December 2011 - SIMA

December 2011 - SIMA

December 2011 - SIMA

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

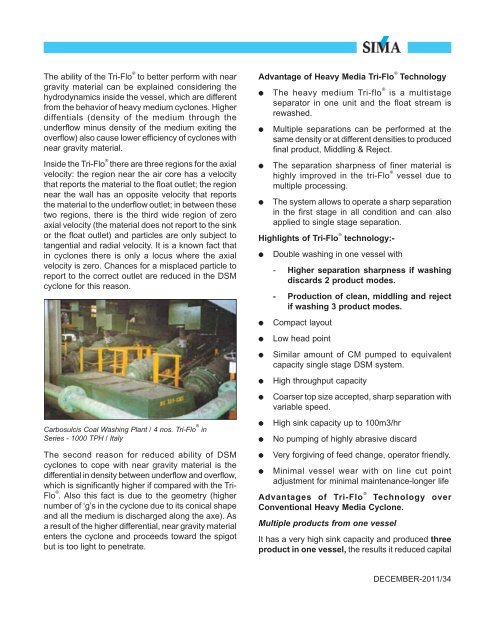

The ability of the Tri-Flo ® to better perform with neargravity material can be explained considering thehydrodynamics inside the vessel, which are differentfrom the behavior of heavy medium cyclones. Higherdiffentials (density of the medium through theunderflow minus density of the medium exiting theoverflow) also cause lower efficiency of cyclones withnear gravity material.Inside the Tri-Flo ® there are three regions for the axialvelocity: the region near the air core has a velocitythat reports the material to the float outlet; the regionnear the wall has an opposite velocity that reportsthe material to the underflow outlet; in between thesetwo regions, there is the third wide region of zeroaxial velocity (the material does not report to the sinkor the float outlet) and particles are only subject totangential and radial velocity. It is a known fact thatin cyclones there is only a locus where the axialvelocity is zero. Chances for a misplaced particle toreport to the correct outlet are reduced in the DSMcyclone for this reason.Carbosulcis Coal Washing Plant / 4 nos. Tri-Flo ® inSeries - 1000 TPH / ItalyThe second reason for reduced ability of DSMcyclones to cope with near gravity material is thedifferential in density between underflow and overflow,which is significantly higher if compared with the Tri-Flo ® . Also this fact is due to the geometry (highernumber of ‘g’s in the cyclone due to its conical shapeand all the medium is discharged along the axe). Asa result of the higher differential, near gravity materialenters the cyclone and proceeds toward the spigotbut is too light to penetrate.Advantage of Heavy Media Tri-Flo ® Technologyl The heavy medium Tri-flo ® is a multistageseparator in one unit and the float stream isrewashed.lllMultiple separations can be performed at thesame density or at different densities to producedfinal product, Middling & Reject.The separation sharpness of finer material ishighly improved in the tri-Flo ®vessel due tomultiple processing.The system allows to operate a sharp separationin the first stage in all condition and can alsoapplied to single stage separation.Highlights of Tri-Flo ® technology:-llllllllllDouble washing in one vessel with- Higher separation sharpness if washingdiscards 2 product modes.- Production of clean, middling and rejectif washing 3 product modes.Compact layoutLow head pointSimilar amount of CM pumped to equivalentcapacity single stage DSM system.High throughput capacityCoarser top size accepted, sharp separation withvariable speed.High sink capacity up to 100m3/hrNo pumping of highly abrasive discardVery forgiving of feed change, operator friendly.Minimal vessel wear with on line cut pointadjustment for minimal maintenance-longer lifeAdvantages of Tri-Flo ®Technology overConventional Heavy Media Cyclone.Multiple products from one vesselIt has a very high sink capacity and produced threeproduct in one vessel, the results it reduced capitalDECEMBER-<strong>2011</strong>/34