THE YEAR-BOOK OF THE COKE OVEN - Coke Oven Managers ...

THE YEAR-BOOK OF THE COKE OVEN - Coke Oven Managers ...

THE YEAR-BOOK OF THE COKE OVEN - Coke Oven Managers ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

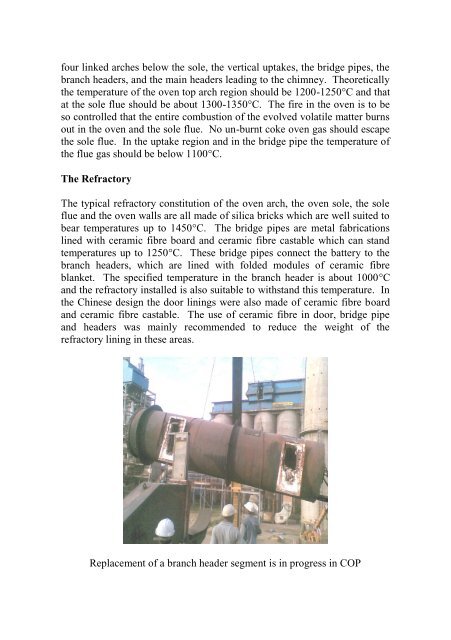

four linked arches below the sole, the vertical uptakes, the bridge pipes, thebranch headers, and the main headers leading to the chimney. Theoreticallythe temperature of the oven top arch region should be 1200-1250°C and thatat the sole flue should be about 1300-1350°C. The fire in the oven is to beso controlled that the entire combustion of the evolved volatile matter burnsout in the oven and the sole flue. No un-burnt coke oven gas should escapethe sole flue. In the uptake region and in the bridge pipe the temperature ofthe flue gas should be below 1100°C.The RefractoryThe typical refractory constitution of the oven arch, the oven sole, the soleflue and the oven walls are all made of silica bricks which are well suited tobear temperatures up to 1450°C. The bridge pipes are metal fabricationslined with ceramic fibre board and ceramic fibre castable which can standtemperatures up to 1250°C. These bridge pipes connect the battery to thebranch headers, which are lined with folded modules of ceramic fibreblanket. The specified temperature in the branch header is about 1000°Cand the refractory installed is also suitable to withstand this temperature. Inthe Chinese design the door linings were also made of ceramic fibre boardand ceramic fibre castable. The use of ceramic fibre in door, bridge pipeand headers was mainly recommended to reduce the weight of therefractory lining in these areas.Replacement of a branch header segment is in progress in COP