TC1652 Controls Workover.qxd - cedip

TC1652 Controls Workover.qxd - cedip

TC1652 Controls Workover.qxd - cedip

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Installation/<strong>Workover</strong>Control Systems

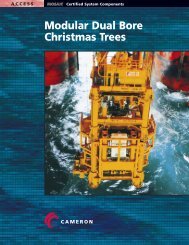

EH control systems for integrated controlof the THRT and SSTT are also available.Major system elements typically include:• HPU and <strong>Workover</strong> Control Panel•<strong>Workover</strong> Reel and Umbilical•Tubing Hanger Reel and Umbilical•<strong>Workover</strong> Control Module andAccumulators• LMRP Pilot Valve Module andAccumulators• Remote <strong>Workover</strong> ControlUnit/Portable Electronic Test UnitShallow Water Horizontal CompletionsIWOCS for shallow water, horizontal completionsprovide DH control of the TRTand tree functions. An EDU installed onthe LMRP/BOP enables disconnection ofthe workover umbilical at the LMRP/BOPinterface.Options are available to operate andmonitor tree functions via the TRT duringinstallation, and test/monitor the DHPTfollowing installation of the tubing hanger.DH control for THRT functions, SSTTfunctions and related control panel functionsare additional options. Major systemelements typically include:• HPU and <strong>Workover</strong> Control Panel•<strong>Workover</strong> Reel and Umbilical•Tubing Hanger Reel and Umbilical• Emergency Disconnect Unit• ROV/Diver Flying Lead Jumpersfrom BOP to TreeDeepwater Horizontal CompletionsIWOCS for deepwater, horizontal completionsprovide EH control of tree functionsand DH control of the TRT via theproduction SCM. An EDU installed on theLMRP/BOP enables disconnection of theworkover umbilical at the LMRP/BOPinterface.Options are available to operate andmonitor tree functions via the TRT duringinstallation, and test/monitor the DHPTfollowing installation of the tubing hanger.DH control for THRT functions, SSTT functionsand related control panel functionsare additional options. EH control systemsfor integrated control of the THRT andSSTT are also available.Major system elements typically include:• HPU and <strong>Workover</strong> Control Panel• <strong>Workover</strong> Reel and Umbilical• Tubing Hanger Reel and Umbilical• Emergency Disconnect Unit• BOP and TRT Accumulator Units• ROV Flying Leads from BOP to Tree• Remote <strong>Workover</strong> ControlUnit/Portable Electronic Test UnitCameron Vertical, Dual-Bore Subsea <strong>Workover</strong> System<strong>Workover</strong> System TerminologyAcronymBOPDHDHPTEDPEDUEHESDHPHPUIWATSIWOCSLMRPLPMDUMTUPETUPLCROVRTUSAMSCMSimOpsSSTTTHRTTRTWHPUWSCMWOCSDescriptionBlowout PreventerDirect HydraulicDownholePressure/TemperatureTransmitterEmergency Disconnect PackageEmergency Disconnect UnitElectro-Hydraulic MultiplexEmergency Shutdown SystemHigh PressureHydraulic Power UnitInstallation <strong>Workover</strong>Autonomous Test SystemInstallation <strong>Workover</strong> ControlSystemLower Marine Riser PackageLow PressureMobile Drilling UnitMaster Telemetry UnitPortable Electronic Test UnitProgrammable Logic ControllerRemotely Operated VehicleRemote Telemetry UnitSubsea Accumulator ModuleSubsea Control ModuleSimultaneous <strong>Workover</strong> andProduction Operation ScenariosSubsea Test TreeTubing Hanger Running ToolTree Running Tool<strong>Workover</strong> Hydraulic Power Unit<strong>Workover</strong> Subsea ControlModule<strong>Workover</strong> Control SystemFIRST OIL/GASO M E R T R A I N I N G P R O G R A M SFATs FIT SIT INSTALL COMMIS. PRODUCTION PMIS* PRODUCTION PMIS* PRODUCTION PMIS* PRODUCTION DECOMMISSIONINGSUPPORTP P O R TP R O D U C T I N T E G R I T Y & H S E P R O G R A M S*P M I S (PLANNED MAINTENANCE & INTERVENTION SUPPORT)3

Installation/<strong>Workover</strong> Control System Equipment<strong>Workover</strong> Hydraulic Power UnitThe WHPU is the primary system componentof theIWOCS. Itprovides thehydraulicpower tooperate thevarious runningtools,and subsea treevalves. WHPUstypically include:• Dual redundant LP and HPpump systems• Dual reservoirs• Filtration to NAS 1638 Class 6• Independent transfer and clean-uppump and filter system•LPand HP accumulation• Local control panels for HPUand workover functions• PLC control for EH systemsThe integrated local control panel<strong>Workover</strong> HydraulicPower Unitprovides control of tree functions, TRT/workover umbilical reel and the THRTumbilical reel.<strong>Workover</strong>/TRT Reel and UmbilicalThe workover/TRT reel and umbilical is areeled, multi-way EH umbilical providingpower and communication connections tocontrol TRT and tree functions. A handheldremote panel enables reel operationfrom an adjacent location. An automaticspooling device ensures correct umbilicallay during deploymentandretrieval. Afailsafe brakepreventsdrum rotationwhen theumbilical issuspended <strong>Workover</strong>/TRT Reel with Umbilicaland duringIWOCS operations. Wet-mateableconnectors terminate the subsea umbilicalelectrical cables when provided for EHoperations or DHPT monitoring, while amulti-way stab plate terminates the subseaumbilical hydraulic hoses.THRT Reel and UmbilicalThe THRT reel and umbilical is a reeled,multi-way hydraulic umbilical providingcommunication connections to controlTHRT functions. A hand-held remotependant enables operation from an adjacentlocation. An automaticspooling deviceensures correctumbilical lay duringdeployment andretrieval, while afailsafe brakeprevents drumrotation when theumbilical issuspended and THRT Reelwith Umbilicalduring operations.Individual hydraulic couplersterminate the subsea umbilical hydraulichoses, while wet-mateable connectorsterminate the electrical cables for DHPTmonitoring.<strong>Workover</strong> Hydraulic Deck JumperThe workover hydraulic deck jumper connectsthe WHPU and workover reel. Thejumper consists of an unarmored thermoplastichydraulic bundle terminated at eachend with stab plates.<strong>Workover</strong> Electrical Deck Jumper PowerThe workover electrical deck jumper interconnectsan EH WHPU and workover reel,providing dual power channels for productionand workover SCMs. The jumperconsists of an armored offshore electricalcable terminated with multi-pin explosionproof connectors at each end.<strong>Workover</strong> Electrical Deck Jumper SignalThe workover electrical deck jumper interconnectsan EH WHPU and workover reel,providing dual communications channelsfor production and workover SCMs Thejumper consists of an armored offshoreelectrical cable terminated with multipinexplosion proof connectors ateach end.THRT Hydraulic Deck JumperThe THRT hydraulic deck jumperinterconnects the WHPU and THRTreel. The jumper consists of an unarmoredthermoplastic hydraulic bundle terminatedwith stab plates at each end.Complete DH Rental IWOCS System - Subsystems left to right - Test Stand, THRT Reel and Umbilical, ESD Station, WHPU, Deck Jumper, Sheave, <strong>Workover</strong> Reel and Umbilical

Umbilical SheavesThe umbilical sheaves assist deploymentof the workover/TRT and THRT controlumbilicals and are sized to ensure that anumbilical cannot be bent beyondJumper Transportation and Storage Basket with Sheaverecommended minimum bend radius.Sheave rollers are made from corrosionresistantmaterial and provide smooth,abrasive free movement of an umbilical.Remote ESD StationThe remoteESD stationconsistsof pushbuttons andindicatorssuitablefor Zone 1hazardousRemote ESD Stationarea operationsand can be reconfigured to meet therig-specific safety requirements. The unitfunctions to initiate a single level shutdownof the IWOCS and a remote shutdownof the subsea production system.Protective covers prevent accidentalinitiation of ESDs.Remote ESD Station Deck Cable/JumperThe remote ESD station deck jumper connectsto the remote ESD station, providingsafe remote communications to operate anESD. The jumper consists of an armoredoffshore electrical cable terminated ateach end with multi-pin, explosion proofconnectors (for deepwater systems) oran unarmored thermoplastic pneumatichydraulic bundle terminated at eachend with stab plates (for shallow watersystems).Portable Electronic Test UnitThe PETU is a multi-purpose systemproviding operator access to productionSCM housekeepinganddiagnosticdata that isnot normallyavailable onthe WHPUPortable Electronic Test Unitoperatingpanels. The PC-based, laptop unitincorporates a power supply, communicationsequipment and interconnecting cablesto enable remote location test and operationdiagnostics. Data is stored on the internalCD-RW drive. The standard portable electronictest unit is suitable for use in “safeareas” only.Jumper BasketThe offshore/lift certified jumper basketprovides for the transportation and storageof deck jumpers and sheaves.EmergencyDisconnectUnitThe EDUenables safedisconnect ofthe surface,rig-mounted,equipmentfrom thefixed subseaEmergency Disconnect Unitequipmentduring drilling unit drift, drive-off or otheremergency situations. The unit consists of amulti-way remotely operated hydraulic andelectrical stab plate at the LMRP/BOP stackinterface, allowing the workover functionsto be disconnected between the tree and theworkover umbilical in the event that thedrilling riser is disconnected from the BOP.EDU Test and Shipping FrameThe EDU test and shipping frame protectsthe EDU from damage during storage andoffshore transportation. The unit enableschecking, flushing and pressure testing ofEDU operations prior to installation onthe BOP.Common Components DH and EH,Vertical and Horizontal Systems<strong>Workover</strong> Hydraulic Power Unit<strong>Workover</strong>/TRT Reel and UmbilicalTubing Hanger Running Tool Reeland Umbilical<strong>Workover</strong> Hydraulic Deck JumperTubing Hanger Running Tool HydraulicDeck JumperUmbilical SheavesRemote Emergency Shutdown StationRemote Emergency Shutdown StationDeck Cable/JumperJumper Deployment BasketUmbilical Clamps (THRTUmbilical-to-Drill Pipe/Riser)<strong>Workover</strong> Control System Radio Link<strong>Workover</strong> Umbilical Test andFlushing UnitInstallation <strong>Workover</strong> AutonomousTest SystemIWATS Tree-to-BOP ConnectorAdditional Components for EHVertical and Horizontal Systems<strong>Workover</strong> Electrical Power Deck Jumper<strong>Workover</strong> Electrical Signal Deck JumperPortable Electronic Test Equipment<strong>Workover</strong> Subsea Control ModuleBOP Accumulator ModuleTree Running Tool Accumulator SetAdditional Components for DHand EH Horizontal SystemsEmergency Disconnect UnitEmergency Disconnect Unit Testand Shipping FrameUmbilical Clamps (Umbilical-to-SCM line)Tree Running Tool-to-Tree Flying LeadTree Flying Lead Parking PlateBOP-to-Tree Flying LeadTree to BOP Parking Plate

Installation/<strong>Workover</strong> Control System EquipmentWSCMThe WSCM uses CAMTROL productioncontrol system technology to provide acompact, lightweight system for operatingvertical tree workover functions and lightintervention control systems. The WSCM iseasily removable on deck for maintenanceand provides dual redundant electronics.Use of a common power and communicationssystem is possible for workover andproduction SCMs, allowing a truly integratedcontrol system.BOP Accumulator ModuleThe BOP accumulator module provideshydraulic power for the production SCMusing dedicated accumulators on eachsupply for systems not configured withsubsea accumulators on the tree. Themodule is mounted to the BOP stack in arobust framework that provides protectionduring BOP handling.TRT Accumulator SetThe TRT accumulators providehydraulic power to the productionSCM to enable testingof the tree when initially run.Accumulators are provided foreach hydraulic supply line.WSCM (cover and HydraQuadsremoved for clarity)Umbilical Clamps – THRTUmbilical-to-Drill Pipe/RiserClamps are provided to clamp theTHRT umbilical to the drill pipe orcompletion riser for tubing hangerdeployment. The clamps ensure theumbilical is adequately attached to preventumbilical damage.Umbilical Clamps –<strong>Workover</strong> Umbilical-to-SCM LineClamps are provided to clamp the workoverumbilical to the drill pipe used fordeployment of the TRT, or to the choke andkill lines during deployment of the BOPstack. The clamps ensure the umbilical isadequately attached at all times to preventany damage to the umbilical.WOCS Radio LinkThe WOCS radio link system provides ahighly secure, line-of-sight, dual channelESD communications link between a MDUand a fixed platform or floating productionsystem. The system is intended for useunder SimOps and provides the ability toinitiate a fully automated shutdown of thesubsea production facility from the MDUor other workover/intervention vessel.Major components of the system includean MTU located on the production facility,and a RTU and ESD panels located on theMDU. Alarms are raised at both ends ofthe link in the event of any communicationerrors or system failures.<strong>Workover</strong> Umbilical Testand Flushing EquipmentThe workover umbilical test and flushingequipment allows all elements of theIWOCS to be flushed and tested prior touse or during routine offshore maintenance.Typical uses include pressure test andflushing, and continuity andinsulation tests.ROV Test Stab FlyingLeadThe ROV/teststab flying leadis a single-line,ROV fly-toplacehydraulicflying leadallowing testingof the treeTRT Accumulatorsconnector gasketand tubinghanger/ HP cap seals. One end of theflying lead is permanently attached to theBOP stack EDU, while the second end isfitted with an ROV fly-to-place hydraulichot stab.TRT-to-Tree Flying LeadThe TRT-to-tree flying lead is a multifunction,ROV fly-to-place electric andhydraulic flying lead allowing operationof the production SCM and control of treefunctions following lockdown of the treewith the TRT connected. The flying leadprovides compensation for the SCMhydraulics from the IWOCS during treeinstallation.Tree Flying Lead Parking PlateThe tree flying lead parking plate allowsparking and protection of the tree flyinglead when not connected to the tree productioncontrols stab plate. A parking plateon the BOP allows flying lead parkingwhen running or retrieving the BOP stackand drilling riser. A second parking plateis fitted to the TRT to allow parking of thetree flying lead following disconnection atthe end of the Tree running sequence priorto recovery of the TRT.ROV Hot Stab Blind ReceptacleThe ROV hot stab blind receptacle isattached to the BOP stack or TRT forparking the ROV test stab flying lead andtesting the IWOCS pressure test line duringthe running or retrieving of the BOP stack.BOP-to-Tree Flying LeadThe BOP-to-tree flying lead is a multifunction,ROV fly-to-place electric andhydraulic flying lead allowing operation ofthe production SCM and control of the treefunctions during installation and workoveroperations with the BOP in place. Theflying lead connects to the BOP stackmountedEDU and accumulator moduleto the production control system stabplate on the tree.IWATS Tree-to-BOP Connectorand EDP Functions Flying LeadThe IWATS tree-to-BOP connector and EDPfunctions flying lead is a multi-function,ROV fly-to-place electric and hydraulicflying lead. It allows operation and testingof the various EPD and BOP connector testports during installation and workoveroperation with the IWATS. The flyinglead interconnects the tree to the EDP andassociated accumulator module and theBOP connector test ports.

Rental IWOCS SpecificationsConfigurable Rental IWOCS Features: Components are suitable for use with the control fluid intended for use. All system filters have beenspecified to ensure fluid is clean to NAS 1638 class 6. A pneumatic line for the remote ESD stations is provided. *Hydraulic fluid provided attwo regulated pressure levels, LP at 345 bar (5000 psi) and HP at 690 bar (10,000 psi).Unit Length Width Height Weight Hydraulic Lines Elect.UmbilicalLine QtyComponent Number (m/ft) (m/ft) (m/ft) (kg/lb)(m/ft)Qty Size bar/psi (2.5 mm 2 )1 3.80/12.5 2.20 /7.2 2.60/8.5 6000/13,3002 3.80/12.5 2.20/7.2 2.60/8.5 6000/13,300HPU*3 3.50/11.5 2.20/7.2 2.60/8.5 7600/16,8004 3.60/11.8 2.20/7.2 2.60/8.5 7000/15,5005 3.50/11.5 2.20/7.2 2.60/8.5 7000/15,5006 3.10/10.2 2.00/6.6 2.00/6.6 4100/90001 3.40/11.2 2.08/6.8 3.15/10.3 9800/21,6007 1/4” 775/11,2505 3/8” 345/50002 300/10002 3.40/11.2 2.08/6.8 3.30/10.8 9800/21,6007 1/4” 775/11,2505 3/8” 345/50002 290/950THRT Reels 3 3.23/10.6 2.23/7.3 3.00/9.8 6100/13,5007 1/4” 860/12,5005 3/8” 345/50003 300/10003 1/4” 860/12,5004 3.41/11.2 3.41/11.2 3.41/11.2 16,350/36,100 7 1/4” 690/10,000 1060/35004 1/4” 345/500010 1/4” 775/11,2501 3.80/12.5 2.50/8.2 3.60/11.8 10,200/22,500 23 3/8” 345/5000 2 300/10002 1/2” 345/500010 1/4” 860/12,5002 3.80/12.5 2.43/8.0 3.35/11.0 8500/18,800 23 3/8” 345/5000 2 300/10002 1/2” 345/500010 1/4” 775/11,2503 3.80/12.5 2.43/8.0 3.60/11.8 11,000/24,300 22 3/8” 345/5000 2 245/800<strong>Workover</strong> 2 1/2” 345/5000Reels 10 1/4” 860/12,5004 3.80/12.5 2.65/8.7 3.55/11.6 9850/21,700 22 3/8” 345/5000 2 300/10002 1/2” 345/500010 1/4” 860/12,5005 3.80/12.5 2.65/8.7 3.55/11.6 9300/20,500 22 3/8” 345/5000 2 300/9842 1/2” 345/50003 1/4” 860/12,5006 3.41/11.2 3.41/11.2 3.41/11.2 16,350/36,100 4 1/4” 690/10,000 1060/350011 3/8” 345/5000Universal 1 3.23/10.6 2.23/7.3 3.00/9.8 8350/18,400 24 1/4” 690/12,500 4 200/650Reels 3 3/8” 690/10,0002 4.06/13.3 3.30/10.8 3.81/12.5 15,000/33,100 4 3/8” 345/5000 4 1000/330017 1/4” 690/10,0003 3/8” 690/10,0003 4.06/13.3 3.30/10.8 3.81/12.5 14,150/32,000 4 3/8” 345/5000 4 1000/330017 1/4” 690/10,000Electrical Reel 1 2.10/6.9 2.71/8.9 2.10/6.9 7300/16,100 10 1060/3500Pre-Configured Rental IWOCS Features: *Hydraulic fluid provided at two regulated pressure levels, LP at 345 bar (5000 psi) and HP at 690bar (10,000 psi). System 1 – PLC control for the EH system. Open-loop, water-based hydraulic fluid. System 2 – Closed loop, synthetic mineral oilfor the DH system.ComponentSystem Length Width Height WeightNumber (m/ft) (m/ft) (m/ft) (kg/lb)Hydraulic LinesQty Size bar/psiElect.Line Qty(2.5 mm 2 )Umbilical(m/ft)HPU* 1 3.60/11.8 2.42/8.0 2.60/8.6 7500/16,600TRT Reel 1 3.80/12.5 2.95/9.8 3.31/10.9 8200/18,1003 1/4” 690/10,0006 1/4” 207/30001100/36096 1/4” 690/10,000<strong>Workover</strong>1 4.10/13.5 3.35/11.0 3.40/11.2 10,200/22,500 3 1/4” 207/3000Reel3 3/8” 345/50002 1100/3609HPU Skid 2 4.72/15.5 2.42/7.9 2.60/8.5 7000/15,600LP 345/5000HP 690/10,0004 1/4” 207/3000TRT Reel 2 3.08/10.1 2.65/8.7 3.28/10.8 6000/13,300 6 1/4” 690/10,000 2 258/8502 1/2” 207/300017 1/4” 207/30006 1/4” 690/10,000<strong>Workover</strong>2 4.00/13.1 3.20/10.5 3.30/10.8 8600/19,000 4 3/8” 207/3000Reel2 3/8” 690/10,000258/8506 1/2” 207/3000

1564511612321Control Line Legend9 82Electrical SignalElectrical Power14107Hydraulic Supply13MODU <strong>Workover</strong> Detail20IWOCS System Components312<strong>Workover</strong> HPU<strong>Workover</strong>/TRT Reel and Umbilical3Umbilical Clamps - Umbilical-to-Choke/Kill Line4THRT Reel and Umbilical5Umbilical Clamps - THRT-to-Drill Pipe/Riser6Umbilical Sheaves278<strong>Workover</strong> Hydraulic Deck Jumper<strong>Workover</strong> Electrical Power Deck Jumper9<strong>Workover</strong> Electrical Signal Deck Jumper10THRT Hydraulic Deck Jumper11Remote ESD Station12Remote ESD Station Deck Cable13Portable Electronic Test Unit14WOCS ESD Radio Equipment15WOCS Radio Link Antenna1616Emergency Disconnect Unit17<strong>Workover</strong> Flying Lead1718BOP Accumulator Module19Tree-to-BOP Jumper18BOP Stack Detail192021Tree-to-BOP Jumper Parking PlateInstallation <strong>Workover</strong> Autonomous Test System

Cameron MOSAIC Subsea CompletionComponents222324Cameron SpoolTree Production SystemProduction ManifoldPipeline End TerminalPlatform ScenarioCameron Drilling System Components252627BOP StackLower Marine Riser PackageDrilling Riser SystemCAMTROL Production Control SystemComponents28293031323334Subsea Control ModuleSCM Mounting BaseElectro-Hydraulic Flying LeadMain <strong>Controls</strong> UmbilicalSubsea Accumulator ModuleSubsea Distribution UnitUmbilical Termination AssemblyCameron EH Drilling Control SystemComponents3536Yellow Control PodBlue Control Pod2229283031

IWOCS ApplicationsMODU <strong>Workover</strong> ScenarioIWATS Scenario122721242635362523323433

Installation <strong>Workover</strong> AutonomousTest System (IWATS)The IWATS uses a standard IWOCSalong with an ROV launch and heavecompensationsystem to enable ROVassisted,free-movement operations forinstallation and workover activities inwater depths to 3000 meters (10,000 feet).IWATS is deployed over the side or sternof a suitable vessel of opportunity, providingmany operational and safety featuresincluding:•Time and congestion are markedlyreduced within the moonpool andassociated working areas, improvingoperations safety and enabling bothsingle well and batch well testing.• The IWATS can be deployed in eitherEH or DH mode and can use the sameumbilical for either application.• The IWATS system can be used withhorizontal as well as vertical subseaproduction trees.• The IWATS can be used to install andretrieve flying leads of all types, SCMs,SAMs, insert-retrievable chokes, treecaps and other tools and equipment.The IWATS umbilical provides hydraulicsupplies (SCMs dual LP and HP, tree test,and other functions) and power and communicationssupplies (for production andworkover SCMs). It is attached to theIWATS via a field-proven EDP, providinga safe and secure connection.The ROV-installed IWATS flying lead isparked locally. When connected, this leadprovides the means to control and monitorworkover and production SCM functionsduring completion or workover operations.Flying lead length and configuration can bemodified to suit specific field layout andwell offset distances.In addition, chemical supplies can beprovided by a separate umbilical hungalong with the system umbilical. Like thehydrualic and communications supplies,the chemical supply line is made up to theEDU unit for protection.38374139IWATS44 452137IWATSUmbilical40 433839Lift CableEmergency Disconnect Package4240IWATS Flying Lead41IWATS Flying Lead Recovery Position42<strong>Workover</strong>/Production SCM43SCM Mounting Base4445Spare Production SCM/SAMSpare Electro-Hydraulic Flying Lead21

Cameron <strong>Controls</strong>6650 Bingle RoadHouston, Texas 77092Tel 713 683 4600Fax 713 683 4729Cameron <strong>Controls</strong>Lueckenweg 129227 Celle, GermanyTel 49 5141 8060Fax 49 5141 806333Cameron <strong>Controls</strong>Badentoy Road, Badentoy ParkPortlethenAberdeen, Scotland AB12 4YATel 44 1224 282 000Fax 44 1224 783 355Cameron <strong>Controls</strong>Rod. Amari Pexoto8000 km 164.5ImboassicaMacae, RJBrazil CEP27920-340Tel 55 22 2763 6331Fax 55 22 2763 6338Visit our website at www.camerondiv.comor contact us at camtrolinfo@camerondiv.comAPI Q1 Quality System Certificate; API 16D Control Systemsfor Drilling Well Control Equipment; API 17D SubseaWellhead and Christmas Tree Equipment; ISO 9001 QualitySystem Certificate; API License # 16D-0012; API License# 17D-0015; ISO 9001 License # 0001SpoolTree, Cameron, CAMSERV, CAMTROL, HydraQuad and MOSAIC aretrademarks of the Cooper Cameron Corporation© Cooper Cameron Corporation, Cameron Division, Printed in USA, 08/02, PP/5M, <strong>TC1652</strong>Worldwide IWOCSPurchased Systems –Electro Hydraulic MultiplexedCustomerProjectNorsk Hydro . . . . . . . . . . . . . . . . .TOGIBritish Petroleum . . . . . . . . . . . . .SchiehallionShell . . . . . . . . . . . . . . . . . . . . . . .MalampayaExxonMobil . . . . . . . . . . . . . . . . .XikombaExxonMobil . . . . . . . . . . . . . . . . .Kizomba APurchased Systems – Direct HydraulicSudoimport . . . . . . . . . . . . . . . . .IWOCSStatoil . . . . . . . . . . . . . . . . . . . . .Gulfaks AStatoil . . . . . . . . . . . . . . . . . . . . .Gulfaks A IITotal Fina Elf . . . . . . . . . . . . . . . .IWOCSAgip . . . . . . . . . . . . . . . . . . . . . . .IWOCSRospo . . . . . . . . . . . . . . . . . . . . . .MareSaga Petroleum . . . . . . . . . . . . . .SnorreAmerada Hess . . . . . . . . . . . . . . .ScottBritish Petroleum (Amoco) . . . . .P15Agip . . . . . . . . . . . . . . . . . . . . . . .ToniAmerada Hess . . . . . . . . . . . . . . .Scott IIMaersk . . . . . . . . . . . . . . . . . . . . .RegnarConocoPhillips . . . . . . . . . . . . . . .LyellChevronTexaco . . . . . . . . . . . . . . .StrathspeyKerr McGee . . . . . . . . . . . . . . . . .GryphonTotal Fina Elf . . . . . . . . . . . . . . . .TchendoRepsol YPF . . . . . . . . . . . . . . . . . .AlbagaBritish Petroleum . . . . . . . . . . . . .PampanoNAM . . . . . . . . . . . . . . . . . . . . . . .L13British Petroleum . . . . . . . . . . . . .SwiftBritish Petroleum . . . . . . . . . . . . .FoinhavenMariner Energy (Hardy) . . . . . . . .IWOCSKerr McGee . . . . . . . . . . . . . . . . .JaniceShell (Enterprise) . . . . . . . . . . . . .PierceBritish Gas . . . . . . . . . . . . . . . . . .Scarab-SaffronSchlumberger . . . . . . . . . . . . . . . .IWOCSRental SystemsExxonMobil . . . . . . . . . . . . . . . . .BucklandTalisman . . . . . . . . . . . . . . . . . . .RossChevronTexaco . . . . . . . . . . . . . . .GalleyTalisman . . . . . . . . . . . . . . . . . . .OrionShell Sarawak . . . . . . . . . . . . . . . .M4ExxonMobil . . . . . . . . . . . . . . . . .NevisBritish Petroleum (Amoco) . . . . .Northwest BellChevronTexaco . . . . . . . . . . . . . . .Captain BAmerada Hess (Triton) . . . . . . . . .Ceiba EPS (Phase 1)Amerada Hess (Triton) . . . . . . . . .Ceiba Phase 1a/1bConocoPhillips . . . . . . . . . . . . . . .McCullochBritish Gas . . . . . . . . . . . . . . . . . .BlakeGmis . . . . . . . . . . . . . . . . . . . . . .BeaulyBritish Petroleum . . . . . . . . . . . . .MadoesAgip (British Borneo) . . . . . . . . . .MorpethAgip (British Borneo) . . . . . . . . . .AlleghenyShell . . . . . . . . . . . . . . . . . . . . . . .Brent SouthShell . . . . . . . . . . . . . . . . . . . . . . .MalampayaTalisman . . . . . . . . . . . . . . . . . . . .BuchanChevronTexaco . . . . . . . . . . . . . . .StrathspeyBHP . . . . . . . . . . . . . . . . . . . . . . .Hamilton