You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

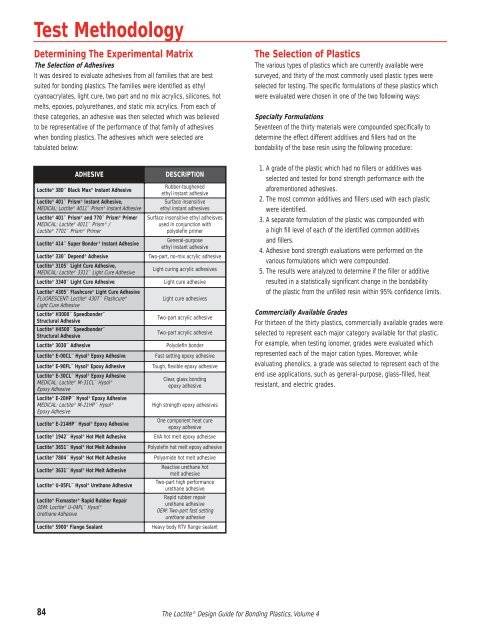

Test MethodologyDetermining The Experimental MatrixThe Selection of AdhesivesIt was desired to evaluate adhesives from all families that are bestsuited for bonding plastics. The families were identified as ethylcyanoacrylates, light cure, two part and no mix acrylics, silicones, hotmelts, epoxies, polyurethanes, and static mix acrylics. From each ofthese categories, an adhesive was then selected which was believedto be representative of the performance of that family of adhesiveswhen bonding plastics. The adhesives which were selected aretabulated below:The Selection of PlasticsThe various types of plastics which are currently available weresurveyed, and thirty of the most commonly used plastic types wereselected for testing. The specific formulations of these plastics whichwere evaluated were chosen in one of the two following ways:Specialty FormulationsSeventeen of the thirty materials were compounded specifically todetermine the effect different additives and fillers had on thebondability of the base resin using the following procedure:ADHESIVE<strong>Loctite</strong> ® 380 Black Max ® Instant Adhesive<strong>Loctite</strong> ® 401 Prism ® Instant Adhesive,MEDICAL: <strong>Loctite</strong> ® 4011 Prism ® Instant Adhesive<strong>Loctite</strong> ® 401 Prism ® and 770 Prism ® PrimerMEDICAL: <strong>Loctite</strong> ® 4011 Prism ® /<strong>Loctite</strong> ® 7701 Prism ® Primer<strong>Loctite</strong> ® 414 Super Bonder ® Instant Adhesive<strong>Loctite</strong> ® 330 Depend ® Adhesive<strong>Loctite</strong> ® 3105 Light Cure Adhesive,MEDICAL: <strong>Loctite</strong> ® 3311 Light Cure Adhesive<strong>Loctite</strong> ® 3340 Light Cure Adhesive<strong>Loctite</strong> ® 4305 Flashcure ® Light Cure AdhesiveFLUORESCENT: <strong>Loctite</strong> ® 4307 Flashcure ®Light Cure Adhesive<strong>Loctite</strong> ® H3000 Speedbonder Structural Adhesive<strong>Loctite</strong> ® H4500 Speedbonder Structural Adhesive<strong>Loctite</strong> ® 3030 Adhesive<strong>Loctite</strong> ® E-00CL Hysol ® Epoxy Adhesive<strong>Loctite</strong> ® E-90FL Hysol ® Epoxy Adhesive<strong>Loctite</strong> ® E-30CL Hysol ® Epoxy AdhesiveMEDICAL: <strong>Loctite</strong> ® M-31CL Hysol ®Epoxy Adhesive<strong>Loctite</strong> ® E-20HP Hysol ® Epoxy AdhesiveMEDICAL: <strong>Loctite</strong> ® M-21HP Hysol ®Epoxy Adhesive<strong>Loctite</strong> ® E-214HP Hysol ® Epoxy Adhesive<strong>Loctite</strong> ® 1942 Hysol ® Hot Melt Adhesive<strong>Loctite</strong> ® 3651 Hysol ® Hot Melt Adhesive<strong>Loctite</strong> ® 7804 Hysol ® Hot Melt Adhesive<strong>Loctite</strong> ® 3631 Hysol ® Hot Melt Adhesive<strong>Loctite</strong> ® U-05FL Hysol ® Urethane Adhesive<strong>Loctite</strong> ® Fixmaster ® Rapid Rubber RepairOEM: <strong>Loctite</strong> ® U-04FL Hysol ®Urethane Adhesive<strong>Loctite</strong> ® 5900 ® Flange SealantDESCRIPTIONRubber-toughenedethyl instant adhesiveSurface insensitiveethyl instant adhesivesSurface insensitive ethyl adheisvesused in conjunction withpolyolefin primerGeneral-purposeethyl instant adhesiveTwo-part, no-mix acrylic adhesiveLight curing acrylic adhesivesLight cure adhesiveLight cure adhesivesTwo-part acrylic adhesiveTwo-part acrylic adhesivePolyolefin bonderFast setting epoxy adhesiveTough, flexible epoxy adhesiveClear, glass bondingepoxy adhesiveHigh strength epoxy adhesivesOne component heat cureepoxy adhesiveEVA hot melt epoxy adheisvePolyolefin hot melt epoxy adhesivePolyamide hot melt adhesiveReactive urethane hotmelt adhesiveTwo-part high performanceurethane adhesiveRapid rubber repairurethane adhesiveOEM: Two-part fast settingurethane adhesiveHeavy body RTV flange sealant1. A grade of the plastic which had no fillers or additives wasselected and tested for bond strength performance with theaforementioned adhesives.2. The most common additives and fillers used with each plasticwere identified.3. A separate formulation of the plastic was compounded witha high fill level of each of the identified common additivesand fillers.4. Adhesive bond strength evaluations were performed on thevarious formulations which were compounded.5. The results were analyzed to determine if the filler or additiveresulted in a statistically significant change in the bondabilityof the plastic from the unfilled resin within 95% confidence limits.Commercially Available GradesFor thirteen of the thirty plastics, commercially available grades wereselected to represent each major category available for that plastic.For example, when testing ionomer, grades were evaluated whichrepresented each of the major cation types. Moreover, whileevaluating <strong>ph</strong>enolics, a grade was selected to represent each of theend use applications, such as general-purpose, glass-filled, heatresistant, and electric grades.84The <strong>Loctite</strong> ® Design Guide for Bonding Plastics, <strong>Volume</strong> 4