You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

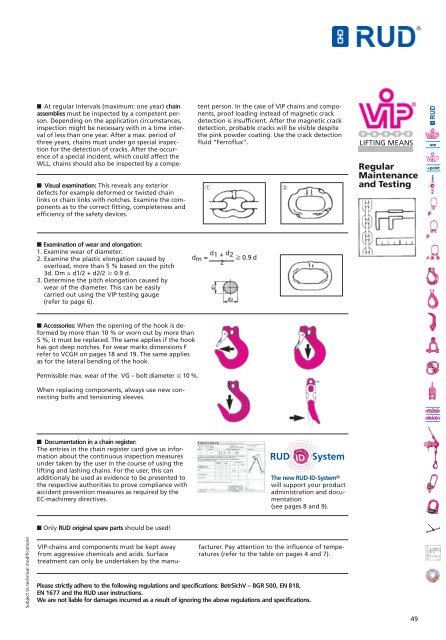

■ Visual examination: This reveals any exteriordefects for example deformed or twisted chainlinks or chain links with notches. Examine the componentsas to the correct fitting, completeness andefficiency of the safety devices.■ At regular intervals (maximum: one year) chainassemblies must be inspected by a competent person.Depending on the application circumstances,inspection might be necessary with in a time intervalof less than one year. After a max. period ofthree years, chains must under go special inspectionfor the detection of cracks. After the occurenceof a special incident, which could affect theWLL, chains should also be inspected by a competentperson. In the case of VIP chains and components,proof loading instead of magnetic crackdetection is insufficient. After the magnetic crackdetection, probable cracks will be visible despitethe pink powder coating. Use the crack detectionfluid “Ferroflux”.➀➁<strong>LIFTING</strong> MEANS®RegularMaintenanceand Testinguse+point■ Examination of wear and elongation:1. Examine wear of diameter.2. Examine the plastic elongation caused byoverload, more than 5 % based on the pitch3d. Dm = d1/2 + d2/2 0.9 d.3. Determine the pitch elongation caused bywear of the diameter. This can be easilycarried out using the VIP testing gauge(refer to page 6).dm = d 1 + d2 0.9 d2■ Accessories: When the opening of the hook is deformedby more than 10 % or worn out by more than5 %, it must be replaced. The same applies if the hookhas got deep notches. For wear marks dimensions Frefer to VCGH on pages 18 and 19. The same appliesas for the lateral bending of the hook.Permissible max. wear of the VG – bolt diameter 10 %.When replacing components, always use new con -necting bolts and tensioning sleeves.MAXI■ Documentation in a chain register:The entries in the chain register card give us informationabout the continuous inspection measuresunder taken by the user in the course of using thelifting and lashing chains. For the user, this canadditionaly be used as evidence to be presented tothe respective authorities to prove compliance withaccident prevention measures as required by theEC-machinery directives.The new <strong>RUD</strong>-ID-System ®will support your productadministration and documentation(see pages 8 and 9).■ Only <strong>RUD</strong> original spare parts should be used!Subject to technical modifications!VIP-chains and components must be kept awayfrom aggressive chemicals and acids. Surfacetreatment can only be undertaken by the manu-facturer. Pay attention to the influence of temperatures(refer to the table on pages 4 and 7).Please strictly adhere to the following regulations and specifications: BetrSichV – BGR 500, EN 818,EN 1677 and the <strong>RUD</strong> user instructions.We are not liable for damages incurred as a result of ignoring the above regulations and specifications.49