Diesel Distributor Fuel-Injection Pumps VE - Gnarlodious

Diesel Distributor Fuel-Injection Pumps VE - Gnarlodious

Diesel Distributor Fuel-Injection Pumps VE - Gnarlodious

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

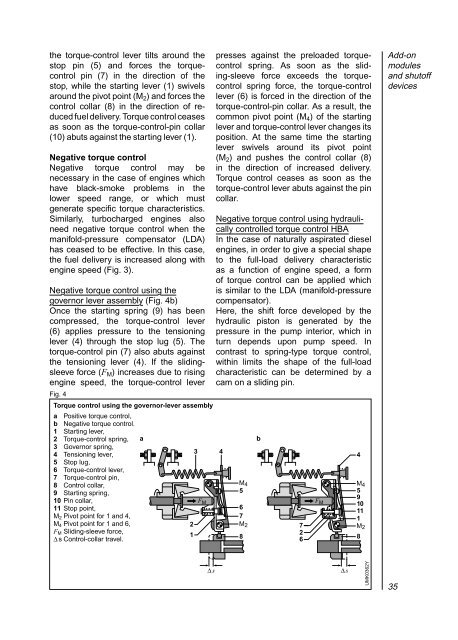

the torque-control lever tilts around thestop pin (5) and forces the torquecontrolpin (7) in the direction of thestop, while the starting lever (1) swivelsaround the pivot point (M 2 ) and forces thecontrol collar (8) in the direction of reducedfuel delivery. Torque control ceasesas soon as the torque-control-pin collar(10) abuts against the starting lever (1).Negative torque controlNegative torque control may benecessary in the case of engines whichhave black-smoke problems in thelower speed range, or which mustgenerate specific torque characteristics.Similarly, turbocharged engines alsoneed negative torque control when themanifold-pressure compensator (LDA)has ceased to be effective. In this case,the fuel delivery is increased along withengine speed (Fig. 3).Negative torque control using thegovernor lever assembly (Fig. 4b)Once the starting spring (9) has beencompressed, the torque-control lever(6) applies pressure to the tensioninglever (4) through the stop lug (5). Thetorque-control pin (7) also abuts againstthe tensioning lever (4). If the slidingsleeveforce (F M ) increases due to risingengine speed, the torque-control leverFig. 4Torque control using the governor-lever assemblya Positive torque control,b Negative torque control.1 Starting lever,2 Torque-control spring, a3 Governor spring,4 Tensioning lever,3 45 Stop lug,6 Torque-control lever,7 Torque-control pin,8 Control collar,9 Starting spring,10 Pin collar,11 Stop point,M 2 Pivot point for 1 and 4,M 4 Pivot point for 1 and 6,2F M Sliding-sleeve force,1∆ s Control-collar travel.presses against the preloaded torquecontrolspring. As soon as the sliding-sleeveforce exceeds the torquecontrolspring force, the torque-controllever (6) is forced in the direction of thetorque-control-pin collar. As a result, thecommon pivot point (M 4 ) of the startinglever and torque-control lever changes itsposition. At the same time the startinglever swivels around its pivot point(M 2 ) and pushes the control collar (8)in the direction of increased delivery.Torque control ceases as soon as thetorque-control lever abuts against the pincollar.Negative torque control using hydraulicallycontrolled torque control HBAIn the case of naturally aspirated dieselengines, in order to give a special shapeto the full-load delivery characteristicas a function of engine speed, a formof torque control can be applied whichis similar to the LDA (manifold-pressurecompensator).Here, the shift force developed by thehydraulic piston is generated by thepressure in the pump interior, which inturn depends upon pump speed. Incontrast to spring-type torque control,within limits the shape of the full-loadcharacteristic can be determined by acam on a sliding pin.M 4567M 28b726F M4M 45910111M 28Add-onmodulesand shutoffdevicesF M∆ s∆ sUMK0362Y35