THE YEAR-BOOK OF THE COKE OVEN - Coke Oven Managers ...

THE YEAR-BOOK OF THE COKE OVEN - Coke Oven Managers ...

THE YEAR-BOOK OF THE COKE OVEN - Coke Oven Managers ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

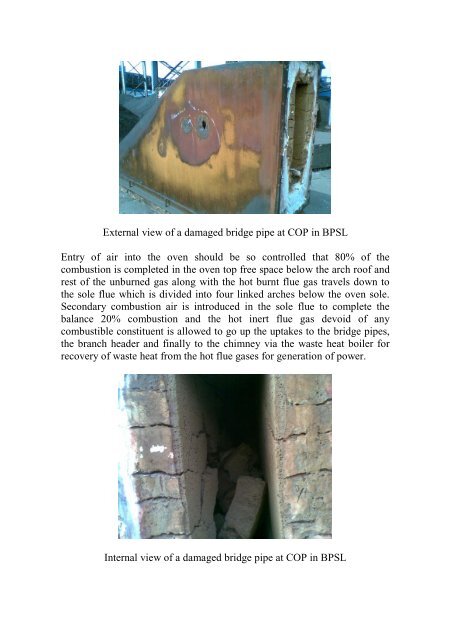

External view of a damaged bridge pipe at COP in BPSLEntry of air into the oven should be so controlled that 80% of thecombustion is completed in the oven top free space below the arch roof andrest of the unburned gas along with the hot burnt flue gas travels down tothe sole flue which is divided into four linked arches below the oven sole.Secondary combustion air is introduced in the sole flue to complete thebalance 20% combustion and the hot inert flue gas devoid of anycombustible constituent is allowed to go up the uptakes to the bridge pipes,the branch header and finally to the chimney via the waste heat boiler forrecovery of waste heat from the hot flue gases for generation of power.Internal view of a damaged bridge pipe at COP in BPSL