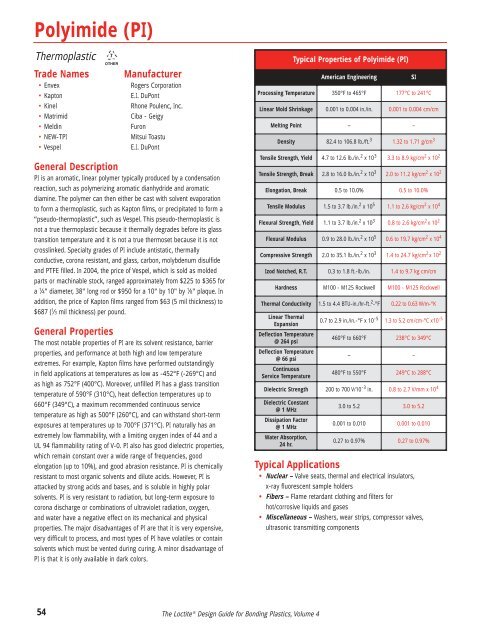

Polyimide (PI)ThermoplasticTrade Names• Envex• Kapton• Kinel• Matrimid• Meldin• NEW-TPI• VespelManufacturerRogers CorporationE.I. DuPontRhone Poulenc, Inc.Ciba - GeigyFuronMitsui ToastuE.I. DuPontGeneral DescriptionPI is an aromatic, linear polymer typically produced by a condensationreaction, such as polymerizing aromatic dianhydride and aromaticdiamine. The polymer can then either be cast with solvent evaporationto form a thermoplastic, such as Kapton films, or precipitated to form a“pseudo-thermoplastic”, such as Vespel. This pseudo-thermoplastic isnot a true thermoplastic because it thermally degrades before its glasstransition temperature and it is not a true thermoset because it is notcrosslinked. Specialty grades of PI include antistatic, thermallyconductive, corona resistant, and glass, carbon, molybdenum disulfideand PTFE filled. In 2004, the price of Vespel, which is sold as moldedparts or machinable stock, ranged approximately from $225 to $365 fora 1 ⁄4" diameter, 38" long rod or $950 for a 10" by 10" by 1 ⁄8" plaque. Inaddition, the price of Kapton films ranged from $63 (5 mil thickness) to$687 ( 1 ⁄3 mil thickness) per pound.General PropertiesThe most notable properties of PI are its solvent resistance, barrierproperties, and performance at both high and low temperatureextremes. For example, Kapton films have performed outstandinglyin field applications at temperatures as low as -452°F (-269°C) andas high as 752°F (400°C). Moreover, unfilled PI has a glass transitiontemperature of 590°F (310°C), heat deflection temperatures up to660°F (349°C), a maximum recommended continuous servicetemperature as high as 500°F (260°C), and can withstand short-termexposures at temperatures up to 700°F (371°C). PI naturally has anextremely low flammability, with a limiting oxygen index of 44 and aUL 94 flammability rating of V-0. PI also has good dielectric properties,which remain constant over a wide range of frequencies, goodelongation (up to 10%), and good abrasion resistance. PI is chemicallyresistant to most organic solvents and dilute acids. However, PI isattacked by strong acids and bases, and is soluble in highly polarsolvents. PI is very resistant to radiation, but long-term exposure tocorona discharge or combinations of ultraviolet radiation, oxygen,and water have a negative effect on its mechanical and <strong>ph</strong>ysicalproperties. The major disadvantages of PI are that it is very expensive,very difficult to process, and most types of PI have volatiles or containsolvents which must be vented during curing. A minor disadvantage ofPI is that it is only available in dark colors.Typical Properties of Polyimide (PI)American EngineeringProcessing Temperature 350°F to 465°F 177°C to 241°CLinear Mold Shrinkage 0.001 to 0.004 in./in. 0.001 to 0.004 cm/cmMelting Point – –Density 82.4 to 106.8 lb./ft. 3 1.32 to 1.71 g/cm 3Tensile Strength, Yield 4.7 to 12.6 lb./in. 2 x 10 3 3.3 to 8.9 kg/cm 2 x 10 2Tensile Strength, Break 2.8 to 16.0 lb./in. 2 x 10 3 2.0 to 11.2 kg/cm 2 x 10 2Elongation, Break 0.5 to 10.0% 0.5 to 10.0%Tensile Modulus 1.5 to 3.7 lb./in. 2 x 10 5 1.1 to 2.6 kg/cm 2 x 10 4Flexural Strength, Yield 1.1 to 3.7 lb./in. 2 x 10 3 0.8 to 2.6 kg/cm 2 x 10 2Flexural Modulus 0.9 to 28.0 lb./in. 2 x 10 5 0.6 to 19.7 kg/cm 2 x 10 4Compressive Strength 2.0 to 35.1 lb./in. 2 x 10 3 1.4 to 24.7 kg/cm 2 x 10 2Izod Notched, R.T. 0.3 to 1.8 ft.-lb./in. 1.4 to 9.7 kg cm/cmHardness M100 - M125 Rockwell M100 - M125 RockwellThermal Conductivity 1.5 to 4.4 BTU-in./hr-ft. 2 -°F 0.22 to 0.63 W/m-°KLinear ThermalExpansionDeflection Temperature@ 264 psiDeflection Temperature@ 66 psiContinuousService Temperature0.7 to 2.9 in./in.-°F x 10 -5 1.3 to 5.2 cm/cm-°C x10 -5460°F to 660°F 238°C to 349°CTypical Applications• Nuclear – Valve seats, thermal and electrical insulators,x-ray fluorescent sample holders• Fibers – Flame retardant clothing and filters forhot/corrosive liquids and gases• Miscellaneous – Washers, wear strips, compressor valves,ultrasonic transmitting componentsSI– –480°F to 550°F 249°C to 288°CDielectric Strength 200 to 700 V/10 -3 in. 0.8 to 2.7 V/mm x 10 4Dielectric Constant@ 1 MHzDissipation Factor@ 1 MHzWater Absorption,24 hr.3.0 to 5.2 3.0 to 5.20.001 to 0.010 0.001 to 0.0100.27 to 0.97% 0.27 to 0.97%54The <strong>Loctite</strong> ® Design Guide for Bonding Plastics, <strong>Volume</strong> 4

ADHESIVE SHEAR STRENGTH(psi)(MPa)PolyimideKAPTON HN5 ml Thick500 Gauge FilmKAPTON HPP-ST5 ml Thick500 Gauge FilmKAPTON HPP-FST5 ml Thick500 Gauge FilmVESPEL SP-1UnfilledVESPEL SP-2115% Gra<strong>ph</strong>iteVESPEL SP-2240% Gra<strong>ph</strong>iteVESPEL SP-21115% Gra<strong>ph</strong>ite10% PTFEVespel, Kapton courtesy of DuPont Polymers<strong>Loctite</strong> ® 380 Black Max ® Instant Adhesive,Rubber Toughened<strong>Loctite</strong> ® 401 Prism ® Instant Adhesive,Surface InsensitiveMEDICAL: <strong>Loctite</strong> ® 4011 Prism ®Instant Adhesive, Surface Insensitive<strong>Loctite</strong> ® 401 Prism ®<strong>Loctite</strong> ® 770 Prism ® PrimerMEDICAL: <strong>Loctite</strong> ® 4011 Prism ® /<strong>Loctite</strong> ® 7701 Prism ® Primer<strong>Loctite</strong> ® 414 Super Bonder ®Instant Adhesive, General Purpose<strong>Loctite</strong> ® 330 Depend ® Adhesive,Two-Part No-Mix Acrylic<strong>Loctite</strong> ® 3105 Light Cure Adhesive,MEDICAL: <strong>Loctite</strong> ® 3311 Light Cure Adhesive<strong>Loctite</strong> ® 3340 Light Cure Adhesive,UV Cationic Epoxy<strong>Loctite</strong> ® 4305 Flashcure ® Light Cure AdhesiveFLUORESCENT: <strong>Loctite</strong> ® 4307 Flashcure ®Light Cure Adhesive<strong>Loctite</strong> ® H3000 Speedbonder Structural Adhesive, General Purpose<strong>Loctite</strong> ® H4500 Speedbonder Structural Adhesive, Metal Bonder<strong>Loctite</strong> ® 3030 Adhesive, Polyolefin Bonder<strong>Loctite</strong> ® E-00CL Hysol ® Epoxy Adhesive,Low Odor<strong>Loctite</strong> ® E-90FL Hysol ® Epoxy Adhesive,Flexible<strong>Loctite</strong> ® E-30CL Hysol ® Epoxy Adhesive,Glass BonderMEDICAL: <strong>Loctite</strong> ® M-31CL Hysol ®Epoxy Adhesive, Glass Bonder<strong>Loctite</strong> ® E-20HP Hysol ® Epoxy Adhesive,Fast SettingMEDICAL: <strong>Loctite</strong> ® M-21HP Hysol ®Epoxy Adhesive, Fast Setting<strong>Loctite</strong> ® E-214HP Hysol ® Epoxy Adhesive,High Strength<strong>Loctite</strong> ® Fixmaster ® High Performance Epoxy<strong>Loctite</strong> ® 1942 Hysol ® Hot Melt Adhesive,EVA Based<strong>Loctite</strong> ® 3651 Hysol ® Hot Melt Adhesive,Polyolefin<strong>Loctite</strong> ® 7804 Hysol ® Hot Melt Adhesive<strong>Loctite</strong> ® 3631 Hysol ® Hot Melt Adhesive,Urethane<strong>Loctite</strong> ® U-05FL Hysol ® Urethane Adhesive,High Strength<strong>Loctite</strong> ® Fixmaster ® Rapid Rubber RepairOEM: <strong>Loctite</strong> ® U-04FL Hysol ®Urethane Adhesive, Fast Setting<strong>Loctite</strong> ® 5900 ® Flange Sealant,Heavy Body RTV Silicone>800 ♓ >800 ♓ >800 ♓ 1550>5.5 ♓ >5.5 ♓ >5.5 ♓ 10.7>800 >800 >800 2200>5.5 >5.5 >5.5 15.2>650 >600 >450 350>4.5 >4.1 >3.1 2.4>800 >5.5 >800 >5.5 >800 >5.5 165011.4>800 >800 >800 1150>5.5 >5.5 >5.5 7.9>800 ♓ >800 >800 800>5.5 ♓ >5.5 >5.5 5.52501.7>550 >3.8 9506.66004.15003.59506.6>1750 >11.7 >1250 >8.6 >1250 >8.6 >950 >6.6 >1050 >7.2 2001.41000.7500.3>550 >3.8 8505.95503.82001.414009.7225015.58505.9235016.25503.810006.95503.88505.94002.810006.95003.52501.74002.85503.86004.17004.82001.42001.4Adhesive Performance<strong>Loctite</strong> ® 401 Prism ® and 414 Super Bonder ® Instant Adhesives achieved the highest bond strengths onthe Vespel polyimide. <strong>Loctite</strong> ® 380 Black Max ® Instant Adhesive achieved the second highest bondstrength. <strong>Loctite</strong> ® 330 Depend ® Adhesive and <strong>Loctite</strong> ® 3105 Light Cure Adhesive achieved the lowestbond strengths on Vespel. <strong>Loctite</strong> ® 380 Black Max ® , 401 Prism ® and 414 Super Bonder ® InstantAdhesives, <strong>Loctite</strong> ® 330 Depend ® 330 Adhesive, <strong>Loctite</strong> ® 3105 and 4305 Flashcure ® Light CureAdhesives, <strong>Loctite</strong> ® E-90FL , E-30FL , E-20HP and E-214HP Hysol ® Epoxy Adhesives, <strong>Loctite</strong> ®Fixmaster ® High Performance Epoxy, and <strong>Loctite</strong> ® 3631 Hysol ® Hot Melt Adhesive all achieved substratefailure on the 5 mil (0.005 in) thick Kapton films.Surface TreatmentsThe use of <strong>Loctite</strong> ® 770 Prism ® Primer, in conjunction with <strong>Loctite</strong> ® 401 Prism ® Instant Adhesive, or<strong>Loctite</strong> ® 4011 Prism ® Medical Device Instant Adhesive with <strong>Loctite</strong> ® 7701 Prism ® Primer, resulted ineither no effect or a statistically significant decrease in the bondability of polyimide.Other Important Information• When bonding polyimide films, an accelerator may be necessaryto speed the cure of cyanoacrylates.• Polyimide is compatible with all <strong>Loctite</strong> ® brand adhesives, sealants, primers, and activators.• Surface cleaners: isopropyl alcohol, <strong>Loctite</strong> ® ODC-Free Cleaner & Degreaser.NOTES: The force applied to the tests specimens exceededthe strength of the material resulting in substrate failurebefore the actual bond strength achieved by theadhesive could be determined.♓ <strong>Loctite</strong> ® 7452 Tak Pak ® Accelerator was used inconjunction with <strong>Loctite</strong> ® 380 Black Max ® InstantAdhesive. The Kapton films were bonded to aluminumlapshears prior to evaluation.The <strong>Loctite</strong> ® Design Guide for Bonding Plastics, <strong>Volume</strong> 4 55