compound casting - a literature review - YMCA University of Science ...

compound casting - a literature review - YMCA University of Science ...

compound casting - a literature review - YMCA University of Science ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

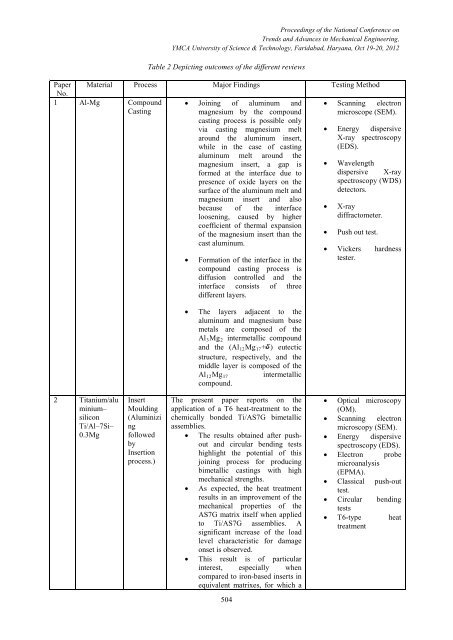

Proceedings <strong>of</strong> the National Conference onTrends and Advances in Mechanical Engineering,<strong>YMCA</strong> <strong>University</strong> <strong>of</strong> <strong>Science</strong> & Technology, Faridabad, Haryana, Oct 19-20, 2012Table 2 Depicting outcomes <strong>of</strong> the different <strong>review</strong>s• Scanning electronPaper Material Process Major Findings Testing MethodNo.1 Al-Mg Compound • Joining <strong>of</strong> aluminum andAl 12 Mg 17 intermetallicCastingmagnesium by the <strong>compound</strong><strong>casting</strong> process is possible onlymicroscope (SEM).via <strong>casting</strong> magnesium melt • Energy dispersivearound the aluminum insert, X-ray spectroscopywhile in the case <strong>of</strong> <strong>casting</strong> (EDS).aluminum melt around themagnesium insert, a gap is • Wavelengthformed at the interface due to dispersive X-raypresence <strong>of</strong> oxide layers on thesurface <strong>of</strong> the aluminum melt andspectroscopy (WDS)detectors.magnesium insert and alsobecause <strong>of</strong> the interface • X-rayloosening, caused by higher diffractometer.coefficient <strong>of</strong> thermal expansion<strong>of</strong> the magnesium insert than the • Push out test.cast aluminum.• Vickers hardness• Formation <strong>of</strong> the interface in the<strong>compound</strong> <strong>casting</strong> process istester.diffusion controlled and theinterface consists <strong>of</strong> threedifferent layers.• The layers adjacent to thealuminum and magnesium basemetals are composed <strong>of</strong> theAl 3 Mg 2 intermetallic <strong>compound</strong>and the (Al 12 Mg 17 + ) eutecticstructure, respectively, and themiddle layer is composed <strong>of</strong> the<strong>compound</strong>.2 Titanium/aluminium–siliconTi/Al–7Si–0.3MgInsertMoulding(AluminizingfollowedbyInsertionprocess.)The present paper reports on theapplication <strong>of</strong> a T6 heat-treatment to thechemically bonded Ti/AS7G bimetallicassemblies.• The results obtained after pushoutand circular bending testshighlight the potential <strong>of</strong> thisjoining process for producingbimetallic <strong>casting</strong>s with highmechanical strengths.• As expected, the heat treatmentresults in an improvement <strong>of</strong> themechanical properties <strong>of</strong> theAS7G matrix itself when appliedto Ti/AS7G assemblies. Asignificant increase <strong>of</strong> the loadlevel characteristic for damageonset is observed.• This result is <strong>of</strong> particularinterest, especially whencompared to iron-based inserts inequivalent matrixes, for which a• Optical microscopy(OM).• Scanning electronmicroscopy (SEM).• Energy dispersivespectroscopy (EDS).• Electron probemicroanalysis(EPMA).• Classical push-outtest.• Circular bendingtests• T6-type heattreatment504