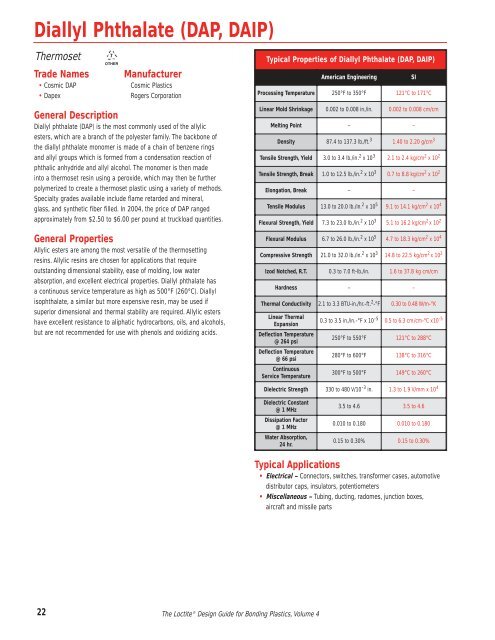

Diallyl Phthalate (DAP, DAIP)ThermosetTrade Names Manufacturer• Cosmic DAPCosmic Plastics• DapexRogers CorporationTypical Properties of Diallyl Phthalate (DAP, DAIP)American EngineeringSIProcessing Temperature 250°F to 350°F 121°C to 171°CGeneral DescriptionDiallyl <strong>ph</strong>thalate (DAP) is the most commonly used of the allylicesters, which are a branch of the polyester family. The backbone ofthe diallyl <strong>ph</strong>thalate monomer is made of a chain of benzene ringsand allyl groups which is formed from a condensation reaction of<strong>ph</strong>thalic anhydride and allyl alcohol. The monomer is then madeinto a thermoset resin using a peroxide, which may then be furtherpolymerized to create a thermoset plastic using a variety of methods.Specialty grades available include flame retarded and mineral,glass, and synthetic fiber filled. In 2004, the price of DAP rangedapproximately from $2.50 to $6.00 per pound at truckload quantities.General PropertiesAllylic esters are among the most versatile of the thermosettingresins. Allylic resins are chosen for applications that requireoutstanding dimensional stability, ease of molding, low waterabsorption, and excellent electrical properties. Diallyl <strong>ph</strong>thalate hasa continuous service temperature as high as 500°F (260°C). Diallyliso<strong>ph</strong>thalate, a similar but more expensive resin, may be used ifsuperior dimensional and thermal stability are required. Allylic estershave excellent resistance to ali<strong>ph</strong>atic hydrocarbons, oils, and alcohols,but are not recommended for use with <strong>ph</strong>enols and oxidizing acids.Linear Mold Shrinkage 0.002 to 0.008 in./in. 0.002 to 0.008 cm/cmMelting Point – –Density 87.4 to 137.3 lb./ft. 3 1.40 to 2.20 g/cm 3Tensile Strength, Yield 3.0 to 3.4 lb./in. 2 x 10 3 2.1 to 2.4 kg/cm 2 x 10 2Tensile Strength, Break 1.0 to 12.5 lb./in. 2 x 10 3 0.7 to 8.8 kg/cm 2 x 10 2Elongation, Break – –Tensile Modulus 13.0 to 20.0 lb./in. 2 x 10 5 9.1 to 14.1 kg/cm 2 x 10 4Flexural Strength, Yield 7.3 to 23.0 lb./in. 2 x 10 3 5.1 to 16.2 kg/cm 2 x 10 2Flexural Modulus 6.7 to 26.0 lb./in. 2 x 10 5 4.7 to 18.3 kg/cm 2 x 10 4Compressive Strength 21.0 to 32.0 lb./in. 2 x 10 3 14.8 to 22.5 kg/cm 2 x 10 2Izod Notched, R.T. 0.3 to 7.0 ft-lb./in. 1.6 to 37.8 kg cm/cmHardness – –Thermal Conductivity 2.1 to 3.3 BTU-in./hr.-ft. 2 -°F 0.30 to 0.48 W/m-°KLinear ThermalExpansionDeflection Temperature@ 264 psiDeflection Temperature@ 66 psiContinuousService Temperature0.3 to 3.5 in./in.-°F x 10 -5 0.5 to 6.3 cm/cm-°C x10 -5250°F to 550°F 121°C to 288°C280°F to 600°F 138°C to 316°C300°F to 500°F 149°C to 260°CDielectric Strength 330 to 480 V/10 -3 in. 1.3 to 1.9 V/mm x 10 4Dielectric Constant@ 1 MHzDissipation Factor@ 1 MHzWater Absorption,24 hr.3.5 to 4.6 3.5 to 4.60.010 to 0.180 0.010 to 0.1800.15 to 0.30% 0.15 to 0.30%Typical Applications• Electrical – Connectors, switches, transformer cases, automotivedistributor caps, insulators, potentiometers• Miscellaneous – Tubing, ducting, radomes, junction boxes,aircraft and missile parts22The <strong>Loctite</strong> ® Design Guide for Bonding Plastics, <strong>Volume</strong> 4

ADHESIVE SHEAR STRENGTH(psi)(MPa)Diallyl PhthalateDAP courtesy of Rogers CorporationRX3-1-525F-p-M Black courtesy of Byncolit N.A. 11 rms<strong>Loctite</strong> ® 380 Black Max ® Instant Adhesive,Rubber Toughened<strong>Loctite</strong> ® 401 Prism ® Instant Adhesive,Surface InsensitiveMEDICAL: <strong>Loctite</strong> ® 4011 Prism ®Instant Adhesive, Surface Insensitive<strong>Loctite</strong> ® 401 Prism ®<strong>Loctite</strong> ® 770 Prism ® PrimerMEDICAL: <strong>Loctite</strong> ® 4011 Prism ® /<strong>Loctite</strong> ® 7701 Prism ® Primer<strong>Loctite</strong> ® 414 Super Bonder ®Instant Adhesive, General Purpose<strong>Loctite</strong> ® 330 Depend ® Adhesive,Two-Part No-Mix Acrylic<strong>Loctite</strong> ® 3105 Light Cure Adhesive,MEDICAL: <strong>Loctite</strong> ® 3311 Light Cure Adhesive<strong>Loctite</strong> ® 3340 Light Cure Adhesive,UV Cationic Epoxy<strong>Loctite</strong> ® 4305 Flashcure ® Light Cure AdhesiveFLUORESCENT: <strong>Loctite</strong> ® 4307 Flashcure ®Light Cure Adhesive<strong>Loctite</strong> ® H3000 Speedbonder Structural Adhesive, General Purpose<strong>Loctite</strong> ® H4500 Speedbonder Structural Adhesive, Metal Bonder<strong>Loctite</strong> ® 3030 Adhesive, Polyolefin Bonder<strong>Loctite</strong> ® E-00CL Hysol ® Epoxy Adhesive,Low Odor<strong>Loctite</strong> ® E-90FL Hysol ® Epoxy Adhesive,Flexible<strong>Loctite</strong> ® E-30CL Hysol ® Epoxy Adhesive,Glass BonderMEDICAL: <strong>Loctite</strong> ® M-31CL Hysol ®Epoxy Adhesive, Glass Bonder<strong>Loctite</strong> ® E-20HP Hysol ® Epoxy Adhesive,Fast SettingMEDICAL: <strong>Loctite</strong> ® M-21HP Hysol ®Epoxy Adhesive, Fast Setting<strong>Loctite</strong> ® E-214HP Hysol ® Epoxy Adhesive,High Strength<strong>Loctite</strong> ® Fixmaster ® High Performance Epoxy<strong>Loctite</strong> ® 1942 Hysol ® Hot Melt Adhesive,EVA Based<strong>Loctite</strong> ® 3651 Hysol ® Hot Melt Adhesive,Polyolefin<strong>Loctite</strong> ® 7804 Hysol ® Hot Melt Adhesive<strong>Loctite</strong> ® 3631 Hysol ® Hot Melt Adhesive,Urethane<strong>Loctite</strong> ® U-05FL Hysol ® Urethane Adhesive,High Strength<strong>Loctite</strong> ® Fixmaster ® Rapid Rubber RepairOEM: <strong>Loctite</strong> ® U-04FL Hysol ®Urethane Adhesive, Fast Setting<strong>Loctite</strong> ® 5900 ® Flange Sealant,Heavy Body RTV SiliconeGRADE RX3-1-525FShort Glass FiberReinforced FlameRetardant Black Coloring,18 rms>1950 >1950 >1700 >1700 >1700 >2550 >13.5 >13.5 >11.7 >11.7 >11.7 >17.6 >3150 >3150 >2350 >2350 >2900 >2900 >21.7 >21.7 >16.2 >16.2 >20.0 >20.0 1501.03002.11501.05503.81000.710507.2>2700 >2700 >3000 >3000 >2750 >2750 >18.6 >18.6 >20.7 >20.7 >19.0 >19.0 3502.43502.42001.4>2500>17.24503.17505.26004.14503.113009.05003.511507.96504.55003.54002.81000.71000.79506.69506.64002.82001.4GRADE RX3-1-525FROUGHENED28 rms14009.73502.4GRADE RX1310Short glass FiberReinforced, GreenColoring, 16 rms6504.54503.1GRADE RX1310ROUGHENED27 rms215014.8145010.0GRADE RX1-510NMineral Filled BlueColoring, 14 rms5003.53002.1GRADE RX1-510NROUGHENED24 rms230015.9170011.7Adhesive PerformanceThe five cyanoacrylates tested, namely <strong>Loctite</strong> ® 401 Prism ® , 4011 and 414 Super Bonder ® , and380 Black Max ® Instant Adhesives, and <strong>Loctite</strong> ® 4305 Flashcure ® Light Cure Adhesive createdbonds which were stronger than the three grades of DAP evaluated. Most of the other adhesivesevaluated showed fair to excellent bond strengths on DAP. There were not statistically significantdifferences between the bondability of the three grades of DAP evaluated.Surface TreatmentsThe use of <strong>Loctite</strong> ® 770 Prism ® Primer, in conjunction with <strong>Loctite</strong> ® 401 Prism ® Instant Adhesive,or <strong>Loctite</strong> ® 4011 Prism ® Medical Device Instant Adhesive with <strong>Loctite</strong> ® 7701 Prism ® Primer,significantly lowered the bond strengths achieved on DAP. Surface roughening caused a statisticallysignificant increase in bond strength when using <strong>Loctite</strong> ® 330 Depend ® Adhesive and <strong>Loctite</strong> ®3105 and 3311 Light Cure Adhesives. The effect of surface roughening on the bond strengthsachieved by cyanoacrylate adhesives could not be determined because both roughened andunroughened DAP bonded with cyanoacrylates resulted in substrate failure.Other Important Information• Allylic esters are compatible with all <strong>Loctite</strong> ® brand adhesives,sealants, primers, and activators.• Surface cleaners: isopropyl alcohol, <strong>Loctite</strong> ® ODC-Free Cleaner & Degreaser.NOTES: The force applied to the tests specimensexceeded the strength of the material resulting insubstrate failure before the actual bond strengthachieved by the adhesive could be determined.The addition of the indicated additive (or surfaceroughening) caused a statistically significant decreasein the bond strength within 95% confidence limits.The addition of the indicated additive (or surfaceroughening) caused a statistically significant increasein the bond strength within 95% confidence limits.The <strong>Loctite</strong> ® Design Guide for Bonding Plastics, <strong>Volume</strong> 4 23