final report on the multiport dryer - Argonne National Laboratory

final report on the multiport dryer - Argonne National Laboratory

final report on the multiport dryer - Argonne National Laboratory

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

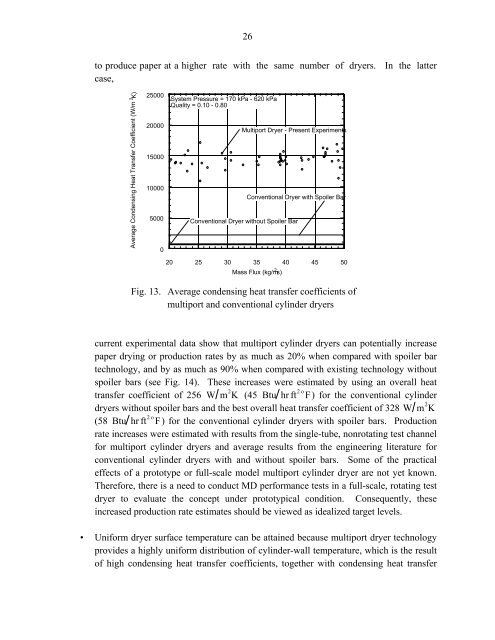

26to produce paper at a higher rate with <strong>the</strong> same number of <strong>dryer</strong>s. In <strong>the</strong> lattercase,Average C<strong>on</strong>densing Heat Transfer Coefficient (W/m 2 K)2500020000150001000050000System Pressure = 170 kPa - 620 kPaQuality = 0.10 - 0.80Multiport Dryer - Present ExperimentsC<strong>on</strong>venti<strong>on</strong>al Dryer with Spoiler BarC<strong>on</strong>venti<strong>on</strong>al Dryer without Spoiler Bar20 25 30 35 40 45 50Mass Flux (kg/m 2 s)Fig. 13. Average c<strong>on</strong>densing heat transfer coefficients of<strong>multiport</strong> and c<strong>on</strong>venti<strong>on</strong>al cylinder <strong>dryer</strong>scurrent experimental data show that <strong>multiport</strong> cylinder <strong>dryer</strong>s can potentially increasepaper drying or producti<strong>on</strong> rates by as much as 20% when compared with spoiler bartechnology, and by as much as 90% when compared with existing technology withoutspoiler bars (see Fig. 14). These increases were estimated by using an overall heattransfer coefficient of 256 W m 2 K (45 Btu hr ft 2o F) for <strong>the</strong> c<strong>on</strong>venti<strong>on</strong>al cylinder<strong>dryer</strong>s without spoiler bars and <strong>the</strong> best overall heat transfer coefficient of 328 W m 2 K(58 Btu hr ft 2o F) for <strong>the</strong> c<strong>on</strong>venti<strong>on</strong>al cylinder <strong>dryer</strong>s with spoiler bars. Producti<strong>on</strong>rate increases were estimated with results from <strong>the</strong> single-tube, n<strong>on</strong>rotating test channelfor <strong>multiport</strong> cylinder <strong>dryer</strong>s and average results from <strong>the</strong> engineering literature forc<strong>on</strong>venti<strong>on</strong>al cylinder <strong>dryer</strong>s with and without spoiler bars. Some of <strong>the</strong> practicaleffects of a prototype or full-scale model <strong>multiport</strong> cylinder <strong>dryer</strong> are not yet known.Therefore, <strong>the</strong>re is a need to c<strong>on</strong>duct MD performance tests in a full-scale, rotating test<strong>dryer</strong> to evaluate <strong>the</strong> c<strong>on</strong>cept under prototypical c<strong>on</strong>diti<strong>on</strong>. C<strong>on</strong>sequently, <strong>the</strong>seincreased producti<strong>on</strong> rate estimates should be viewed as idealized target levels.• Uniform <strong>dryer</strong> surface temperature can be attained because <strong>multiport</strong> <strong>dryer</strong> technologyprovides a highly uniform distributi<strong>on</strong> of cylinder-wall temperature, which is <strong>the</strong> resultof high c<strong>on</strong>densing heat transfer coefficients, toge<strong>the</strong>r with c<strong>on</strong>densing heat transfer