Optical Remote Control Compatible, High-Accuracy Digital Indicator

Optical Remote Control Compatible, High-Accuracy Digital Indicator

Optical Remote Control Compatible, High-Accuracy Digital Indicator

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

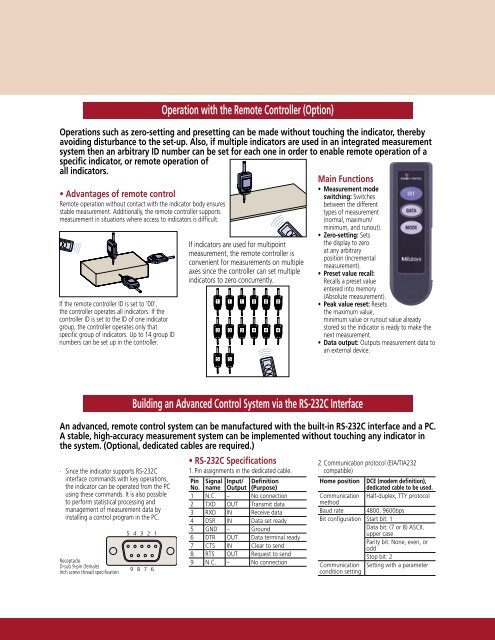

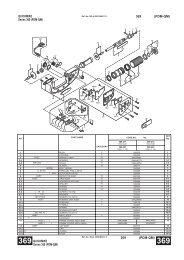

Operations such as zero-setting and presetting can be made without touching the indicator, therebyavoiding disturbance to the set-up. Also, if multiple indicators are used in an integrated measurementsystem then an arbitrary ID number can be set for each one in order to enable remote operation of aspecific indicator, or remote operation ofall indicators.• Advantages of remote control<strong>Remote</strong> operation without contact with the indicator body ensuresstable measurement. Additionally, the remote controller supportsmeasurement in situations where access to indicators is difficult.If the remote controller ID is set to '00',the controller operates all indicators. If thecontroller ID is set to the ID of one indicatorgroup, the controller operates only thatspecific group of indicators. Up to 14 group IDnumbers can be set up in the controller.Operation with the <strong>Remote</strong> <strong>Control</strong>ler (Option)If indicators are used for multipointmeasurement, the remote controller isconvenient for measurements on multipleaxes since the controller can set multipleindicators to zero concurrently.Main Functions• Measurement modeswitching: Switchesbetween the differenttypes of measurement(normal, maximum/minimum, and runout).• Zero-setting: Setsthe display to zeroat any arbitraryposition (Incrementalmeasurement).• Preset value recall:Recalls a preset valueentered into memory(Absolute measurement).• Peak value reset: Resetsthe maximum value,minimum value or runout value alreadystored so the indicator is ready to make thenext measurement.• Data output: Outputs measurement data toan external device.An advanced, remote control system can be manufactured with the built-in RS-232C interface and a PC.A stable, high-accuracy measurement system can be implemented without touching any indicator inthe system. (Optional, dedicated cables are required.)· Since the indicator supports RS-232Cinterface commands with key operations,the indicator can be operated from the PCusing these commands. It is also possibleto perform statistical processing andmanagement of measurement data byinstalling a control program in the PC.ReceptacleD-sub 9-pin (female)Inch screw thread specificationBuilding an Advanced <strong>Control</strong> System via the RS-232C Interface5 4 3 2 19 876• RS-232C Specifications1. Pin assignments in the dedicated cable.Pin Signal DefinitionNo. name Output (Purpose)1 N.C. – No connection2 TXD OUT Transmit data3 RXD IN Receive data4 DSR IN Data set ready5 GND – Ground6 DTR OUT Data terminal ready7 CTS IN Clear to send8 RTS OUT Request to send9 N.C. – No connection2. Communication protocol (EIA/TIA232compatible)Home position DCE (modem definition),dedicated cable to be used.Communication Half-duplex, TTY protocolmethodBaud rate 4800, 9600bpsBit configuration Start bit: 1Data bit: (7 or 8) ASCII,upper caseParity bit: None, even, oroddStop bit: 2Communication Setting with a parametercondition setting