complete torches - Rapid Welding and Industrial Supplies Ltd

complete torches - Rapid Welding and Industrial Supplies Ltd

complete torches - Rapid Welding and Industrial Supplies Ltd

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

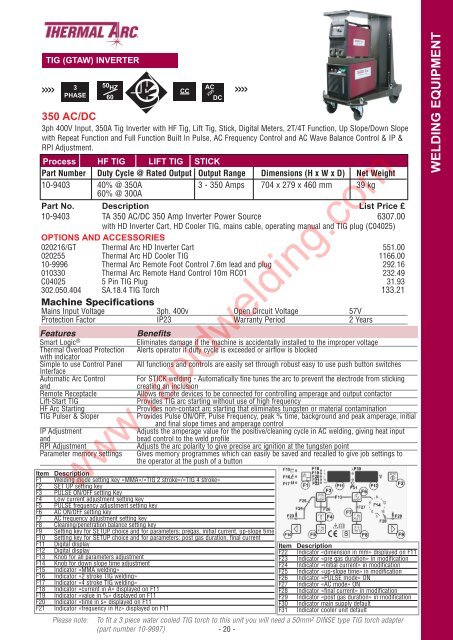

TIG (GTAW) INVERTER3 50 HZAC>>>> CC>>>>PHASE 60DC>>>>350 AC/DC3ph 400V Input, 350A Tig Inverter with HF Tig, Lift Tig, Stick, Digital Meters, 2T/4T Function, Up Slope/Down Slopewith Repeat Function <strong>and</strong> Full Function Built In Pulse, AC Frequency Control <strong>and</strong> AC Wave Balance Control & IP &RPI Adjustment.Process HF TIG LIFT TIG STICKPart Number Duty Cycle @ Rated Output Output Range Dimensions (H x W x D) Net Weight10-9403 40% @ 350A 3 - 350 Amps 704 x 279 x 460 mm 39 kg60% @ 300APart No. Description List Price £10-9403 TA 350 AC/DC 350 Amp Inverter Power Source 6307.00with HD Inverter Cart, HD Cooler TIG, mains cable, operating manual <strong>and</strong> TIG plug (C04025)OPTIONS AND ACCESSORIES020216/GT Thermal Arc HD Inverter Cart 551.00020255 Thermal Arc HD Cooler TIG 1166.0010-9996 Thermal Arc Remote Foot Control 7.6m lead <strong>and</strong> plug 292.16010330 Thermal Arc Remote H<strong>and</strong> Control 10m RC01 232.49C04025 5 Pin TIG Plug 31.93302.050.404 SA.18.4 TIG Torch 133.21Machine SpecificationsMains Input Voltage 3ph. 400v Open Circuit Voltage 57VProtection Factor IP23 Warranty Period 2 YearsFeaturesSmart Logic ®Thermal Overload Protectionwith indicatorSimple to use Control PanelInterfaceAutomatic Arc Control<strong>and</strong>Remote ReceptacleLift-Start TIGHF Arc StartingTIG Pulser & SloperIP Adjustment<strong>and</strong>RPI AdjustmentParameter memory settingsBenefitsEliminates damage if the machine is accidentally installed to the improper voltageAlerts operator if duty cycle is exceeded or airflow is blockedAll functions <strong>and</strong> controls are easily set through robust easy to use push button switchesFor STICK welding - Automatically fine tunes the arc to prevent the electrode from stickingcreating an inclusionAllows remote devices to be connected for controlling amperage <strong>and</strong> output contactorProvides TIG arc starting without use of high frequencyProvides non-contact arc starting that eliminates tungsten or material contaminationProvides Pulse ON/OFF, Pulse Frequency, peak % time, background <strong>and</strong> peak amperage, initial<strong>and</strong> final slope times <strong>and</strong> amperage controlAdjusts the amperage value for the positive/cleaning cycle in AC welding, giving heat inputbead control to the weld profileAdjusts the arc polarity to give precise arc ignition at the tungsten pointGives memory programmes which can easily be saved <strong>and</strong> recalled to give job settings tothe operator at the push of a buttonwww.rapidwelding.comItem DescriptionF1 <strong>Welding</strong> mode setting key «MMA»/«TIG 2 stroke»/«TIG 4 stroke»F2 SET UP setting keyF3 PULSE ON/OFF setting KeyF4 Low current adjustment setting keyF5 PULSE frequency adjustment setting keyF6 AC ON/OFF setting keyF7 AC frequency adjustment setting keyF8 Cleaning/penetration balance setting keyF9 Setting key for SETUP choice <strong>and</strong> for parameters: pregas, initial current, up-slope timeF10 Setting key for SETUP choice <strong>and</strong> for parameters: post gas duration, final currentF11 Digital displayItem DescriptionF12 Digital displayF22 Indicator «dimension in mm» displayed on F11F13 Knob for all parameters adjustmentF23 Indicator «pre gas duration» in modificationF14 Knob for down slope time adjustmentF24 Indicator «initial current» in modificationF15 Indicator «MMA welding»F25 Indicator «up-slope time» in modificationF16 Indicator «2 stroke TIG welding»F26 Indicator «PULSE mode» ONF17 Indicator «4 stroke TIG welding»F27 Indicator «AC mode» ONF18 Indicator «current in A» displayed on F11F28 Indicator «final current» in modificationF19 Indicator «value in %» displayed on F11F29 Indicator «post gas duration» in modificationF20 Indicator «time in s» displayed on F11F30 Indicator main supply defaultF21 Indicator «frequency in Hz» displayed on F11F31 Indicator cooler unit defaultPlease note: To fit a 3 piece water cooled TIG torch to this unit you will need a 50mm 2 DINSE type TIG torch adapter(part number 10-9997)- 20 -WELDING EQUIPMENT