Environmental Initiatives - hino global

Environmental Initiatives - hino global

Environmental Initiatives - hino global

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

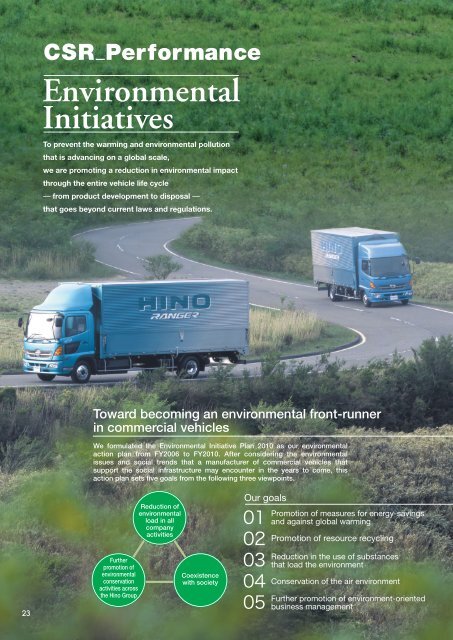

<strong>Environmental</strong><strong>Initiatives</strong>To prevent the warming and environmental pollutionthat is advancing on a <strong>global</strong> scale,we are promoting a reduction in environmental impactthrough the entire vehicle life cycle— from product development to disposal —that goes beyond current laws and regulations.Toward becoming an environmental front-runnerin commercial vehiclesWe formulated the <strong>Environmental</strong> Initiative Plan 2010 as our environmentalaction plan from FY2006 to FY2010. After considering the environmentalissues and social trends that a manufacturer of commercial vehicles thatsupport the social infrastructure may encounter in the years to come, thisaction plan sets five goals from the following three viewpoints.Reduction ofenvironmentalload in allcompanyactivitiesOur goalsPromotion of measures for energy-savingsand against <strong>global</strong> warmingPromotion of resource recyclingFurtherpromotion ofenvironmentalconservationactivities acrossthe Hino GroupCoexistencewith societyReduction in the use of substancesthat load the environmentConservation of the air environmentFurther promotion of environment-orientedbusiness management

<strong>Environmental</strong> <strong>Initiatives</strong><strong>Environmental</strong> performance improvements and initiatives (see pgs 25 and 26)Hybrid system technology at Hino MotorsFurther improving the fuel efficiency with Hino’s original hybrid systemFuel efficiency improvementsOffering products with superior environmental performance and energy savings as well as productsand services that support energy-efficient drivingTechnology compatible with the Japanese New Long-Term EmissionRegulations for the year 2005 and low-emission heavy-duty vehiclesDrastically reducing NOx and PM emissions through improvements to our engines based on ourDPR (Diesel Particulate active Reduction) clean diesel systemNOx and PM reduction technologyContinually creating new technologies to improve environmental performance based on years oftechnological innovationPromoting 3R and reduction of substances with environmental loadReducing substances with environmental load in products in addition to promoting automobilerecyclingReducing environmental load in production and distribution (see pg. 27)Preventing of <strong>global</strong> warmingDecreasing CO2 emissions by promoting energy-saving activitiesConsidering the areas surroundings our plantsImplementing soil and groundwater clean up while preventing soil pollutionfrom oil leakageManaging chemical substancesPreventing use of highly toxic substances while complying with the Pollutant Releaseand Transfer Register (PRTR) LawReducing wasteDecreasing all waste produced in business activities,including incinerated waste and direct landfill wasteReducing CO2 emissions by improving logisticsDecreasing not only CO2 emissions as well as the amount of distribution materialby improving distribution efficiency<strong>Environmental</strong> conservation activities of the Hino Group (see pg. 28)Consolidated environmental managementDeploying <strong>global</strong> consolidated environmental management through seven overseasaffiliates, while promoting consolidated environmental managementthrough 22 domestic affiliates<strong>Environmental</strong> conservation activities at dealers in JapanOperating an eco-management dealer certification system to promote environmentalconservation activities among dealersEco-plant activitiesPromoting environmental measures at the planning of plant construction,focusing on compliance with laws and regulations,prevention of environmental issuesand improving of environmental performance

<strong>Environmental</strong> <strong>Initiatives</strong>Improvement of <strong>Environmental</strong> Performance and <strong>Initiatives</strong>Hino Motors has been making sustained effort to develop eco-environmentally friendlyproducts, such as diesel hybrid vehicles, with the aim of becoming a front-runnerin the industry for this technology. It covers for a broad area that is, not only hardware,such as engines, but also systems to support eco-friendly driving.Hino motor’s hybrid technologyFeatures of the hybrid system(1) Energy regeneration(fuel efficiency improvement andreduction of CO2 emissions)Deceleration energy that used tobe wasted is now converted intoelectricity and stored in a batteryto be reused as electric power.(2) Motor(reduction of emissions, blacksmoke and noise)On start-up and acceleration, themotor is driven and the engine isassisted.(3) Retarder (safety improvement)The electric motor works as anauxiliary brake.(4) StarterWithout a general starter motor,hybrid system actuates theengine.The first available hybrid buscommercially in the worldAfter successful monitor testing of electricbuses in 1973, Hino Motors started developing theHIMR *1 with the intent of integrating diesel powerwith electricity. We advanced the development,believing in the possibility of a system that realizesboth high-level fuel efficiency and clean emissions.As a result, in 1991, we commercialized, for the firsttime in the world, a large-sized diesel-electric hybridbus with an inverter-controlled motor-generator.Since then, after making various improvementsin the Hino hybrid technology, we released thehybrid light-duty truck in 2003 as the first cab-overhybrid light-duty truck in the world.Advantage of Hino hybrid technologyThe advantage of Hino hybrid technology is inthe know-how accumulated over many years ofR&D.The key point is how to control the power line.With an abundance of know-how on control, basedon a quarter century of experience, Hino Motors hasthe technological capability to capitalize on theadvantages of hybrid system vehicles.Popularization of hybrid system vehiclesIn FY2006, the sales volume for Hino hybridbuses and trucks in Japan totaled 1,211 units or2.3% of the total sales volume for Hino Motors. Thetotal number of units sold since 1991 exceeds 4,000units.Hino Motors responds to society’s demand forenvironmental conservation by promoting thedevelopment of environmental technology, such asFor the <strong>global</strong> environmentHino Motors believes that our corporatephilosophy is to develop and produce vehicles withexcellent environmental performance.A strong motivation to “do as much as we canfor the good of the public” drives us to continuedevelopment and production of hybrid systemtrucks and buses with even better performance.In FY2006, we were the first manufacture toproduce a hybrid light-duty truck that met theJapanese 2015 Fuel Efficiency Standards andachieved the same first for large-sized hybrid routebuses in FY2007. Both achievements wereattributable to the new hybrid unit system.Fifthgeneration1994 regulations1998 regulationsTechnology for reducing NOx and PM emissionsEmissions levels of hybrid vehicleswith Japanese regulations2003 regulations2005regulationsFourthgenerationThirdgenerationSecondgenerationFirstgenerationthe DPR clean diesel system and combined EGR *2system, with the goal of reducing NOx *3 and PM *4emissions.*1 HIMR:abbreviation for Hybrid InverterControlled Motor and Retarder system*2 EGR: Exhaust Gas Recirculation*3 NOx: Nitrogen Oxide*4 PM: Particulate Material

<strong>Environmental</strong> <strong>Initiatives</strong>Fuel efficiency improvementsEarly compliance with the Japanese2015 Fuel Efficiency StandardHino Motors achieves both superior environmentalperformance and low-fuel consumption on the basisof our fuel-efficient engine technology.Our hybrid light-duty trucks and a part of ourheavy-duty trucks and buses achieved earlycompliance with the Japanese 2015 Fuel EfficiencyStandard for heavy-duty vehicles that came intoeffect in April 2006. We are also contributing toeconomic efficiency through high fuel efficiency.Supporting fuel savings in operationsTo bring the already excellent fuel-efficiency ofthe vehicle to its maximum, Hino Motors hasdeveloped and brought to market the Drive Master ,a support system for fuel-efficient driving.Technological compliance with the Japanese New Long-Term EmissionRegulations for the year 2005 and Low-Emission Heavy-duty VehiclesTrucks and buses complying with the New JapaneseLong-Term Emission Regulations for the year 2005low-emission heavy-duty vehicles(First in Japan)Exceedsthe 10%NOx and PMreduction requiredby the JapaneseNew Long-TermEmission Regulationsfor the year 2005Hino 700Hino 500Hino 300**Co-developed with Toyota Motor CorporationExceedsthe 10% PMPM reduction requiredby the JapaneseNew Long-TermEmission RegulationsHino large-sizedsight-seeing busHino route busHino town busWith environmental performance as a priority,Hino Motors has been early in developing the cleandiesel engine. Improvement of the engine based on theDPR (Diesel Particulate active Reduction) clean dieselsystem drastically decreases NOx and PM emissionsat the same time. As a result, our diesel enginecomplies with the strict regulation, Japanese NewLong-Term Emission Regulations, for the year 2005.Striving as a front-runner in environmentalperformance, we released the first truck in Japan toexceed the 10% NOx and PM level reduction that isrequired by the Japanese New Long-Term EmissionRegulations for the year 2005, placing it at the top oflow-emission heavy-duty vehicles.Drive MasterThe Ministry of Land, Infrastructureand Transport(MLIT) of Japan operates aprogram for assessmentand certification of vehicleemission reduction performance,with the goal ofpromoting more vehicles with high emissionreduction performance. In addition,the Ministry certifies vehicles that achieveearly compliance with the fuel efficiencystandards stipulated by the ActConcerning the Rational Use of Energy(Energy Conservation Law). In June2006, Hino Motors acquired MLIT certificationfor certain models as Low EmissionVehicles and as vehicles complyingwith the 2015 Fuel Efficiency Standards.This logo identifies HinoMotor’s eco-friendlytrucks and buses thatuse the latest ultra-lowexhaust emission technologies. The logoappears on all Hino Motors vehicles inJapan that comply with the JapaneseNew Long-Term Emission Regulationsfor the year 2005. With the earth and atree arranged on an oval-shaped base,the logo expresses eco-friendliness.Vehicles meeting 2015 Fuel Efficiency Standards in JapanHino 700 (met by some models)Automobile acquisition tax reduced by 2%Promoting 3R *5 and reduction of substances with environmental load.Initiative for automobile recyclingTo conform with the Automobile Recycling Law(Law for the Recycling of End-of-Life Vehicles) ofJapan that came into effect in 2005, we haveimplemented a process for recovery, processing andrecycling of three main materials from end-of-lifevehicles, namely ASR (shredder residue), airbagsand CFCs with the help of related businesses in Japan.Also, at the product development stage, we arepromoting eco-friendly manufacturing by usingeasily recycled materials and, where possible, easilydisassembled designs, thereby actively pursuing theeffective utilization of resources and the formation ofa recycling society.Results of recycling in 2006 (in Japan)ItemASRAirbagsCFCsAmount recovered3,385t323units1,202kgRecycling ratio65%95%-----Legal standard30%85%-----Reduction of substanceswith environmental loadWe are actively pursuing the formation of arecycling society and the effective utilization ofresources, by promoting eco-friendly manufacturingat the product development stage. At the end of2006, we have nearly reached the voluntary targetset by the Japan Automobile ManufacturersAssociation for reduction of four substances withenvironmental impact (lead, mercury, cadmium andhexavalent chromium) in products.Hino large-sized sight-seeing bus(except for High Decker Short)Automobile acquisition tax reduced by 2%Firstsmall-sizedlight-duty truck/hybrid truck tocomplywith the 2015Fuel EfficiencyStandardsHino 300Automobile acquisition tax reduced by 2.7%according to the Preferential Measuresfor Low-Emission VehiclesHino route bus (met by some models)Automobile acquisition tax reduced by 2%*5 3R: Reduce, Reuse and Recycle

<strong>Environmental</strong> <strong>Initiatives</strong>Reducing environmental loadin production and distributionWe are actively reducing of environmental load at the production stage,based on the <strong>Environmental</strong> Initiative Plan for 2010 (Fourth Voluntary Plan), started in 2005.Transitions in total CO2emissions and basic unitin JapanTotal CO2 emissions Basic unit1,000-CO2 tonsCO2 basic unit(1,000-CO2/million yen)Target comparedwith to FY1990lelvelThese data differ from last yearin total emissions and basicunit due to a revision in thecalculation method for CO2emissions.*1 PRTR Law:Abbreviation for PollutantRelease and Transfer Register.The PRTR defines the methodsfor understanding, gathering andreleasing data showing the name,amount, and source of hazardouschemical substances that arereleased into the environment, orincluded in waste and carriedaway from the plant.*2 Emission:The total amount of materials(fare-paying) and waste (inversefair-paying) that are carried awayfrom the Hino Group.*3 Distribution Improvement Meeting:A meeting attended by therelevant divisions in the companywith the aim to comprehensivelyimprove distribution activities.FYPrevention of <strong>global</strong> warmingIn 2006, we decreased our CO2 emissions by11% and CO2 emissions per total sales by 42%compared with 1990, through sustained energysavingactivities in Japan, including the consolidationof the painting line at the Hamura Plant.We are working toward a <strong>global</strong> target – toreduce by 2010 the CO2 emissions per total sales by10% compared with the CO2 emissions per totalsales in 2003.Considering the areassurrounding our plantsConsidering the environmental effect on theareas surrounding our plants in Japan and overseas,Hino promote activities preventing to put out ofnoise, vibration, and odor, as well as soil pollution.Particularly a new plant constructing, we arepromoting eco-plant activities (see pg. 28) throughwhich environmental measures are included at theplanning.Managing chemical substancestHino Motors complies with the PRTR Law. *1When new distribution materials are procured, weapply an assessment system to confirm the contentof the chemical substances in advance, to preventthe use of highly toxic substances, from thestandpoints of environment, and health and safety.In Japan and abroad, we apply our own list ofbanned chemical substances and use the list forinstruction.Reducing wasteIn addition to shutting down our in-houseincinerators September 2006 in Japan, we arepromoting further recycling activities. We are alsoworking in parallel on reducing direct landfill waste.We formulated an action plan in 2006 consideringthe reduction of all emissions *2 from our company,and are promoting activities based on this plan.We are working on the reduction of waste fromour overseas facilities as well, having shared ouremission reduction policy overseas in 2006.Total fordomesticplantsReuseAmount of emissions(target for reduction)Details of waste disposal in FY2006Waste volume(includingrecycledcasting sand)119,257tIn house reuse48,572t 40.7 %FinishedproductsReducing CO2 emissionsby improving distribution1 reuse in the sameprocess2 reuse in otherprocesses3 reuse within Groupcompanies4 fare-paying recycling5 inverse onerouscosts recycling6 wasteOutside (including inverse-onerous costs)68,606t (57.5 %)Incinerated waste (in house and outside) 1,677t (1.4%)Direct landfill waste 20t (0.02 %)Other externally waste 382t (0.3 %)To reduce CO2 emissions as well as distributioncosts, the Distribution Improvement Meeting *3 issupporting improvement activities for all domesticoperating divisions and overseas subsidiarycompanies, to improve loading rate, rotation rate,modal shifting and shortening of transport routes.For the packing and packaging materials, weare looking to reduce usage by promotingconversion to returnable materials. The conversionwill not only apply to domestic shipments, but alsoto overseas shipments.http://www.<strong>hino</strong>.co.jp/e/04/4_07.htm

<strong>Environmental</strong> <strong>Initiatives</strong><strong>Environmental</strong> conservation activitiesof the Hino GroupStriving to be an environmental leader, Hino Motors is workingon environmental conservation as the total Hino Group.Consolidated environmental managementInitiative on consolidated environmentwith domestic affiliatesHino Motors has provided guidelines onconsolidated environmental management to 22environmentally consolidated companies in Japan.We are promoting the sharing of environmentalactivities and other environmental informationthrough the Production Environment Working GroupMeeting for Domestic Affiliated Companies that isheld twice a year.We are also promoting distribution of environmentalinformation to the five production subsidiarycompanies in Japan that have a particularly largeaffect on the environment, through the Consolidated<strong>Environmental</strong> Management Session Meeting. Weformulated the Hino Global EMS, into which our ownrequirements were incorporated in addition to ISO14001 requirements.Environment conservationactivities at dealers in JapanHino Motors has been using Dealer <strong>Environmental</strong>Management Systems since FY2002 in cooperationwith all domestic dealers.When a dealer (office) is judged to be implementing100% of the requirements of the Dealer <strong>Environmental</strong>Guidelines *4 after an audit of the conditions ofcompliance, the system certifies the company (office)as an Eco-Management Dealer.In FY2006, 186 offices out of 220 in 41 companiesreceived Eco-Management Dealer certification.Among these, 25 companies received certificationfor all of their offices.We are actively promoting joint environmentalconservation activities with our domestic dealers.Eco-Management Dealer certification ceremonyProduction Environment Working Group Meetingfor Domestic Affiliated Companies<strong>Initiatives</strong> as a <strong>global</strong> companyHino Motors is sharing <strong>global</strong> consolidatedenvironmental management the environmentalaction plan, which looks to the future, with sevenoverseas affiliated production companies.At the Overseas Manufacturing CompaniesMeeting held at the Hino plant in November 2006,each representative presented an interim report andexamples of energy-saving activities.We will continue to formulate a Group climateas each initiative is promptly shared among allmembers under the common target of the Group.Eco-plant activitiesHino Motors is promoting eco-plant activities inJapan and overseas. These activities introduceenvironmental measures at the planning stage ofplant construction from the viewpoints of legalcompliance, prevention of environmental issues andimprovement of environmental performance.In FY2006, we deployed an eco-plant projectproposal in Japan and overseas and then conductedan on-site in-house audit of the relevant plants afterthe start-up of operations to make sure that theplanned items had been incorporated into theconstruction. We will further advance our activities toconstruct eco-plants that prevent environmentalissues by extending these activities to affiliatedcompanies.A convivial party at the Overseas ManufacturingCompanies MeetingEco-plant*4 Dealer <strong>Environmental</strong> Guideline:This guideline is published fordomestic dealers every year afterincorporating environmentrelatedlaws and Hino’s owninitiatives.

<strong>Environmental</strong> <strong>Initiatives</strong>FY2006 Initiative for each plant at Hino MotorsHeadquarters/Hino PlantAcquisition of ISO 14001certification:March 24, 2001Environment ManagementCoordinatorHead Office and Hino PlantTakehiko NakanoPlant overviewAddress: 3-1-1 Hinodai, Hino-shi, TokyoMajor products: Hino medium-and heavy-dutytrucksEmployees: 5,277 (as of March 31, 2007)Site area: 447,081 m 2Total floor space: 400,640 m 2<strong>Environmental</strong> policies1.Harmonious coexistence with society and theenvironment2.Sustained improvements and prevention ofenvironmental contaminations3.Compliance with laws and regulations4.Mottainai is the basis for everything5.Enhancement of each individual’senvironmental awarenessStriving to become a plant that serves society andcontributes to the true affluence the world.At our Headquarters and the Hino Plant, we are improving our environmentalperformance by setting a goal for our environmental initiatives, and pursuing thisgoal to minimize environmental impact both in production and in distribution, whilecontinuing to supply products with leading environmental performance to society.In our energy-saving resource-saving and resource-saving activities, allpersonnel are working with the consciousness of mottainai a Japanese feeling ofpreventing waste, and making efforts to eliminate muda, mura, and muri Japanesewords that mean unprofitable, unsteady and unreasonable. Because our plant islocated in a residential zone, it is important that we do not disturb our neighborswith nuisances, such as noise, vibration or odors. Consequently, we are ensuringpreventive measures are in place for these potential problems. To realizeharmonious coexistence with society and the environment, our aim is to become aplant that serves society and contributes to the true affluence the world.Winner of 2005, Highest Award, Kanto Region Electricity Usage Rationalization CommitteeWinner of 2006, Highest Award, Kanto Region Electricity Usage Rationalization CommitteeHamura PlantAcquisition of ISO 14001 certification:March 10, 1999Environment ManagementCoordinatorHamura PlantKazuharu TanakaPlant overviewAddress: Address: 3-1-1 Midorigaoka,Hamura-shi, TokyoMajor products: Hino;light-duty trucks,Toyota;Dyna, Hilux Surf, FJ Cruiser, Route VanEmployees: 2,930 (as of March 31, 2007)Site area: 750,770 m 2Total floor space: 376,859 m 2<strong>Environmental</strong> policies1.Promotion of business activities in harmonywith the natural environment2.Effective utilization of limited resources3.Development of a partnership with the localcommunityStriving to become an eco-friendly plantAt the Hamura Plant, we are working on sustained environmental improvementwith striving becoming an eco-friendly plant, advocating the environmental policy ofpromoting business activities in harmony with nature.While complying with existing environmental laws, we are engaged in plantwideimprovement activities to achieve the goals set by our own environmentconservation plan.We are actively promoting energy-saving and resource-saving activities toeffectively utilize limited resources. We are also developing smoother workflows byupgrading safety condition and quality level. As a result, we have reduced theenvironmental impact of the whole plant. We will also actively interact with people inthe local community, and establish a good partnership with the community.Winner of October 2004, the Chairman’s Award, High Pressure Gas Safety Institute of JapanWinner of February 2005, Director-General’s Award, for Natural Resources and Energy AgencyWinner of November 2005, Prevention Manager’s Award, Tokyo Fire DepartmentFebruary 2006, Highest Award, Kanto Region Electricity Usage Rationalization CommitteeWinner of July 2006, Champion, Firefighting Training BoardWinner of February 2007, Highest Award, Kanto Region Electricity Usage Rationalization CommitteNitta PlantAcquisition of ISO 14001 certification:March 27, 2000Environment ManagementCoordinatorNitta PlantAkihiko YoshikawaPlant overviewAddress: 10-1 Nittahayakawa-cho, Ota-shi,Gunma PrefectureMajor products: Medium- and light-duty truckengines, medium- and heavy-duty trucktransmissions, and medium-duty truck axlesEmployees: 1,171 (as of March 31, 2007)Site area: 393,932 m 2Total floor space: 177,715 m 2<strong>Environmental</strong> policies1.Harmony with the community and harmoniouscoexistence with the environment2.Prevention is the basis for everything3.Compliance with laws and regulations4.No waste and no wasteful use5.Enhancement of each individual’senvironmental awarenessStriving to become a people-friendly, environment-friendly clean plantAt the Nitta Plant, located in a lush green setting, we have positioned the 3Ss(seiri, seiton and seisou, Japanese words that mean well-organized, well-arrangedand clean) as the basis for all plant activities. We are also promoting environmentalconservation and improvement activities with a sustained awareness ofenvironmental impact through the Nitta Plant Environment Policy.By working to cut off the source of environmental load at the upstream part ofproduction activities in particular, we are ensuring the alleviation of environmentalrisk. As a further initiative for reducing environmental impact, all plant personnel areaiming at higher goals for the prevention of <strong>global</strong> warming. At the same time, wewill make efforts to maintain a clean plant that is friendly to people and theenvironment.Winner of 2002, Director-General’s Award (electrical division),Natural Resources and Energy AgencyWinner of 2003, Energy Conservation Activity Excellent Group Award, Kanto Bureau of Economy,Trade and IndustryWinner of 2004, Director-General’s Award (heat division),Natural Resources and Energy Agencyhttp://www.<strong>hino</strong>.co.jp/e/04/4_07.htm

<strong>Environmental</strong> <strong>Initiatives</strong>Ome Parts CenterAcquisition of ISO 14001 certification:January 11, 2002Center overviewAddress: 1-5-1 Suehiro-cho, Ome-shi, TokyoDescription of business: Management andtransport of service partsEmployees: 67 (as of March 31, 2007)Site area: 26,288 m 2Total floor space: 31,533 m 2<strong>Environmental</strong> policiesCSR ReportHino Motors,Ltd.20071. Harmonious coexistence with the environment2. Prevention and sustained improvement3. Compliance with laws and regulations4. Streamlining the flow of goods5. Enhancing each individual’s environmentalawarenessOme Parts CenterThe center manages truck and bus parts andcomponents, and transports them nationwide.Editor’s PostscriptHidaka Delivery CenterAcquisition of ISO 14001 certification:January 11, 2002Center overviewAddress: 689-1 Kamikayama, Hidaka-shi,Saitama PrefectureDescription of business: Management andtransport of products (trucks)Employees: 20 (as of March 31, 2007)Site area: 265,989 m 2Total floor space: 9,865 m 2<strong>Environmental</strong> policies1. Harmonious coexistence with theenvironment2. Prevention and sustained improvement3. Compliance with laws and regulations4. Streamlining flow of goods5. Enhancing each individual’s environmentalawarenessTamachi OfficeAcquisition of ISO 14001 certification:April 25, 2003Center overviewAddress: 4-11-3 Shiba, Minato-ku, TokyoDescription of business: Vehicle sales andgeneral administrationEmployees: 346 (as of March 31, 2007)Site area: 1,136 m 2Total floor space: 8,743 m 2<strong>Environmental</strong> policies1. For to customer confidence in ourenvironmental efforts2. Contamination prevention and sustainedimprovement3. Compliance with laws and regulations4. No waste and no wasteful use5. Enhancement of each individual’senvironmental awareness6. Effective collaboration with dealersnationwideHidaka Delivery CenterThe deposit and delivering center of assembled truckschassis and transports them to body builder anddealers nation wide.Tamachi OfficeThis is the office that is in charge of generaladministration for domestic sales operations.We would like to thank you forreading the Hino Motors CSR Report.The FY2006 reporting periodwas the year when Hino Motors essentiallystarted CSR activities. Itwas a particularly big changeover forus to establish “The Hino Credo” byreviewing the corporate philosophywe held for 15 years from the perspectivesof the current businessenvironment and CSR.This year we shifted edify ofthe report from the <strong>Environmental</strong>Affairs Division to the CooperatePlanning Division. Although we experiencedsome difficulties in arrangingsuitable content for the CSRReport, as well as in making a majorchange to the editorial style, we expectthat the information found inthis report on Hino Motors’ CSR activitieswill clarify our initiatives forstakeholders and highlight our challenges.Hino Motors will continue contributingto the development of anaffluent society, mainly by addressingchallenges through the transportationof people and goods. We willalso continue improving the contentof the report, so that it may becomemore readable and understandablefor stakeholders. We hope thatthrough this report, you will deepenyour understanding of Hino Motors’activities.