/09, BSF 42.09<br />

and BSS 46.14.<br />

Our BSA 1404 HD, launched last September,<br />

is now our most popular trailer concrete<br />

pump in India. At the Excon trade<br />

fair in November 2009, we were the first<br />

to exhibit a homologated M 42 and a M 46<br />

in semi-trailer version - marketable with<br />

the Indian truck. These are machines that<br />

surprised everyone and which are ideal as<br />

a large boom for airports, flyovers, liquid<br />

gas tanks, cooling towers and other types<br />

of large construction projects.<br />

PM: And to what extent have you built up<br />

your service organisation so far?<br />

SL: We now already have 13 bases, distributed<br />

throughout the country, such as in<br />

Delhi, Mumbai, Goa, Bangalore and Chennai,<br />

to name but a few. In addition, we have<br />

The modern <strong>Putzmeister</strong> plant in Goa, with an area of 100,000 m 2 , produces for<br />

the Indian market.<br />

of course also invested predominantly in<br />

the qualification of our people in sales and<br />

service.<br />

PM: How has this expansion been possible<br />

in such a short time?<br />

SL: There are several reasons. One of these<br />

is our Indian employees who are willing<br />

to learn. They have learnt very quickly<br />

with the help of experts from Germany. In<br />

addition, their training was very practical:<br />

in the after-sales service, during training<br />

and in the consultation and implementation<br />

of concrete placement in construction<br />

projects.<br />

PM: Are there examples of this?<br />

SL: Our pumps have been used in very<br />

many projects, such as the construction<br />

of the underground railway in Delhi, the<br />

sports complexes of the Commonwealth<br />

Games, many steel and power plants, etc.<br />

The most famous projects include Ruby<br />

Mill (high-rise in Mumbai), the biggest refinery<br />

in the world by ESSAR and Reliance<br />

in Jamnagar as well as the airports in Delhi<br />

and Mumbai, which were realised by L&T,<br />

India‘s biggest construction firm.<br />

PM: Finally, a completely different question:<br />

What are you expecting from Bauma <strong>2010</strong>?<br />

SL: First, we‘re excited that India is the<br />

partner country for this year‘s Bauma. We<br />

hope that many customers will visit us at<br />

this worldwide trade fair for construction<br />

machinery, that we will be able to make<br />

new contacts and that they will ultimately<br />

take away a positive impression of the capability<br />

of the <strong>Putzmeister</strong> Group. n<br />

Michael Schmid-<br />

Lindenmayer<br />

Managing Director,<br />

<strong>Putzmeister</strong><br />

Concrete Machines<br />

Pvt. Ltd. in Goa,<br />

India<br />

<strong>Putzmeister</strong><br />

Goa, India<br />

<strong>Putzmeister</strong> distributors and Service are<br />

to be found all over India by now.<br />

35<br />

36<br />

37<br />

Best experiences<br />

Vascon Engineers Limited, based in<br />

Mumbai, is a distinguished Indian construction<br />

firm with revenue of more<br />

than EUR 100 million. It focuses on construction<br />

projects in the fields of infrastructure,<br />

real estate and hotels. Vascon<br />

Engineers Ltd. has more than 20 years<br />

experience in the planning, development,<br />

construction and administration<br />

of a wide range of projects throughout<br />

India and has already received many<br />

awards from the Builders Association of<br />

India (BAI).<br />

For its construction projects, Vascon<br />

relies on state-of-the-art construction<br />

machinery. This includes 6 BSA 1407 D<br />

During the ritual, a coconut is broken<br />

until its milk leaks out.<br />

In the “pooja” ceremony, thanks are<br />

given for the new object and a blessing<br />

is sought.<br />

38<br />

39<br />

stationary pumps. A very prestigious reference<br />

is the 190 m tall „Ruby Mill“ office<br />

complex project in Mumbai (the current<br />

height of construction is 160 m). This construction<br />

project is a classic example of how<br />

mechanisation improves construction or<br />

cycle times and safety standards. For concrete<br />

placement, two M 32 stationary booms<br />

and two BSA 1408 HD concrete pumps by<br />

<strong>Putzmeister</strong>, which are more efficient than<br />

the BSA 1407, are used.<br />

Mr. Manoj Kallur, Vice President Projects<br />

of Vascon Engineers Ltd. says: “We have already<br />

been collaborating with <strong>Putzmeister</strong><br />

for a long time and have had excellent experiences.<br />

The <strong>Putzmeister</strong> team provides<br />

Here, the person conducting the ceremony,<br />

knocks the hard, dry coconut shell on a<br />

hard surface until a crack appears and the<br />

shell breaks. The sweet coconut milk leaks<br />

out and the drops are sprinkled over the<br />

venerated object.<br />

The nut is then broken up completely. The<br />

1 to 2 cm thick flesh is peeled out, cut into<br />

cubes and distributed among the people<br />

taking part in the ceremony as a “Prasadam”.<br />

Indians understand “Prasadam” to<br />

mean holy food, which is first offered to<br />

god and then to the bystanders.<br />

This ritual has meanwhile been adopted by<br />

nearly all religious communities in India,<br />

and is celebrated today when valuable<br />

objects are obtained or before the start of<br />

any new project. For example, for the first<br />

use of a new vehicle, the laying of the foundation<br />

stone of a new building or the dedication<br />

of a bridge, etc.<br />

Of course, at <strong>Putzmeister</strong> too in India, the<br />

delivery of a new truck-mounted concrete<br />

pump is celebrated with a “breaking the<br />

coconut” ritual.<br />

us with excellent technical support and<br />

helps us to use the machines optimally.<br />

The extraordinary good service provision<br />

is a big strength. The excellent boom<br />

merits particular mention. It has significantly<br />

simplified an important process<br />

and saved us a significant amount of<br />

time and effort in concreting.” n<br />

The Blessing Ritual: Breaking the coconut<br />

Foreign visitors who are not familiar with the traditions of the Indian subcontinent are<br />

always amazed at certain ceremonies and rituals in India. They are usually of a religious<br />

origin. A very common tradition, for example, is the centuries-old ritual of „breaking the<br />

coconut“.<br />

This usually takes place in conjunction<br />

with a “pooja” ceremony, during which<br />

attention is drawn to new things, thanks<br />

are expressed to the Almighty and the blessing<br />

of the divinities is solicited. n<br />

40<br />

Vishvakarma – “God of the machines”<br />

Vishvakarma is the Hindu god of handicraft.<br />

According to Indian myth, he<br />

not only constructed the cities and<br />

palaces of the gods, but also the universe<br />

itself.<br />

He is worshipped by all tradesmen,<br />

engineers and architects on the subcontinent.<br />

n<br />

14 PM 4300 GB PM 4300 GB 15<br />

41

Bauma partner country India<br />

Not only for India – robust and<br />

cost-effective trailer concrete pump<br />

The BSA 1004 HD was originally developed<br />

for the Indian market. It was to be<br />

particularly robust, easy to use and, above<br />

all, cheap to purchase and operate.<br />

And to enable it to be towed from one<br />

construction site to the next on the at times<br />

very poor roads, the extremely compact<br />

machine was equipped with a reinforced<br />

chassis and leaf sprung running gear. Add<br />

to this a modified trailer hitch, which is<br />

also suitable for tractor towing.<br />

The design of the concrete pump unit took<br />

into account that, in some emerging markets,<br />

concrete is often pumped relatively<br />

dry, with a low cement content, unbalanced<br />

grading curve and aggregate consisting<br />

exclusively of broken material.<br />

The specialist for site-made mix<br />

The machine was designed to enable even<br />

mixed concrete to be pumped reliably on<br />

the construction site. To reduce wear, <strong>Putzmeister</strong><br />

India has retained hard-chromed<br />

delivery cylinders as well as particularly<br />

wear-resistant spare parts in the concrete<br />

area. This concrete pump is recommended<br />

for outputs of 40m 3 /h and delivery heights<br />

of up to approx. 100 m.<br />

The BSA 1004 HD has no CE mark and is<br />

therefore not intended for sale or operation<br />

in European countries as yet. As a robust<br />

and compact machine, and with its excellent<br />

price-performance ratio, it is especially<br />

suitable for use in Asia and Africa. n<br />

45<br />

The BSA 1004 HD in India corresponds to the BSA 1404.<br />

Working elephants are not uncommon in<br />

India. No wonder then, that a <strong>Putzmeister</strong><br />

machine feels at home here.<br />

Basic data BSA 1004 HD**<br />

Length 5,677 mm<br />

Width 1,740 mm<br />

Height 2,080 mm<br />

Weight 3,500 kg<br />

Theor. delivery rate 39 / 26* m3 /h<br />

Delivery pressure 70 /105* bar<br />

Diameter delivery cylinder 180 mm<br />

Delivery cylinder stroke 1,000 mm<br />

Strokes / minute 26 / 17*<br />

Engine power 49 kW<br />

Hopper volume aprox. 600 L<br />

Filling heigth 1,300 mm<br />

Transfer tube S 2018 PN<br />

Flap straight 150 mm<br />

Control System VHS<br />

* Values indicate piston side; ** corresponds to the BSA1404 in India<br />

43<br />

42<br />

44<br />

New high-performance<br />

pump for mining tailings<br />

and fly ash<br />

<strong>Putzmeister</strong> Solid Pumps GmbH presents<br />

a particularly high-pressure resistant and<br />

expandable high-density solids pump for<br />

material transport underground: the HSP<br />

25100 SP. This pump system is of particular<br />

interest for gold, diamond and zinc/<br />

lead mines which need to stabilise their<br />

pitheads, backfill demineralised chambers<br />

economically or pump fine-grained<br />

excavated material out of the processing<br />

plant.<br />

The HSP 25100 SP is a large-volume pump<br />

with two individually-controlled delivery<br />

pistons. PSP specifically designed the<br />

pump to convey mining tailings and to<br />

pump fly ash over great distances. In order<br />

to achieve as constant a delivery as possible<br />

without pressure peaks, <strong>Putzmeister</strong><br />

can, on request, equip these mining pumps<br />

with the PCF control (PCF: Pressure Constant<br />

Flow).<br />

The HSP pump head is modular in design.<br />

This makes a noticeable contribution to<br />

reducing operating costs. The replacement<br />

of worn parts now only involves repla-<br />

cing the actual worn-out components and<br />

no longer encompasses the entire pump<br />

head.<br />

Lowering operating costs with<br />

the right service<br />

<strong>Putzmeister</strong> Solid Pumps GmbH focuses<br />

strongly on the subject of reducing operating<br />

costs. There are numerous different<br />

ways of achieving this, depending on the<br />

country, operational requirements and cost<br />

structure. For this purpose, <strong>Putzmeister</strong><br />

offers both technical advice and training<br />

for service engineers.<br />

Project consultation increases<br />

efficiency<br />

One of PSP‘s strengths is professional advise<br />

on the handling, storage and delivery<br />

of high-density substances. In the mining<br />

industry, the company‘s is often consulted<br />

by operators and planners long before the<br />

plant is commissioned.<br />

A key factor in this is that the engineers<br />

at <strong>Putzmeister</strong> Solid Pumps GmbH bring<br />

At the silver mine in San Bartolomé (Bolivia), two HSP 25100 pumps convey the<br />

residue of washed-out sludge into a dumping ground.<br />

46<br />

together their specialist knowledge of the<br />

machines and their experiences in pumping<br />

high-density solids, with the pressure<br />

and flow characteristics of the media and in<br />

calculating and configuring pump systems.<br />

This, along with details about the procedure<br />

and the desired delivery rate, allows better<br />

alternative solutions to be developed.<br />

This pays off - in lower costs and faster processes<br />

with increased safety. n<br />

For further information:<br />

www.putzmeister-solid-pumps.de<br />

Clever detail solutions:<br />

The modular pump head of the<br />

new <strong>Putzmeister</strong> mining pump<br />

HSP 25100 SP<br />

Simple opening of the pump heads<br />

for quicker inspection and replacement<br />

of wear parts<br />

16 PM 4300 GB PM 4300 GB 17<br />

Mining<br />

47<br />

48<br />

49

Mining and tunneling<br />

Deep in the heart<br />

of the dark continent<br />

The <strong>Putzmeister</strong> wet shotcrete machines<br />

are used worldwide.<br />

Here, the SPM 407 P works in a copper<br />

mine in the “copper belt”. This is the name<br />

for Africa‘s biggest copper mining region<br />

deep in the heart of the continent.<br />

50 51<br />

52 53 54<br />

55 56<br />

57<br />

Handmade shotcrete<br />

The SPM 702 is represented at the trade<br />

fair stand by its big brother. The lightweight,<br />

compact concrete pump can be<br />

used for a wide range of applications,<br />

such as concrete spraying, mortar injection<br />

and other concreting projects.<br />

It is very well suited to narrow tunnel<br />

pipes and can be used optimally both for<br />

securing the head with shotcrete, and for<br />

floor and arch concreting of crossways.<br />

The pump is available with a truck-mounted<br />

chassis or a carriage-like base structure.<br />

Of course, the machine operators have<br />

received intensive training at the time of<br />

commissioning. This is part of the worldwide<br />

<strong>Putzmeister</strong> Service, which ensures that<br />

our customers are able to make the most of<br />

their new machines. n<br />

If equipped with an additive tank, it is constructed<br />

on a double-axle long trailer.<br />

The integrated metering device guarantees<br />

additive delivery proportional to the concrete<br />

output and therefore guarantees economical<br />

and efficient use of the expensive<br />

chemicals. n<br />

The new SPM 4207: concrete spraying<br />

specially for small tunnel cross-sections<br />

The Bauma innovation for concrete<br />

spatter in mines and tunnels is specially<br />

designed for small cross-sections, with<br />

its boom reach of 8.5 m.<br />

The new SPM 4207 is the result of the<br />

experience made on construction sites<br />

throughout the world in recent years with<br />

the predecessor model SPM 407.<br />

The highlight:<br />

Even in the PC variant with additionally<br />

integrated screw compressor, it remains<br />

as compact and flexible as the predecessor<br />

model. This was a particular request from<br />

customers and makes its use significantly<br />

more mobile and independent than with<br />

the previously available machines with<br />

similar dimensions.<br />

The basis for this is an intelligent chassis<br />

concept as a platform, on which different<br />

customer-specific requirements can be realised.<br />

During development, great emphasis<br />

was placed on a very robust frame, which<br />

is adapted to the highest stresses of working<br />

in a tunnel.<br />

Other advantages of the new<br />

shotcrete machine:<br />

• a cost-saving Additive Management<br />

System<br />

• an on-board computer with multi-<br />

linguistic colour display for showing per-<br />

formance data, mixture breakdown,<br />

error diagnostics, warnings, etc.<br />

• safety driver‘s cab in accordance with<br />

the ROPS/FOPS ordinance<br />

• xenon working lights<br />

• protected support legs<br />

• optional turbocharger for diesel engine<br />

for use at high altitudes<br />

In addition, there are option packages,<br />

which can be adapted to the different conditions<br />

in mines and tunnels, such as: mine<br />

tyres, cable drum with up to 100 m, catalytic<br />

converter, diesel particle filter, integrated<br />

fire protection system, high-pressure<br />

cleaner or a water pump (operable both via<br />

diesel and electric motor). n<br />

The SPM 4207 PC in use in a copper mine in Aljustrel (Portugal)<br />

Basic data SPM 4207 P SPM 4207 PC<br />

Lenght 6,250 mm 6,970 mm<br />

Width 2,000 mm 2,000 mm<br />

Height 2,450 mm 2,450 mm<br />

Weight 6,900 Kg 8,400 Kg<br />

Spraying arm / Reach Aliva 302 / 8,5 m Aliva 302 / 8,5 m<br />

Theoretical output 4 – 20 m3 /h 4 – 20 m3 /h<br />

Concrete maximal pressure 65 bar 65 bar<br />

Climbing ability longitude (SAE norm) 48 % 35 %<br />

Engine 47.5 kW 47.5 kW<br />

Further information: marketing@putzmeister.es<br />

59<br />

Dry run in simulation<br />

Mining and tunneling<br />

You have to learn the right way to control<br />

shotcrete machines. In order to avoid<br />

unnecessary material consumption<br />

and beginner‘s operating errors, <strong>Putzmeister</strong><br />

has developed a simulation programme<br />

with which you can learn and<br />

practice the operation of the control<br />

units virtually.<br />

You are welcome to try out our<br />

simulation at Bauma.<br />

18 PM 4300 GB PM 4300 GB 19<br />

58

Services<br />

The differences between genuine (left) and copies (right) are not always as obvious<br />

as with these oil filters, but they are nearly always bad for the customer.<br />

Beware of cheap parts<br />

and dumping offers!<br />

Nothing is so tempting as a low price.<br />

But imitation parts can often be more<br />

expensive and not everything that has<br />

the same number is always the same.<br />

APS manager, Uwe Tichy, describes the<br />

differences.<br />

PM: Mr. Tichy, with <strong>Putzmeister</strong> genuine<br />

parts, you are trying to clearly distinguish<br />

yourself from offers by so-called pirates.<br />

Why?<br />

UT: First and foremost, we want to ensure<br />

that the machines work reliably and safely<br />

for our customers. The higher the availability<br />

of our pumps, the more satisfied our<br />

customers will be. Often, however, minor<br />

details such as poorly fitting replacement<br />

and wear parts can cause faults which lead<br />

to an unexpected failure.<br />

PM: But reality shows that they work well<br />

at times.<br />

UT: In this case working well simply<br />

means that the machine runs. The question<br />

is whether or not it pumps economically.<br />

Unnecessarily high downtimes or excessive<br />

wear costs are not noticed in some<br />

circumstances.<br />

Here, it is clear that the price of a part is<br />

often only one side of the coin. Service life,<br />

effects on the pumping behaviour of the<br />

machine and operational safety are just as<br />

important and cost-intensive, but are not<br />

as easily measurable as the price.<br />

60<br />

PM: What are the differences in the<br />

imitation parts?<br />

UT: Concrete pump manufacturers need<br />

larger quantities of parts than the imitators<br />

and have also learnt from the mistakes of<br />

the 90s and made their replacement part<br />

prices more marketable. Therefore, the<br />

imitators have to make savings in order<br />

to remain cheaper. They do this by cutting<br />

costs in terms of the material, processing<br />

or by deliberately ignoring safety regula-<br />

tions and standards.<br />

PM: Do you have an example?<br />

UT: Yes. If, for example, you put less natural<br />

rubber and, consequently, more soot<br />

into a rubber component, it will naturally<br />

be cheaper. But the abrasion values, tearresistance<br />

and therefore the service life<br />

will suffer significantly. This occurs above<br />

all in seals and delivery pistons.<br />

It is only partially dependent on where<br />

the part was produced, for manufacturers<br />

too make international purchases. The<br />

only important thing is that the part complies<br />

with the technical requirements and<br />

quality regulations.<br />

PM: But customers must keep an eye on<br />

their costs, and not all of them always need<br />

a high-quality part.<br />

UT: That‘s true. That‘s why <strong>Putzmeister</strong><br />

genuine parts includes a wide range of<br />

wear parts and delivery lines. The range<br />

includes very cost-effective parts, which<br />

are perfectly adequate for a machine with<br />

a relatively low output per year. These cheaper<br />

parts can also be a good alternative in<br />

regions with less abrasive aggregates. On<br />

the other hand, wherever the annual output<br />

is very high, we recommend using our<br />

highly wear-resistant parts, which we are<br />

continuously developing and optimising.<br />

PM: And is this ultimately worth it for the<br />

customer?<br />

UT: We are convinced that it is. Even with<br />

the “cheap” genuine parts, the fit, quality<br />

and interaction with the other components<br />

are just right. The quality requirements are<br />

documented during the design stage and in<br />

the drawing and do not develop at random<br />

during production<br />

This is evident not least of all in the fact<br />

that we offer service life guarantees in<br />

many cases, or service contracts through to<br />

a full service agreement. In this case, with<br />

our genuine parts, we take on the risk ourselves<br />

and can say that, in our experience,<br />

this is also worth it for us.<br />

61<br />

Copies can also be dangerous.<br />

Here is a cheap hose clamp, which was<br />

cast instead of forged.<br />

PM: How can I recognise a genuine part?<br />

UT: Unfortunately, this isn‘t quite so easy<br />

as there are many counterfeits with PM<br />

marking or which are promoted as being<br />

“from original manufacturer”. Imitators<br />

and dealers are not deterred by anything<br />

in this respect. - In principle, the most reliable<br />

and easiest thing to do is to buy the<br />

parts from the manufacturer or one of its<br />

authorised sales partners. n<br />

Uwe Tichy<br />

Director After Sales<br />

and Parts Service<br />

62<br />

A mobile bypass filter extends the service<br />

life and makes savings on oil changes<br />

PM wear parts –<br />

top grade in<br />

two quality levels<br />

Depending on the region and the aggregates<br />

available there, all parts that come<br />

into direct contact with concrete during<br />

pumping are subject to high levels of wear.<br />

These parts include the S transfer tube,<br />

spectacle wear plate and rings, etc. and<br />

last but not least, the delivery line. The difference<br />

in wear by low to highly abrasive<br />

The latest version of the PM spectacle<br />

wear plate consists completely of hard<br />

metal and has up to 6 times higher service<br />

life than built-up welded parts.<br />

63<br />

64<br />

Keep costs down with<br />

inspection and maintenance<br />

It is in particular during times when concrete<br />

pumps are utilised less that investments<br />

in ongoing maintenance prove to<br />

be a kind of “insurance” against cost<br />

explosions.<br />

In such times, unplanned high costs due<br />

to failures or the replacement of expensive<br />

components can no longer be generated at<br />

short notice via earnings.<br />

One easy way of lowering costs is to fit a<br />

bypass filter, which significantly improves<br />

the oil quality by means of fine particle filtering.<br />

Examples from maintenance agreements<br />

with this option show that even after<br />

4000 operating hours the hydraulic fluid<br />

did not require replacement and there was<br />

no damage in the hydraulic system.<br />

materials can be extremely great. To reduce<br />

part costs and extend the replacement<br />

intervals, <strong>Putzmeister</strong> uses high-quality<br />

genuine PM wear parts even for standard<br />

equipment.<br />

So, for example, the Duro 22 hard builtup<br />

welded spectacle wear plate can achieve<br />

a service life of 40,000 m 3 with average<br />

concrete. Moreover, due to the manufacturing<br />

process, typical cracks occur during<br />

the cooling down period, which are a<br />

characteristic of great hardness and wearresistance.<br />

In terms of even longer service lives, <strong>Putzmeister</strong><br />

is exhibiting a new generation of<br />

hard metal wear parts at the trade fair. The<br />

hard metal plates, which are applied to the<br />

full surface with no cracks, have been additionally<br />

reinforced at the critical edges.<br />

This has improved the wear characteristics<br />

overall and prevents early breakage<br />

of individual plates. n<br />

Installation of the filter has therefore already<br />

paid for itself after the first oil change<br />

is due, as the costs of the filter, depending<br />

on the size of the machine, are roughly<br />

equal to the costs of the oil change. The<br />

oil quality is simply inspected at the 500<br />

hour service, together with the operability<br />

of the filter.<br />

For more information on this and on complete<br />

service packages through to the full<br />

maintenance agreement, speak to the<br />

PM service specialists at the trade fair<br />

stand or anytime after the trade fair. At<br />

<strong>Putzmeister</strong> Services, in addition to the<br />

technical aspect of the solution, you can<br />

also obtain important tips on correct maintenance<br />

and operation in the context of<br />

inspection and training packages. n<br />

Wear under control<br />

65<br />

Anyone who values safety and wants<br />

to use his delivery line to the full cannot<br />

avoid checking or measuring the<br />

wall thickness. Two devices for doing<br />

this can be tried out by the machine<br />

operator in the service area on the<br />

Bauma.<br />

These are ultimately<br />

simple devices<br />

for reducing<br />

wear costs.<br />

20 PM 4300 GB PM 4300 GB 21<br />

Services<br />

66

Mortar machines<br />

The piston pump P 13 –<br />

the “offroad plastering machine”<br />

The robust piston pump proves its worth worldwide under the toughest conditions.<br />

To date, there has been a serious problem<br />

for businesses wishing to process<br />

site-made mix with a plastering machine.<br />

Although sand is locally available in<br />

abundance in regions like South America<br />

or the Middle East, it could often not be<br />

used even there in the pumps which<br />

were used. The new <strong>Putzmeister</strong> P 13 KA<br />

230 plastering machine can already process<br />

virtually every type of sand up to a<br />

grain size of 10 mm. This has been made<br />

possible by redesigning a KA 230 type<br />

piston pump which can also handle the<br />

most arduous of plastering tasks.<br />

Many companies on construction sites<br />

around the world have themselves found a<br />

way of producing their own mixes directly<br />

on site. However, the locally available<br />

sands which used to be employed for plastering<br />

by hand are often unsuitable for<br />

processing in conventional pumps. As a<br />

result, suitable sand has to be bought in and<br />

in some cases transported to the construction<br />

site across considerable distances. The<br />

costs which this generated were once the<br />

main reason why many companies were<br />

unwilling to switch from manual work to<br />

machine technology.<br />

This is no longer a problem thanks to the<br />

new P 13 from <strong>Putzmeister</strong> with the KA<br />

230 piston pump. The KA 230 was specially<br />

developed for processing all locally<br />

occurring types of sand up to a grain<br />

size of 10 mm and even the most difficult<br />

of mortars.<br />

The allrounder for all hardnesses<br />

The new KA 230 dual piston pump has a<br />

specially developed larger pump head and<br />

has been specifically optimised to handle<br />

difficult types of material. It is extremely<br />

robust and low-wearing. It operates according<br />

to the successful dual piston principle<br />

with one working piston and one compensating<br />

piston. It can also be used to process<br />

other materials, of course, such as<br />

prebagged internal and external plaster,<br />

bentonite slurries, finishing plaster, insulating<br />

plaster, cement plaster, lime cement<br />

plaster and even light wall mortar. Thus,<br />

it has proven to be a surprisingly versatile<br />

allrounder that can be used in any difficult<br />

situation.<br />

When designing the whole P 13 concept,<br />

<strong>Putzmeister</strong> kept in mind that this machine<br />

is intended for use mainly on sites around<br />

the world where the harshest of conditions<br />

67<br />

can be found. A deliberate decision was<br />

therefore taken to use as few electronic<br />

components as possible. All functions and<br />

operating elements of the P 13 are purely<br />

mechanical and therefore particularly<br />

robust and insusceptible to malfunction.<br />

Diesel power package with<br />

offroad quality<br />

The P 13 is driven by a 2 cylinder diesel<br />

engine with 12.5 kW. With this, it achieves<br />

a delivery pressure of up to 40 bar. The<br />

compulsory mixer, vibrating screen and<br />

pneumatic remote control on the spraying<br />

machine are practical equipment that come<br />

as standard. On request, the P 13 is also<br />

available with a fully road-approved chassis.<br />

This means, the „offroader“ can get to<br />

any construction site easily.<br />

Therefore the new piston pump from <strong>Putzmeister</strong><br />

is a real match for any challenge<br />

around the world. n<br />

Internet: www.mortarmachines.com<br />

Premiere at Bauma <strong>2010</strong><br />

This year again, <strong>Putzmeister</strong> Mörtelmaschinen<br />

GmbH will be present at<br />

the <strong>Putzmeister</strong> Group‘s stand. Here,<br />

it will exhibit an extensive crosssection<br />

of its product line. In addition<br />

to screed conveyors, plastering<br />

machines and fine concrete pumps,<br />

products such as paint pumps, fine<br />

plaster spray pumps and Dynajet professional<br />

high pressure cleaners will<br />

also be on display.<br />

However, <strong>Putzmeister</strong> Mörtelmaschinen<br />

is not only presenting a full range of<br />

further developments and innovations<br />

at Bauma. In Munich, an exclusive<br />

complete product line will be presented<br />

as an innovation.<br />

68<br />

Of course, after years of operation, the work performed is apparent on used machines.<br />

So that you do not notice its age, they are restored at <strong>Putzmeister</strong> by qualified technicians.<br />

<strong>Putzmeister</strong> used machines –<br />

first class from second hand<br />

The demand for used machines in<br />

manufacturer quality is uninterrupted.<br />

But beware: With second hand truckmounted<br />

concrete pumps in particular,<br />

it is not necessarily obvious whether or<br />

not the apparently cheap offer of a used<br />

machine dealer is also actually worth<br />

the price.<br />

For only the manufacturer has the technical<br />

know-how and detailed knowledge<br />

of the construction of individual components<br />

and on the method of operation<br />

of electronic or hydraulically controls.<br />

That‘s why <strong>Putzmeister</strong> is presenting the<br />

PM used machinery centre in a separate<br />

stand area.<br />

For every currently available machine,<br />

detailed documentation with photos, technical<br />

data, mileages, operating hours, etc. is<br />

available. In addition, examples show how<br />

thoroughly reworked the second hand concrete<br />

pumps restored in the manufacturer‘s<br />

plant actually are, or what work could still<br />

be performed by the manufacturer – and<br />

at what cost.<br />

69 70<br />

71 72<br />

This includes, for example, replacing wear<br />

parts and bearings, inspecting and, if<br />

necessary, replacing functional fluids, performing<br />

refits, updates of technically compatible<br />

software and final acceptance, just<br />

like for new machines. n<br />

Internet: www.putzmeister.de<br />

Your contact persons via e-mail:<br />

wehnera@pmw.de<br />

and marcecm@pmw.de<br />

Services<br />

That is our goal: Satisfied customers with machines that are as good as new ones.<br />

22 PM 4300 GB PM 4300 GB 23<br />

73

BAUMA booth layout<br />

<strong>Putzmeister</strong> at Bauma <strong>2010</strong><br />

Esser<br />

Open air area block F9, stand no. 906 / 7<br />

Brinkmann<br />

Open air area block F9, stand no. 906 / 8<br />

Truck-mounted conrete pumps<br />

64<br />

BSF 20-4.09 SANIMA<br />

BSF 36-4.16 H LS<br />

BSF 42-5.16 H LS<br />

BSF 49-5.16 H<br />

BSF 58-5.16 H LS<br />

BSS 70-5.16 H<br />

Pumi truckmixer pumps<br />

PUMI 24-3.67 CS<br />

PUMI 31-4.89 S<br />

Rotor pumping unit<br />

Telescopic Belt Conveyor<br />

Telebelt TBS 130<br />

Mining and tunneling<br />

Sika PM 4207 PC<br />

BSA 1003 D<br />

Allentown AST 25<br />

Mining<br />

HSP 25100 SP<br />

Solutions for the prefabricated parts industry<br />

BQ 06<br />

Stationary concrete pumps<br />

MX 30-3 Multi<br />

BSA 1004 D<br />

BSA 1408 E<br />

BSA 2110 HP D<br />

BSA 14000 SHP D<br />

Mortar machines<br />

Mixokret M 740 D<br />

Mixokret M 760 DHBS<br />

Mixokret M 700 E<br />

P 718 TD<br />

P 13 KA 230<br />

MP 25<br />

S5 EV/TM<br />

SP11 BUR<br />

Services<br />

CPD – Project consultation<br />

APS – Customer service<br />

and spare parts<br />

Delivery line systems<br />

Strobot 406 S<br />

Stromixer D 1000<br />

Trans Mix 3500 LB<br />

Dynajet UHP 170<br />

Dynajet 350 md<br />

Dynajet 800 me<br />

Used machines<br />

Customer trainings<br />

Ergonic control systems<br />

Fleet management<br />

All rights and technical amendments reserved · Some of the illustrations show special machine variants and snapshots which do not always comply with the<br />

regulations of the Industrial Employers‘ Liability Insurance Association. · © <strong>2010</strong> by <strong>Putzmeister</strong> Concrete Pumps GmbH · Printed in Germany (3.51003)<br />

PM 4300 GB