Diesel Distributor Fuel-Injection Pumps VE - Gnarlodious

Diesel Distributor Fuel-Injection Pumps VE - Gnarlodious

Diesel Distributor Fuel-Injection Pumps VE - Gnarlodious

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

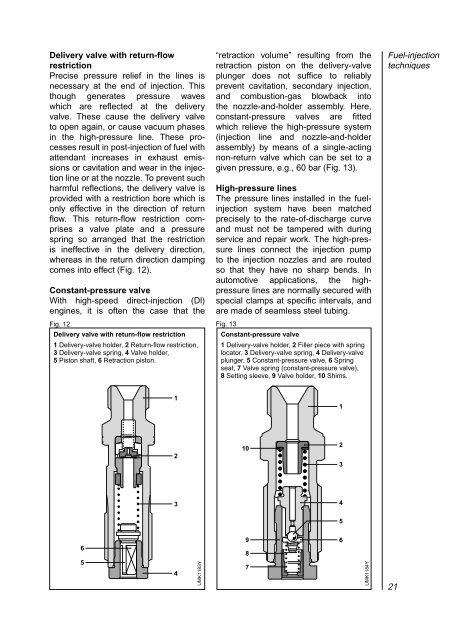

Delivery valve with return-flowrestrictionPrecise pressure relief in the lines isnecessary at the end of injection. Thisthough generates pressure waveswhich are reflected at the deliveryvalve. These cause the delivery valveto open again, or cause vacuum phasesin the high-pressure line. These processesresult in post-injection of fuel withattendant increases in exhaust emissionsor cavitation and wear in the injectionline or at the nozzle. To prevent suchharmful reflections, the delivery valve isprovided with a restriction bore which isonly effective in the direction of returnflow. This return-flow restriction comprisesa valve plate and a pressurespring so arranged that the restrictionis ineffective in the delivery direction,whereas in the return direction dampingcomes into effect (Fig. 12).Constant-pressure valveWith high-speed direct-injection (Dl)engines, it is often the case that theFig. 12Delivery valve with return-flow restriction1 Delivery-valve holder, 2 Return-flow restriction,3 Delivery-valve spring, 4 Valve holder,5 Piston shaft, 6 Retraction piston.“retraction volume” resulting from theretraction piston on the delivery-valveplunger does not suffice to reliablyprevent cavitation, secondary injection,and combustion-gas blowback intothe nozzle-and-holder assembly. Here,constant-pressure valves are fittedwhich relieve the high-pressure system(injection line and nozzle-and-holderassembly) by means of a single-actingnon-return valve which can be set to agiven pressure, e.g., 60 bar (Fig. 13).High-pressure linesThe pressure lines installed in the fuelinjectionsystem have been matchedprecisely to the rate-of-discharge curveand must not be tampered with duringservice and repair work. The high-pressurelines connect the injection pumpto the injection nozzles and are routedso that they have no sharp bends. Inautomotive applications, the highpressurelines are normally secured withspecial clamps at specific intervals, andare made of seamless steel tubing.Fig. 13Constant-pressure valve1 Delivery-valve holder, 2 Filler piece with springlocator, 3 Delivery-valve spring, 4 Delivery-valveplunger, 5 Constant-pressure valve, 6 Springseat, 7 Valve spring (constant-pressure valve),8 Setting sleeve, 9 Valve holder, 10 Shims.<strong>Fuel</strong>-injectiontechniques1121023345654UMK1183Y9876UMK1184Y21