Indoor Unit Outdoor Unit CS-PS9NKV CS-PS12NKV CS ... - Panasonic

Indoor Unit Outdoor Unit CS-PS9NKV CS-PS12NKV CS ... - Panasonic

Indoor Unit Outdoor Unit CS-PS9NKV CS-PS12NKV CS ... - Panasonic

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

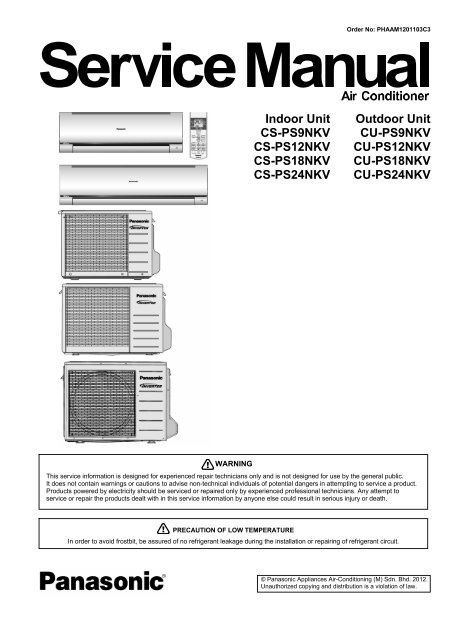

Order No: PHAAM1201103C3<strong>Indoor</strong> <strong>Unit</strong><strong>CS</strong>-<strong>PS9NKV</strong><strong>CS</strong>-<strong>PS12NKV</strong><strong>CS</strong>-PS18NKV<strong>CS</strong>-PS24NKV<strong>Outdoor</strong> <strong>Unit</strong>CU-<strong>PS9NKV</strong>CU-<strong>PS12NKV</strong>CU-PS18NKVCU-PS24NKVWARNINGThis service information is designed for experienced repair technicians only and is not designed for use by the general public.It does not contain warnings or cautions to advise non-technical individuals of potential dangers in attempting to service a product.Products powered by electricity should be serviced or repaired only by experienced professional technicians. Any attempt toservice or repair the products dealt with in this service information by anyone else could result in serious injury or death.PRECAUTION OF LOW TEMPERATUREIn order to avoid frostbit, be assured of no refrigerant leakage during the installation or repairing of refrigerant circuit.© <strong>Panasonic</strong> Appliances Air-Conditioning (M) Sdn. Bhd. 2012.Unauthorized copying and distribution is a violation of law.

TABLE OF CONTENTS1. Safety Precautions .............................................32. Specification .......................................................53. Location of Controls and Components............93.1 <strong>Indoor</strong> <strong>Unit</strong> ....................................................93.2 <strong>Outdoor</strong> <strong>Unit</strong> .................................................93.3 Remote Control ............................................94. Dimensions .......................................................104.1 <strong>Indoor</strong> <strong>Unit</strong> ..................................................104.2 <strong>Outdoor</strong> <strong>Unit</strong> ...............................................125. Refrigeration Cycle Diagram ...........................145.1 <strong>CS</strong>-<strong>PS9NKV</strong> CU-<strong>PS9NKV</strong><strong>CS</strong>-<strong>PS12NKV</strong> CU-<strong>PS12NKV</strong> ....................145.2 <strong>CS</strong>-PS18NKV CU-PS18NKV<strong>CS</strong>-PS24NKV CU-PS24NKV ....................156. Block Diagram ..................................................166.1 <strong>CS</strong>-<strong>PS9NKV</strong> CU-<strong>PS9NKV</strong> ........................166.2 <strong>CS</strong>-<strong>PS12NKV</strong> CU-<strong>PS12NKV</strong> ....................176.3 <strong>CS</strong>-PS18NKV CU-PS18NKV ....................186.4 <strong>CS</strong>-PS24NKV CU-PS24NKV ....................197. Wiring Connection Diagram ............................207.1 <strong>Indoor</strong> <strong>Unit</strong> ..................................................207.2 <strong>Outdoor</strong> <strong>Unit</strong> ...............................................228. Electronic Circuit Diagram ..............................268.1 <strong>Indoor</strong> <strong>Unit</strong> ..................................................268.2 <strong>Outdoor</strong> <strong>Unit</strong> ...............................................289. Printed Circuit Board .......................................329.1 <strong>Indoor</strong> <strong>Unit</strong> ..................................................329.2 <strong>Outdoor</strong> <strong>Unit</strong> ...............................................3410. Installation Instruction.....................................3910.1 Select the Best Location.............................3910.2 <strong>Indoor</strong> <strong>Unit</strong> ..................................................4010.3 <strong>Outdoor</strong> <strong>Unit</strong> ...............................................4411. Operation Control.............................................4711.1 Basic Function ............................................4711.2 <strong>Indoor</strong> Fan Motor Operation .......................4811.3 <strong>Outdoor</strong> Fan Motor Operation ....................4811.4 Airflow Direction..........................................4911.5 Timer Control..............................................4911.6 Random Auto Restart Control ....................5011.7 Indication Panel..........................................5012. Protection Control............................................5112.1 Restart Control (Time Delay SafetyControl).......................................................5112.2 30 Seconds Forced Operation ...................5112.3 Total Running Current Control ...................5112.4 IPM (Power Transistor) PreventionControl ........................................................5112.5 Low Pressure Prevention Control(Gas Leakage Detection) ...........................5212.6 Compressor Tank Temperature RiseProtection Control.......................................52212.7 Low Frequency Protection Control 1......... 5212.8 Low Frequency Protection Control 2......... 5212.9 <strong>Outdoor</strong> Air Temperature Control.............. 5212.10 Cooling Overload Control .......................... 5312.11 Freeze Prevention Control ........................ 5312.12 Freeze Prevention Control 2 ..................... 5312.13 Dew Prevention Control ............................ 5312.14 Odor Cut Control ....................................... 5313. Servicing Mode................................................ 5413.1 Auto Off/On Button .................................... 5413.2 Remote Control Button.............................. 5514. Troubleshooting Guide................................... 5614.1 Refrigeration Cycle System....................... 5614.2 Breakdown Self Diagnosis Function.......... 5814.3 Error Code Table....................................... 5914.4 Troubleshooting Flowchart ........................ 6015. Disassembly and Assembly Instructions ..... 8115.1 <strong>CS</strong>-PS9/12NKV ......................................... 8115.2 <strong>CS</strong>-PS18/24NKV ....................................... 8516. Technical Data ................................................. 8916.1 Operation Characteristics.......................... 8917. Exploded View and Replacement Parts List. 9717.1 <strong>Indoor</strong> <strong>Unit</strong> ................................................. 9717.2 <strong>Outdoor</strong> <strong>Unit</strong> ............................................ 101

1. Safety Precautions• Read the following “SAFETY PRECAUTIONS” carefully before perform any servicing.• Electrical work must be installed or serviced by a licensed electrician. Be sure to use the correct rating of thepower plug and main circuit for the model installed.• The caution items stated here must be followed because these important contents are related to safety. Themeaning of each indication used is as below. Incorrect installation or servicing due to ignoring of the instructionwill cause harm or damage, and the seriousness is classified by the following indications.WARNINGCAUTIONThis indication shows the possibility of causing death or serious injuryThis indication shows the possibility of causing injury or damage to properties.• The items to be followed are classified by the symbols:This symbol denotes item that is PROHIBITED from doing.• Carry out test run to confirm that no abnormality occurs after the servicing. Then, explain to user the operation,care and maintenance as stated in instructions. Please remind the customer to keep the operating instructions forfuture reference.WARNING1. Do not modify the machine, part, material during repairing service.2. If wiring unit is supplied as repairing part, do not repair or connect the wire even only partial wire break. Exchange the whole wiring unit.3. Do not wrench the fasten terminal. Pull it out or insert it straightly.4. Engage dealer or specialist for installation and servicing. If installation of servicing done by the user is defective, it will cause water leakage,electrical shock or fire.5. Install according to this installation instructions strictly. If installation is defective, it will cause water leakage, electric shock or fire.6. Use the attached accessories parts and specified parts for installation and servicing. Otherwise, it will cause the set to fall, water leakage, fireor electrical shock.7. Install at a strong and firm location which is able to withstand the set’s weight. If the strength is not enough or installation is not properly done,the set will drop and cause injury.8. For electrical work, follow the local national wiring standard, regulation and the installation instruction. An independent circuit and single outletmust be used. If electrical circuit capacity is not enough or defect found in electrical work, it will cause electrical shock or fire.9. This equipment is strongly recommended to install with Earth Leakage Circuit Breaker (ELCB) or Residual Current Device (RCD). Otherwise, itmay cause electrical shock and fire in case equipment breakdown or insulation breakdown.10. Do not use joint cable for indoor / outdoor connection cable. Use the specified indoor / outdoor connection cable, refer to installation instructionCONNECT THE CABLE TO THE INDOOR UNIT and connect tightly for indoor / outdoor connection. Clamp the cable so that no external forcewill be acted on the terminal. If connecting or fixing is not perfect, it will cause heat up or fire at the connection.11. Wire routing must be properly arranged so that control board cover is fixed properly. If control board cover is not fixed perfectly, it will causeheat-up or fire at the connection point of terminal, fire or electrical shock.12. When install or relocate air conditioner, do not let any substance other than the specified refrigerant, eg.air etc. mix into refrigeration cycle(piping). (Mixing of air etc. will cause abnormal high pressure in refrigeration cycle and result in explosion, injury etc.).13. Do not install outdoor unit near handrail of veranda. When installing air-conditioner unit at veranda of high rise building, child mayclimb up to outdoor unit and cross over the handrail and causing accident.14. This equipment must be properly earthed. Earth line must not be connected to gas pipe, water pipe, earth of lightning rod andtelephone. Otherwise, it may cause electric shock in case equipment breakdown or insulation breakdown.15. Keep away from small children, the thin film may cling to nose and mouth and prevent breathing.16. Do not use unspecified cord, modified cord, joint cord or extension cord for power supply cord. Do not share the single outlet withother electrical appliances. Poor contact, poor insulation or over current will cause electrical shock or fire.17. Tighten the flare nut with torque wrench according to specified method. If the flare nut is over-tightened, after a long period, the flare maybreak and cause refrigerant gas leakage.18. In case of using existing (R22) pipes during installation of R410 models, must carry out pump down properly to collect back therefrigerant and oil before installation new unit.Thickness of copper pipes used with R410A must be more than 0.6mm. Never use copper pipes thinner than 0.6mm.It is desirable that the amount of residual oil is less than 40 mg/10m.3

19. During installation, before run the compressor, confirm the refrigerant pipes are fixed. Operation of compressor without fixing the piping,setting the valves at open condition, a burst may occur and cause injury.20. During pump down operation, stop the compressor before remove the refrigerant piping. (Removal of refrigeration piping while compressor isoperating and valves are opened condition will cause suck-in of air, abnormal high pressure in refrigeration cycle and result in explosion,injury etc.)21. After completion of installation or service, confirm there is no leakage or refrigerant gas. It may generate toxic gas when the refrigerantcontacts with fire.22. Ventilate if there is refrigerant gas leakage during operation. It may cause toxic gas when refrigerant contacts with fire.23. Do not insert your fingers or other objects into the unit, high speed rotating fan may cause injury.24. Must not use other parts except original parts describe in catalog and manual.25. Using of refrigerant other than the specified type may cause product damage, burst and injury etc.CAUTION1. Do not install the unit at place where leakage of flammable gas may occur. In case gas leaks and accumulates at surrounding of theunit, it may cause fire.2. Carry out drainage piping as mentioned in installation instructions. If drainage is not perfect, water may enter the room and damagethe furniture.3. Tighten the flare nut with torque wrench according to specified method. If the flare nut is over-tightened, after a long period, the flaremay break and cause refrigerant gas leakage.4. Do not touch outdoor unit air inlet and aluminium fin. It may cause injury.5. Select an installation location which is easy for maintenance.6. Pb free solder has a higher melting point than standard solder; typically the melting point is 50°F – 70°F (30°C – 40°C) higher. Please usea high temperature solder iron. In case of the soldering iron with temperature control, please set it to 700 ± 20°F (370 ± 10°C).Pb free solder will tend to splash when heated too high (about 1100°F / 600°C).7. Power supply connection to the air conditioner. Connect the power supply cord of the air conditioner to the mains using one of the followingmethods.Power supply point shall be the place where there is ease for access for the power disconnection in case of emergency. In some countries,permanent connection of this room air conditioner to the power supply is prohibited.i. Power supply connection to the receptacle using a power plug.Use an approved 15/16A (1.0 ~ 1.75HP) or 16A (2.0HP) or 20A (2.5HP) power plug with earth pin for the connection to the socket.ii. Power supply connection to a circuit breaker for the permanent connection.Use an approved 16A (1.0 ~ 2.0HP) or 20A (2.5HP) circuit breaker for the permanent connection. It must be a double pole switch with aminimum 3.0 mm contact gap.8. Do not release refrigerant during piping work for installation, servicing, reinstallation and during repairing a refrigerant parts. Takecare of the liquid refrigerant, it may cause frostbite.9. Installation or servicing work: It may need two people to carry out the installation or servicing work.10. Do not install this appliance in a laundry room or other location where water may drip from the ceiling, etc.11. Do not sit or step on the unit, you may fall down accidentally.12. Do not touch the sharp aluminum fins or edges of metal parts.If you are required to handle sharp parts during installation or servicing, please wear hand glove.Sharp parts may cause injury4

2. SpecificationCoolingModel<strong>Indoor</strong> <strong>CS</strong>-<strong>PS9NKV</strong> <strong>CS</strong>-<strong>PS12NKV</strong><strong>Outdoor</strong> CU-<strong>PS9NKV</strong> CU-<strong>PS12NKV</strong>Performance Test Condition JIS JISPower SupplyCapacityPhase, Hz Single, 60 Single, 60V 220 220Min. Mid. Max. Min. Mid. Max.kW 0.84 2.54 3.15 0.92 3.06 4.00BTU/h 2860 8660 10700 3140 10400 13600kJ/h 3020 9140 11340 3310 11020 14400Running Current A - 3.4 - - 4.0 -Input Power W 225 680 885 260 820 1.17kEERW/W 3.73 3.74 3.56 3.54 3.73 3.42BTU/hW 12.71 12.74 12.09 12.08 12.68 11.62kJ/hW 13.42 13.44 12.81 12.73 13.44 12.31Power Factor % - 91 - - 93 -<strong>Indoor</strong> Noise (H / L / QLo) dB-A 36 / 26 / - 38 / 28 / -<strong>Outdoor</strong> Noise (H / L / QLo) dB-A 46 / - / - 47 / - / -Max Current (A) / Max Input Power (W) 6.2 / 1.12k 7.4 / 1.43kCompressor<strong>Indoor</strong> Fan<strong>Outdoor</strong> FanSpeedStarting Current (A) 3.4 4.0Type Hermetic Motor / Rotary Hermetic Motor / RotaryMotor Type Brushless (6 poles) Brushless (6 poles)Output Power W 650 650Type Cross-flow fan Cross-flow fanMaterial ASG20K1 ASG20K1Motor Type Induction (4 poles) Induction (4 poles)Input Power W 54.5 54.5Output Power W 16 16Lo rpm 720 720Me rpm 870 890Hi rpm 1020 1060Type Propeller PropellerMaterial PP Resin PP ResinMotor Type Induction (6 poles) Induction (6 poles)Input Power W - -Output Power W 20 28Speed Hi rpm 820 820Moisture Removal L/h (Pt/h) 1.6 (3.4) 1.7 (3.6)<strong>Indoor</strong> Airflow<strong>Outdoor</strong>AirflowRefrigerationCycleLo m 3 /min (ft 3 /m) 6.5 (230) 6.8 (240)Me m 3 /min (ft 3 /m) 8.3 (293) 8.8 (311)Hi m 3 /min (ft 3 /m) 10.1 (355) 10.9 (385)Hi m 3 /min (ft 3 /m) 22.0 (780) 31.2 (1100)Control Device Capillary Tube Capillary TubeRefrigerant Oil cm 3 FV50S (320) FV50S (320)Refrigerant Type g (oz) R410A, 740 (26.1) R410A, 690 (24.4)5

PipingDimensionHeight(I/D / O/D) mm (inch) 290 (11-7/16) / 511 (20-1/8) 290 (11-7/16) / 542 (21-11/32)Width (I/D / O/D) mm (inch) 870 (34-9/32) / 650 (25-19/32) 870 (34-9/32) / 780 (30-23/32)Depth (I/D / O/D) mm (inch) 214 (8-7/16) / 230 (9-1/16) 214 (8-7/16) / 289 (11-13/32)Weight Net (I/D / O/D) kg (lb) 9 (20) / 23 (51) 9 (20) / 29 (64)Pipe Diameter (Liquid / Gas) mm (inch) 6.35 (1/4) / 9.52 (3/8) 6.35 (1/4) / 12.7 (1/2)Standard length m (ft) 7.5 (24.6) 7.5 (24.6)Length range (min – max) m (ft) 3 (9.8) ~ 15 (49.2) 3 (9.8) ~ 15 (49.2)I/D & O/D Height different m (ft) 5.0 (16.4) 5.0 (16.4)Additional Gas Amount g/m (oz/ft) 15 (0.2) 15 (0.2)Length for Additional Gas m (ft) 7.5 (24.6) 7.5 (24.6)Drain Hose<strong>Indoor</strong> HeatExchanger<strong>Outdoor</strong>HeatExchangerAir FilterInner Diameter mm 16 16Length mm 550 550Fin Material Aluminium (Pre coated) Aluminium (Pre coated)Fin Type Slit Fin Slit FinRow x Stage x FPI 2 x 15 x 17 2 x 15 x 17Size (W x H x L) mm 610 x 315 x 25.4 610 x 315 x 25.4Fin Material Aluminium (Blue coated) Aluminium (Blue coated)Fin Type Slit Fin Louver FinRow x Stage x FPI 2 x 23 x 17 1 x 20 x 19Size (W x H x L) mm 25.4 x 483 x 553.4:573.4 22 x 508 x 708Material Polypropelene PolypropeleneType One-touch One-touchPower Supply <strong>Indoor</strong> <strong>Indoor</strong>Power Supply Cord A 10 10Thermostat - -Protection Device - -<strong>Indoor</strong> Operation Range<strong>Outdoor</strong> Operation RangeDRY BULB WET BULB DRY BULB WET BULBMaximum 32 23 32 23Minimum 16 11 16 11Maximum 43 26 43 26Minimum 16 11 16 111. Cooling capacities are based on indoor temperature of 27°C DRY BULB (80.6°F DRY BULB), 19.0°C WET BULB (66°F WET BULB) andoutdoor air temperature of 35°C DRY BULB (95°F DRY BULB), 24°C WET BULB (75.2°F WET BULB)6

CoolingModel<strong>Indoor</strong> <strong>CS</strong>-PS18NKV <strong>CS</strong>-PS24NKV<strong>Outdoor</strong> CU-PS18NKV CU-PS24NKVPerformance Test Condition JIS JISPower SupplyCapacityPhase, Hz Single, 60 Single, 60V 220 220Min. Mid. Max. Min. Mid. Max.kW 1.10 5.15 6.00 1.12 5.87 6.70BTU/h 3750 17600 20500 3820 20000 22800kJ/h 3960 18540 21600 4030 21130 24120Running Current A - 7.0 - - 8.5 -Input Power W 290 1.49k 1.74k 320 1.83k 2.10kEERW/W 3.79 3.46 3.45 3.50 3.21 3.19BTU/hW 12.93 11.81 11.78 11.94 10.93 10.86kJ/hW 13.66 12.44 12.41 12.59 11.55 11.49Power Factor % - 97 - - 98 -<strong>Indoor</strong> Noise (H / L / QLo) dB-A 45 / 36 / - 46 / 37 / -<strong>Outdoor</strong> Noise (H / L / QLo) dB-A 49 / - / - 49 / - / -Max Current (A) / Max Input Power (W) 9.5 / 2.07k 12.5 / 2.50kCompressor<strong>Indoor</strong> Fan<strong>Outdoor</strong> FanSpeedStarting Current (A) 7.0 8.5Type Hermetic Motor / Rotary Hermetic Motor / RotaryMotor Type Induction (6-poles) Induction (4-poles)Output Power W 900 900Type Cross-flow fan Cross-flow fanMaterial ASG30K1 ASG30K1Motor Type Transistor (8-poles) Transistor (8-poles)Input Power W 94.8 94.8Output Power W 40 40Lo rpm 930 960Me rpm 1110 1140Hi rpm 1300 1330Type Propeller PropellerMaterial PP Resin PP ResinMotor Type Induction (6-poles) Induction (6-poles)Input Power W - -Output Power W 40 66Speed Hi rpm 840 790Moisture Removal L/h (Pt/h) 2.9 (6.1) 3.2 (6.8)<strong>Indoor</strong> Airflow<strong>Outdoor</strong>AirflowRefrigerationCycleDimensionLo m 3 /min (ft 3 /m) 12.5 (441) 13.2 (466)Me m 3 /min (ft 3 /m) 15.2 (537) 16.0 (565)Hi m 3 /min (ft 3 /m) 18.1 (640) 18.9 (670)Hi m 3 /min (ft 3 /m) 31.2 (1100) 46.0 (1620)Control Device Expansion Valve Capillary TubeRefrigerant Oil cm 3 FV50S (450) FV50S (450)Refrigerant Type g (oz) R410A, 1.04k (36.7) R410A, 900 (31.8)Height(I/D / O/D) mm (inch) 290 (11-7/16) / 542 (21-11/32) 290 (11-7/16) / 695 (27-3/8)Width (I/D / O/D) mm (inch) 1070 (42-5/32) / 780 (30-23/32) 1070 (42-5/32) / 875 (34-15/32)Depth (I/D / O/D) mm (inch) 240 (9-15/32) / 289 (11-13/32) 240 (9-15/32) / 320 (12-5/8)Weight Net (I/D / O/D) kg (lb) 12 (26) / 31 (68) 12 (26) / 44 (97)7

PipingPipe Diameter (Liquid / Gas) mm (inch) 6.35 (1/4) / 12.70 (1/2) 6.35 (1/4) / 15.88 (5/8)Standard length m (ft) 5.0 (16.4) 5.0 (16.4)Length range (min – max) m (ft) 3 (9.8) ~ 20 (65.6) 3 (9.8) ~ 20 (65.6)I/D & O/D Height different m (ft) 15 (49.2) 15 (49.2)Additional Gas Amount g/m (oz/ft) 15 (0.2) 20 (0.2)Length for Additional Gas m (ft) 10 (32.8) 10 (32.8)Drain Hose<strong>Indoor</strong> HeatExchanger<strong>Outdoor</strong>HeatExchangerAir FilterInner Diameter mm 16 16Length mm 550 550Fin Material Aluminium (Pre coated) Aluminium (Pre coated)Fin Type Slit Fin Slit FinRow x Stage x FPI 2 x 15 x 17 2 x 15 x 17Size (W x H x L) mm 810 x 315 x 25.4 810 x 315 x 25.4Fin Material Aluminium (Blue coated) Aluminium (Blue coated)Fin Type Slit Fin Slit FinRow x Stage x FPI 2 x 24 x 17 1 x 31 x 19Size (W x H x L) mm 25.4 x 504 x 693.4:713.4 12.7 x 651.0 x 868.0Material Polypropelene PolypropeleneType One-touch One-touchPower Supply <strong>Indoor</strong> <strong>Indoor</strong>Power Supply Cord A 15 20Thermostat - -Protection Device - -<strong>Indoor</strong> Operation Range<strong>Outdoor</strong> Operation RangeDRY BULB WET BULB DRY BULB WET BULBMaximum 32 23 32 23Minimum 16 11 16 11Maximum 43 26 43 26Minimum 16 11 16 111. Cooling capacities are based on indoor temperature of 27°C DRY BULB (80.6°F DRY BULB), 19.0°C WET BULB (66°F WET BULB) andoutdoor air temperature of 35°C DRY BULB (95°F DRY BULB), 24°C WET BULB (75.2°F WET BULB)8

3. Location of Controls and Components3.1 <strong>Indoor</strong> <strong>Unit</strong>3.2 <strong>Outdoor</strong> <strong>Unit</strong>3.3 Remote Control9

4. Dimensions4.1 <strong>Indoor</strong> <strong>Unit</strong>4.1.1 <strong>CS</strong>-<strong>PS9NKV</strong> <strong>CS</strong>-<strong>PS12NKV</strong>10

4.1.2 <strong>CS</strong>-PS18NKV <strong>CS</strong>-PS24NKV11

4.2 <strong>Outdoor</strong> <strong>Unit</strong>4.2.1 CU-<strong>PS9NKV</strong>4.2.2 CU-<strong>PS12NKV</strong> CU-PS18NKV12

4.2.3 CU-PS24NKV13

5. Refrigeration Cycle Diagram5.1 <strong>CS</strong>-<strong>PS9NKV</strong> CU-<strong>PS9NKV</strong> <strong>CS</strong>-<strong>PS12NKV</strong> CU-<strong>PS12NKV</strong>14

5.2 <strong>CS</strong>-PS18NKV CU-PS18NKV <strong>CS</strong>-PS24NKV CU-PS24NKV15

6. Block Diagram6.1 <strong>CS</strong>-<strong>PS9NKV</strong> CU-<strong>PS9NKV</strong>16

6.2 <strong>CS</strong>-<strong>PS12NKV</strong> CU-<strong>PS12NKV</strong>17

6.3 <strong>CS</strong>-PS18NKV CU-PS18NKV18

6.4 <strong>CS</strong>-PS24NKV CU-PS24NKV19

7. Wiring Connection Diagram7.1 <strong>Indoor</strong> <strong>Unit</strong>7.1.1 <strong>CS</strong>-<strong>PS9NKV</strong> <strong>CS</strong>-<strong>PS12NKV</strong>20

7.1.2 <strong>CS</strong>-PS18NKV <strong>CS</strong>-PS24NKV21

7.2 <strong>Outdoor</strong> <strong>Unit</strong>7.2.1 CU-<strong>PS9NKV</strong>Resistance of Compressor WindingsMODELCU-<strong>PS9NKV</strong>CONNECTION5RS092XCE21U-V 1.152ΩU-W 1.152ΩV-W 1.152Ω22

7.2.2 CU-<strong>PS12NKV</strong>Resistance of Compressor WindingsMODELCU-<strong>PS12NKV</strong>CONNECTION5RS092XCD21U-V 1.152ΩU-W 1.152ΩV-W 1.152Ω23

7.2.3 CU-PS18NKVResistance of Compressor WindingsMODELCU-PS18NKVCONNECTION5RD132XDA21U-V 1.152ΩU-W 1.152ΩV-W 1.152Ω24

7.2.4 CU-PS24NKVResistance of Compressor WindingsMODELCU-PS24NKVCONNECTION5RD132XBA21U-V 1.897ΩU-W 1.907ΩV-W 1.882Ω25

8. Electronic Circuit Diagram8.1 <strong>Indoor</strong> <strong>Unit</strong>8.1.1 <strong>CS</strong>-<strong>PS9NKV</strong> <strong>CS</strong>-<strong>PS12NKV</strong>26

8.1.2 <strong>CS</strong>-PS18NKV <strong>CS</strong>-PS24NKV27

8.2 <strong>Outdoor</strong> <strong>Unit</strong>8.2.1 CU-<strong>PS9NKV</strong>28

8.2.2 CU-<strong>PS12NKV</strong>29

8.2.3 CU-PS18NKV30

8.2.4 CU-PS24NKV31

9. Printed Circuit Board9.1 <strong>Indoor</strong> <strong>Unit</strong>9.1.1 Main Printed Circuit Board9.1.1.1 <strong>CS</strong>-<strong>PS9NKV</strong> <strong>CS</strong>-<strong>PS12NKV</strong>32

9.1.1.2 <strong>CS</strong>-PS18NKV <strong>CS</strong>-PS24NKV9.1.2 Indicator and Receiver Printed Circuit Board33

9.2 <strong>Outdoor</strong> <strong>Unit</strong>9.2.1 Main Printed Circuit Board9.2.1.1 CU-<strong>PS9NKV</strong>34

9.2.1.2 CU-<strong>PS12NKV</strong>35

9.2.1.3 CU-PS18NKV36

9.2.1.4 CU-PS24NKV37

9.2.2 Noise Filter Printed Circuit Board9.2.2.1 CU-<strong>PS9NKV</strong>38

10. Installation Instruction10.1 Select the Best Location10.1.1 <strong>Indoor</strong> <strong>Unit</strong>• Do not install the unit in excessive oil fume areasuch as kitchen, workshop and etc.• There should not be any heat source or steamnear the unit.• There should not be any obstacles blocking the aircirculation.• A place where air circulation in the room is good.• A place where drainage can be easily done.• A place where noise prevention is taken intoconsideration.• Do not install the unit near the door way.• Ensure the spaces indicated by arrows from thewall, ceiling, fence or other obstacles.• Recommended installation height for indoor unitshall be at least 2.5 m.10.1.3 <strong>Indoor</strong>/<strong>Outdoor</strong> <strong>Unit</strong> InstallationDiagram10.1.2 <strong>Outdoor</strong> <strong>Unit</strong>• If an awning is built over the unit to prevent directsunlight or rain, be careful that heat radiation fromthe condenser is not obstructed.• There should not be any animal or plant whichcould be affected by hot air discharged.• Keep the spaces indicated by arrows from wall,ceiling, fence or other obstacles.• Do not place any obstacles which may cause ashort circuit of the discharged air.• If piping length is over the [piping length foradditional gas], additional refrigerant should beadded as shown in the table.Example: For PS9***If the unit is installed at 10 m distance, the quantity ofadditional refrigerant should be 50 g….(10-7.5) m x20 g/m = 38 g.39

10.2 <strong>Indoor</strong> <strong>Unit</strong>10.2.1 How to Fix Installation PlateThe mounting wall shall be strong and solid enough to prevent if from the vibration.ModelDimension○1 ○2 ○3 ○4 ○5 ○6PS9***, PS12*** 485mm 82mm 165mm 158mm 43mm 95mmPS18***, PS24*** 585mm 82mm 165mm 158mm 169mm 219mmThe center of installation plate should be at more than at right and left of the wall.The distance from installation plate edge to ceiling should more than .From installation plate left edge to unit’s left side is .From installation plate right edge to unit’s right side is .○B: For left side piping, piping connection for liquid should be about from this line.: For left side piping, piping connection for gas should be about from this line.1 Mount the installation plate on the wall with 5 screws or more (at least 5 screws).(If mounting the unit on the concrete wall, consider using anchor bolts.)o Always mount the installation plate horizontally by aligning the marking-off line with the thread and usinga level gauge.2 Drill the piping plate hole with ø70 mm hole-core drill.o Line according to the left and right side of the installation plate. The meeting point of the extendedline is the center of the hole. Another method is by putting measuring tape at position as shown in thediagram above. The hole center is obtained by measuring the distance namely 128 mm for left andright hole respectively.o Drill the piping hole at either the right or the left and the hole should be slightly slanting to the outdoorside.10.2.2 To Drill a Hole in the Wall andInstall a Sleeve of Piping1 Insert the piping sleeve to the hole.2 Fix the bushing to the sleeve.3 Cut the sleeve until it extrudes about 15 mmfrom the wall.CAUTIONWhen the wall is hollow, please be sure to use thesleeve for tube assembly to prevent dangerscaused by mice biting the connection cable.4 Finish by sealing the sleeve with putty orcaulking compound at the final stage.40

10.2.3 <strong>Indoor</strong> <strong>Unit</strong> Installation10.2.3.1 For the right rear piping10.2.3.2 For the right and right bottompiping10.2.3.3 For the embedded piping(This can be used for left rear piping and bottompiping also.)41

10.2.4 Connect the Cable to the <strong>Indoor</strong> <strong>Unit</strong>1 The inside and outside connection cable can be connected without removing the front grille.2 Connection cable between indoor unit and outdoor unit shall be approved polychloroprene sheathed 4 x1.5 mm 2 (1.0 ~ 1.5HP) or 4 x 2.5 mm 2 (2.0 ~ 2.5HP) flexible cord, type designation 245 IEC 57 or heaviercord. Do not use joint connection cable. Replace the wire if the existing wire (from concealed wiring, orotherwise) is too short.oSecure the connection cable onto the control board with the holder.42

Note:• Isolating Devices (Disconnecting means) should have minimum 3.0 mm contact gap.• Ensure the colour of wires of outdoor unit and the terminal Nos. are the same to the indoor’s respectively.• Earth wire shall be Yellow/Green (Y/G) in colour and longer than other AC wires as shown in the figure for theelectrical safety in case of the slipping out of the cord from the anchorage.10.2.5 Wire Stripping And Connecting Requirement10.2.6 Cutting and flaring the piping1 Please cut using pipe cutter and then remove the burrs.2 Remove the burrs by using reamer. If burrs is not removed, gas leakage may be caused. Turn the piping enddown to avoid the metal powder entering the pipe.3 Please make flare after inserting the flare nut onto the copper pipes.43

10.3 <strong>Outdoor</strong> <strong>Unit</strong>10.3.1 Install the <strong>Outdoor</strong> <strong>Unit</strong>• After selecting the best location, start installation to <strong>Indoor</strong>/<strong>Outdoor</strong> <strong>Unit</strong> Installation Diagram.1 Fix the unit on concrete or rigid frame firmly and horizontally by bolt nut (ø10 mm).2 When installing at roof, please consider strong wind and earthquake.Please fasten the installation stand firmly with bolt or nails.ABCModel A B C DPS9*** 474 mm 87 mm 18.5 mm 261 mmPS12***, PS18*** 570 mm 105 mm 18.5 mm 320 mmPS24*** 613 mm 131 mm 16 mm 360.5 mmD10.3.2 Connect the Piping10.3.2.1 Connecting the piping to indoorPlease make flare after inserting flare nut (locate at jointportion of tube assembly) onto the copper pipe. (In caseof using long piping)Do not overtighten, overtightening may cause gas leakagePiping sizeTorque6.35 mm (1/4”) [18 N•m (1.8 kgf.m)]9.52 mm (3/8”) [42 N•m (4.3 kgf.m)]12.7 mm (1/2”) [55 N•m (5.6 kgf.m)]15.88 mm (5/8”) [65 N•m (6.6 kgf.m)]19.05 mm (3/4”) [100 N•m (10.2 kgf.m)]Connect the piping• Align the center of piping and sufficiently tighten theflare nut with fingers.• Further tighten the flare nut with torque wrench inspecified torque as stated in the table.10.3.2.2 Connecting the piping to outdoorDecide piping length and then cut by using pipe cutter.Remove burrs from cut edge.Make flare after inserting the flare nut (locate at valve)onto the copper pipe.Align center of piping to valves and then tighten withtorque wrench to the specified torque as stated in thetable.Spanneror WrenchTorquewrench44

10.3.3 Evacuation of the EquipmentWHEN INSTALLING AN AIR CONDITIONER, BE SURE TO EVACUATE THE AIR INSIDE THE INDOOR UNIT ANDPIPES in the following procedure.1 Connect a charging hose with a push pin to the Low side of a charging set and the service port of the 3-wayvalve.o Be sure to connect the end of the charging hose with the push pin to the service port.2 Connect the center hose of the charging set to a vacuum pump.3 Turn on the power switch of the vacuum pump and make sure that the needle in the gauge moves from0 cmHg (0 MPa) to -76 cmHg (-0.1 MPa). Then evacuate the air approximately ten minutes.4 Close the Low side valve of the charging set and turn off the vacuum pump. Make sure that the needle in thegauge does not move after approximately five minutes.Note: BE SURE TO TAKE THIS PROCEDURE IN ORDER TO AVOID REFRIGERENT GAS LEAKAGE.5 Disconnect the charging hose from the vacuum pump and from the service port of the 3-way valve.6 Tighten the service port caps of the 3-way valve at a torque of 18 N•m with a torque wrench.7 Remove the valve caps of both of the 2-way valve and 3-way valve. Position both of the valves to “OPEN”using a hexagonal wrench (4 mm).8 Mount valve caps onto the 2-way valve and the 3-way valve.o Be sure to check for gas leakage.45

10.3.4 Connect the cable to the <strong>Outdoor</strong> <strong>Unit</strong>1 Remove the control board cover from the unit by loosening the screw.2 Connection cable between indoor unit and outdoor unit shall be approved polychloroprene sheathed 4 x1.5 mm 2 (1.0 ~ 1.5HP) or 4 x 2.5 mm 2 (2.0 ~ 2.5HP) flexible cord, type designation 245 IEC 57 or heaviercord. Do not use joint connection cable. Replace the wire if the existing wire (from concealed wiring, orotherwise) is too short.3 Secure the cable onto the control board with the holder (clamper).4 Attach the control board cover back to the original position with the screw.5 For wire stripping and connection requirement, refer to instruction 10.2.4 of the indoor unit.• Earth wire shall be Yellow/Green (Y/G) in colour and longer than the other AC wires for safety reason.10.3.5 Piping Insulation1 Please carry out insulation at pipe connection portion as mentioned in <strong>Indoor</strong>/<strong>Outdoor</strong> <strong>Unit</strong> InstallationDiagram. Please wrap the insulated piping end to prevent water from going inside the piping.2 If drain hose or connecting piping is in the room (where dew may form), please increase the insulation byusing POLY-E-FOAM with thickness 6 mm or above.46

11. Operation Control11.1 Basic FunctionInverter control, which equipped with a microcomputer in determining the most suitable operation mode as timepasses, automatically adjusts output power for maximum comfort always. In order to achieve the suitable operationmode, the microcomputer maintains the set temperature by measuring the temperature of the environment andperforming temperature shifting. The compressor at outdoor unit is operating following the frequency instructed bythe microcomputer at indoor unit that judging the condition according to internal setting temperature and intake airtemperature.11.1.1 Internal Setting TemperatureOnce the operation starts, remote control setting temperature will be taken as base value for temperature shiftingprocesses. These shifting processes are depending on the air conditioner settings and the operation environment.The final shifted value will be used as internal setting temperature and it is updated continuously whenever theelectrical power is supplied to the unit.Remote Control Setting Temperature16°C ~ 30°C<strong>Indoor</strong> Air Temperature Shifting<strong>Outdoor</strong> Air Temperature ShiftingSetting Temperature Limit Checking(Min: 16°C; Max: 33°C)Internal Setting Temperature11.1.2 Cooling Operation11.1.2.1 Thermostat control• Compressor is OFF when intake Air Temperature - Internal Setting Temperature < -0.5°C.• Compressor is ON after waiting for 3 minutes, if the Intake Temperature - Internal Setting Temperature >Compressor OFF point.11.1.3 Soft Dry Operation11.1.3.1 Thermostat control• Compressor is OFF when Intake Temperature - Internal Setting Temperature < -1.0°C.• Compressor is ON after waiting for 3 minutes, if the Intake Air Temperature - Internal Setting Temperature >Compressor OFF point.11.1.3.2 Automatic Operation• This mode can be set using remote control and the operation is decided by indoor intake air temperature.• During operation mode judgment at the beginning of the Auto Mode operation, indoor fan motor (with speed ofLo-) is running for 30 seconds to detect the indoor intake air temperature.• The operation mode is decided based on below chart.23°CCoolingoperationSoft Dryoperation<strong>Indoor</strong> intakeAir Temp• After the operation mode is decided, the unit operation will follow the respective operation mode control.47

11.2 <strong>Indoor</strong> Fan Motor Operation11.2.1 Basic Rotation Speed• Manual Fan Speedo Fan motor’s number of rotation is determined according to remote control setting.Remote control ○ ○ ○ ○ ○Tab Hi Me+ Me Me- Lo• Auto Fan Speedo According to room temperature and setting temperature, indoor fan speed is determined automatically.o The indoor fan will operate according to pattern below.Fan Speed a b c d e f g h a bHigherMediumLower[1 pattern : 10s]• Feedback controlo Immediately after the fan motor is started, feedback control is performed once every second.o During fan motor on, if fan motor feedback ≥ 2550 rpm or

11.4 Airflow Direction• There are two types of airflow, vertical airflow (directed by horizontal vane) and horizontal airflow (directed byvertical vanes).• Control of airflow direction can be automatic (angles of direction is determined by operation mode, heatexchanger temperature and intake air temperature) and manual (angles of direction can be adjusted usingremote control).11.4.1 Vertical AirflowOperationModeCoolingSoft DryAirflowVane Angle (°)Direction 1 2 3 4 5Auto 10 ~ 40Manual 10 17.5 25 32.5 40Auto 10 ~ 40Manual 10 17.5 25 32.5 40PS9/12NKOperationModeCoolingSoft DryAirflowVane Angle (°)Direction 1 2 3 4 5Auto 5 ~ 35Manual 5 12.5 20 27.5 35Auto 5 ~ 35Manual 5 12.5 20 27.5 35PS18/24NK• Automatic vertical airflow direction can be set using remote control; the vane swings up and down within theangles as stated above. When the air conditioner is stopped using remote control, the vane will shift to closeposition.• Manual vertical airflow direction can be set using remote control; the angles of the vane are as stated above andthe positions of the vane are as figure below. When the air conditioner is stopped using remote control, the vanewill shift to close position.11.4.2 Horizontal AirflowThe horizontal airflow direction louvers can be adjusted manually by hand.11.5 Timer Control11.5.1 ON Timer ControlON timer can be set using remote control, where the unit with timer set will start operation earlier than the settingtime. This is to provide a comfortable environment when reaching the set ON time.60 minutes before the set ON time, indoor (at fan speed of Lo-) and outdoor fan motor start operation for 30 secondsto determine the indoor intake air temperature and outdoor air temperature in order to judge the operation startingtime.From the above judgment, the decided operation will start operation earlier than the set time as shown below.<strong>Indoor</strong> intake airtemperature (°C)30255 min10 min15 min30 35<strong>Outdoor</strong> airtemperature (°C)Cooling / Soft Dry49

11.5.2 OFF Timer ControlOFF timer can be set using remote control, where the unit with timer set will stop at set OFF time.Notes:1 By pressing ON/OFF operation button, the ON Timer or OFF Timer setting will not be cancelled.2 To cancel the previous timer setting, press CANCEL button.3 To activate the previous timer setting, press SET button.4 If main power supply is switched off, the Timer setting will be cancelled.11.6 Random Auto Restart Control• When the power supply is cut off during the operation of air conditioner, the compressor will re-operate withinthree to four minutes. There are 10 patterns to be selected randomly after power supply resumes.• This control is not applicable during OFF/ON Timer setting.• This control can be omitted by open the circuit of JP1 at indoor unit printed circuit board.11.7 Indication PanelLED POWER TIMERColor Green OrangeLight ON Operation ON Timer Setting ONLight OFF Operation OFF Timer Setting OFFNote:• If POWER LED blinks, the possible operation of the unit is operation mode judgment, or ON timer sampling.• If TIMER LED blinks, there is an abnormal operation occurs.50

12. Protection Control12.1 Restart Control (Time Delay Safety Control)• The compressor will not turn on within 3 minutes from the moment operation stops, although the unit is turned onagain by pressing OFF/ON button at remote control within this period.• This control is not applicable if the power supply is cut off and on again.• This phenomenon is to balance the pressure inside the refrigerant cycle.12.2 30 Seconds Forced Operation• Once the air conditioner is turned on, the compressor will not stop within 30 seconds in a normal operationalthough the intake air temperature has reached the thermo-off temperature. However, force stop by pressing theOFF/ON button at the remote control is permitted or the Auto OFF/ON button at indoor unit.• The reason for the compressor to force operation for minimum 30 seconds is to allow the refrigerant oil run in afull cycle and return back to the outdoor unit.12.3 Total Running Current Control• When the outdoor unit total running current (AC) exceeds X value, the frequency instructed for compressoroperation will be decreased.• If the running current does not exceed X value for 5 seconds, the frequency instructed will be increased.• However, if total outdoor unit running current exceeds Y value, compressor will be stopped immediately for 3minutes.Model PS9*** PS12*** PS18*** PS24***Operation Mode X (A) Y (A) X (A) Y (A) X (A) Y (A) X (A) Y (A)Cooling / Soft Dry (A) 5.5 15.0 6.8 15.0 10.4 14.8 12.9 19.0Cooling / Soft Dry (B) 5.0 15.0 6.3 15.0 9.5 14.8 12.4 19.0• The first 30 minutes of cooling operation, (A) will be applied.38.5°C(B)(A)37.5°C<strong>Outdoor</strong> air temperature12.4 IPM (Power Transistor) Prevention Control• Overheating Prevention Controlo When the IPM temperature rises to 100°C, compressor operation will stop immediately.o Compressor operation restarts after 3 minutes the temperature decreases to 95°C.• DC Peak Current Controlo When electric current to IPM exceeds set value of 18.5A, the compressor will stop operate. Then, operationwill restart after 3 minutes.o If the set value exceeds again more than 30 seconds after the compressor starts, the operation will restartafter 2 minutes.o If the set value exceeds again within 30 seconds after the compressor starts, the operation will restart after 1minute. If this condition repeats continuously for 7 times, all indoor and outdoor relays will be cut off.51

12.5 Low Pressure Prevention Control (Gas Leakage Detection)• Control start conditionso For 5 minutes, the compressor continuously operates and outdoor total current is between 0.65A and 1.65A.o During Cooling and Soft Dry operation:<strong>Indoor</strong> suction temperature – indoor piping temperature is below 4°C• Control contentso Compressor stops (and restart after 3 minutes).o If the conditions above happened 2 times within 20 minutes, the unit will:• Stop operation• Timer LED blinks and “F91” indicated.12.6 Compressor Tank Temperature Rise Protection Control• Control start conditionso For 5 minutes, the compressor continuously operates and outdoor total current is between 0.65A and 1.65A.o During Cooling and Soft Dry operation:• <strong>Indoor</strong> suction temperature -indoor piping temperature is below 4°C.• <strong>Indoor</strong> temperature and outdoor temperature is 30±5°C.• Remote Control setting 16°C and Hi Fan Speed.• Control contentso Compressor stops (and restart after 3 minutes)o If the conditions above happened 2 times within 20 minutes, the unit will:• Stop operation• Timer LED blinks and “F91” indicated.12.7 Low Frequency Protection Control 1• When the compressor operates at frequency lower than 24Hz continued for 20 minutes, the operation frequencywill be changed to 23Hz for 2 minutes.12.8 Low Frequency Protection Control 2• When all below conditions comply, the compressor frequency will changed to lower frequency.Temperature, T, for:Cooling / Soft Dry<strong>Indoor</strong> intake air (°C) T < 15 or T ≥ 30<strong>Outdoor</strong> air (°C) T < 16 or T ≥ 38<strong>Indoor</strong> heat exchanger (°C) T < 3012.9 <strong>Outdoor</strong> Air Temperature Control• The compressor operating frequency is regulated in accordance to the outdoor air temperature as shown in thediagram below.• This control will begin 1 minute after the compressor starts.• Compressor frequency will adjust based on outdoor air temperature.38°CFreeLimited Frequency37°C<strong>Outdoor</strong> air temperature52

12.10 Cooling Overload Control• Pipe temperature limitation / restriction.o Detects the outdoor pipe temperature and carry out restriction / limitation below (Limit the compressoroperation frequency)o The compressor stops if outdoor pipe temperature exceeds 61°C.o If the compressor stops 4 times in 20 minutes, Timer LED blinks (“F95” indicated: <strong>Outdoor</strong> high pressure riseprotection)12.11 Freeze Prevention Control• When indoor heat exchanger temperature is lower than 0°C continuously for 6 minutes, compressor will stopsoperation.• Compressor will resume its operation 3 minutes after the indoor heat exchanger is higher than 13°C.• At the same time, indoor fan speed will be higher than during its normal operation.• If the indoor heat exchanger temperature is higher than 13°C for 5 minutes, the fan speed will return to its normaloperation.12.12 Freeze Prevention Control 2• Control start conditionso During Cooling operation and soft dry operation• During Thermo OFF condition, <strong>Indoor</strong> intake temperature is less than 10°C or• Compressor stops for freeze prevention controlo Either one of the conditions above occurs 5 times in 60 minutes.• Control contentso Operation stopso Timer LED blinks and “H99” indicated12.13 Dew Prevention Control• To prevent dew formation at indoor unit discharge area.• This control will be activated if:o Cooling mode or Quiet mode is activated.o Remote control setting temperature is less than 25°C.o Fan Speed is at CLo or QLo.o Room temperature is constant (±1°C) for 30 minutes.o Compressor is continuously running.• Fan speed will be adjusted accordingly in this control.o Fan speed will be increased slowly if the unit is in quiet mode but no change in normal cooling mode.12.14 Odor Cut Control• To reduce the odor released from the unit.o Start Condition• AUTO FAN Speed is selected during COOL or DRY operation.• During freeze prevention control and timer preliminary operation, this control is not applicable.o Control content• Depends on compressor conditions:1. Compressor OFF → Compressor ON.The indoor unit fan stops temporarily and then starts to blow at minimum airflow for 30 seconds.2. Compressor ON → Compressor OFF.The indoor unit fan stops for 90 seconds and then blows at minimum airflow for 20 seconds.53

13. Servicing Mode13.1 Auto Off/On ButtonAuto OFF/ONButton PressedAuto Operation5 secTest Run Operation(Forced Cooling Operation)Auto OFF/ONButton PressedStop1 AUTO OPERATION MODEThe Auto Operation will be activated immediately once the Auto OFF/ON button is pressed. This operationcan be used to operate air conditioner with limited function if remote control is misplaced or malfunction.2 TEST RUN OPERATION (FOR PUMP DOWN/SERVICING PURPOSE)The Test Run Operation will be activated if the Auto OFF/ON button is pressed continuously for more than 5seconds. A “beep” sound will be heard at the fifth seconds, in order to identify the starting of this operation.The Auto OFF/ON button may be used together with remote control to set / change the advance setting of airconditioner operation.Main unit always continue Test Run (forced cooling) operation.5 sec 8 sec 11 sec 16 secAuto Operation Test Run Operation Remote Control Number Remote Control Receiving(Forced Cooling Operation) Switch ModeSound OFF/ONBeep Beep x 2 Beep x 3 Beep x 4Press “AC Reset”, thenany key at remote controlPress “AC Reset”, then“Check” at remote control3 REMOTE CONTROL NUMBER SWITCH MODEThe Remote Control Number Switch Mode will be activated if the Auto OFF/ON button is pressedcontinuously for more than 11 seconds (3 “beep” sounds will occur at 11 th seconds to identify the RemoteControl Number Switch Mode is in standby condition), press “AC Reset” button and then press any button atremote control to transmit and store the desired transmission code to the EEPROM.There are 4 types of remote control transmission code could be selected. The indoor unit will only operatewhen received signal with same transmission code from remote control. This could prevent signalinterference when there are 2 or more units installed nearby together.To change remote control transmission code, short or open jumpers at the remote control printed circuitboard.Remote Control Printed Circuit BoardJumper A (J-A) Jumper B (J-B) Remote Control No.Short Open A (Default)Open Open BShort Short COpen Short D4 REMOTE CONTROL RECEIVING SOUND OFF/ON MODEThe Remote Control Receiving Sound OFF/ON Mode will be activated if the Auto OFF/ON button is pressedcontinuously for more than 16 seconds (4 “beep” sounds will occur at 16 th seconds to identify the RemoteControl Receiving Sound OFF/ON Mode is in standby condition) and press “AC Reset” button and then press“Check” button at remote control.Press Auto OFF/ON button to toggle remote control receiving sound.- Short “beep”: Turn ON remote control receiving sound.- Long “beep”: Turn OFF remote control receiving sound.After Auto OFF/ON button is pressed, the 20 seconds counter for Remote Control Receiving Sound OFF/ONMode is restarted.54

13.2 Remote Control Button13.2.1 SET Button• To check remote control transmission code and store the transmission code to EEPROMo Press “Set” button for more than 10 seconds by using pointero Press “Timer Set” button unit a “beep” sound is heard as confirmation of transmission code change.13.2.2 RESET (RC) Button• To clear and restore the remote control setting to factory default.o Press once to clear the memory13.2.3 TIMER ▲• To change indoor unit indicators’ intensity:o Press continuously for 5 seconds.13.2.4 TIMER ▼• To change remote control display from Degree Celsius (°C) to Degree Fahrenheit (°F)o Press continuously for 10 seconds.55

14. Troubleshooting Guide14.1 Refrigeration Cycle SystemIn order to diagnose malfunctions, ensure the air conditioner is freefrom electrical problems before inspecting the refrigeration cycle.Such problems include insufficient insulation, problem with thepower source, malfunction of a compressor and a fan. The normaloutlet air temperature and pressure of the refrigeration cycledepends on various conditions, the standard values for them areshown in the table to the right.Normal Pressure and Outlet Air Temperature (Standard)Gas Pressure Outlet airMpaTemperature(kg/cm 2 G)(°C)Cooling Mode 0.9 ~ 1.2 (9 ~ 12) 12 ~ 16Condition: <strong>Indoor</strong> fan speed = High<strong>Outdoor</strong> temperature = 35°C at cooling mode.Compressor operate at rated frequencyDifferent in the intakeand outletair temperaturesMore than 8°C(15 minutes after anoperation is started) atcooling mode.Normal• Measuring the airtemperature differentLess than 8°C at the cooling modeValue of electric currentduring operationHigher than specifiedDusty condenserpreventing heat radiation• Measuring electric currentduring operationExcessive amountof refrigerantLower than specifiedGas sidepressureCoolingModeHighInefficient compressor• Measuring gas sidepressureLowInsufficient refrigerantLowClogged strainer orcapillary cube56

14.1.1 Relationship between the condition of the air conditioner and pressure andelectric currentCondition of theCooling Modeair conditioner Low Pressure High Pressure Electric current during operationInsufficient refrigerant(gas leakage)Clogged capillary tube orstrainer Short circuit in the indoor unit Heat radiation deficiencyof the outdoor unit Inefficient compression • Carry out the measurement of pressure, electric current, and temperature fifteen minutes after an operation is started.57

14.2 Breakdown Self Diagnosis Function14.2.1 Self Diagnosis Function (Three Digits Alphanumeric Code)• Once error occurred during operation, the unit will stop its operation, and Timer LED blinks.• Although Timer LED goes off when power supply is turned off, if the unit is operated under a breakdowncondition, the LED will ON again.• In operation after breakdown repair, the Timer LED will not blink. The last error code (abnormality) will be storedin IC memory.14.2.2 To Make a Diagnosis1 Timer LED starts to blink and the unit automatically stops the operation.2 Press the CHECK button on the remote control continuously for 5 seconds.3 “- -“ will be displayed on the remote control display.Note: Display only for “- -“ (No signal transmission, no receiving sound andno Power LED blinking)4 Press the TIMER ▲ or ▼ button on the remote control. The code “H00” (noabnormality) will be displayed and signal will be transmit to the main unit.5 Each press of the button (▲ or ▼) will increase error code number andtransmit error code signal to the main unit.6 When the latest abnormality code on the main unit and code transmittedfrom the remote control are matched, Power LED will light up for 30seconds and a “beep” sound (continuously for 4 seconds) will be heard. Ifno codes are matched, Power LED will light up for 0.5 seconds and nosound will be heard.7 The breakdown diagnosis mode will be canceled unless pressing theCHECK button continuously for 5 seconds or operating the unit for 30seconds.8 The LED will be off if the unit is turned off or the RESET button on the mainunit is pressed.14.2.3 To Display Memorized Error Code (Protective Operation)1 Turn power on.2 Press the CHECK button on the remote control3 “- -“ will be displayed on the remote control display.Note: Display only for “- -“ (No signal transmission, no receiving sound and no Power LED blinking)4 Press the TIMER ▲ or ▼ button on the remote control. The code “H00” (no abnormality) will be displayedand signal will be transmit to the main unit.5 Each press of the button (▲ or ▼) will increase error code number and transmit error code signal to the mainunit.6 When the latest abnormality code on the main unit and code transmitted from the remote control are matched,Power LED will light up for 30 seconds and a “beep” sound (continuously for 4 seconds) will be heard. If nocodes are matched, Power LED will light up for 0.5 seconds and no sound will be heard.7 The breakdown diagnosis mode will be canceled unless pressing the CHECK button continuously for 5seconds or operating the unit for 30 seconds.8 The same diagnosis can be repeated by turning power on again.14.2.4 To Clear Memorized Error Code after Repair (Protective Operation)1 Turn power on (in standby condition).2 Press the AUTO button for 5 seconds (a “beep” sound is heard) on the main unit to operate the unit atForced Cooling Operation Mode.3 Press the CHECK button on the remote control for about 1 second with a pointed object to transmit signal tomain unit. A “beep” sound is heard, and the Error Code is cleared.14.2.5 Temporary Operation (Depending On Breakdown Status)1 Press the Auto OFF/ON button on the main unit (a “beep” sound is heard) to operate the unit. (Remotecontrol is enable again).2 The unit can be temporarily be used until repaired.Error Code Operation Temporary itemsH23CoolingH27, H28 CoolingEmergency Operationwith limited power58

14.3 Error Code TableDiagnosisEmergencyAbnormality / Protection control Abnormality JudgmentdisplayOperationPrimary location to verifyH00 No abnormality detected - Normal operationH11 <strong>Indoor</strong> / <strong>Outdoor</strong> abnormalcommunication> 1 min after startingoperation<strong>Indoor</strong> fan operationonly• Internal / external cable connection• <strong>Indoor</strong> / outdoor PCBH12 Connection capability rank abnormality Continuously for 90 sec- -after power suppliedH14 <strong>Indoor</strong> intake air temperature sensorabnormalityContinue for 5 sec. - • Intake air temperature sensor(defective or disconnected)H15 <strong>Outdoor</strong> compressor temperature sensorabnormalityContinue for 5 sec. - • Compressor temperature sensor(defective or disconnected)H16 <strong>Outdoor</strong> current transformer open circuit - - • <strong>Outdoor</strong> PCB• IPM (Power transistor) moduleH19 <strong>Indoor</strong> fan motor mechanism locked 7 occurrencescontinuously- • <strong>Indoor</strong> PCB• Fan motorH23 <strong>Indoor</strong> heat exchanger temperaturesensor abnormalityContinue for 5 sec. ○ • Heat exchanger temperature sensor(defective or disconnected)H27 <strong>Outdoor</strong> air temperature sensorabnormalityContinue for 5 sec. ○ • <strong>Outdoor</strong> temperature sensor(defective or disconnected)H28 <strong>Outdoor</strong> heat exchanger temperaturesensor abnormalityContinue for 5 sec. ○ • <strong>Outdoor</strong> heat exchangertemperature sensor (defective ordisconnected)H30 <strong>Outdoor</strong> discharge pipe temperaturesensor abnormalityContinue for 5 sec. ○ • <strong>Outdoor</strong> discharge pipe temperaturesensor (defective or disconnected)H33 <strong>Indoor</strong> / outdoor wrong connection - - • <strong>Indoor</strong> / outdoor supply voltageH38 <strong>Indoor</strong> / outdoor mismatch (brand code) - - -H97 <strong>Outdoor</strong> fan motor mechanism locked 2 occurrences within 30minutes- • <strong>Outdoor</strong> PCB• <strong>Outdoor</strong> Fan MotorH98 <strong>Indoor</strong> temperature rise abnormality - - • Air filter dirty• Air circulation short circuitH99 <strong>Indoor</strong> heat exchanger freeze prevention- - • Insufficient refrigerantprotection• Air filter dirtyF11 4 way valve switching failure * 4 occurrences within 30- • 4-way valveminutes• v-coilF90 System and compressor microcomputer 2 occurrences within 5- • Compressorcommunication error(for S10*** only)seconds• <strong>Outdoor</strong> PCBF90 Power factor correction abnormality 4 occurrences within 20- • <strong>Outdoor</strong> PCBminutesF91 Refrigerant cycle abnormal 2 occurrences within 20minutes- • No refrigerant ( 3-way valve isclosed)F93 <strong>Outdoor</strong> compressor abnormal revolution 4 occurrences within 20- • <strong>Outdoor</strong> compressorminutesF95 Cooling high pressure protection 4 occurrences within 20- • <strong>Outdoor</strong> refrigerant circuitF96Intelligent power transistor overheatingprotectionminutesF97 Compressor temperature rise protectioncontrolF98 Total running current protection 3 times occurrence withinF99<strong>Outdoor</strong> direct current (DC) peakdetection- • Excess refrigerant• Improper heat radiation• IPM (Power transistor)4 times occurrence within- • Insufficient refrigerant20 minutes• Compressor- • Excess refrigerant20 minutes• Improper heat radiation7 times occurrencecontinuously- • <strong>Outdoor</strong> PCB• IPM (Power transistor)• CompressorNote:“○” – Frequency measured and fan speed fixed“ * ”– For cooling only model, it is the indication when indoor heat exchanger sensor or indoor air intake sensor hasabnormality.The memory data of error code is erased when the power supply is cut off, or press the Auto Switch until “beep”sound heard following by pressing the CHECK button at remote control.Although operation forced to stop when abnormality detected, emergency operation is possible for certain errors(refer to Error Code Table) by using remote control or Auto OFF/ON button at indoor unit. However, the remotecontrol signal receiving sound is changed from one “beep” to four “beep” sounds.59

14.4 Troubleshooting Flowchart14.4.1 H11 (<strong>Indoor</strong>/<strong>Outdoor</strong> Abnormal Communication)Malfunction Decision Conditions• During startup and operation of cooling and heating, the data received from outdoor unit in indoor unit signaltransmission is checked whether it is normal.Malfunction Caused• Faulty indoor unit PCB.• Faulty outdoor unit PCB.• <strong>Indoor</strong> unit-outdoor unit signal transmission error due to wrong wiring.• <strong>Indoor</strong> unit-outdoor unit signal transmission error due to breaking of wire in the connection wires between theindoor and outdoor units.• <strong>Indoor</strong> unit-outdoor unit signal transmission error due to disturbed power supply waveform.Troubleshooting60

14.4.2 H12 (<strong>Indoor</strong>/<strong>Outdoor</strong> Capacity Rank Mismatched)Malfunction Decision Conditions• During startup, error code appears when different types of indoor and outdoor units are interconnected.Malfunction Caused• Wrong models interconnected.• Wrong indoor unit or outdoor unit PCBs mounted.• <strong>Indoor</strong> unit or outdoor unit PCBs defective.• <strong>Indoor</strong>-outdoor unit signal transmission error due to wrong wiring.• <strong>Indoor</strong>-outdoor unit signal transmission error due to breaking of wire 3 in the connection wires between the indoorand outdoor units.Troubleshooting61

14.4.3 H14 (<strong>Indoor</strong> Intake Air Temperature Sensor Abnormality)Malfunction Decision Conditions• During startup and operation of cooling and heating, the temperatures detected by the indoor intake airtemperature sensor are used to determine sensor errors.Malfunction Caused• Faulty connector connection.• Faulty sensor.• Faulty PCB.Troubleshooting62

14.4.4 H15 (Compressor Temperature Sensor Abnormality)Malfunction Decision Conditions• During startup and operation of cooling and heating, the temperatures detected by the outdoor compressortemperature sensor are used to determine sensor errors.Malfunction Caused• Faulty connector connection.• Faulty sensor.• Faulty PCB.Troubleshooting63

14.4.5 H16 (<strong>Outdoor</strong> Current Transformer Open Circuit)Malfunction Decision Conditions• A current transformer (CT) is detected by checking the compressor running frequency (≥ rated frequency) andCT detected input current (less than 1.14A) for continuously 20 seconds.Malfunction Caused• CT defective• <strong>Outdoor</strong> PCB defective• Compressor defective (low compression)Troubleshooting64

14.4.6 H19 (<strong>Indoor</strong> Fan Motor – DC Motor Mechanism Locked)Malfunction Decision Conditions• The rotation speed detected by the Hall IC during fan motor operation is used to determine abnormal fan motor(feedback of rotation > 2550rpm or < 50rpm)Malfunction Caused• Operation stops due to short circuit inside the fan motor winding.• Operation stops due to breaking of wire inside the fan motor.• Operation stops due to breaking of fan motor lead wires.• Operation stops due to Hall IC malfunction.• Operation error due to faulty indoor unit PCB.Troubleshooting65

14.4.7 H23 (<strong>Indoor</strong> Pipe Temperature Sensor Abnormality)Malfunction Decision Conditions• During startup and operation of cooling and heating, the temperatures detected by the indoor heat exchangertemperature sensor are used to determine sensor errors.Malfunction Caused• Faulty connector connection.• Faulty sensor.• Faulty PCB.Troubleshooting66

14.4.8 H27 (<strong>Outdoor</strong> Air Temperature Sensor Abnormality)Malfunction Decision Conditions• During startup and operation of cooling and heating, the temperatures detected by the outdoor air temperaturesensor are used to determine sensor errors.Malfunction Caused• Faulty connector connection.• Faulty sensor.• Faulty PCB.Troubleshooting67

14.4.9 H28 (<strong>Outdoor</strong> Pipe Temperature Sensor Abnormality)Malfunction Decision Conditions• During startup and operation of cooling and heating, the temperatures detected by the outdoor pipe temperaturesensor are used to determine sensor errors.Malfunction Caused• Faulty connector connection.• Faulty sensor.• Faulty PCB.Troubleshooting68

14.4.10 H33 (Unspecified Voltage between <strong>Indoor</strong> and <strong>Outdoor</strong>)Malfunction Decision Conditions• The supply power is detected for its requirement by the indoor/outdoor transmission.Malfunction Caused• Wrong models interconnected.• Wrong indoor unit and outdoor unit PCBs used.• <strong>Indoor</strong> unit or outdoor unit PCB defective.Troubleshooting69

14.4.11 H98 (<strong>Indoor</strong> High Pressure Protection)Error Code will not display (no Timer LED blinking) but store in EEPROMMalfunction Decision Conditions• During heating operation, the temperature detected by the indoor pipe temperature sensor is above 60°C.Malfunction Caused• Clogged air filter of the indoor unit• Dust accumulation on the indoor unit heat exchanger• Air short circuit• Detection error due to faulty indoor pipe temperature sensor• Detection error due to faulty indoor unit PCBTroubleshooting70

14.4.12 H99 (<strong>Indoor</strong> Freeze Prevention Protection: Cooling or Soft Dry)Malfunction Decision Conditions• Freeze prevention control takes place (when indoor pipe temperature is lower than 2°C)Malfunction Caused• Clogged air filter of the indoor unit• Dust accumulation on the indoor unit heat exchanger• Air short circuit• Detection error due to faulty indoor pipe temperature sensor• Detection error due to faulty indoor unit PCBTroubleshooting71

14.4.13 F11 (<strong>Indoor</strong> Pipe Temperature Sensor Abnormality)Malfunction Decision Conditions• When cooling operation, when indoor pipe temperature or indoor heat exchanger temperature sensor is above45°C.Malfunction Caused• Faulty connector connection.• Faulty indoor pipe temperature sensor.• Faulty indoor main PCB.Troubleshooting72

14.4.14 F90 (Power Factor Correction Protection)Malfunction Decision Conditions• During startup and operation of cooling and heating, when Power Factor Correction (PFC) protection circuitry atthe outdoor unit main PCB senses abnormal high DC voltage level.Malfunction Caused• DC voltage peak due to power supply surge.• DC voltage peak due to compressor windings not uniform.• Faulty outdoor PCB.Troubleshooting73

14.4.15 F91 (Refrigeration Cycle Abnormality)Malfunction Decision Conditions• During cooling, compressor frequency = Fcmax.• During cooling and heating operation, running current: 0.65A < I < 1.65A.• During cooling, indoor intake - indoor pipe < 4°C.Malfunction Caused• Refrigerant shortage (refrigerant leakage)• Poor compression performance of compressor.• 2/3 way valve closed.• Detection error due to faulty indoor intake air or indoor pipe temperature sensors.Troubleshooting74

14.4.16 F93 (Compressor Rotation Failure)Malfunction Decision ConditionsA compressor rotation failure is detected by checking the compressor running condition through the positiondetection circuit.Malfunction Caused• Compressor terminal disconnect• <strong>Outdoor</strong> PCB malfunctionTroubleshooting75

14.4.17 F95 (Cooling High Pressure Abnormality)Malfunction Decision ConditionsDuring operation of cooling, when outdoor unit heat exchanger high temperature data (61°C) is detected by theoutdoor pipe temperature sensor.Malfunction Caused• <strong>Outdoor</strong> pipe temperature rise due to short circuit of hot discharge air flow.• <strong>Outdoor</strong> pipe temperature rise due to defective of outdoor fan motor.• <strong>Outdoor</strong> pipe temperature rise due to defective outdoor pipe temperature sensor.• <strong>Outdoor</strong> pipe temperature rise due to defective outdoor unit PCB.Troubleshooting76

14.4.18 F96 (IPM Overheating)Malfunction Decision ConditionsDuring operating of cooling and heating, when IPM temperature data (100°C) is detected by the IPM temperaturesensor.Malfunction Caused• IPM overheats due to short circuit of hot discharge air flow.• IPM overheats due to defective of outdoor fan motor.• IPM overheats due to defective of internal circuitry of IPM.• IPM overheats due to defective IPM temperature sensor.Troubleshooting77

14.4.19 F97 (Compressor Overheating)Malfunction Decision ConditionsDuring operation of cooling and heating, when compressor tank temperature data (112°C) is detected by thecompressor tank temperature sensor.Malfunction Caused• Refrigerant shortage (refrigerant leakage).• 2/3 way valve closed.• Detection error due to faulty compressor tank temperature sensor.Troubleshooting78

14.4.20 F98 (Input Over Current Detection)Malfunction Decision ConditionsDuring cooling and heating operation, when an input over-current (X value in Total Running Current Control) isdetected by checking the input current value being detected by current transformer (CT) with the compressor running.Malfunction Caused• Over-current due to compressor failure.• Over-current due to defective outdoor unit PCB.• Over-current due to defective inverter main circuit electrolytic capacitor.• Over-current due to excessive refrigerant.Troubleshooting79

14.4.21 F99 (Output Over Current Detection)Malfunction Decision ConditionsDuring operation of cooling and heating, when an output over-current (18.5A) is detected by checking the current thatflows in the inverter DC peak sensing circuitry.Malfunction Caused• DC peak due to compressor failure.• DC peak due to defective power transistor(s).• DC peak due to defective outdoor unit PCB.Troubleshooting• Checking the power transistor• Never touch any live parts for at least 10 minutes after turning off the circuit breaker.• If unavoidable necessary to touch a live part, make sure the power transistor’s supply voltage is below 50V usingthe tester.• For the UVW, make measurement at the Faston terminal on the board of the relay connector.Tester’s negative terminal Power transistor (+) UVW Power transistor (-) UVWTester’s positive terminal UVW Power transistor (+) UVW Power transistor (-)Normal resistanceSeveral kΩ to several MΩAbnormal resistance0 or ∞80

15. Disassembly and Assembly InstructionsWARNINGHigh Voltage is generated in the electrical parts area by the capacitor. Ensure that the capacitor has discharged sufficiently before proceeding withrepair work. Failure to heed this caution may result in electric shocks.15.1 <strong>CS</strong>-PS9/12NKV15.1.1 <strong>Indoor</strong> Electronic Controllers, Cross Flow Fan and <strong>Indoor</strong> Fan Motor RemovalProcedures15.1.1.1 To remove front grilleFigure 115.1.2 To remove electronic controllerFigure 281

Figure 3 Figure 415.1.3 To remove discharge grille10. Pull out to remove the drain hosefrom the discharge grille11. Then pull the discharge grilledownward gently to dismantle itFigure 582

15.1.4 To remove control board12. Remove 4 screws holding thecontrol board then pull out thecontrol board.Figure 615.1.5 To remove cross flow fan and indoor fan motor13. Remove the screw that holdingthe cross flow fan and fan motoraxis.Figure 715. Remove the bearing by pulling itout gently14. Remove the screw from theevaporator.Figure 883

16. Push the holdfast to the left and lift up the evaporator.Evaporator17. Remove the cross flow fan from the unit bypulling it to the left and downward.Figure 918. Fan motor can be removed after theremoval of cross flow fan.Reminder: To reinstall the fan motor, adjustthe fan motor connector to 45° towards youbefore fixing control board.Figure 10Reminder: To reinstall the cross flowfan, ensure cross flow fan is in line asshown in figure 1084

WARNINGHigh Voltage is generated in the electrical parts area by the capacitor. Ensure that the capacitor has discharged sufficiently before proceeding withrepair work. Failure to heed this caution may result in electric shocks.15.2 <strong>CS</strong>-PS18/24NKV15.2.1 <strong>Indoor</strong> Electronic Controllers, Cross Flow Fan and <strong>Indoor</strong> Fan Motor RemovalProcedures15.2.1.1 To remove front grilleFigure 1115.2.2 To remove electronic controllerFigure 1285

Figure 13 Figure 1415.2.3 To remove discharge grilleFigure 1586

15.2.4 To remove control boardFigure 1615.2.5 To remove cross flow fan and indoor fan motorFigure 17Figure 1887

Figure 19Figure 2088

16. Technical Data16.1 Operation Characteristics16.1.1 <strong>CS</strong>-<strong>PS9NKV</strong> CU-<strong>PS9NKV</strong>• Cooling Characteristico Room temperature: 27°C (DBT), 19°C (WBT)o Operation condition: High fan speedo Piping length: 7.5mo Compressor Frequency = FcOutlet AirTempeature (°C)16.10015.90015.70015.50015.30015.10014.90014.70014.50014.30030 31 32 33 34 35 36 37 38 39 40 41 42 43<strong>Outdoor</strong> Air Temperature (°C)220CoolingCapacity (kW)2.8002.7002.6002.5002.4002.3002.2002.10030 31 32 33 34 35 36 37 38 39 40 41 42 43<strong>Outdoor</strong> Air Temperature (°C)4.0003.800Current(A)3.6003.4003.2003.00030 31 32 33 34 35 36 37 38 39 40 41 42 43<strong>Outdoor</strong> Air Temperature (°C)1.1701.160Gas Side PipingPressure (MPa)1.1501.1401.1301.12030 31 32 33 34 35 36 37 38 39 40 41 42 43<strong>Outdoor</strong> Air Temperature (°C)89

• Piping Length Characteristico Room temperature: 27°C (DBT), 19°C (WBT)o Operation condition: High fan speedo <strong>Outdoor</strong> temperature: 35°C (DBT), 24°C (WBT)o Compressor Frequency = Fc15.30022015.200Outlet AirTemperature (°C)15.10015.00014.90014.8003 4 5 6 7 8 9 10 11 12 13 14 15Piping Length (m)2.700CoolingCapacity (kW)2.6002.5002.4003 4 5 6 7 8 9 10 11 12 13 14 15Piping Length (m)1.1541.152Gas Side PipingPressure (MPa)1.1501.1481.1461.1441.1421.1403 4 5 6 7 8 9 10 11 12 13 14 15Piping Length (m)3.4503.400Current(A)3.3503.3003 4 5 6 7 8 9 10 11 12 13 14 15Piping Length (m)90

16.1.2 <strong>CS</strong>-<strong>PS12NKV</strong> CU-<strong>PS12NKV</strong>• Cooling Characteristico Room temperature: 27°C (DBT), 19°C (WBT)o Operation condition: High fan speedo Piping length: 7.5mo Compressor Frequency = Fc16.90022016.400Outlet AirTempeature (°C)15.90015.40014.90030 31 32 33 34 35 36 37 38 39 40 41 42 43<strong>Outdoor</strong> Air Temperature (°C)CoolingCapacity (kW)3.3003.2003.1003.0002.9002.8002.7002.60030 31 32 33 34 35 36 37 38 39 40 41 42 43<strong>Outdoor</strong> Air Temperature (°C)4.7004.500Current(A)4.3004.1003.9003.70030 31 32 33 34 35 36 37 38 39 40 41 42 43<strong>Outdoor</strong> Air Temperature (°C)1.1101.100Gas Side PipingPressure (MPa)1.0901.0801.0701.06030 31 32 33 34 35 36 37 38 39 40 41 42 43<strong>Outdoor</strong> Air Temperature (°C)91

• Piping Length Characteristico Room temperature: 27°C (DBT), 19°C (WBT)o Operation condition: High fan speedo <strong>Outdoor</strong> temperature: 35°C (DBT), 24°C (WBT)o Compressor Frequency = Fc22015.90015.800Outlet AirTemperature (°C)15.70015.60015.50015.4003 4 5 6 7 8 9 10 11 12 13 14 15Piping Length (m)3.200CoolingCapacity (kW)3.1003.0002.9003 4 5 6 7 8 9 10 11 12 13 14 15Piping Length (m)1.100Gas Side PipingPressure (MPa)1.0951.0901.0851.0803 4 5 6 7 8 9 10 11 12 13 14 15Piping Length (m)4.0504.000Current(A)3.9503.9003 4 5 6 7 8 9 10 11 12 13 14 15Piping Length (m)92

16.1.3 <strong>CS</strong>-PS18NKV CU-PS18NKV• Cooling Characteristico Room temperature: 27°C (DBT), 19°C (WBT)o Operation condition: High fan speedo Piping length: 5mo Compressor Frequency = Fc15.50022015.300Outlet AirTempeature (°C)15.10014.90014.70014.50030 31 32 33 34 35 36 37 38 39 40 41 42 43<strong>Outdoor</strong> Air Temperature (°C)5.6005.400CoolingCapacity (kW)5.2005.0004.8004.60030 31 32 33 34 35 36 37 38 39 40 41 42 43<strong>Outdoor</strong> Air Temperature (°C)8.1007.600Current(A)7.1006.6006.10030 31 32 33 34 35 36 37 38 39 40 41 42 43<strong>Outdoor</strong> Air Temperature (°C)1.0301.020Gas Side PipingPressure (MPa)1.0101.0000.9900.9800.9700.96030 31 32 33 34 35 36 37 38 39 40 41 42 43<strong>Outdoor</strong> Air Temperature (°C)93

• Piping Length Characteristico Room temperature: 27°C (DBT), 19°C (WBT)o Operation condition: High fan speedo <strong>Outdoor</strong> temperature: 35°C (DBT), 24°C (WBT)o Compressor Frequency = Fc22015.30015.200Outlet AirTemperature (°C)15.10015.00014.90014.80014.7003 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20Piping Length (m)5.200CoolingCapacity (kW)5.1005.0004.9003 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20Piping Length (m)0.9950.990Gas Side PipingPressure (MPa)0.9850.9800.9750.9703 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20Piping Length (m)7.1007.000Current(A)6.9006.8006.7006.6003 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20Piping Length (m)94

16.1.4 <strong>CS</strong>-PS24NKV CU-PS24NKV• Cooling Characteristico Room temperature: 27°C (DBT), 19°C (WBT)o Operation condition: High fan speedo Piping length: 5mo Compressor Frequency = Fc16.20022016.000Outlet AirTempeature (°C)15.80015.60015.40015.20030 31 32 33 34 35 36 37 38 39 40 41 42 43<strong>Outdoor</strong> Air Temperature (°C)6.3006.100CoolingCapacity (kW)5.9005.7005.5005.30030 31 32 33 34 35 36 37 38 39 40 41 42 43<strong>Outdoor</strong> Air Temperature (°C)10.0009.500Current(A)9.0008.5008.0007.50030 31 32 33 34 35 36 37 38 39 40 41 42 43<strong>Outdoor</strong> Air Temperature (°C)0.960Gas Side PipingPressure (MPa)0.9400.9200.9000.88030 31 32 33 34 35 36 37 38 39 40 41 42 43<strong>Outdoor</strong> Air Temperature (°C)95

• Piping Length Characteristico Room temperature: 27°C (DBT), 19°C (WBT)o Operation condition: High fan speedo <strong>Outdoor</strong> temperature: 35°C (DBT), 24°C (WBT)o Compressor Frequency = Fc16.00022015.900Outlet AirTemperature (°C)15.80015.70015.60015.50015.4003 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20Piping Length (m)6.0005.900CoolingCapacity (kW)5.8005.7005.6003 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20Piping Length (m)0.9150.910Gas Side PipingPressure (MPa)0.9050.9000.8950.8903 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20Piping Length (m)8.6008.5008.400Current(A)8.3008.2008.1008.0003 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20Piping Length (m)96

17. Exploded View and Replacement Parts List17.1 <strong>Indoor</strong> <strong>Unit</strong>17.1.1 <strong>CS</strong>-<strong>PS9NKV</strong> <strong>CS</strong>-<strong>PS12NKV</strong>NoteThe above exploded view is for the purpose of parts disassembly and replacement.The non-numbered parts are not kept as standard service parts.97