SIMATIC IPC The More Industrial PC - Siemens

SIMATIC IPC The More Industrial PC - Siemens

SIMATIC IPC The More Industrial PC - Siemens

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

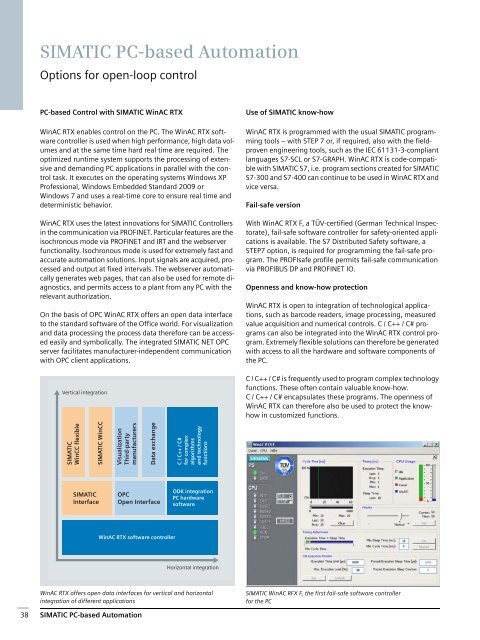

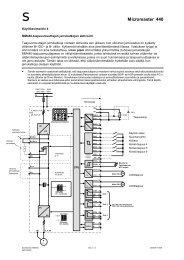

<strong>SIMATIC</strong> <strong>PC</strong>-based AutomationOptions for open-loop control<strong>PC</strong>-based Control with <strong>SIMATIC</strong> WinAC RTXWinAC RTX enables control on the <strong>PC</strong>. <strong>The</strong> WinAC RTX softwarecontroller is used when high performance, high data volumesand at the same time hard real time are required. <strong>The</strong>optimized runtime system supports the processing of extensiveand demanding <strong>PC</strong> applications in parallel with the controltask. It executes on the operating systems Windows XPProfessional, Windows Embedded Standard 2009 orWindows 7 and uses a real-time core to ensure real time anddeterministic behavior.WinAC RTX uses the latest innovations for <strong>SIMATIC</strong> Controllersin the communication via PROFINET. Particular features are theisochronous mode via PROFINET and IRT and the webserverfunctionality. Isochronous mode is used for extremely fast andaccurate automation solutions. Input signals are acquired, processedand output at fixed intervals. <strong>The</strong> webserver automaticallygenerates web pages, that can also be used for remote diagnostics,and permits access to a plant from any <strong>PC</strong> with therelevant authorization.On the basis of O<strong>PC</strong> WinAC RTX offers an open data interfaceto the standard software of the Office world. For visualizationand data processing the process data therefore can be accessedeasily and symbolically. <strong>The</strong> integrated <strong>SIMATIC</strong> NET O<strong>PC</strong>server facilitates manufacturer-independent communicationwith O<strong>PC</strong> client applications.Vertical integrationUse of <strong>SIMATIC</strong> know-howWinAC RTX is programmed with the usual <strong>SIMATIC</strong> programmingtools – with STEP 7 or, if required, also with the fieldprovenengineering tools, such as the IEC 61131-3-compliantlanguages S7-SCL or S7-GRAPH. WinAC RTX is code-compatiblewith <strong>SIMATIC</strong> S7, i.e. program sections created for <strong>SIMATIC</strong>S7-300 and S7-400 can continue to be used in WinAC RTX andvice versa.Fail-safe versionWith WinAC RTX F, a TÜV-certified (German Technical Inspectorate),fail-safe software controller for safety-oriented applicationsis available. <strong>The</strong> S7 Distributed Safety software, aSTEP7 option, is required for programming the fail-safe program.<strong>The</strong> PROFIsafe profile permits fail-safe communicationvia PROFIBUS DP and PROFINET IO.Openness and know-how protectionWinAC RTX is open to integration of technological applications,such as barcode readers, image processing, measuredvalue acquisition and numerical controls. C / C++ / C# programscan also be integrated into the WinAC RTX control program.Extremely flexible solutions can therefore be generatedwith access to all the hardware and software components ofthe <strong>PC</strong>.C / C++ / C# is frequently used to program complex technologyfunctions. <strong>The</strong>se often contain valuable know-how.C / C++ / C# encapsulates these programs. <strong>The</strong> openness ofWinAC RTX can therefore also be used to protect the knowhowin customized functions.<strong>SIMATIC</strong>WinCC flexible<strong>SIMATIC</strong> WinCCVisualizationThird-partymanufacturersData exchangeC / C++ / C#for complexalgorithmsand technologyfunctions<strong>SIMATIC</strong>InterfaceO<strong>PC</strong>Open InterfaceODK integration<strong>PC</strong> hardwaresoftwareWinAC RTX software controllerHorizontal integrationWinAC RTX offers open data interfaces for vertical and horizontalintegration of different applications<strong>SIMATIC</strong> WinAC RFX F, the first fail-safe software controllerfor the <strong>PC</strong>38<strong>SIMATIC</strong> <strong>PC</strong>-based Automation