PCB Depaneling Laser System LPKF MicroLine 350Ci

PCB Depaneling Laser System LPKF MicroLine 350Ci

PCB Depaneling Laser System LPKF MicroLine 350Ci

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

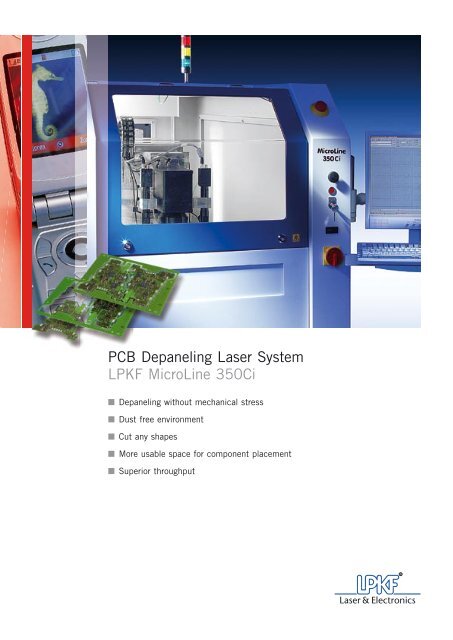

<strong>PCB</strong> <strong>Depaneling</strong> <strong>Laser</strong> <strong>System</strong><strong>LPKF</strong> <strong>MicroLine</strong> <strong>350Ci</strong>■ <strong>Depaneling</strong> without mechanical stress■ Dust free environment■ Cut any shapes■ More usable space for component placement■ Superior throughput

<strong>Laser</strong> cutStress free cutting and improved productivity:Introducing laser technology for depaneling<strong>Depaneling</strong> of modern HD circuit boards can be frustrating.Avoiding damaging small, sensitive components, maintainingthe close tolerances required by densely packed boards andavoiding the pollution caused by mechanical routers are allpart of the challenge.The <strong>LPKF</strong> <strong>MicroLine</strong> <strong>350Ci</strong> meets these challenges byusing laser technology for depaneling and routing. Non-contactcutting with a laser means no mechanical stress on the boardsor components, no debris, and no extra cost for tooling. Thehigh positioning accuracy of the <strong>350Ci</strong> allows for componentplacement closer to the edge of a board. The laser beam isable to cut intricate shapes and also increases the net usablearea on the panels.Produce more challenging designsThe <strong>MicroLine</strong> <strong>350Ci</strong> will cut arbitrary shapes without any mechanicalimpact on the circuit. <strong>PCB</strong> designers will enjoy theliberty to place components closer to the edge of the board orto utilize more intricate shapes to better fit the form factor ofthe final product.Cutting arbitrary shapes withsmallest tool diametersHigh productivityThe superior cutting speed of the <strong>MicroLine</strong> <strong>350Ci</strong> providesbetter overall productivity than traditional depaneling methods,especially with thinner materials.Maximum Cutting Speed FR4Superior quality and instant turnaround<strong>Laser</strong> cutting is significantly more precise than other depanelingmethods. It doesn’t generate any debris or dust that couldaffect sensitive electronic components. The system worksstraight from CAD data and does not require specific tooling,so even small quantities can be produced instantly.Feed Rate (millimeter per sec.)400350300250200150100500.5 1 1.5Material Thickness (millimeter)

<strong>LPKF</strong> <strong>MicroLine</strong> <strong>350Ci</strong> – Integrate Tomorrow’s Technologyin Today’s Production LineThe dual camera system providesinstant fiducial recognitionon the entire working areafor optimal productivity.The integrated dust and fumeextraction provides a clean workingenvironment for guaranteedsuperior production quality.The cartridge loading systemaccommodates custom holdingfixtures for maximum efficiency.The intuitive CAM software iseasy to use and compatible withall industry standards includingGerber, ODB++, DXF, Excellon,HP-GL, and others.Compact and easy to integrateWith its small footprint the <strong>LPKF</strong> <strong>MicroLine</strong> <strong>350Ci</strong> can beeasily integrated into an existing <strong>PCB</strong> assembly line or usedas a stand-alone system. The software features extensivelaser control functions combined with an easy-to-use GUI forday-to-day operation.<strong>LPKF</strong> has been providing prototyping and production equipmentto the electronic industry for almost 30 years. Our systemsare designed with superior precision, minimum maintenancerequirements and maximum uptime in mind. <strong>LPKF</strong>provides a directly employed worldwide service staff supportingyou every step of the way.

Specifications <strong>LPKF</strong> <strong>MicroLine</strong> <strong>350Ci</strong>Working areaOverall accuracy<strong>Laser</strong> source<strong>Laser</strong> safetyDimensions (W/H/D)WeightFacility connectionsPowerChillerFume extractionAirApplicationsSemiautomatic depanelization of populatedcircuit boards.MaterialsMaximum material thicknessMaximum component heightAutomated loading station440 mm x 310 mm x 30 mm±20 µmCO 2 laserClass 11,264 mm x 1,670 mm x 2,023 mmca. 1,600 kg3 phase 400 V + N + PE, 50/60 Hz, 32 A, power consumption 8 kVADI water, 2.5 kVA, min. 7 l/min, 23 °C ±1 °C150 CFM (250 m 3 /h)@80” w.c. (20,000 pa), 3 psi (0,2 bar), carbon filtration required90 psi (6 bar)FR4, FR3, FR2, Polyester, Polyimid, PMMA, Polyamid, Prepreg0.8” (2 mm)top side 1.2” (30 mm)bottom side 0.6” (15 mm)custom designed loading station available<strong>LPKF</strong> <strong>Laser</strong> & Electronics AGOsteriede 7D-30827 GarbsenGermanyPhone +49 (0) 5131-70 95-0Fax +49 (0) 5131-70 95-90info@lpkf.dewww.lpkf.com<strong>LPKF</strong>-Distributor<strong>LPKF</strong> AG, 117562-1005-EN