compound casting - a literature review - YMCA University of Science ...

compound casting - a literature review - YMCA University of Science ...

compound casting - a literature review - YMCA University of Science ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

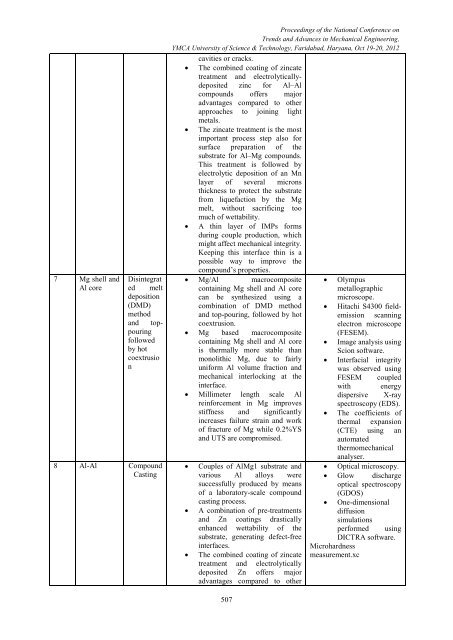

7 Mg shell andAl coreDisintegrated meltdeposition(DMD)methodand toppouringfollowedby hotcoextrusion8 Al-Al CompoundCastingProceedings <strong>of</strong> the National Conference onTrends and Advances in Mechanical Engineering,<strong>YMCA</strong> <strong>University</strong> <strong>of</strong> <strong>Science</strong> & Technology, Faridabad, Haryana, Oct 19-20, 2012cavities or cracks.• The combined coating <strong>of</strong> zincatetreatment and electrolyticallydepositedzinc for Al–Al<strong>compound</strong>s <strong>of</strong>fers majoradvantages compared to otherapproaches to joining lightmetals.• The zincate treatment is the mostimportant process step also forsurface preparation <strong>of</strong> thesubstrate for Al–Mg <strong>compound</strong>s.This treatment is followed byelectrolytic deposition <strong>of</strong> an Mnlayer <strong>of</strong> several micronsthickness to protect the substratefrom liquefaction by the Mgmelt, without sacrificing toomuch <strong>of</strong> wettability.• A thin layer <strong>of</strong> IMPs formsduring couple production, whichmight affect mechanical integrity.Keeping this interface thin is apossible way to improve the<strong>compound</strong>’s properties.• Mg/Al macrocompositecontaining Mg shell and Al corecan be synthesized using acombination <strong>of</strong> DMD methodand top-pouring, followed by hotcoextrusion.• Mg based macrocompositecontaining Mg shell and Al coreis thermally more stable thanmonolithic Mg, due to fairlyuniform Al volume fraction andmechanical interlocking at theinterface.• Millimeter length scale Alreinforcement in Mg improvesstiffness and significantlyincreases failure strain and work<strong>of</strong> fracture <strong>of</strong> Mg while 0.2%YSand UTS are compromised.• Couples <strong>of</strong> AlMg1 substrate andvarious Al alloys weresuccessfully produced by means<strong>of</strong> a laboratory-scale <strong>compound</strong><strong>casting</strong> process.• A combination <strong>of</strong> pre-treatmentsand Zn coatings drasticallyenhanced wettability <strong>of</strong> thesubstrate, generating defect-freeinterfaces.• The combined coating <strong>of</strong> zincatetreatment and electrolyticallydeposited Zn <strong>of</strong>fers majoradvantages compared to other• Olympusmetallographicmicroscope.• Hitachi S4300 fieldemissionscanningelectron microscope(FESEM).• Image analysis usingScion s<strong>of</strong>tware.• Interfacial integritywas observed usingFESEM coupledwith energydispersive X-rayspectroscopy (EDS).• The coefficients <strong>of</strong>thermal expansion(CTE) using anautomatedthermomechanicalanalyser.• Optical microscopy.• Glow dischargeoptical spectroscopy(GDOS)• One-dimensionaldiffusionsimulationsperformed usingDICTRA s<strong>of</strong>tware.Microhardnessmeasurement.xc507