THE YEAR-BOOK OF THE COKE OVEN - Coke Oven Managers ...

THE YEAR-BOOK OF THE COKE OVEN - Coke Oven Managers ...

THE YEAR-BOOK OF THE COKE OVEN - Coke Oven Managers ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

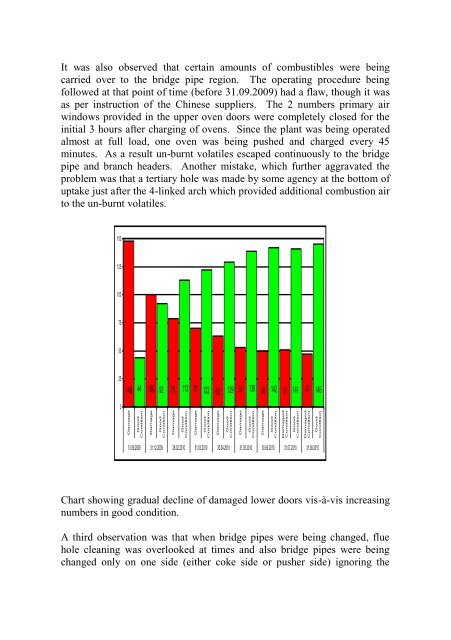

DamageGoodConditionDamageGoodConditionDamageGoodConditionDamageGoodConditionDamageGoodConditionDamageGoodConditionDamageGoodConditionDamagedConditionGoodConditionDamagedConditionGoodConditionIt was also observed that certain amounts of combustibles were beingcarried over to the bridge pipe region. The operating procedure beingfollowed at that point of time (before 31.09.2009) had a flaw, though it wasas per instruction of the Chinese suppliers. The 2 numbers primary airwindows provided in the upper oven doors were completely closed for theinitial 3 hours after charging of ovens. Since the plant was being operatedalmost at full load, one oven was being pushed and charged every 45minutes. As a result un-burnt volatiles escaped continuously to the bridgepipe and branch headers. Another mistake, which further aggravated theproblem was that a tertiary hole was made by some agency at the bottom ofuptake just after the 4-linked arch which provided additional combustion airto the un-burnt volatiles.150125100755025148441009279113701226312953139501425114147 145031.09.2009 31.12.2009 28.02.2010 31.03.2010 30.04.2010 31.05.2010 30.06.2010 31.07.2010 31.08.2010Chart showing gradual decline of damaged lower doors vis-à-vis increasingnumbers in good condition.A third observation was that when bridge pipes were being changed, fluehole cleaning was overlooked at times and also bridge pipes were beingchanged only on one side (either coke side or pusher side) ignoring the