December 2011 - SIMA

December 2011 - SIMA

December 2011 - SIMA

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

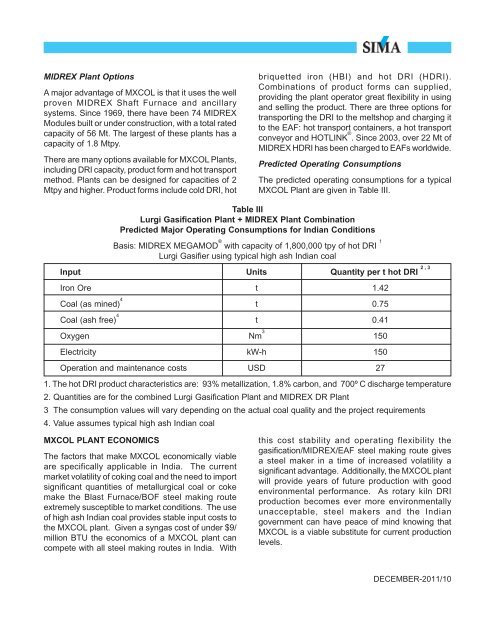

MIDREX Plant OptionsA major advantage of MXCOL is that it uses the wellproven MIDREX Shaft Furnace and ancillarysystems. Since 1969, there have been 74 MIDREXModules built or under construction, with a total ratedcapacity of 56 Mt. The largest of these plants has acapacity of 1.8 Mtpy.There are many options available for MXCOL Plants,including DRI capacity, product form and hot transportmethod. Plants can be designed for capacities of 2Mtpy and higher. Product forms include cold DRI, hotbriquetted iron (HBI) and hot DRI (HDRI).Combinations of product forms can supplied,providing the plant operator great flexibility in usingand selling the product. There are three options fortransporting the DRI to the meltshop and charging itto the EAF: hot transport containers, a hot transportconveyor and HOTLINK ® . Since 2003, over 22 Mt ofMIDREX HDRI has been charged to EAFs worldwide.Predicted Operating ConsumptionsThe predicted operating consumptions for a typicalMXCOL Plant are given in Table III.Table IIILurgi Gasification Plant + MIDREX Plant CombinationPredicted Major Operating Consumptions for Indian ConditionsBasis: MIDREX MEGAMOD ® with capacity of 1,800,000 tpy of hot DRI 1Lurgi Gasifier using typical high ash Indian coalInput Units Quantity per t hot DRI 2 , 3Iron Ore t 1.42Coal (as mined) 4 t 0.75Coal (ash free) 4 t 0.41Oxygen Nm 3 150Electricity kW-h 150Operation and maintenance costs USD 271. The hot DRI product characteristics are: 93% metallization, 1.8% carbon, and 700º C discharge temperature2. Quantities are for the combined Lurgi Gasification Plant and MIDREX DR Plant3 The consumption values will vary depending on the actual coal quality and the project requirements4. Value assumes typical high ash Indian coalMXCOL PLANT ECONOMICSThe factors that make MXCOL economically viableare specifically applicable in India. The currentmarket volatility of coking coal and the need to importsignificant quantities of metallurgical coal or cokemake the Blast Furnace/BOF steel making routeextremely susceptible to market conditions. The useof high ash Indian coal provides stable input costs tothe MXCOL plant. Given a syngas cost of under $9/million BTU the economics of a MXCOL plant cancompete with all steel making routes in India. Withthis cost stability and operating flexibility thegasification/MIDREX/EAF steel making route givesa steel maker in a time of increased volatility asignificant advantage. Additionally, the MXCOL plantwill provide years of future production with goodenvironmental performance. As rotary kiln DRIproduction becomes ever more environmentallyunacceptable, steel makers and the Indiangovernment can have peace of mind knowing thatMXCOL is a viable substitute for current productionlevels.DECEMBER-<strong>2011</strong>/10