PE Pipe Technical Catalogue (PDF) - Pipelife Norge AS

PE Pipe Technical Catalogue (PDF) - Pipelife Norge AS

PE Pipe Technical Catalogue (PDF) - Pipelife Norge AS

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

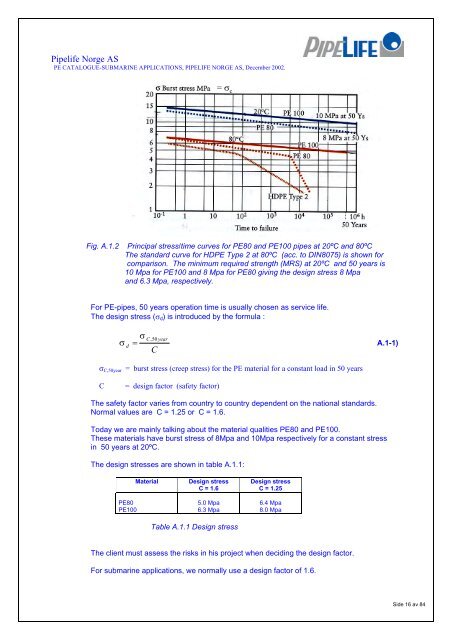

<strong>Pipe</strong>life <strong>Norge</strong> <strong>AS</strong><strong>PE</strong> CATALOGUE-SUBMARINE APPLICATIONS, PI<strong>PE</strong>LIFE NORGE <strong>AS</strong>, December 2002.= σ cFig. A.1.2 Principal stress/time curves for <strong>PE</strong>80 and <strong>PE</strong>100 pipes at 20ºC and 80ºCThe standard curve for HD<strong>PE</strong> Type 2 at 80ºC (acc. to DIN8075) is shown forcomparison. The minimum required strength (MRS) at 20ºC and 50 years is10 Mpa for <strong>PE</strong>100 and 8 Mpa for <strong>PE</strong>80 giving the design stress 8 Mpaand 6.3 Mpa, respectively.For <strong>PE</strong>-pipes, 50 years operation time is usually chosen as service life.The design stress (σ d ) is introduced by the formula :σC,50yearσd= A.1-1)Cσ C,50year = burst stress (creep stress) for the <strong>PE</strong> material for a constant load in 50 yearsC= design factor (safety factor)The safety factor varies from country to country dependent on the national standards.Normal values are C = 1.25 or C = 1.6.Today we are mainly talking about the material qualities <strong>PE</strong>80 and <strong>PE</strong>100.These materials have burst stress of 8Mpa and 10Mpa respectively for a constant stressin 50 years at 20ºC.The design stresses are shown in table A.1.1:<strong>PE</strong>80<strong>PE</strong>100MaterialDesign stressC = 1.65.0 Mpa6.3 MpaDesign stressC = 1.256.4 Mpa8.0 MpaTable A.1.1 Design stressThe client must assess the risks in his project when deciding the design factor.For submarine applications, we normally use a design factor of 1.6.Side 16 av 84