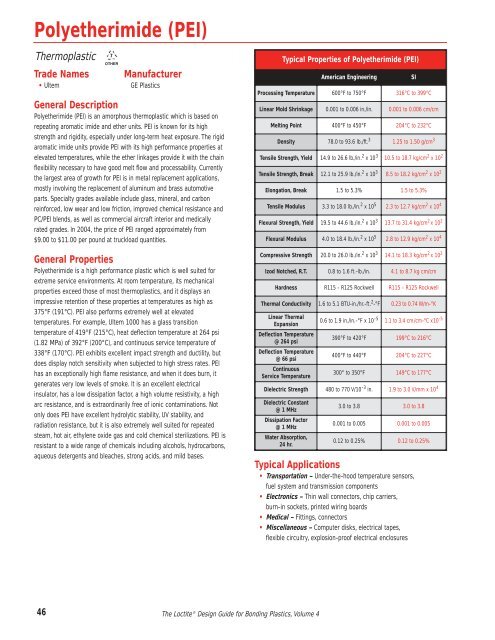

Polyetherimide (PEI)ThermoplasticTrade Names• UltemManufacturerGE PlasticsGeneral DescriptionPolyetherimide (PEI) is an amor<strong>ph</strong>ous thermoplastic which is based onrepeating aromatic imide and ether units. PEI is known for its highstrength and rigidity, especially under long-term heat exposure. The rigidaromatic imide units provide PEI with its high performance properties atelevated temperatures, while the ether linkages provide it with the chainflexibility necessary to have good melt flow and processability. Currentlythe largest area of growth for PEI is in metal replacement applications,mostly involving the replacement of aluminum and brass automotiveparts. Specialty grades available include glass, mineral, and carbonreinforced, low wear and low friction, improved chemical resistance andPC/PEI blends, as well as commercial aircraft interior and medicallyrated grades. In 2004, the price of PEI ranged approximately from$9.00 to $11.00 per pound at truckload quantities.General PropertiesPolyetherimide is a high performance plastic which is well suited forextreme service environments. At room temperature, its mechanicalproperties exceed those of most thermoplastics, and it displays animpressive retention of these properties at temperatures as high as375°F (191°C). PEI also performs extremely well at elevatedtemperatures. For example, Ultem 1000 has a glass transitiontemperature of 419°F (215°C), heat deflection temperature at 264 psi(1.82 MPa) of 392°F (200°C), and continuous service temperature of338°F (170°C). PEI exhibits excellent impact strength and ductility, butdoes display notch sensitivity when subjected to high stress rates. PEIhas an exceptionally high flame resistance, and when it does burn, itgenerates very low levels of smoke. It is an excellent electricalinsulator, has a low dissipation factor, a high volume resistivity, a higharc resistance, and is extraordinarily free of ionic contaminations. Notonly does PEI have excellent hydrolytic stability, UV stability, andradiation resistance, but it is also extremely well suited for repeatedsteam, hot air, ethylene oxide gas and cold chemical sterilizations. PEI isresistant to a wide range of chemicals including alcohols, hydrocarbons,aqueous detergents and bleaches, strong acids, and mild bases.Typical Properties of Polyetherimide (PEI)American EngineeringProcessing Temperature 600°F to 750°F 316°C to 399°CLinear Mold Shrinkage 0.001 to 0.006 in./in. 0.001 to 0.006 cm/cmMelting Point 400°F to 450°F 204°C to 232°CDensity 78.0 to 93.6 lb./ft. 3 1.25 to 1.50 g/cm 3Tensile Strength, Yield 14.9 to 26.6 lb./in. 2 x 10 3 10.5 to 18.7 kg/cm 2 x 10 2Tensile Strength, Break 12.1 to 25.9 lb./in. 2 x 10 3 8.5 to 18.2 kg/cm 2 x 10 2Elongation, Break 1.5 to 5.3% 1.5 to 5.3%Tensile Modulus 3.3 to 18.0 lb./in. 2 x 10 5 2.3 to 12.7 kg/cm 2 x 10 4Flexural Strength, Yield 19.5 to 44.6 lb./in. 2 x 10 3 13.7 to 31.4 kg/cm 2 x 10 2Flexural Modulus 4.0 to 18.4 lb./in. 2 x 10 5 2.8 to 12.9 kg/cm 2 x 10 4Compressive Strength 20.0 to 26.0 lb./in. 2 x 10 3 14.1 to 18.3 kg/cm 2 x 10 2Izod Notched, R.T. 0.8 to 1.6 ft.-lb./in. 4.1 to 8.7 kg cm/cmHardness R115 - R125 Rockwell R115 - R125 RockwellThermal Conductivity 1.6 to 5.1 BTU-in./hr.-ft. 2 -°F 0.23 to 0.74 W/m-°KLinear ThermalExpansionDeflection Temperature@ 264 psiDeflection Temperature@ 66 psiContinuousService Temperature0.6 to 1.9 in./in.-°F x 10 -5 1.1 to 3.4 cm/cm-°C x10 -5390°F to 420°F 199°C to 216°C400°F to 440°F 204°C to 227°CTypical Applications• Transportation – Under-the-hood temperature sensors,fuel system and transmission components• Electronics – Thin wall connectors, chip carriers,burn-in sockets, printed wiring boards• Medical – Fittings, connectors• Miscellaneous – Computer disks, electrical tapes,flexible circuitry, explosion-proof electrical enclosuresSI300° to 350°F 149°C to 177°CDielectric Strength 480 to 770 V/10 -3 in. 1.9 to 3.0 V/mm x 10 4Dielectric Constant@ 1 MHzDissipation Factor@ 1 MHzWater Absorption,24 hr.3.0 to 3.8 3.0 to 3.80.001 to 0.005 0.001 to 0.0050.12 to 0.25% 0.12 to 0.25%46The <strong>Loctite</strong> ® Design Guide for Bonding Plastics, <strong>Volume</strong> 4

ADHESIVE SHEAR STRENGTH(psi)(MPa)Polyetherimide (PEI)UNFILLED RESINULTEM GRADE 10103 rmsGRADE 1010ROUGHENED47 rmsGRADE 210010% Glass ReinforcedGRADE 240040% Glass ReinforcedGRADE 345345% Glass/SilicaReinforcedGRADE 4001Unreinforced,with LubricantGRADE CRS5001Unreinforced, ChemicallyResistant GradeGRADE 780125% Carbon ReinforcedGRADE LTX100APEI/PC Blend InjectionMolding Grade<strong>Loctite</strong> ® 380 Black Max ® Instant Adhesive,Rubber Toughened1501.010507.23502.411507.913009.01501.04503.19506.67505.2Ultem Grade 1000 NAT Courtesy of GE Plastics<strong>Loctite</strong> ® 401 Prism ® Instant Adhesive,Surface InsensitiveMEDICAL: <strong>Loctite</strong> ® 4011 Prism ®Instant Adhesive, Surface Insensitive<strong>Loctite</strong> ® 401 Prism ®<strong>Loctite</strong> ® 770 Prism ® PrimerMEDICAL: <strong>Loctite</strong> ® 4011 Prism ® /<strong>Loctite</strong> ® 7701 Prism ® Primer<strong>Loctite</strong> ® 414 Super Bonder ®Instant Adhesive, General Purpose<strong>Loctite</strong> ® 330 Depend ® Adhesive,Two-Part No-Mix Acrylic<strong>Loctite</strong> ® 3105 Light Cure Adhesive,MEDICAL: <strong>Loctite</strong> ® 3311 Light Cure Adhesive<strong>Loctite</strong> ® 3340 Light Cure Adhesive,UV Cationic Epoxy<strong>Loctite</strong> ® 4305 Flashcure ® Light Cure AdhesiveFLUORESCENT: <strong>Loctite</strong> ® 4307 Flashcure ®Light Cure Adhesive<strong>Loctite</strong> ® H3000 Speedbonder Structural Adhesive, General Purpose<strong>Loctite</strong> ® H4500 Speedbonder Structural Adhesive, Metal Bonder<strong>Loctite</strong> ® 3030 Adhesive, Polyolefin Bonder<strong>Loctite</strong> ® E-00CL Hysol ® Epoxy Adhesive,Low Odor<strong>Loctite</strong> ® E-90FL Hysol ® Epoxy Adhesive,Flexible<strong>Loctite</strong> ® E-30CL Hysol ® Epoxy Adhesive,Glass BonderMEDICAL: <strong>Loctite</strong> ® M-31CL Hysol ®Epoxy Adhesive, Glass Bonder<strong>Loctite</strong> ® E-20HP Hysol ® Epoxy Adhesive,Fast SettingMEDICAL: <strong>Loctite</strong> ® M-21HP Hysol ®Epoxy Adhesive, Fast Setting<strong>Loctite</strong> ® E-214HP Hysol ® Epoxy Adhesive,High Strength<strong>Loctite</strong> ® Fixmaster ® High Performance Epoxy13509.33002.111007.65003.5225015.51501.0>2050 >14.1 7505.23502.45503.86504.510006.913509.311507.99006.211007.6245016.9200013.8200013.88005.5225015.510507.25003.59006.27004.8175012.110006.98505.9215014.8170011.713009.0165011.413509.3200013.8150010.3150010.36504.53002.17004.85503.814009.72001.410507.27004.8>1800 1550>12.4 10.712508.613509.3185012.87505.214009.714009.76504.511007.68005.5355024.5Adhesive Performance<strong>Loctite</strong> ® 4305 Flashcure ® Light Cure Adhesive achieved the highest bond strengths on the PEI, typicallyachieving substrate failure. <strong>Loctite</strong> ® 401 Prism ® , 4011 Prism ® Medical Device and 414 Super Bonder ®Instant Adhesives, <strong>Loctite</strong> ® 3105 Light Cure Adhesive, <strong>Loctite</strong> ® E-90FL and E-30CL Hysol ® EpoxyAdhesives, <strong>Loctite</strong> ® 3631 Hysol ® Hot Melt Adhesive, and <strong>Loctite</strong> ® Fixmaster ® High Performance Epoxynormally achieved the high bond strengths on the various grades of Ultem which were evaluated.However, the performance of each adhesive varied from grade to grade. <strong>Loctite</strong> ® 3340 Light CureAdhesive typically achieved the lowest bond strength on unfilled PEI.Surface TreatmentsSurface roughening caused large, statistically significant increases in the bond strengths achieved on PEI.The use of <strong>Loctite</strong> ® 770 Prism ® Primer, in conjunction with <strong>Loctite</strong> ® 401 Prism ® Instant Adhesive, or<strong>Loctite</strong> ® 4011 Prism ® Medical Device Instant Adhesive with <strong>Loctite</strong> ® 7701 Prism ® Primer, caused asignificant decrease in the bond strengths achieved on most of the grades of Ultem which wereevaluated.Other Important Information• Good solvents for use with PEI are methylene chloride and n-methylpyrrolidone.• An accelerator may be necessary to speed the cure of cyanoacrylates on unfilled grades of PEI.• Some grades of PEI have been found to be incompatible with cyanoacrylate adhesives.• Surface cleaners: isopropyl alcohol, <strong>Loctite</strong> ® ODC-Free Cleaner & Degreaser.<strong>Loctite</strong> ® 1942 Hysol ® Hot Melt Adhesive,EVA Based3002.1<strong>Loctite</strong> ® 3651 Hysol ® Hot Melt Adhesive,Polyolefin1501.0<strong>Loctite</strong> ® 7804 Hysol ® Hot Melt Adhesive2501.7<strong>Loctite</strong> ® 3631 Hysol ® Hot Melt Adhesive,Urethane<strong>Loctite</strong> ® U-05FL Hysol ® Urethane Adhesive,High Strength<strong>Loctite</strong> ® Fixmaster ® Rapid Rubber RepairOEM: <strong>Loctite</strong> ® U-04FL Hysol ®Urethane Adhesive, Fast Setting<strong>Loctite</strong> ® 5900 ® Flange Sealant,Heavy Body RTV Silicone14009.74503.15003.52501.7NOTES: The force applied to the tests specimens exceededthe strength of the material resulting in substrate failurebefore the actual bond strength achieved by theadhesive could be determined.The addition of the indicated additive (or surfaceroughening) caused a statistically significant decrease inthe bond strength within 95% confidence limits.The addition of the indicated additive (or surfaceroughening) caused a statistically significant increase inthe bond strength within 95% confidence limits.The <strong>Loctite</strong> ® Design Guide for Bonding Plastics, <strong>Volume</strong> 4 47