You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

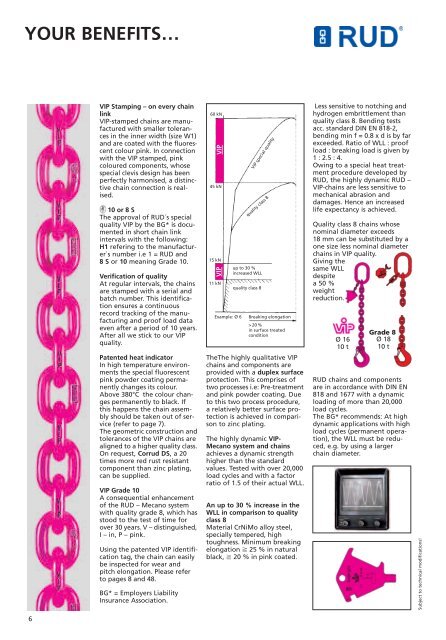

YOUR BENEFITS…VIP Stamping – on every chainlinkVIP-stamped chains are manufacturedwith smaller tolerancesin the inner width (size W1)and are coated with the fluorescentcolour pink. In connectionwith the VIP stamp ed, pinkcoloured components, whosespecial clevis design has beenperfectly harmonised, a distinctivechain connection is real -ised.10 or 8 SThe approval of <strong>RUD</strong>´s specialquality VIP by the BG* is documentedin short chain linkintervals with the following:H1 refering to the manufacturer`snumber i.e 1 = <strong>RUD</strong> and8 S or 10 meaning Grade 10.Verification of qualityAt regular intervals, the chainsare stamped with a serial andbatch number. This identificationensures a con tinuousrecord tracking of the manufacturingand proof load dataeven after a period of 10 years.After all we stick to our VIPquality.Patented heat indicatorIn high temperature environmentsthe special fluorescentpink powder coating permanentlychanges its colour.Above 380°C the colour changespermanently to black. Ifthis happens the chain assemblyshould be taken out of service(refer to page 7).The geometric construction andtolerances of the VIP chains arealigned to a higher quality class.On request, Corrud DS, a 20times more red rust resistantcomponent than zinc plating,can be supplied.VIP Grade 10A consequential enhancementof the <strong>RUD</strong> – Mecano systemwith quality grade 8, which hasstood to the test of time forover 30 years. V – distinguished,I – in, P – pink.Using the patented VIP identificationtag, the chain can easilybe inspected for wear andpitch elongation. Please referto pages 8 and 48.BG* = Employers LiabilityInsurance Association.60 kNVIP45 kN15 kNVIP11 kNExample: Ø 6VIP special qualityquality class 8up to 30 %increased WLLquality class 8Breaking elongation>20%in surface treatedconditionTheThe highly qualitative VIPchains and components areprovided with a duplex surfaceprotection. This comprises oftwo processes i.e: Pre-treatmentand pink powder coating. Dueto this two process procedure,a relatively better surface protectionis achieved in comparisonto zinc plating.The highly dynamic VIP-Mecano system and chainsachieves a dynamic strengthhigher than the standardvalues. Tested with over 20,000load cycles and with a factorratio of 1.5 of their actual WLL.An up to 30 % increase in theWLL in comparison to qualityclass 8Material CrNiMo alloy steel,specially tempered, hightoughness. Minimum breakingelongation 25 % in naturalblack, 20 % in pink coated.Less sensitive to notching andhydrogen embrittlement thanquality class 8. Bending testsacc. standard DIN EN 818-2,bending min f = 0.8 x d is by farexceeded. Ratio of WLL : proofload : breaking load is given by1 : 2.5 : 4.Owing to a special heat treatmentprocedure developed by<strong>RUD</strong>, the highly dynamic <strong>RUD</strong> –VIP-chains are less sensitive tomechanical abrasion anddamages. Hence an increasedlife expectancy is achieved.Quality class 8 chains whosenominal diameter exceeds18 mm can be substituted by aone size less nominal diameterchains in VIP quality.Giving thesame WLLdespitea 50 %weightreduction.Ø 1610 tGrade 8Ø 1810 t<strong>RUD</strong> chains and componentsare in accordance with DIN EN818 and 1677 with a dynamicloading of more than 20,000load cycles.The BG* recommends: At highdynamic applications with highload cycles (permanent operation),the WLL must be reduced,e.g. by using a largerchain diameter.Subject to technical modifications!6