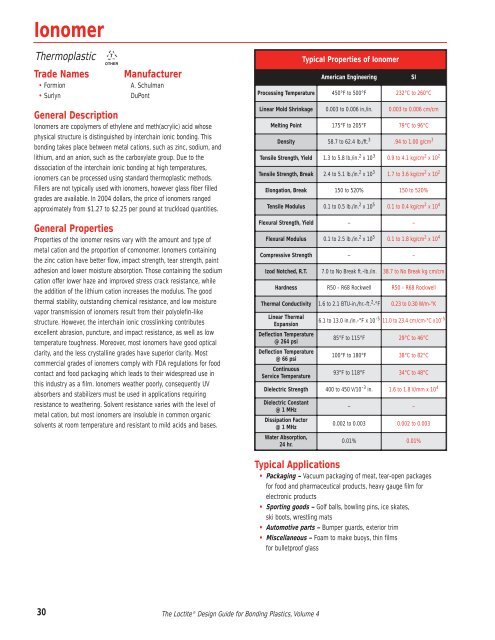

IonomerThermoplasticTrade Names• Formion• SurlynManufacturerA. SchulmanDuPontTypical Properties of IonomerAmerican EngineeringSIProcessing Temperature 450°F to 500°F 232°C to 260°CGeneral DescriptionIonomers are copolymers of ethylene and meth(acrylic) acid whose<strong>ph</strong>ysical structure is distinguished by interchain ionic bonding. Thisbonding takes place between metal cations, such as zinc, sodium, andlithium, and an anion, such as the carboxylate group. Due to thedissociation of the interchain ionic bonding at high temperatures,ionomers can be processed using standard thermoplastic methods.Fillers are not typically used with ionomers, however glass fiber filledgrades are available. In 2004 dollars, the price of ionomers rangedapproximately from $1.27 to $2.25 per pound at truckload quantities.General PropertiesProperties of the ionomer resins vary with the amount and type ofmetal cation and the proportion of comonomer. Ionomers containingthe zinc cation have better flow, impact strength, tear strength, paintadhesion and lower moisture absorption. Those containing the sodiumcation offer lower haze and improved stress crack resistance, whilethe addition of the lithium cation increases the modulus. The goodthermal stability, outstanding chemical resistance, and low moisturevapor transmission of ionomers result from their polyolefin-likestructure. However, the interchain ionic crosslinking contributesexcellent abrasion, puncture, and impact resistance, as well as lowtemperature toughness. Moreover, most ionomers have good opticalclarity, and the less crystalline grades have superior clarity. Mostcommercial grades of ionomers comply with FDA regulations for foodcontact and food packaging which leads to their widespread use inthis industry as a film. Ionomers weather poorly, consequently UVabsorbers and stabilizers must be used in applications requiringresistance to weathering. Solvent resistance varies with the level ofmetal cation, but most ionomers are insoluble in common organicsolvents at room temperature and resistant to mild acids and bases.Linear Mold Shrinkage 0.003 to 0.006 in./in. 0.003 to 0.006 cm/cmMelting Point 175°F to 205°F 79°C to 96°CDensity 58.7 to 62.4 lb./ft. 3 .94 to 1.00 g/cm 3Tensile Strength, Yield 1.3 to 5.8 lb./in. 2 x 10 3 0.9 to 4.1 kg/cm 2 x 10 2Tensile Strength, Break 2.4 to 5.1 lb./in. 2 x 10 3 1.7 to 3.6 kg/cm 2 x 10 2Elongation, Break 150 to 520% 150 to 520%Tensile Modulus 0.1 to 0.5 lb./in. 2 x 10 5 0.1 to 0.4 kg/cm 2 x 10 4Flexural Strength, Yield – –Flexural Modulus 0.1 to 2.5 lb./in. 2 x 10 5 0.1 to 1.8 kg/cm 2 x 10 4Compressive Strength – –Izod Notched, R.T. 7.0 to No Break ft.-lb./in. 38.7 to No Break kg cm/cmHardness R50 - R68 Rockwell R50 - R68 RockwellThermal Conductivity 1.6 to 2.1 BTU-in./hr.-ft. 2 -°F 0.23 to 0.30 W/m-°KLinear ThermalExpansionDeflection Temperature@ 264 psiDeflection Temperature@ 66 psiContinuousService Temperature6.1 to 13.0 in./in.-°F x 10 -5 11.0 to 23.4 cm/cm-°C x10 -585°F to 115°F 29°C to 46°C100°F to 180°F 38°C to 82°C93°F to 118°F 34°C to 48°CDielectric Strength 400 to 450 V/10 -3 in. 1.6 to 1.8 V/mm x 10 4Dielectric Constant@ 1 MHzDissipation Factor@ 1 MHzWater Absorption,24 hr.– –0.002 to 0.003 0.002 to 0.0030.01% 0.01%Typical Applications• Packaging – Vacuum packaging of meat, tear-open packagesfor food and <strong>ph</strong>armaceutical products, heavy gauge film forelectronic products• Sporting goods – Golf balls, bowling pins, ice skates,ski boots, wrestling mats• Automotive parts – Bumper guards, exterior trim• Miscellaneous – Foam to make buoys, thin filmsfor bulletproof glass30The <strong>Loctite</strong> ® Design Guide for Bonding Plastics, <strong>Volume</strong> 4

ADHESIVE SHEAR STRENGTH(psi)(MPa)IonomerGRADE 79404 rms7940 ROUGHENED68 rmsGRADE 89404 rms8940 ROUGHENED68rmsGRADE 99504 rmsSurlym courtesy of E.I. DuPont7940 ROUGHENED68 rms<strong>Loctite</strong> ® 380 Black Max ® Instant Adhesive,Rubber Toughened<strong>Loctite</strong> ® 401 Prism ® Instant Adhesive,Surface InsensitiveMEDICAL: <strong>Loctite</strong> ® 4011 Prism ®Instant Adhesive, Surface Insensitive<strong>Loctite</strong> ® 401 Prism ®<strong>Loctite</strong> ® 770 Prism ® PrimerMEDICAL: <strong>Loctite</strong> ® 4011 Prism ® /<strong>Loctite</strong> ® 7701 Prism ® Primer<strong>Loctite</strong> ® 414 Super Bonder ®Instant Adhesive, General Purpose<strong>Loctite</strong> ® 330 Depend ® Adhesive,Two-Part No-Mix Acrylic<strong>Loctite</strong> ® 3105 Light Cure Adhesive,MEDICAL: <strong>Loctite</strong> ® 3311 Light Cure Adhesive<strong>Loctite</strong> ® 3340 Light Cure Adhesive,UV Cationic Epoxy<strong>Loctite</strong> ® 4305 Flashcure ® Light Cure AdhesiveFLUORESCENT: <strong>Loctite</strong> ® 4307 Flashcure ®Light Cure Adhesive<strong>Loctite</strong> ® H3000 Speedbonder Structural Adhesive, General Purpose<strong>Loctite</strong> ® H4500 Speedbonder Structural Adhesive, Metal Bonder<strong>Loctite</strong> ® 3030 Adhesive, Polyolefin Bonder<strong>Loctite</strong> ® E-00CL Hysol ® Epoxy Adhesive,Low Odor<strong>Loctite</strong> ® E-90FL Hysol ® Epoxy Adhesive,Flexible<strong>Loctite</strong> ® E-30CL Hysol ® Epoxy Adhesive,Glass BonderMEDICAL: <strong>Loctite</strong> ® M-31CL Hysol ®Epoxy Adhesive, Glass Bonder<strong>Loctite</strong> ® E-20HP Hysol ® Epoxy Adhesive,Fast SettingMEDICAL: <strong>Loctite</strong> ® M-21HP Hysol ®Epoxy Adhesive, Fast Setting<strong>Loctite</strong> ® E-214HP Hysol ® Epoxy Adhesive,High Strength<strong>Loctite</strong> ® Fixmaster ® High Performance Epoxy<strong>Loctite</strong> ® 1942 Hysol ® Hot Melt Adhesive,EVA Based<strong>Loctite</strong> ® 3651 Hysol ® Hot Melt Adhesive,Polyolefin<strong>Loctite</strong> ® 7804 Hysol ® Hot Melt Adhesive<strong>Loctite</strong> ® 3631 Hysol ® Hot Melt Adhesive,Urethane<strong>Loctite</strong> ® U-05FL Hysol ® Urethane Adhesive,High Strength<strong>Loctite</strong> ® Fixmaster ® Rapid Rubber RepairOEM: <strong>Loctite</strong> ® U-04FL Hysol ®Urethane Adhesive, Fast Setting<strong>Loctite</strong> ® 5900 ® Flange Sealant,Heavy Body RTV Silicone2001.4>1200 †>8.3 † 2001.4>1200 †>8.3 † 500.38005.5>1200 † >1200 † >1200 † >1200 † >1200 † >1200 †>8.3 † >8.3 † >8.3 † >8.3 † >8.3 † >8.3 †>1200 † >1200 † >1200 † >1200 † >1200 † >1200 †>8.3 † >8.3 † >8.3 † >8.3 † >8.3 † >8.3 †>1200 † >1200 † >1200 † >1200 † >1200 † >1200 †>8.3 † >8.3 † >8.3 † >8.3 † >8.3 † >8.3 †4503.14503.13502.43502.43502.43502.4>1200 † >1200 † >1200 † >1200 † >1200 † >1200 †>8.3 † >8.3 † >8.3 † >8.3 † >8.3 † >8.3 †2501.713509.31000.71000.7165011.4175012.1170011.7150010.410507.2NOTTESTED8005.52501.71501.02001.46504.512508.66504.52001.4Adhesive Performance<strong>Loctite</strong> ® 4011 Prism ® and 414 Super Bonder ® Instant Adhesives and <strong>Loctite</strong> ® 3105 Light CureAdhesive all created bonds which were stronger than the ionomer substrate. <strong>Loctite</strong> ® 4305 Flashcure ®Light Cure Adhesive, <strong>Loctite</strong> ® E-00CL and E-30CL Hysol ® Epoxy Adhesives, and <strong>Loctite</strong> ® U-05FL Hysol ®Urethane Adhesive all achieved bond strengths comparable to the adhesives that achieved substratefailure. <strong>Loctite</strong> ® H3000 and H4500 Speedbonder Structural Adhesives both achieved the lowest bondstrengths. There was no statistically significant difference between the bondability of the three grades ofSurlyn evaluated, with the exception of the low bond strengths achieved by <strong>Loctite</strong> ® 380 Black Max ®Instant Adhesive on Surlyn 9950.Surface TreatmentsSurface roughening caused a large, statistically significant increase in the bond strengths achieved by<strong>Loctite</strong> ® 380 Black Max ® Instant Adhesive, but had no statistically significant effect with <strong>Loctite</strong> ® 330 Depend ® Adhesive. The effect of <strong>Loctite</strong> ® 770 Prism ® Primer or <strong>Loctite</strong> ® 7701 Prism ® Primer, andsurface roughening with <strong>Loctite</strong> ® 4011 Prism ® , 4011 Prism ® Medical Device and 414 Super BonderInstant Adhesives or <strong>Loctite</strong> ® 3105 and 3311 Light Cure Adhesives could not be determined becausewith all the treated and untreated ionomer, the bonds created were stronger than the ionomer substrate.Other Important Information• Ionomers can be stress cracked by uncured cyanoacrylate adhesives, so any excessadhesive should be removed from the surface immediately.• Surface cleaners: isopropyl alcohol, <strong>Loctite</strong> ® ODC-Free Cleaner & Degreaser.NOTES:† Due to the severe deformation of the block shearspecimens, testing was stopped before the actual bondstrength achieved by the adhesive could be determined(the adhesive bond never failed).NOT TESTED: Substrate melted at adhesivecure temperature.The addition of the indicated additive (or surfaceroughening) caused a statistically significant increasein the bond strength within 95% confidence limits.The <strong>Loctite</strong> ® Design Guide for Bonding Plastics, <strong>Volume</strong> 4 31