final report on the multiport dryer - Argonne National Laboratory

final report on the multiport dryer - Argonne National Laboratory

final report on the multiport dryer - Argonne National Laboratory

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

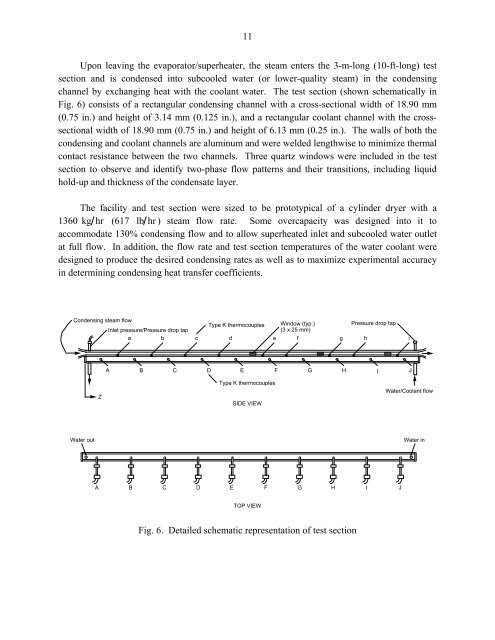

11Up<strong>on</strong> leaving <strong>the</strong> evaporator/superheater, <strong>the</strong> steam enters <strong>the</strong> 3-m-l<strong>on</strong>g (10-ft-l<strong>on</strong>g) testsecti<strong>on</strong> and is c<strong>on</strong>densed into subcooled water (or lower-quality steam) in <strong>the</strong> c<strong>on</strong>densingchannel by exchanging heat with <strong>the</strong> coolant water. The test secti<strong>on</strong> (shown schematically inFig. 6) c<strong>on</strong>sists of a rectangular c<strong>on</strong>densing channel with a cross-secti<strong>on</strong>al width of 18.90 mm(0.75 in.) and height of 3.14 mm (0.125 in.), and a rectangular coolant channel with <strong>the</strong> crosssecti<strong>on</strong>alwidth of 18.90 mm (0.75 in.) and height of 6.13 mm (0.25 in.). The walls of both <strong>the</strong>c<strong>on</strong>densing and coolant channels are aluminum and were welded lengthwise to minimize <strong>the</strong>rmalc<strong>on</strong>tact resistance between <strong>the</strong> two channels. Three quartz windows were included in <strong>the</strong> testsecti<strong>on</strong> to observe and identify two-phase flow patterns and <strong>the</strong>ir transiti<strong>on</strong>s, including liquidhold-up and thickness of <strong>the</strong> c<strong>on</strong>densate layer.The facility and test secti<strong>on</strong> were sized to be prototypical of a cylinder <strong>dryer</strong> with a1360 kg hr (617 lb hr ) steam flow rate. Some overcapacity was designed into it toaccommodate 130% c<strong>on</strong>densing flow and to allow superheated inlet and subcooled water outletat full flow. In additi<strong>on</strong>, <strong>the</strong> flow rate and test secti<strong>on</strong> temperatures of <strong>the</strong> water coolant weredesigned to produce <strong>the</strong> desired c<strong>on</strong>densing rates as well as to maximize experimental accuracyin determining c<strong>on</strong>densing heat transfer coefficients.C<strong>on</strong>densing steam flowInlet pressure/Pressure drop tapType K <strong>the</strong>rmocouplesWindow (typ.)(3 x 25 mm)Pressure drop tapabcdefghiA B C D E F G H IJZType K <strong>the</strong>rmocouplesSIDE VIEWWater/Coolant flowWater outWater inABCDEFGHIJTOP VIEWFig. 6. Detailed schematic representati<strong>on</strong> of test secti<strong>on</strong>