High Standards, Local Support

High Standards, Local Support

High Standards, Local Support

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

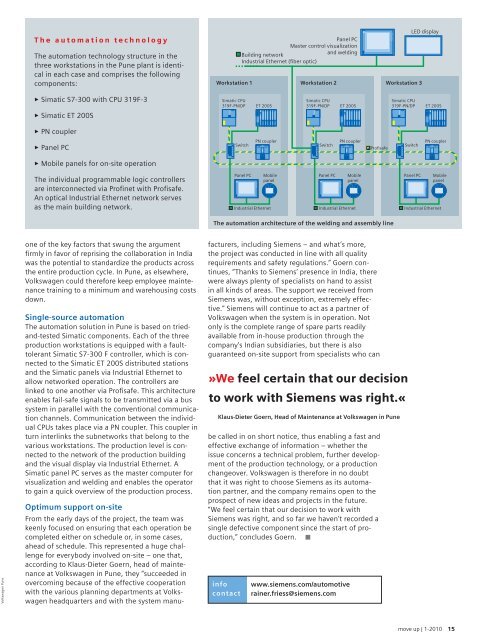

The automation technologyThe automation technology structure in thethree workstations in the Pune plant is identicalin each case and comprises the followingcomponents:Panel PCMaster control visualizationBuilding networkand weldingIndustrial Ethernet (fiber optic)Workstation 1 Workstation 2 Workstation 3LED display3 Simatic S7-300 with CPU 319F-33 Simatic ET 200SSimatic CPU319F-PN/DPET 200SSimatic CPU319F-PN/DPET 200SSimatic CPU319F-PN/DPET 200S3 PN coupler3 Panel PCSwitchPN couplerSwitchPN couplerProfisafeSwitchPN coupler3 Mobile panels for on-site operationThe individual programmable logic controllersare interconnected via Profinet with Profisafe.An optical Industrial Ethernet network servesas the main building network.Panel PCMobilepanelIndustrial EthernetPanel PCMobilepanelIndustrial EthernetPanel PCMobilepanelIndustrial EthernetThe automation architecture of the welding and assembly lineVolkswagen Puneone of the key factors that swung the argumentfirmly in favor of reprising the collaboration in Indiawas the potential to standardize the products acrossthe entire production cycle. In Pune, as elsewhere,Volkswagen could therefore keep employee maintenancetraining to a minimum and warehousing costsdown.Single-source automationThe automation solution in Pune is based on triedand-testedSimatic components. Each of the threeproduction workstations is equipped with a faulttolerantSimatic S7-300 F controller, which is connectedto the Simatic ET 200S distributed stationsand the Simatic panels via Industrial Ethernet toallow networked operation. The controllers arelinked to one another via Profisafe. This architectureenables fail-safe signals to be transmitted via a bussystem in parallel with the conventional communicationchannels. Communication between the individualCPUs takes place via a PN coupler. This coupler inturn interlinks the subnetworks that belong to thevarious workstations. The production level is connectedto the network of the production buildingand the visual display via Industrial Ethernet. ASimatic panel PC serves as the master computer forvisualization and welding and enables the operatorto gain a quick overview of the production process.facturers, including Siemens – and what’s more,the project was conducted in line with all qualityrequirements and safety regulations.” Goern continues,“Thanks to Siemens’ presence in India, therewere always plenty of specialists on hand to assistin all kinds of areas. The support we received fromSiemens was, without exception, extremely effective.”Siemens will continue to act as a partner ofVolkswagen when the system is in operation. Notonly is the complete range of spare parts readilyavailable from in-house production through thecompany’s Indian subsidiaries, but there is alsoguaranteed on-site support from specialists who can»We feel certain that our decisionto work with Siemens was right.«Klaus-Dieter Goern, Head of Maintenance at Volkswagen in Punebe called in on short notice, thus enabling a fast andeffective exchange of information – whether theissue concerns a technical problem, further developmentof the production technology, or a productionchangeover. Volkswagen is therefore in no doubtthat it was right to choose Siemens as its automationpartner, and the company remains open to theprospect of new ideas and projects in the future.“We feel certain that our decision to work withSiemens was right, and so far we haven’t recorded asingle defective component since the start of production,”concludes Goern. pOptimum support on-siteFrom the early days of the project, the team waskeenly focused on ensuring that each operation becompleted either on schedule or, in some cases,ahead of schedule. This represented a huge challengefor everybody involved on-site – one that,according to Klaus-Dieter Goern, head of maintenanceat Volkswagen in Pune, they “succeeded inovercoming because of the effective cooperationwith the various planning departments at Volkswagenheadquarters and with the system manuinfocontactwww.siemens.com/automotiverainer.friess@siemens.commove up | 1-2010 15