MicroMaster 6SE92 - ECT Sales & Service

MicroMaster 6SE92 - ECT Sales & Service

MicroMaster 6SE92 - ECT Sales & Service

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

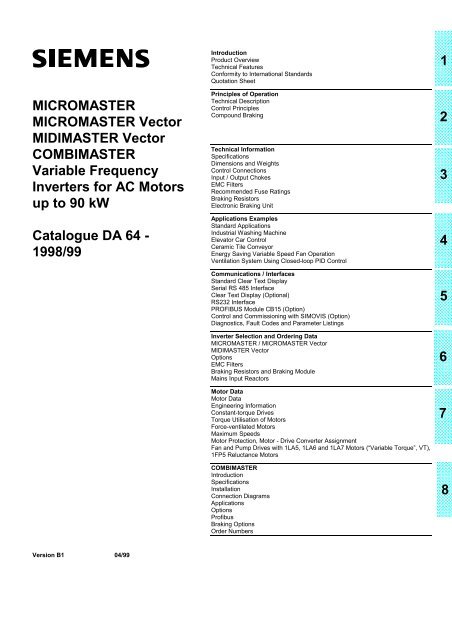

MICROMASTERMICROMASTER VectorMIDIMASTER VectorCOMBIMASTERVariable FrequencyInverters for AC Motorsup to 90 kWCatalogue DA 64 -1998/99IntroductionProduct OverviewTechnical FeaturesConformity to International StandardsQuotation SheetPrinciples of OperationTechnical DescriptionControl PrinciplesCompound BrakingTechnical InformationSpecificationsDimensions and WeightsControl ConnectionsInput / Output ChokesEMC FiltersRecommended Fuse RatingsBraking ResistorsElectronic Braking UnitApplications ExamplesStandard ApplicationsIndustrial Washing MachineElevator Car ControlCeramic Tile ConveyorEnergy Saving Variable Speed Fan OperationVentilation System Using Closed-loop PID ControlCommunications / InterfacesStandard Clear Text DisplaySerial RS 485 InterfaceClear Text Display (Optional)RS232 InterfacePROFIBUS Module CB15 (Option)Control and Commissioning with SIMOVIS (Option)Diagnostics, Fault Codes and Parameter ListingsInverter Selection and Ordering DataMICROMASTER / MICROMASTER VectorMIDIMASTER VectorOptionsEMC FiltersBraking Resistors and Braking ModuleMains Input ReactorsMotor DataMotor DataEngineering InformationConstant-torque DrivesTorque Utilisation of MotorsForce-ventilated MotorsMaximum SpeedsMotor Protection, Motor - Drive Converter AssignmentFan and Pump Drives with 1LA5, 1LA6 and 1LA7 Motors (“Variable Torque”, VT),1FP5 Reluctance MotorsCOMBIMASTERIntroductionSpecificationsInstallationConnection DiagramsApplicationsOptionsProfibusBraking OptionsOrder Numbers12345678Version B1 04/99

MICROMASTERMICROMASTER VectorMIDIMASTER VectorIntroduction1. Introduction 1/11.1 Product Overview 1/11.2 Technical Features 1/21.3 Conformity to International Standards 1/31.3.1 CE Mark 1/31.3.2 Electromagnetic Compatibility 1/3Quotation Sheet 1/4

MICROMASTERMICROMASTER VectorMIDIMASTER VectorIntroduction1. INTRODUCTIONThe MICROMASTER, MICROMASTER Vector, andMIDIMASTER Vector family of standard drives from Siemensuses the latest IGBT power technology and are the result ofmany years of experience in the field of inverter technology.A fully compatible range is offered from 120W to 75kW, or upto 90kW for applications with a quadratic speed/torquecharacteristic, with high performance Sensorless VectorControl as standard. This offers the user the benefits of hightorque and dynamic performance across a broad spectrum ofapplications.A parallel range of non-vector drives, the MICROMASTER,from 120W to 7.5kW is ideal for embedded control of low endmachines.For the ultimate in variable speed drive packaging, theCOMBIMASTER is on offer (see Section 8), combining motorand inverter in one compact unit.Ease of use, an excellent price/performance ratio andcompact size are guaranteed, along with conformance to thehighest quality and reliability standards in the world.1.1 Product OverviewThe MICROMASTER, MICROMASTER Vector andMIDIMASTER Vector are intended for use anywhere in theworld and therefore support a wide range of mains voltages:- An RS485 serial interface is standard, allowing up to 31drives to be networked to a PLC or PC.- The drive may be enabled via the keypad, via digitalinputs or over the standard RS485 serial interface.- The motor speed setpoint can be selected, using a digitalsetpoint, motorised potentiometer, fixed frequency,analogue input or via the serial link.- Mixed mode control is also available, allowing drivecontrol and setpoint input to be from different sources.- A DC injection brake is incorporated, allowing DC to beoutput even when the motor is stationary.- The drives can be configured to start automaticallyfollowing a mains break or after a fault.- The parameter sets are fully compatible between thedifferent product types, reducing the learning time.- All drives are certified in accordance with VDE, UL andCanadian UL, and are manufactured to ISO9001.- All drives conform to the requirements of the EC lowvoltage directive 73/23/EEC and have been awarded theCE mark.- All drives are guaranteed Y2K (year 2000) compliant.1/3 phase 208-240V±15%3 phase 380 - 500V±10%3 phase 525 - 575V±15% (MIDIMASTERVector only)Two levels of operational characteristics are offered:- MICROMASTER Vector/MIDIMASTER Vector offer highperformance Sensorless Vector Control for high torque atlow speeds and excellent dynamic performance. Thisallows use of the drive even in demanding applicationssuch as lifts, hoists and industrial washing machines.- MICROMASTER offers standard open loop V/F Controland is ideal for simple applications such as pumps andfans.- Both ranges of drives benefit from the standard inclusionof a PID controller (PI for the MICROMASTER) for closedloop process control.- All the products make use of the same, simple to use,standard user interface consisting of seven push buttonsand LED display.- User-friendly screwless terminals are used for the controlconnections.Siemens DA 64 – 1998/99 (04/99) 1/1

IntroductionMICROMASTERMICROMASTER VectorMIDIMASTER Vector1.2 Technical FeaturesDRIVE MICROMASTER MICROMASTERVectorMains VoltagePower Ranges1 AC 230V3 AC 230V3 AC 380-500V3 AC 525-575V1 AC 208 V-240 V±10%3 AC 208 V-240 V±10%3 AC 380 V - 500 V±10%120 W - 3.0 kW120 W - 4.0 kW370 W - 7.5 kWMIDIMASTER Vector3 AC 208 V - 240 V±10%3 AC 380 V - 500 V±10%3 AC 525 V - 575 V±15%5.5 (VT 7.5)kW – 45 (VT 45)kW11 (VT 15)kW – 75 (VT 90)kW2.2 (VT 4)kW – 37 (VT 45)kWProtection Level IP20/NEMA1 IP21/NEMA1 or IP56Conformance to55011 A EMC1 AC 230V3 AV 230V3 AC 380-500V3 AC 525-575VConformance to55011 B EMC1 AC 230V3 AV 230V3 AC 380-500V3 AC 525-575VIntegrated FilterFootprint FilterFootprint FilterFootprint FilterFootprint FilterFootprint FilterFootprint FilterFootprint FilterIntegrated FilterIntegrated FilterIntegrated FilterIntegrated FilterExternal FilterExternal FilterExternal FilterExternal FilterTemperature Range 0 – 50 o C 0 – 40 o CControl Method V/F Sensorless Vector, FCC, V/FOverload Capability 1 )50% for 60 sec1.5 x rated outputcurrent for 60 sec1.5 x rated output current for 60 sec2 x rated output current for 3 secProtection FeaturesUndervoltage, Overvoltage, Overload, Short-circuit, Earth Fault, Motor Pull-out, Motor Overtemperature,Drive OvertemperatureMaximum MotorCable Lengthsee Section 3 see Section 3Frequency Range 0 – 400 Hz 0 – 650 Hz 0-650 HzSetpoint ResolutionDigital Inputs3 configurable(19 functions)0.01 Hz6 configurable (24 functions)Fixed Frequencies 7 8Ramp Times 2Relay Outputs1 configurable110 V AC / 0.3 A30 V DC / 1.0 A2 configurable240 V AC / 0.8 A30 V DC / 2 AAnalogue Inputs 1 2Analogue Outputs - 1 configurable 2 configurableSerial InterfaceRS485Braking Compound Braking Braking Chopper External Braking ModuleProcess Control PI PID1 ) The overload capability relates to the rated output current of the drives (MICROMASTER and MICROMASTER Vector) and to therated output currents for operation with constant torque (CT, MIDIMASTER Vector).Duty cycle duration must be at least 5 mins.Table 1:Technical Features1/2 Siemens DA 64 – 1998/99 (04/99)

MICROMASTERMICROMASTER VectorMIDIMASTER VectorIntroduction1.3 Conformity to International Standards1.3.1 CE Mark:The MICROMASTER, MICROMASTER Vector andMIDIMASTER Vector frequency inverters comply with therequirements of the Low Voltage Directive, 73/23/EEC. The CEMark on the units demonstrates this conformity. A declaration ofconformity can be issued. The units are certified to comply withthe following standards:EN60204-1EN60146-1-1Safety of Machinery, ElectricalEquipment or MachinesGeneral Requirements forSemiconductor converters and linecommutated converters1.3.2 Electromagnetic Compatibility:The MICROMASTER, MICROMASTER Vector andMIDIMASTER Vector frequency inverters will, when correctlyinstalled and put to their intended use, satisfy therequirements of the Directive 89/336/EEC concerningElectromagnetic Compatibility. If the guidelines on installationto reduce the effects of EMI are followed, the relevantrequirements for CE certification of the machine will be met.The table below lists the measured results for emissions ofand immunity to interference for MICROMASTER,MICROMASTER Vector and MIDIMASTER Vector inverters.The inverters were installed according to the guidelines withshielded motor cables, shielded control cables and optionalmains filters (except for the single phase units):Test Measurement Tested Value Required limit forEN50081/EN50082RFI Emissions EN55011 and Conducted via Mains cable and 1/3 AC 230/400/460V with integral Class AEN55022radiated through airfilter>= Class A1/3 AC with external filter >= Class B Class B(leads - related emissions only)ESD ImmunityEN61000-4-2ESD through airESD through direct contactLevel 4: 15 kVLevel 4: 8 kV8 kV4 kVElectric Field ImmunityEN61000-4-3Electric Field applied to unit 10 V/m 26-1000 MHz 10 V/mBurst Interference ImmunityEN61000-4-4Applied to all cable terminations:Mains LeadsMotor LeadsControl LeadsBraking Resistor/Module LeadsDC Link LeadsLevel 4: 4 kVLevel 4: 4 kV4 kVLevel 4: 4 kVLevel 4: 4 kV2 kV2 kV2 kV2 kV2 kVSurge ImmunityEN61000-4-5Applied to all mains cables:4 kV Non-symmetric2 kV Symmetric4 kV Non-symmetric2 kV SymmetricTable 2:EMC ConformitySiemens DA 64 – 1998/99 (04/99) 1/3

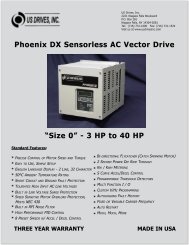

IntroductionMICROMASTERMICROMASTER VectorMIDIMASTER VectorQuotation Sheet<strong>6SE92</strong> MICROMASTER IP20/NEMA10.12 to 3kW 1 phase 230V AC0.12 to 4kW 3 phase 230V AC0.37 to 7.5kW 3 phase 380 to 500V AC6SE32 MICROMASTER Vector IP20/NEMA 10.12 to 3kW 1 phase 230V AC0.12 to 4kW 3 phase 230V AC0.37 to 7.5kW 3 phase 380 to 500V AC6SE32 MIDIMASTER Vector IP21/NEMA1 or IP565.5 to 45kW (7.5 to 60kW Variable Torque) 3 phase 230V AC11 to 75kW (15 to 90kW Variable Torque) 3 phase 380 to 500V AC2.2 to 37kW (4 to 45kW Variable Torque) 3 phase 525 to 575V ACTechnical dataRated connection voltage .................. VRated mains frequency .................. HzRated output current at M = const .................. AOverload capacity (up to 50% for 60sec) .................. AOverload capacity (up to 100% for 3sec) .................. ARated output current at M ∼ n 2 .................. AOverload capacity (up to 10% for 60sec) ..................Rated output at M = const .................. kWRated output at M ∼ n 2 .................. kWOutput frequency from..................to............. HzEMC conformance (EN55011, class A or B) ..................Maximum ambient air temperature (40/50° C) .................. °CDegree of protection (IP20/IP21/IP56) ..................Dimensions (HxWxD) ........x........x........ mmWeight .................. kgMICROMASTER, Order No. ...................................MICROMASTER Vector, Order No ...................................MIDIMASTER Vector, Order No ...................................Voltage source DC link inverters with pulse width modulatedoutputs. Latest generation IGBT technology in the output stagefor high efficiency speed control of three phase AC motors. Unitspre-configured for quick commissioning.Units are UL and CUL listed and designed and built in a factoryaccorded with ISO9001 VDE/EN certification. Full digital controlin microprocessor technology.All units complies with the requirements of the low voltagedirective 73/23 EEC. The units are certified for compliance withCE marks.Power Section3 phase diode bridge input or single phase mains filter withdiode bridge input. High temperature DC link capacitors. Sixpulse self commutating IGBT inverter output stage.Switching and Protective DevicesPre-charging input circuit using relay.Motor ControlOpen loop V/F control with configurable voltage boost (<strong>6SE92</strong>).Field-oriented Vector control using high accuracy output currentmonitoring with a self adapting motor model (6SE32).Standard Local Operator PanelKeys to switch the motor on and off, change the direction ofrotation, inching, up/down and parameterisation.Four digit 7 segment display for setpoint, actual values,parameter values and fault messages.Optional Intelligent Operator PanelDot-matrix LCD display for multilingual text-driven configuration.Non-volatile storage of up to 10 parameter sets. Parameter setupload and download facilities. Master mode for networking upto 31 drives together. RS232 interface.Direct PC connection possible to read and write parameter setsindependently of the inverter.1/4 Siemens DA 64 – 1998/99 (04/99)

MICROMASTERMICROMASTER VectorMIDIMASTER VectorIntroductionConnector terminal strip for external operationMICROMASTER <strong>6SE92</strong>3 configurable 24V binary inputs with 18 selectablefunctions. (isolated, contacts, DC30V/2A, AC110V/0.3A)1 configurable relay output with 13 selectable functions.1 analogue input for setpoint input 0/2 -10V.1 power supply 15V/50mA for PID sensor and binaryinputs.1 power supply 10 V/10 mA for setpoint potentiometer.Evaluation of a Motor PTC temperature sensor against abinary output is possible.All terminals fully short-circuit proof.MICROMASTER Vector 6SE32MIDIMASTER Vector 6SE326 configurable 24V binary inputs with 24 selectablefunctions.2 configurable relay outputs (isolated contacts, DC30V/2A, AC 240V/08A) with 13 selectable functions.1 analogue input for setpoint input 0/2 -10V, 0/4 - 20mA,.±10V1 additional analogue input 0/2 - 10V, 0/4 - 20mA, forsetpoint or PID input.1 configurable analogue output with 6 selectablefunctions (0/4 - 20mA (MICROMASTER Vector).2 analogue outputs with 6 selectable functions each(MIDIMASTER Vector).1 Motor PTC temperature sensor connection.1 power supply 15V/50mA for PID sensor and binaryinputs.1 power supply 10 V/10 mA for setpoint potentiometer.All terminals fully short-circuit proof.Standard Automation InterfaceRS485 serial interface with USS protocol for the connection ofup to 31 drives, maximum bus speed 19.2kBd.Optional High Speed Automation InterfacePROFIBUS DP module for the connection of up to 125 drives,maximum bus speed 12MBd.CANbus Module, supporting CAN OPEN protocolStandard FunctionsMICROMASTER <strong>6SE92</strong>MICROMASTER Vector 6SE32MIDIMASTER Vector 6SE32Open loop V/F speed control for one or several asynchronous,synchronous or reluctance motors.0 - 650Hz (400Hz for <strong>6SE92</strong>) output frequency with 0.01Hzresolution.50% overload capability as a percentage of nominal current for60 seconds.Integrated PID controller, for, e.g. pressure or temperaturecontrol.RS485 serial interface.Sequence control for an external brake.Flying start for controlling a motor that is already spinning.Automatic restart for starting a motor automatically followingmains break or fault.Flexible setpoint input via fixed frequencies, analogue input,motorised potentiometer or serial interface.Flexible control interface allowing control via keypad, digitalinputs or serial interface.Configurable integral DC brake.Compound braking for dynamic stopping without externalcomponents.Additive setpoint input via analogue input and fixedfrequency/digital setpoint input and control from differentsources.Programmable ramp generator (0 - 650 sec) with S-curvecapability.8 configurable fixed frequencies (7 for the <strong>6SE92</strong>).4 fadeable frequency ranges for suppressing resonances.Standard integral EMC filter meeting EN55011 class A for singlephase units.Additional Standard Functions 6SE32MICROMASTER Vector 6SE32MIDIMASTER Vector 6SE32Sensorless Vector Control for achieving a high dynamicperformance with standard asynchronous motors.100% overload capability as a percentage of nominal current for3 seconds.Integrated braking chopper with configurable duty cycle(MICROMASTER Vector).Option RangeConsole radio interference filter for 208 - 240V / 380 - 500V, EN55011 class A or B compliant (MICROMASTER andMICROMASTER Vector).External interference filter for 208 - 240 V/380 - 500 V - EN55011 Class A or B compliant (MIDIMASTER Vector).Mains choke.Brake resistors (MICROMASTER Vector, MIDIMASTER Vector).Brake units (MIDIMASTER Vector).Output dV/dt filters.Output chokes.Multi-lingual Clear Text Operator Panel.SIMOVIS PC commissioning and diagnostics program runningunder Windows 95 or NT.CB15 PROFIBUS DP Module.CAN Bus Module, supporting the CAN OPEN protocol.Siemens DA 64 – 1998/99 (04/99) 1/5

MICROMASTERMICROMASTER VectorMIDIMASTER VectorPrinciples of Operation2. Technical Description 2/12.1 Power Section 2/12.1.1 Thermal Protection and Automatic De-rating 2/12.1.2 Fast Current Limit 2/12.1.3 Operation from Unearthed Supplies 2/12.1.4 Vector Control Principles 2/22.1.5 Sensorless Vector Control 2/22.1.6 Flash Floating Point Processor 2/22.1.7 Benefits of Sensorless Vector Control 2/22.1.8 Vector Operating Range 2/32.1.9 MICROMASTER and MICRO/MIDIMASTER Vector 2/4(in V/f mode)2.1.10 MICRO/MIDIMASTER Vector (in FCC mode) 2/42.1.11 MICRO/MIDIMASTER Vector (Sensorless Vector Control mode) 2/52.1.12 Torque and Speed Response 2/52.2 Closed Loop PID Control 2/62.3 Compound Braking TM 2/62.3.1 Merits of COMPOUND BRAKING TM v’s DC Injection 2/7and Regenerative Braking

MICROMASTERMICROMASTER VectorMIDIMASTER VectorPrinciples of Operation2. TECHNICAL DESCRIPTIONThe MICROMASTER, MICROMASTER Vector andMIDIMASTER Vector form a family of inverters that havebeen designed to connect directly to the mains utility powersupply. They are self-contained units housing all thecomponents required for their operation.Depending on the supply voltage, power output and level offunctionality requirement, the series consists of threevariants; MICROMASTER, MICROMASTER Vector andMIDIMASTER Vector. The MICROMASTER should beconsidered as the low cost option for simple applications.It comprises of three frame sizes offering IP20 protection. TheMICROMASTER Vector is form and fit identical to theMICROMASTER, however its functionality and dynamicperformance is much superior with the addition of SensorlessVector Control, additional I/O and larger intelligent powermodules to cope with the additional overload requirements.The MIDIMASTER Vector has identical features to theMICROMASTER Vector whilst extending its power range to75kW (90kW variable torque). In standard form the protectionrating is IP21, however it is also available in IP56 (NEMA 4).2.1 Power SectionAll inverters contain fully integrated power modules mountedon high efficiency heatsinks, cooled by software-controlledfans. Heat dissipation is such that no thermal derating isrequired for ambient temperatures up to 50°C (40°C forMIDIMASTER Vector).All of the units are fitted with an uncontrolled input rectifier, acapacitor-buffered DC voltage link and a PWM inverter withIGBT output device.When the unit is connected to the line supply, the DC link ispre-charged via resistors and pre-charging relays, thuslimiting the level of inrush current.The DC link voltage is then converted into a pulsed variablefrequency and voltage system, using latest generation lowloss IGBTs combined with fully optimised PWM (PulsedWidth Modulation) waveforms, offering the followingadvantages:• Lower inverter and motor losses.• Motor voltage frequency range: 0 to 650 Hz.• Motor voltage range: 0 V to the line supply voltage.• Almost sinusoidal motor currents.• High motor utilisation.• Silent motor operation using high switching frequenciesup to 16 kHz.• Inverter protected against short-circuits and earth faults.MICROMASTERs (MM12/2 to MM300/2) specified for usewith three phase 230V AC supplies may also be used forsingle phase 230V AC inputs. All single phase and threephase 230V MICROMASTERs may be operated from anominal 2ph 208V AC supply.Caution:Connection of a 400V 3ph supply to a 1ph or 3ph 230Vinverter will destroy the inverter.2.1.1 Thermal Protection and AutomaticDe-ratingLosses within the power module rise with increasing switchingfrequencies, leading to higher heatsink temperatures.Operation of the inverter outside its recommended ambientoperating temperature would normally trip the inverter with anover-temperature fault code. To avoid such nuisance tripping,the MICRO/MIDIMASTER Vector automatically reduces itsswitching frequency ( e.g. from 16kHz to 8kHz), thus reducingthe temperature of the heatsink, enabling the application tocontinue running - trip free. Should the load or ambienttemperature then reduce, the inverter will first check to see ifit is safe to increase the switching frequency again and thendo so.2.1.2 Fast Current LimitFast Current Limit (FCL) is a cycle by cycle hardware currentlimit built into the inverter. Its threshold is set slightly belowthe software over-current trip threshold (F002) and reactsmuch quicker, thus preventing spurious and unwanted tripswhen sudden loads are applied or fast accelerationsrequested.2.1.3 Operation from Unearthed SuppliesThe MICROMASTER/MICROMASTER Vector range can beconnected directly to an unearthed line supply. Whilstoperating from such a supply, if one of the input phases isconnected directly to earth the inverter will continue to runwithout consequential damage.The MICROMASTER/MICROMASTER Vector will trip with anover-current alarm if one of the motor output phases isshorted to earth.The MIDIMASTER Vector (at 2kHz) will continue to operate ifone of the motor output phases is shorted to earth. Operationabove 40Hz or at near full load current may result in an overcurrenttrip.Two or more phases shorted to earth will always result in anover-current trip.An OFF command will not isolate the inverter from the mains.An additional main switch or contactor should be provided toelectrically isolate the unit from the line supply.Slow-acting line fuses can also be used for protectionAll MICROMASTER and MICROMASTER Vector units mayalso be connected directly to a suitably rated clean DC supplyusing the DC link connections provided.Siemens DA 64 – 1998/99 (04/99) 2/1

Principles of OperationMICROMASTERMICROMASTER VectorMIDIMASTER Vector2.1.4 Vector Control PrinciplesWhat is vector control?This is easiest explained through comparison with a DCmachine.In a DC Machine, the field is a separatewinding and therefore the armature current(Torque) and field current (Flux) can becontrolled independently.Independent control of the Flux andTorque producing currents permitsoptimum performance, i.e. Torque at zerospeed, rapid response to load changes etc..SupplyAC InverterEncoderPosition FeedbackTh e ,In an AC Machine, the stator windingcurrents set the Flux and the Torque;therefore it is difficult to control theTorque and Flux separately.Control of the magnitude of the current,will not allow independent control.Therefore the magnitude and phase -“the Vector” - of the current must becontrolled.AC MotorIn order to control the Torque and Flux in the AC motor, the stator current must becontrolled in magnitude and phase, i.e. the Vector quantity.To control the phase with reference to the rotor, the rotor position must be known.Hence for full vector control, an encoder must be used to tell the inverter the rotorposition.2.1.5 Sensorless Vector ControlMany applications do not need and cannot justify theadditional expense of an encoder.For an inverter to simulate the attributes of an encoder, thesoftware algorithm has to accurately calculate the rotorposition and speed by mathematically modelling thefundamental properties of the motor.To do this the inverter must:• Monitor the output voltage and current very accurately.• Calculate motor parameters (Rotor, Stator resistance,leakage inductance etc.).• Accurately model the motor thermal characteristics.• Adapt motor parameters in the light of motor operatingconditions.• Have the ability to perform very rapid mathematicalcalculations. This was made possible using an in-housedesigned custom ASIC;loadperformance criteria. As a result, torque production increasesto 150% or more at 0.5Hz and to over 200% at 2.5Hz andthrough the use of a motor thermal adaptation model, theperformance is maintained over the complete temperaturerange.The entire MICRO/MIDIMASTER Vector series offer anoverload capability of 200% for 3 seconds, making theinverters particularly suitable for arduous applications such ashoists and lifts.Calculation of motor constants is not necessary, this is doneautomatically, leaving the user only entering motorparameters and vector tuning parameters to fine tune theinverter.2.1.6 Flash Floating Point ProcessorSensorless Vector Control is a highly demanding real timecontrol process which is typically achieved using DSPprocessors, RISC processors or multiple microprocessors.The Siemens solution relieves the microprocessor of timeconsuming repetitive tasks and provides floating pointmathematics capability in a custom ASIC. The floating pointcapability means that control equations are implementedverbatim without continuous re-scaling steps. Through theuse of such a system, arithmetic overflows do not happenand full accuracy is always available. The overall result is areliable product with repeatable dynamic performance.The floating point processor is implemented using entirelycombinatorial logic, hence the term ‘Flash Floating PointProcessor’ with performance levels approaching 3 Mflops.The algorithm adopted by the MICRO/MIDIMASTER Vector isvirtually identical to that used in the widely acceptedMASTERDRIVE range.2.1.7 Benefits of Sensorless Vector Control• Excellent speed control with inherent slip compensation.• High Torque at low speed without excessive boost.• Lower losses, higher efficiency.• Higher dynamic performance - better response to steploads.• Stable operation with large motors.• Better performance at current limit with improved slipcontrol.• The Flash Floating Point Processor (F²P²).Siemens, pioneers in this technology, has brought within astandard product, almost closed loop vector performancewithout the need for an encoder.This has been achieved through the use of a bespoke FlashFloating Point Processor, performing the millions ofcalculations per second required to achieve the stringent2/2 Siemens DA 64 – 1998/99 (04/99)

MICROMASTERMICROMASTER VectorMIDIMASTER VectorPrinciples of Operation2.1.8 Vector Operating Rangeinformation and the accuracy of the inverter’s currentmonitoring.2.55Frequency (Hz)Constant current regionConstant current + searching orientation regionFully orientated Vector controlOperation in Sensorless Vector Control (SVC) requires the ratingplate data of the connected induction motor to be accuratelyentered (parameters P080 to P085). These parameters arefactory set with the data of Siemens 4-pole 1LA5 motors, andmust be adapted if other motors are used. Once SVC mode isinvoked (P077=3), the next time the inverter is run, CAL willappear on the display for several seconds, during which time theinverter fully optimises itself and calculates motor modelcharacteristics such as stator resistance, leakage inductance,rotor and stator thermal time constants etc.The ‘Calibration’ routine must be performed on a cold motorsince the inverter automatically compensates itself forchanges in motor temperature.SVC can be used only for induction motors and for singlemotor drives or multi-motor drives with a mechanicallycoupled load.SVC cannot be used for:• Synchronous or reluctance motors.The above diagram illustrates the sensorless vector operatingregions for the MICRO/MIDIMASTER Vector.Constant current regionIn this region the inverter acts like a current source andindependent of load will output the value of currentprogrammed into parameter P083.E.g. for a 750W motor, P083 may be set to 3.4A, therefore,regardless of the motor load (full load or no load), the motorcurrent will remain at 3.4A.Continuous Boost (P078) and Starting Boost (P079) areactive in this region and offer up to 250% boost capability.This region is active below approximately 5Hz (whilst the outputfrequency is ramping up from zero) and below 2.5Hz (whilst theoutput frequency is ramping down from a frequency above 5Hz).The 2.5Hz hysterisis bandwidth is present to prevent oscillationbetween the two operating modes. The 2.5Hz and 5Hz valuesshown are approximately 5% and 10% of the value programmedin P081 - the nominal rating plate frequency for motor.Constant current and searching orientation regionWhilst operating in this region and the output frequency isramping up, the back emf from the motor begins to build up. Withthis information the system will search and lock onto the rotorspeed - once locked, it will stay locked until the output frequencyis requested to go below 2.5Hz. Slip compensation is also activein this region.Fully oriented Vector controlIn this region, the inverter knows the orientation of the motorand will maintain the frequency setpoint within the operationalboundaries of the inverter. Variations in ambient temperature,stator resistance, motor slip etc., are fully compensated forover the complete load operating region.Sensorless Vector Control is a true closed loop system anddepends very much on the integrity of the motor rating plate• Multi-motor drives, group drives (several motorsconnected in parallel at the drive converter output).• Motors with power ratings less than half of the inverterrating.• Motors with current requirements greater than those theinverter can supply. i.e. I motor > P083 max.In the above cases, a V/f characteristic must beparameterised:• P077=0 for applications with linear torquecharacteristics• P077=2 for applications with pump or fancharacteristics (square-law torque characteristics,variable torque, VT)The ‘flying start’ feature in both MICROMASTER Vector andMIDIMASTER Vector depend on the vector algorithm andtherefore must follow the same rules which govern SVCoperation.The above restrictions also apply to inverters configured tooperate in Flux Current Control mode (FCC, P077=1). Thisfeature has been retained within the vector range to maintainbackward compatibility with previous generation MICRO andMIDIMASTERs.For MIDIMASTER, when a square-law torque characteristic isused, it permits a significantly higher motor current, wherebyin almost all cases, the rated output is achieved using thenext largest motor (the motor current can be increased viaparameter P083).For a specific output, fan and pump drives can have a smallerdrive converter.Siemens DA 64 – 1998/99 (04/99) 2/3

Principles of OperationMICROMASTERMICROMASTER VectorMIDIMASTER Vector2.1.9 MICROMASTER and MICRO/MIDIMASTER Vector (in V/f mode)Open loop frequency control for single-motor and multi-motor drives with induction motors, without any high demands regardingdynamic performance. e.g. pumps and fans, simple traversing drives.ConverterU dV/f charactersticU d- CorrectionUU*U stRampGeneratorfGatingunitn*fo/c tripH/WcurrenttripInom (P083)CurrentdetectionIM2.1.10 MICRO/MIDIMASTER Vector (in FCC mode)U dU d CorrectionV/f characteristicUfU m U*_ +U stRampGeneratorGatingunitn*++f-+Effective atf > f sCurrentlimitingcontrollerSlipcompensationFCC+_CurrentdetectionIEffective at f < f sI istMV/f control without speed detection2/4 Siemens DA 64 – 1998/99 (04/99)

MICROMASTERMICROMASTER VectorMIDIMASTER VectorPrinciples of Operation2.1.11 MICRO/MIDIMASTER Vector (Sensorless Vector Control mode)Preferably used for single-motor drives with induction motors, from low to high demands regarding dynamic performance, at speedsetting ranges of up to 1:10. Suitable for most industrial applications such as extruders, packaging machines, industrial washingmachines, lifts and hoists.EMF computerfor pre-controlConverterI Start *I - Controller++n*RampGeneratordn*/dt+-++n-controllerMAcc.I *M*M*↓IW*IW*IW-controller++U*CoordtransformerUd-Corr-ectionUStGatingunitf < f s+ff > f s+Effective at f > f sLoadControlf+Iw istIµ istMotor Modelwith vectortransformationUI+f Slipn calculatedM2.1.12 Torque and Speed ResponseSiemens DA 64 – 1998/99 (04/99) 2/5

Principles of OperationMICROMASTERMICROMASTER VectorMIDIMASTER Vector2.1.12.1 Properties of Different Control VersionsOperating Mode V/f FCC SVCDigital setpoint resolution 0.01Analogue setpoint resolution10 BitInternal frequency resolution 0.01Speed accuracy- constant torque region- field weakening region>2%

MICROMASTERMICROMASTER VectorMIDIMASTER VectorPrinciples of Operation2.3.1 Merits of COMPOUND BRAKING TM v’s DC Injection and Regenerative BrakingRegenerative Braking• Energy dissipated in external resistor.• Excellent braking torque.• Smooth.• In control.• Speed reduces linearly and smoothly.DC Injection Braking• Energy dissipated in motor.• Poor braking torque.• Smooth.• No control of ramp down.• 30 - 40% effectiveness of regenerative braking.• Stopping of motor shaft unknown.COMPOUND BRAKING• Energy dissipated in motor.• Good braking torque.• In control.• 50-60% effectiveness of regenerative braking.• Speed reduces linearly.• Slight speed ripple may be seen due to oscillating torque -dependent on load inertia.Siemens DA 64 – 1998/99 (04/99) 2/7

MICROMASTERMICROMASTER VectorMIDIMASTER VectorTechnical Selection Information3. Technical Information 3/13.1 Technical Comparison Table 3/13.2 Dimensions and Weights 3/23.3 IP Protection 3/53.4 Control Connections 3/63.5 Mains Input 3/83.6 Mains Harmonics and Supply Impedance 3/93.7 Maximum Motor Cable Lengths 3/103.8 Derating 3/113.8.1 Voltage and Current Derating with Respect to Altitude 3/113.8.2 Maximum Output Current with Respect to Pulse Frequency 3/113.8.3 Maximum Output Pulse Frequency with Respect to Line Input 3/12Voltage3.9 Recommended Fuse Ratings 3/133.10 Compliance with EMC Directive 3/143.11 Footprint Filters for MICROMASTER and MICROMASTER 3/17Vector3.12 dV/dt Output Filters 3/273.13 Input Chokes 3/283.14 MICROMASTER Vector - Braking Resistors 3/323.15 Electronic Braking Module (EBU) & Braking Resistors for 3/33MIDIMASTER Vector

MICROMASTERMICROMASTER VectorMIDIMASTER VectorTechnical Information3.1 Technical Comparison TablePower Range120 W – 3 kW 230 V 1 AC120 W – 4 kW 230 V 3 AC370 W - 7.5 kW 400 V 3 ACVoltage Range 208 – 240 V +/-10%380 – 500 V +/- 10%MICROMASTER <strong>6SE92</strong> MICROMASTER Vector 6SE32 MIDIMASTER Vector 6SE32120 W – 3 kW 230 V 1 AC120 W – 4 kW 230 V 3 AC370 W - 7.5 kW 400 V 3 AC208 – 240 V +/-10%380 – 500 V +/- 10%Input Frequency 47-63 Hz 47-63 Hz 47-63 Hz5.5 kW – 45 kW 230 V 3 AC11 kW – 75 kW 400 V 3 AC2.2 kW – 37 kW 575 V 3 AC208 – 240 V +/-10%380 – 500 V +/- 10%525 – 575 V +/- 15%Power Factor cos Φ ≥ 0.98, Total λ ≥ 0.7 cos Φ ≥ 0.98, Total λ ≥ 0.7 cos Φ ≥ 0.98, Total λ ≥ 0.7Power On/Power Off cycles100,000 (max. guaranteed) 5 secinterval100,000 (max. guaranteed) 5 secinterval100,000 (max. guaranteed) 5 secintervalInrush Current No greater than nominal input current No greater than nominal input current No greater than nominal input currentInverter Efficiency 97% 97% 97%Operating Temperature 0- 50 °C 0- 50 °C 0- 40 °C (50 °C without cover)Storage Temperature -40 to +70°C -40 to +70°C -40 to +70°CRelative Humidity 95% non-condensing 95% non-condensing 95% non-condensingSide by side mounting No clearance required No clearance required No clearance required for IP21 & IP20units.Clearance between IP56 units to begreater than 150mm.Degree of protection IP20 / NEMA 1(FSA units require optional gland plateto meet NEMA1)IP20 / NEMA 1(FSA units require optional gland plateto meet NEMA1)Cooling Method Software-controlled fan cooling Software-controlled fan cooling Fan coolingOutput Frequency 0 – 400 Hz 0 – 650 Hz 0 – 650 HzOutput FrequencyResolution0.01 Hz 0.01 Hz 0.01 HzIP21 / NEMA 1(Optional IP56 / NEMA 4 alsoavailable)Overload Capability 1.5 x rated output current for 60 secs 1.5 x rated output current for 60 secs2 x rated output current for 3 secsControl Method V/f SVC, FCC, V/f SVC, FCC, V/fDigital Inputs 3 (> 7.5V = high, 33V max) 6 (> 7.5V = high, 33V max) 6 (> 7.5V = high, 33V max)Analogue input 10-10 V/PI input10 bit resolution, floating differentialinput0-10 V, 0/4-20 mA-10 V / +10 V bipolar10 bit resolution, floating differentialinputAnalogue input 2 N/A 0-10 V, 0/4-20 mAPID input, 10 bit resolutionAnalogue output 1 N/A 0/4 – 20 mAwith 500Ω max. load10 bit resolution0-10 V, 0/4-20 mA-10 V/ +10 V bipolar10 bit resolution, floating differentialinput0-10 V, 0/4-20 mAPID input, 10 bit resolution0/4 – 20 mA500Ω max. load10 bit resolutionAnalogue output 2 N/A N/A 0/4 – 20 mA500Ω max. loadRelay output 1 30 V DC 1 A, 110 V AC 0.3 A,Normally Open Contacts30 V DC 2 A, 240 V AC 0.8 AChangeover ContactsRelay output 2 N/A 30 V DC 2 A, 240 V AC 0.8 ANormally open contacts30 V DC 2 A, 240 V AC 0.8 AChangeover Contacts30 V DC 2 A, 240 V AC 0.8 ANormally open contactsRS485 Interface D-type D-type / terminal strip D-type / terminal stripBraking Chopper N/A Built-in Optional external moduleCompound Braking Yes Yes YesFast Current Limit Yes Yes YesPID closed loop control Built-in PI Built-in PID Built-in PIDMotor Protection - external PTC input on digital input Dedicated PTC input Dedicated PTC inputMotor Protection - internal I²t I²t (UL approved) I²t (UL approved)Inverter ProtectionLine to Earth short circuit protectionLine to Line short circuit protectionOvertemperature protectionOvervoltage protectionOvercurrent protectionLine to Earth short circuit protectionLine to Line short circuit protectionOvertemperature protectionOvervoltage protectionOvercurrent protectionLine to Earth short circuit protectionLine to Line short circuit protectionOvertemperature protectionOvervoltage protectionOvercurrent protectionSiemens DA 64 – 1998/99 (04/99) 3/1

Technical InformationMICROMASTERMICROMASTER VectorMIDIMASTER Vector3.2 Dimensions and WeightsWAH1HFH1Depth DHDIN Rail∅MICROMASTER and MICROMASTERVector inverters must be secured to asuitable vertical surface by M4 bolts,washers and nuts.Frame size A units requires two bolts. (M4)∅ = 4.5 mmFrame size B requires four bolts. (M4)DW2 bolts M42 nuts M42 washers M4Frame size C requires four bolts. (M5)Frame Size AWW1∅BHH1H1Depth DH∅ = 4.8 mm (B)∅ = 5.6 mm (C)WDFrame size B:4 bolts M44 nuts M44 washers M4WFrame Sizes BW1Frame size C:4 bolts M54 nuts M54 washers M5CHH1H1Depth DH∅∅= 4.8 mm (B)∅ = 5.6 mm (C)WDFrame size B:4 bolts M44 nuts M44 washers M4Frame Sizes CFrame size C:4 bolts M54 nuts M54 washers M5ModelMM12MM25MM37MM55MM75MM110MM150MM220MM300MM400MM550MM750MMxxx1 AC 230 VClass A FilterAAAAABBCC---MMxxx/21/3 AC 230 VWithout FilterAAAAABBCCC--MMxxx/33 AC 400 -500V WithoutFilter--AAAAABBCCCFrameSizeABCH175184215xxxW73149185Frame Dimensions (mm)xxxD141172195H1160174204W1-138174F55--Weight(kg/lb)0.8 / 1.82.6 / 5.75 / 11Table 1:MICROMASTER and MICROMASTER Vector Frame Sizes3/2 Siemens DA 64 – 1998/99 (04/99)

MICROMASTERMICROMASTER VectorMIDIMASTER VectorTechnical InformationWW1H1Depth DHH∅∅ = 8.5 mmDWFrame Sizes 4, 5 and 64 bolts M84 nuts M84 washers M8MIDIMASTER Vector - Frame Size 4, 5 and 6IP21 StandardIP20 with integrated filterWW1H1Depth DHH∅∅ = 8.5 mmDWFrame Size 76 bolts M86 nuts M86 washers M8MIDIMASTER Vector - Frame Size 7IP21 standardIP20 with integrated filterW1H1Depth DH∅∅ = 8.5 mm(6 bolts M8 - FS7)(6 nuts M8 - FS7)(6 washers M8 - FS7)WFrame Sizes 4, 5 and 64 bolts M84 nuts M84 washers M8MIDIMASTER Vector - Frame sizes 4, 5, 6 and 7IP56 protectedSiemens DA 64 – 1998/99 (04/99) 3/3

Technical InformationMICROMASTERMICROMASTER VectorMIDIMASTER VectorMIDIMASTER VectorFrame SizeTable 2:Type 3 AC 208 – 240 V 3 AC 400 – 500 V 3 AC 525 – 575 VMDV220/4MDV400/4MDV550/2MDV550/4MDV750/2MDV750/3MDV750/4MDV1100/2MDV1100/3MDV1100/4MDV1500/2MDV1500/3MDV1500/4MDV1850/2MDV1850/3MDV1850/4MDV2200/2MDV2200/3MDV2200/4MDV3000/2MDV3000/3MDV3000/4MDV3700/2MDV3700/3MDV3700/4MDV4500/2MDV4500/3MDV5500/3MDV7500/3--4-4--5--6--6--6--7--7--7--------4--4--5--5--6--6--6--77744-4--4--4--5--5--6--6--6----MIDIMASTER Vector Frame SizesFrame Dimensions (mm)Standard Model: IP21 / NEMA 1FrameSize H W D H1 W14567450550650850xxxx275275275420xxxx210210285310430530630830235235235374Model with Integrated EMC Filter: IP20 / NEMA 1FrameSize H W D H1 W145677008009201150xxxx275275275420xxxx2102102853106807809001130235235235374Model with enhanced protection: IP56 / NEMA 4/12Framesize H W D H1 W145676757758751150xxxx360360360500xxxx3514224835706497498491112313313313451Weight(approx) kg11152756Weight(approx) kg19243990Weight(approx) kg304054100Note:Dimension “D” for the IP21 and the IP20 units includes the front control panel. If an OPM2 Clear Text Display is fitted then anadditional 30mm will be required.Dimension D for the IP56 units does NOT include the front panel access door - add 25mm to include this extra depth.Table 3:MIDIMASTER Vector Dimensions & Weights3/4 Siemens DA 64 – 1998/99 (04/99)

MICROMASTERMICROMASTER VectorMIDIMASTER VectorTechnical Information3.3 IP ProtectionThe IP number defines the levelof Ingress Protection (IP) for theparticular inverter.MICROMASTER andMICROMASTER Vector modelshave an IP rating of IP20 (USequivalent NEMA 1).MIDIMASTER Vector modelshave an IP rating of IP21 (USequivalent NEMA 1) or IP56(US equivalent NEMA 4/12).First NumberIPXxx0 No protection1 Protected against solidobjects of 50mm or bigger2 Protected against solidobjects of 12mm or biggerSecond NumberIPxXx0 No protection1 Protected against water fallingvertically2 Protected against direct spraysup to 15 deg. From verticalThird Number (notquoted)IPxxX0 No protection1 Protected against0.225J impact2 Protected against0.375J impactTable 4 explains what thenumbers in the IP rating meanin terms of ingress protection:3 Protected against solidobjects of 2.5mm or bigger4 Protected against solidobjects of 1mm or bigger3 Protected against direct spraysup to 60 deg. From vertical4 Protected against sprays fromall directions3 Protected against0.5J impact5 Protected against2.0J impact5 Protected against dust(limited ingress)5 Protected against low pressurejets from all directions7 Protected against6.0J impact6 Protected against dust(totally)6 Protected against high pressurejets from all directions9 Protected against20.0J impact7 Protected against immersionbetween 15cm and 1m8 Protected against immersionunder pressureFigure 2: MIDIMASTER Vector IP56 - Cubicle InstallationThe IP56 / NEMA 4/12 MIDIMASTER Vector unit can be installed within a larger enclosure with its heatsink protruding though theback plate of the cubicle. This installation method ensures that the heat from the inverter is dissipated into the outside environmentwithout the need for additional cooling fans. The IP56 protection rating is thus maintained.Siemens DA 64 – 1998/99 (04/99) 3/5

Technical InformationMICROMASTERMICROMASTER VectorMIDIMASTER Vector3.4 Control ConnectionsMICROMASTER:PE1/3 AC 230 V3 AC 380 - 500 VSI≥ 4.7 kΩV: 0 - 10 V2 - 10 V OR AIN+AIN-1234+10V0VADJogPE~L/L1, N/L2orL/L1, N/L2, L3–24 V+ORDIN1DIN2DIN3567CPUPRS485DC+DC-Power Supply forPI FeedbackTransduceror other load.89+15V0VRL1RL1BRL1C10113 ~PEU, V, WMControl PanelOutput Relay(normally open)max. 0.3 A / 110 V AC1 A / 30 V DC(resistive rating)Front PanelRS485 D-typeP10+ 0V AIN+ AIN- DIN1 DIN2 DIN3 P15+1 2 3 4 5 6 7 8 9 10 110V5916RL1B(NO)RL1C(COM)0VB/PA/N5V(max.250mA)Power Supply(+10 V, max. 10 mA)Digital Inputs(7.5 - 33 V, max. 5 mA)Analogue Input(0/2 - 10 V)(input impedance = 70 kΩ)Power SupplyforPI FeedbackTransducer or otherload)(+15 V, max. 50 mA)3/6 Siemens DA 64 – 1998/99 (04/99)

MICROMASTERMICROMASTER VectorMIDIMASTER VectorTechnical InformationMICROMASTER Vector / MIDIMASTER Vector Control - Connections:PE3 AC 208 - 230 V3 AC 380 - 500 V3 AC 525 - 575 VSIV: 0 - 10 VOR2 - 10 V≥4.7kΩI: 0 - 20 mA OR4 - 20 mAAIN1+DC-AIN1-–24 V+ DIN1DIN2DIN3DIN4AIN2/PIDAIN2/PID1234567891011+10V0VAD+15VADCPUJogPRS485PE~L1, L2, L3DCEBB+ (MMV only)A1OUT12DAO13Motor143 ~DIN515DIN616DIP Switches17RL11819201 2 3 4 5 6(Note:Switch 6 notused)RL2212223+5VN-P+242526RS485PEA2OUT+ (MD only) 27 DAA2OUT 13*For MIDIMASTER: Terminal 23 +5VTerminal 26 PEPEU, V, W*For MICROMASTER:Terminal 23 PETerminal 26 +5VMSiemens DA 64 – 1998/99 (04/99) 3/7

Technical InformationMICROMASTERMICROMASTER VectorMIDIMASTER VectorOutput Relaysmax. 2.0A / 110 V AC0.8 A / 230 V AC (overvoltage cat.2) or 2A/ 30 V DC(resistive rating)P10+ 0V AIN+ AIN- DIN1 DIN2 DIN3 DIN4 P15+ PIDIN+ PIDIN-1 2 3 4 5 6 7 8 9 10 11AOUT+ AOUT-PTC PTC DIN5 DIN612 13 14 15 16 17 18 19 20 21 22RL1A(NC)RL1B RL1C(NO) (COM)RL2B(NO)RL2C(COM)Power Supply(+10 V, max. 10 mA)Analogue Input 1-10 V to +10 V0/2 10 V(input impedance 70 kΩ)or0/4 20 mA(resistance = 300Ω)23 24 25 26Digital Inputs(7.5 - 33 V, max. 5 mA)Power Supply forPID FeedbackTransducer(+15 V, max. 50 mA)Analogue input 20 10 Vor0 20 mAAnalogue Output0/4 - 20 mA(500Ω load)*For MIDIMASTER: Terminal 23+5VTerminal 26 PEMotor temp. protection inputNote: For PTC motor thermalprotection, P087 = 1Digital Inputs(7.5 - 33 V, max.5 mA)590VN-P+165V (max. 250mA)PEN-P+RS485(for USS protocol)P5V+*For MICROMASTER: Terminal 23 PETerminal 26+5VControl TerminalsFront PanelRS485 D-typeMICROMASTER Vector / MIDIMASTER Vector control connections3.5 Mains InputThe inverters are compatible with mains supplies which do not inject interference above the limits specified in the followingstandards:IEC / EN 61000-4-4: Fast transients / burst interference: 4 kV(VDE 0847 Part 4-4)IEC / EN 61000-4-5: Voltage surges: 4 kV (common mode)(VDE 0847 Part 4-5)2 kV (differential mode)IEC / EN 61000-4-11: Voltage dips: 30% reduction 60 ms(VDE 0847 Part 4-1110% reduction 100 msVoltage interruptions:>95% for 5 secsVoltage fluctuations: V nom +/- 10%IEC / EN 61000-2-4: Compatibility levels in industrial plants for low-frequency conducted disturbances(VDE 0839 Part 2-4) Class 3, 10% THD3/8 Siemens DA 64 – 1998/99 (04/99)

MICROMASTERMICROMASTER VectorMIDIMASTER VectorTechnical Information3.6 Mains Harmonics and Supply ImpedanceMains HarmonicsWhen the inverter is operating it gives rise to a non-sinusoidal current from the mains supply with harmonics. The approximatepercentage of the fundamental of these harmonics, based on a 1% mains impedance, is shown in the table below. The amplitudeof the harmonics can be reduced by fitting input chokes. The order numbers of suitable chokes providing an additional impedanceof 2% or 4% are shown in the tables below.Supply ImpedanceThe ratio of inverter rated power/mains short circuit power should never be less than 0.5%. This means that the voltage drop whenthe inverter is fully loaded should be greater than or equal to 0.5% of the nominal voltage. If the mains impedance is below thisvalue the lifetime of the electrolytic capacitors could be reduced. To overcome this effect, 2% input chokes should be fitted. If afurther reduction of harmonic currents is required, 4% input chokes can be fitted.Inverter typeSupply VoltageHarmonic numberorder(1 = baseharmonic)Harmonic current relative tomains harmonics with 1%mains impedance(%)Harmonic current relative tomains harmonics with 2%mains impedance(%)Harmonic current relative tomains harmonics with 4%mains impedance(%)230 V 1AC 1 100 100 1003 87.9 83.1 76.25 68.2 56.9 41.37 45.5 29.2 14.39 24.2 10.8 6.311 9.1 7.7 6.313 6.1 6.2 3.2230 V 3 AC 1 100 100 100(Inverter 22 kW) 5 32 29.2 26.07 9.6 7.9 6.911 7.8 7.0 5.913 3.7 3.6 3.4400/500 V 3 AC 1 100 100 100(Inverter 37 kW) 5 42.7 37.8 32.67 17.7 13.2 9.211 6.7 7.1 6.913 4.0 3.5 3.3Siemens DA 64 – 1998/99 (04/99) 3/9

Technical InformationMICROMASTERMICROMASTER VectorMIDIMASTER Vector3.7 Maximum Motor Cable LengthsInverter PowerkWRatedvoltageVMICROMASTER / MICROMASTER Vector0.12 - 1.5 208-240±10%2.2 – 4.0 208-240±10%0.37 - 1.5 380-500± 10%2.2 – 3.0 380-500± 10%4.0 - 7.5 380-500± 10%MIDIMASTER Vector5.5 208-240±10%7.5 - 11 208-240±10%15 - 22 208-240±10%30 - 45 208-240±10%7.5 - 18.5 380-500± 10%22 - 37 380-500± 10%45 - 75 380-500± 10%2.2 - 18.5 525-575± 10%22 - 37 525-575± 10%Size Without output choke With output chokeUnscreenedcablemScreenedcablemUnscreenedcablemA, B 200 200 250 225C 185 150 235 185A 110 80 185 125B 170 140 220 170C 200 200 300 2504 200 50 250 804, 5 300 200 350 2256 300 300 350 3257 300 300 350 3254, 5 150 75 200 1006 200 150 250 1757 300 300 350 3254,5 100 100 150 1256 150 150 200 175ScreenedcablemThe maximum cable lengths quoted above relate to constant torque applications under the following conditions:• Rated voltage:Max. 460V for MICROMASTER, MICROMASTER Vector and MIDIMASTER Vector voltage range 3AC 380 - 500 V• Pulse frequency as supplied:16 kHz max. for 230 V MICROMASTER and MICROMASTER Vector4 kHz max. For 400 V MICROMASTER, MICROMASTER Vector and all MIDIMASTER Vector equipment• Overload:1.5 x rated output current for MICROMASTER and MICROMASTER Vector1.5 x rated output current for MIDIMASTER Vector in constant torque applicationsTo extend the cable lengths:1. Use the smallest inverter model from the next size range.2. Use an output choke (see sections 6.32, 6.33).Note:Optimal operation in ‘Vector control’ mode is compromised by very long motor cables. In this situation the powerprocurement system in the inverter is unable to replicate the motor sufficiently accurately.3/10 Siemens DA 64 – 1998/99 (04/99)

MICROMASTERMICROMASTER VectorMIDIMASTER VectorTechnical Information3.8 Derating3.8.1 Voltage and Current Derating with Respect to Altitude100Permissible rated input voltageas a percentage of thenominal voltage100Permissible rated input currentas a percentage of thenominal current90908080707060601000 2000 3000 4000500Installation altitudein m above sea1000 2000 3000 4000500Installation altitudein m above sea3.8.2 Maximum Output Current with respect to the Pulse FrequencyDue to higher switching losses at increased switching frequencies, certain inverters may have their maximum continuous current(100%) derated if the switching frequency is changed from the default valueModel% of full load de-rating16 kHz 8 kHzMMV75/3 80 100MMV110/3 50 80MMV150/3 50 80MMV220/3 80 100MMV300/3 50 80MMV400/3 50 80MMV550/3 50 80MMV750/3 50 80Note:If switching frequency is 2 kHz or 4 kHz then derating does not occur on the above inverters.Siemens DA 64 – 1998/99 (04/99) 3/11

Technical InformationMICROMASTERMICROMASTER VectorMIDIMASTER VectorModel% of full load de-rating16 kHz 8 kHzMDV550/2 39 75MDV750/2 64 90MDV1100/2 55 75MDV1500/2 38 68MDV1850/2 43 79MDV2200/2 38 68MDV750/3 55 100MDV1100/3 39 75MDV1500/3 64 90MDV1850/3 55 75MDV2200/3 40 75MDV3000/3 47 88MDV3700/3 40 75MDV550/4 75 100MDV750/4 55 100MDV1100/4 39 75MDV1500/4 64 90MDV1850/4 55 75Note: On all Frame Size 6 575V and all Frame Size 7 MIDIMASTER Vector inverters, the switching frequency can only be either 2kHz or 4kHz3.8.3 Maximum Output Pulse Frequency with Respect to Line Input VoltagePulsefrequencyMICROMASTER Vector only16kHz8 kHz4 kHz2 kHzNote: This derating function isdone automatically.0 480 540 Line input voltage (Vac)3/12 Siemens DA 64 – 1998/99 (04/99)

MICROMASTERMICROMASTER VectorMIDIMASTER VectorTechnical Information3.9 Recommended Fuse RatingsMICROMASTER, MICROMASTER Vector, MIDIMASTER VectorMains Supply VoltageVersionsMM = MICROMASTERMMV = MICROMASTER VectorMDV = MIDIMASTER VectorRecommendedFuse RatingARecommendedFuse(duty class gL)Order codeMaximum cablediameter(mm 2 )1 AC 230 V MM12, MMV12, MM25, MMV25, MM37, MMV37 10 3NA3803 41 AC 230 V,3 AC 230 V (b)MM55, MMV55, MM75, MMV75 16 3NA3805 4MM110, MMV110, MM150, MMV150, 20 3NA3807 4MM220, MMV220 25 3NA3810 4MM300, MMV300 (a) 32 3NA3812 4MM12/2, MMV12/2, MM25/2, MMV25/2, MM37/2,MMV37/2, MM55/2, MMV55/2, MM75/2, MMV75/210 3NA3803 4MM110/2, MMV110/2, MM150/2, MMV150/2 16 3NA3805 4MM220/2, MMV220/2 20 3NA3807 4MM300/2, MMV300/2 (a) 25 3NA3810 4MM400/2, MMV400/2 (c) 32 3NA3812 43 AC 380 V - 500 V MM37/3, MMV37/3, MM55/3, MMV55/3, MM75/3,MMV75/3, MM110/3, MMV110/3, MM150/3,MMV150/3,10 3NA3803 4MM220/3, MMV220/3, MM300/3, MMV300/3 16 3NA3805 4MM400/3, MMV400/3, MM550/3, MMV550/3 20 3NA3807 4MM750/3, MMV750/3 25 3NA3810 43 AC 230 V MDV550/2 50 3NA3820 16MDV750/2, MDV1110/2 63 3NA3822 35MDV1500/2 80 3NA3824 35MDV1850/2, MDV2200/2 100 3NA3830 35MDV3000/2 160 3NA3036 95MDV3700/2, 4500/2 200 3NA3140 953 AC 380 V - 500 V MDV750/3, MDV1100/3 35 3NA3814 16MDV1500/3, MDV1850/3 50 3NA3820 35MDV2200/3, MDV3000/3 80 3NA3824 35MDV3700/3 100 3NA3830 35MDV4500/3 125 3NA3032 95MDV5500/3 160 3NA3036 95MDV7500/3 200 3NA3140 953 AC 525 V - 575 V MDV220/4, MDV400/4 10 3NA3803-6 16MDV550/4 16 3NA3805-6 16MDV750/4 25 3NA3810-6 16MDV1100/4, MDV1500/4 35 3NA3814-6 16, 35MDV1850/4, MDV2200/4 50 3NA3820-6 35MDV3000/4 63 3NA3822-6 35MDV3700/4 80 3NA3824-6 35Table 3:Recommended Slow-acting Line Fuses(a)(b)MM(V(300 and MM(V)300/2 require an external choke (e.g. 4EM6100-3CB) and a 30 A mains fuse for single phase.Assumes 3-phase supply. If a single-phase supply is used, the input current ratings and fuses for single-phaseMICROMASTERS will apply.(c) Operation only on 3 AC 230 V.Siemens DA 64 – 1998/99 (04/99) 3/13

Technical InformationMICROMASTERMICROMASTER VectorMIDIMASTER Vector3.10 Compliance with EMC DirectiveAll manufacturers / assemblers of electrical apparatus whichperforms a complete intrinsic function which is placed on themarket as a single unit intended for the end user must complywith the EMC directive EEC/89/336 after January 1996. Thereare three routes by which the manufacturer/assembler candemonstrate compliance:1. Self-CertificationThis is a manufacturer's declaration that the Europeanstandards applicable to the electrical environment forwhich the apparatus is intended have been met. Onlystandards which have been officially published in theOfficial Journal of the European Community can becited in the manufacturer's declaration.2. Technical Construction FileA technical construction file can be prepared for theapparatus describing its EMC characteristics. This filemust be approved by a ‘Competent Body’ appointedby the appropriate European government organisation.This approach allows the use of standards which arestill in preparation.3. EC Type-Examination CertificateThis approach is only applicable to radiocommunication transmitting apparatus.The MICROMASTER, MICROMASTER Vector andMIDIMASTER Vector units do not have an intrinsic functionuntil connected with other components (e.g. a motor).Therefore, the basic units are not allowed to be CE markedfor compliance with the EMC directive. However, full detailsare provided below of the EMC performance characteristics ofthe products when they are installed in accordance with thewiring recommendations in section 9.3.Three classes of EMC performance are available as detailedbelow. Note that these levels of performance are onlyachieved when using the default switching frequency (or less)and a maximum motor cable length of 25 m.Class 1: General IndustrialCompliance with the EMC Product Standard for Power Drive Systems EN 61800-3 for use in Second Environment (Industrial)and Restricted Distribution.EMC Phenomenon Standard LevelEmissions:Radiated Emissions EN 55011 (VDE 0875 Part 11) Level A1 *Conducted Emissions EN 61800-3 (VDE 0160 Part 100) *Immunity:Electrostatic Discharge EN 61000-4-2 (VDE 0847 Part 4-2) 8 kV air dischargeBurst Interference EN 61000-4-4 (VDE 0847 Part 4-4) 2 kV power cables, 1 kV controlRadio Frequency Electromagnetic Field IEC 1000-4-3 (VDE 0847 Part 4-3) 26-1000 MHz, 10 V/m* Emission limits not applicable inside a plant where no other consumers are connected to the same electricity supply transformer3/14 Siemens DA 64 – 1998/99 (04/99)

MICROMASTERMICROMASTER VectorMIDIMASTER VectorTechnical InformationClass 2: Filtered IndustrialThis level of performance will allow the manufacturer/assembler to self-certify their apparatus for compliance with the EMCdirective for the industrial environment as regards the EMC performance characteristics of the power drive system. Performancelimits are as specified in the Generic Industrial Emissions and Immunity standards EN 50081-2 and EN 50082-2.EMC Phenomenon Standard LevelEmissions:Radiated Emissions EN 55011 (VDE 0875 Part 11) Level A1Conducted Emissions EN 55011 (VDE 0875 Part 11) Level A1Immunity:Supply Voltage Distortion EN 61000-2-4 (VDE 0839 Part 2-4)Voltage Fluctuations, Dips, Unbalance, Frequency Variations IEC 1000-2-1Magnetic Fields EN 61000-4-8 (VDE 0847 Part 4-8) 50 Hz, 30 A/mElectrostatic Discharge EN 61000-4-2 (VDE 0847 Part 4-2) 8 kV air dischargeBurst Interference EN 61000-4-4 (VDE 0847 Part 4-4) 2 kV power cables, 2 kV controlRadio Frequency Electromagnetic Field, amplitude modulated ENV 50 140 (VDE 0847 Part 3) 80-1000 MHz, 10 V/m, 80% AM, powerand signal linesRadio-frequency Electromagnetic Field,pulse modulatedENV 50 204 (VDE V 0847 Part 204)900 MHz, 10 V/m 50% duty cycle, 200 Hzrepetition rateClass 3: Filtered - for residential, commercial and light industryThis level of performance will allow the manufacturer / assembler to self-certify compliance of their apparatus with the EMCdirective for the residential, commercial and light industrial environment as regards the EMC performance characteristics of thepower drive system. Performance limits are as specified in the generic emission and immunity standards EN 50081-1 and EN50082-1.EMC Phenomenon Standard LevelEmissions:Radiated Emissions EN 55022 (VDE 0878 Part 22) Level B1Conducted Emissions EN 55022 (VDE 0878 Part 22) Level B1Immunity:Electrostatic Discharge EN 61000-4-2 (VDE 0847 Part 4-2) 8 kV air dischargeBurst Interference EN 61000-4-4 (VDE 0847 Part 4-4) 1 kV power cables, 0.5 kV controlNote:The MICROMASTER, MICROMASTER Vector and MIDIMASTER Vector units are intended exclusively for professionalapplications. Therefore, they do not fall within the scope of the harmonics emissions specification EN 61000-3-2.Compliance Table (MM & MMV):Model No.EMC ClassMM12 - MM300, MMV12 - MMV300 Class 2MM12/2 - MM400/2, MMV12/2 - MMV400/2 Class 1MM12/2 - MM400/2, MMV12/2 - MMV400/2 with external filter (see table) 1 phase input only Class 2*MM37/3 - MM750/3, MMV37/3 - MMV750/3 Class 1MM37/3 - MM750/3, MMV37/3 - MMV750/3 with external filter (see selection table) Class 2*Compliance Table (MDV):Model No.EMC ClassMDV550/2 - MDV4500/2 Class 1MDV750/3 - MDV7500/3 with class A external filter (see table) Class 2*MDV750/3 - MDV3700/3 with class B external filter (see table) Class 3MDV750/4 - MDV3700/4 Class 1* If the installation of the inverter reduces the radio frequency field emissions (e.g. by installation in a steel enclosure), Class 3radiated emission limits will typically be met.Siemens DA 64 – 1998/99 (04/99) 3/15

Technical InformationMICROMASTERMICROMASTER VectorMIDIMASTER VectorFilter Part Numbers and Standards:Inverter Model No. Class A Filter Part No. Class B Filter Part No. StandardMM12 - MM300Built-in EN 55011 / EN 55022MMV12 - MMV300MM12/2 - MM25/26SE3290-0BA87-0FB0 EN 55011 / EN 55022MMV12/2 - MMV25/2MM37/2 - MM75/26SE3290-0BA87-0FB2 EN 55011 / EN 55022MMV37/2 - MMV75/2MM110/2 - MM150/26SE3290-0BB87-0FB4 EN 55011 / EN 55022MMV110/2 - MMV150/2MM220/2 - MM300/26SE3290-0BC87-0FB4 EN 55011 / EN 55022MMV220/2 - MMV300/2MM37/3 - MM150/36SE3290-0DA87- 0FA1 6SE3290-0DA87-0FB1 EN 55011 / EN 55022MMV37/3 - MMV150/3MM220/3 - MM300/36SE3290-0DB87- 0FA3 6SE3290-0DB87-0FB3 EN 55011 / EN 55022MMV220/3 - MMV300/3MM400/3 - MM750/36SE3290-0DC87- 0FA4 6SE3290-0DC87-0FB4 EN 55011 / EN 55022MMV400/3 - MMV750/3MDV550/2 6SE3290-0DG87- 0FA5 6SE2100-1FC20 EN 55011 / EN 55022MDV750/2 6SE3290-0DH87- 0FA5 6SE2100-1FC20 EN 55011 / EN 55022MDV1100/2 - MDV1850/2 6SE3290-0DJ87- 0FA6 6SE2100-1FC21 EN 55011 / EN 55022MDV2200/2 6SE3290-0DJ87- 0FA6 EN 55011 / EN 55022MDV3000/2 - MDV4500/2 6SE3290-0DK87- 0FA7 EN 55011 / EN 55022MDV 750/3 - MDV1100/3 6SE3290-0DG87- 0FA5 6SE2100-1FC20 EN 55011 / EN 55022MDV1500/3 - MDV1850/3 6SE3290-0DH87- 0FA5 6SE2100-1FC20 EN 55011 / EN 55022MDV2200/3 - MDV3700/3 6SE3290-0DJ87- 0FA6 6SE2100-1FC21 EN 55011 / EN 55022MDV4500/3 - MDV7500/3 6SE3290-0DK87- 0FA7 EN 55011 / EN 55022Note:Maximum mains supply voltage when filters are fitted is 460 V for MIDIMASTER Vector and 480 V for MICROMASTER /MICROMASTER Vector.It is not permissible to use radio interference suppression filters and filters to reduce cable-borne noise when the inverter isconnected to un-earthed supplies.3/16 Siemens DA 64 – 1998/99 (04/99)

MICROMASTERMICROMASTER VectorMIDIMASTER VectorTechnical Information3.11 EMC Footprint Filters for MICROMASTER and MICROMASTER VectorMains PowerInputControl CableFootprint FilterMetal Back-plateUse suitable flat earth braid(6SE3290-0XX87-8FK0)Fix motor and control cablescreens securely to metal backplate using suitable metal clips.Figure 3.11.1:Wiring guidelines to minimise effects of EMI - MICROMASTER and MICROMASTER Vector Frame Size AMains PowerInputFootprint FilterMetal Back-plateControlCableFix motor and control cablescreen securely to metal backplate using suitable metal clips.Figure 3.11.2:Wiring guidelines to minimise effects of EMI - MICROMASTER and MICROMASTER Vector Frame Size BSiemens DA 64 – 1998/99 (04/99) 3/17

Technical InformationMICROMASTERMICROMASTER VectorMIDIMASTER VectorFootprint FilterMains PowerInputMetal Back-plateFix motor and control cablescreen securely to metal backplate using suitable metal clips.Figure 3.11.3 Wiring guidelines to minimise effects of EMI - MICROMASTER and MICROMASTER Vector Frame Size CThe inverters are designed to operate in an industrial environmentwhere a high level of Electro-Magnetic Interference (EMI) can beexpected. Usually, good installation practices will ensure safe andtrouble-free operation. If problems are encountered, the followingguidelines may prove useful. In particular, grounding of the system atthe inverter, as described below, may prove effective.(1) Ensure that all equipment in the cubicle is well earthedusing short, thick earthing cable connected to a commonstar point or busbar. It is particularly important that anycontrol equipment that is connected to the inverter (suchas a PLC) is connected to the same earth or star point asthe inverter via a short, thick link. Flat conductors (e.g.braids or metal brackets) are preferred as they have lowerimpedance at high frequencies.The return earth from motors controlled by the invertershould be connected directly to the earth connection (PE)on the associated inverter.(2) On the MIDIMASTER Vector, use saw-tooth washerswhen mounting the inverter and ensure that a goodelectrical connection is made between the heatsinkand the panel, removing paint if necessary.(3) Wherever possible, use screened leads forconnections to the control circuitry. Terminate theends of the cable neatly, ensuring that unscreenedwires are as short as possible. Use cable glandswhenever possible.(4) Separate the control cables from the power connections asmuch as possible, using separate trunking, etc. If controland power cables cross, arrange the cables so that theycross at 90° if possible.(5) Ensure that contactors in the cubicle are suppressed, eitherwith R-C suppressors for AC contactors or ‘flywheel’ diodesfor DC contactors, fitted to the coils. Varistor suppressors arealso effective. This is particularly important if the contactorsare controlled from the relay on the inverter.(6) Use screened or armoured cables for the motorconnections and ground the screen at both ends viathe cable glands.(7) If the drive is to be operated in an Electro-magnetic noisesensitiveenvironment, the RFI filter should be used toreduce the conducted and radiated interference from theinverter. For optimum performance, there should be a goodconductive bond between filter and metal mounting plate.(8) If a line EMC filter and commutating reactors aresimultaneously used, then the line EMC filter must belocated between the drive converter and commutatingreactor (line choke).3/18 Siemens DA 64 – 1998/99 (04/99)

MICROMASTERMICROMASTER VectorMIDIMASTER VectorTechnical InformationMICROMASTER AND MICROMASTER Vector - Footprint filter dimensions6SE3290-0BA87-0FB0, 6SE3290-0BA87-0FB2174Terminal 2.5mm 2Rated Torque of screw 0.7 NmRating Label4 x Fixing holes∅ 4.8mm160 ± 0.4Nema 1 Gland plate fixings.M4 (thread depth max. 5mm)Earth Stud, M4Rated Torque 1.5 Nmgn / yeInverter mounting holesM4 (thread depth max. 5mm)187 ± 0.5200litz wire AWG16-Style 1015fork crimpstud size 3.5mminside wire crimp diameter 2.3mmView A6SE3290-0DA87-0FA1,6SE3290-0DA87-0FB174Terminal 2.5mm 2Rated Torque of screw 0.7 NmRating Label4 x Fixing holes∅ 4.8mm160 ± 0.4Nema 1 Gland plate fixings.M4 (thread depth max. 5mm)Earth Stud, M4Rated Torque 1.5 NmInverter mounting holesM4 (thread depth max. 5mm)litz wire AWG16-Style 1015fork crimpstud size 3.5mminside wire crimp diameter 2.3mmView ASiemens DA 64 – 1998/99 (04/99) 3/19

Technical InformationMICROMASTERMICROMASTER VectorMIDIMASTER Vector6SE3290-0BB87-0FB4Terminal 4 mm 2Rated Torque of screw 1.5 NmRating Label4 x Fixing holes∅ 4.8mmInverter mounting holes x 4M4 (thread depth max. 5mm)Tightening Torque 1.5Nm max.ReducerPg16 - Pg9Cable Gland Pg9Earth Stud, M4Rated Torque 1.5 NmFork crimpStud size 3.5mmInside wire crimp diameter 3.4mmHexagonal flat nut Pg16Rated torque 7.0 NmLitz wire AWG12 - Style 10156SE3290-0DB87-0FA3, 6SE3290-0DB87-0FB3Terminal 2.5 mm 2Rated Torque of screw 0.7 NmRating Label4 x Fixing holes∅ 4.8mmInverter mounting holes x 4M4 (thread depth max. 5mm)Tightening Torque 1.5Nm max.ReducerPg16 - Pg9Earth Stud, M4Rated Torque 1.5 NmFork crimpStud size 3.5mmInside wire crimp diameter 2.3mmCable Gland Pg9Hexagonal flat nut Pg16Rated torque 7.0 NmLitz wire AWG12 - Style 10153/20 Siemens DA 64 – 1998/99 (04/99)

MICROMASTERMICROMASTER VectorMIDIMASTER VectorTechnical Information6SE3290-0BC87-0FB4Terminal 4 mm 2Rated Torque of screw 1.5 NmRating Label4 x Fixing holes∅ 5.8mmEarth Stud, M4Rated Torque 1.5 NmInverter mounting holes x 4M5 (thread depth max. 5mm)Tightening Torque 3.0NmReducerPg16 - Pg9Fork crimpStud size 3.5mmInside wire crimp diameter 3.4mmCable Gland Pg9Hexagonal flat nut Pg16Rated torque 7.0 NmLitz wire AWG12 - Style 10156SE3290-0DC87-0FA4, 6SE3290-0DC87-0FB4Terminal 4 mm 2Rated Torque of screw 1.5 NmRating Label4 x Fixing holes∅ 5.8mmEarth Stud, M4Rated Torque 1.5 NmInverter mounting holes x 4M5 (thread depth max. 5mm)Tightening Torque 3.0NmReducerPg16 - Pg9Fork crimpStud size 3.5mmInside wire crimp diameter 3.4mmCable Gland Pg9Hexagonal flat nut Pg16Rated torque 7.0 Nm Litz wire AWG12 - Style 1015Siemens DA 64 – 1998/99 (04/99) 3/21

Technical InformationMICROMASTERMICROMASTER VectorMIDIMASTER Vector6SE3290-0DG87-0FA53/22 Siemens DA 64 – 1998/99 (04/99)

MICROMASTERMICROMASTER VectorMIDIMASTER VectorTechnical Selection Information6SE3290-0DH87-0FA5Siemens DA 64 – 1998/99 (04/99) 3/23

Technical InformationMICROMASTERMICROMASTER VectorMIDIMASTER Vector6SE3290-0DJ87-0FA63/24 Siemens DA 64 – 1998/99 (04/99)

MICROMASTERMICROMASTER VectorMIDIMASTER VectorTechnical Selection Information6SE3290-0DK87-0FA7Siemens DA 64 – 1998/99 (04/99) 3/25

Technical InformationMICROMASTERMICROMASTER VectorMIDIMASTER Vector6SE2100-1FC20 Class B EMC Input Filtermax.91M6 connecting boltsmax. 281max. 2311156.6DA64-5005max.125.8Labeling210mmconnecting terminalsL1L2L3PESupplyLoadL1L2L3PE140max.1566SE2100-1FC21 Class B EMC Input Filtermax.141M10 connecting boltsmax. 409max. 33182.5 82.56.6DA64-5004Labelingmax.141225mmconnecting terminalsL1L2L3PESupplyLoadL1L2L3PE155max.1713/26 Siemens DA 64 – 1998/99 (04/99)

MICROMASTERMICROMASTER VectorMIDIMASTER VectorTechnical Information3.12 dV/dt Output Filters(MASTER DRIVES series)Frame Size EdV/dt Output Filters Frame Sizes B and Cd HcD1)bfa 1)WdH cefba1)WDdV/dt Output Filter Frame Size: E&SOutput dV/dt Filters - Dimensions and WeightsFilter Frame Size B C EH [mm] 425 600 1050W [mm] 135 180 250D [mm] 350 350 350a [mm] 67.5 90 45 1 )b [mm] 16 16 10c [mm] 100 100 350d [mm] 250 250 400f [mm] 425 600 1025Weight approx. [kg] 20 27 55B: 6SE7016-2FB87-1FD06SE7021-5FB87-1FD0C: 6SE7022-2FC87-1FD06SE7023-4FC87-1FD06SE7024-7FC87-1FD0E: 6SE7026-0HE87-1FD06SE7028-2HE87-1FD01) 2 lugs, left and rightFor further details see DA65.10Siemens DA 64 – 1998/99 (04/99) 3/27

Technical InformationMICROMASTERMICROMASTER VectorMIDIMASTER Vector3.13 Input chokes4EP three-phase line reactorsI Ln ≤ 35,5 ADimensionsWith terminals,for any arrangement of the reactorn4n2l1he1nn3d3d1d2d11)n2n4l2n1n3b1n 3 and n 4 mounting holes acc. to EN 60852-4n 1 and n 2 mounting holes acc. to DIN 41308Three-phase input chokeTypeb 1max.mmd 1mmd 2mmd 3mmemax.mmhmax.mml 1max.mml 2max.mmn 1±IT12mmn 2±IT12mmn 3±IT12mmn 4±IT12mm4EP32 57.5 4.8 9 M4 56 108 78 88.5 34 1) 42.5 79.54EP33 64 4.8 9 M4 55 122 96 124 33 1) 44 1124EP34 73 4.8 9 M4 59 122 96 124 42 1) 53 1124EP35 68 4.8 9 M4 57 139 120 148 39 90 48 1364EP36 78 4.8 9 M4 62 139 120 148 49 90 58 1364EP37 73 5.8 11 M5 60 159 150 178 49 113 53 1664EP38 88 5.8 11 M5 67 159 150 178 64 113 68 1664EP39 99 7 13 M6 62 181 182 219 56 136 69 2014EP40 119 7 13 M6 72 181 182 219 76 136 89 201Retaining slot at the centre of the footTerminal 8WA9200 (for I Ln ≤ 15 A) Cross-sections: Solid 0.5 mm² to 6.0 mm²Stranded 1.5 mm² to 4.0 mm²Terminal RKW 110 or TRKSD 10 Cross-sections: Solid 1.0 mm² to 16.0 mm²(for I Ln 16 A to 35.5 A) Stranded 1.0 mm² to 10.0 mm²3/28 Siemens DA 64 – 1998/99 (04/99)

MICROMASTERMICROMASTER VectorMIDIMASTER VectorTechnical Information4EP three-phase line reactorsI LN 36 A to 50 ADimensionsWith terminals,for any arrangement of the reactorn4n21nn3d3d1l1d2ehn 3 and n 4 mounting holes acc. to EN 60852-4n 1 and n 2 mounting holes acc. to DIN 41308n2n4l2n1n3b1b 1 d 1 d 2 d 3 e h l 1 l 2 n 1 n 2 n 3 n 4Three-phase input choke max. max. max. max. max. ±IT12 ±IT12 ±IT12 ±IT12mm mm mm mm mm mm mm mm mm mm mm mmType4EP38 88 5.8 11 M5 86 193 150 178 64 113 68 1664EP39 99 7 13 M6 91.5 220 182 219 56 136 69 2014EP40 119 7 13 M6 101.5 220 182 219 76 136 89 201Terminal 8WA1304 (for I Ln 40 A to 50 A) Cross-sections: Solid 1.0 mm² to 16.0 mm²Stranded 10.0 mm² to 25.0 mm²Stranded 2.5 mm 2 to 16.0 mm 2Associated grounding terminal, EK 16/35 Solid 2.5 mm² to 16.0 mm²Stranded 4.0 mm² to 16.0 mm²Siemens DA 64 – 1998/99 (04/99) 3/29

Technical InformationMICROMASTERMICROMASTER VectorMIDIMASTER Vector4EP three-phase line reactorsI Ln ≥ 51 ADimensionsWith terminals,for any arrangement of the reactorn4n2l1he1nnd1 d2n2n1n4 n3l2b 1n 3 and n 4 mounting holes acc. to EN 60852-4n 1 and n 2 mounting holes acc. to DIN 41308b 1 d 1 d 2 d 3 e h l 1 l 2 n 1 n 2 n 3 n 4Three-phase line reactor max. max. max. max. max. ±IT12 ±IT12 ±IT12 ±IT12mm mm mm mm mm mm mm mm mm mm mm mmType4EP38 88 5.8 11 M5 76 153 150 178 64 113 68 1664EP39 99 7 13 M6 73 179 182 219 56 136 69 2014EP40 119 7 13 M6 83 179 182 219 76 136 89 201Flat connectora 1 a 2 a 3 a 4 a 5Rated current I LnA mm mm mm mm mma551 to 80 30 20 3 10 981 to 200 35 25 5 12.5 11aa 143d3a2a33/30 Siemens DA 64 – 1998/99 (04/99)

MICROMASTERMICROMASTER VectorMIDIMASTER VectorTechnical Information4EU three-phase line reactorsDimensionsWith flat connectors,for mounting the reactor on horizontal surfacesl 4el 1hd 3n 4n 2n 2l 2n 1b 1Mounting holesThree-phase mains chokeTypeb 1max.mmd 1mmd 2mmd 3mmemax.mmHmax.mml 1max.mml 2max.mml 4max.mmn 1± IT12mmn 2± IT12mm124EU24 104 7 13 M6 80 220 219 206 196 70 176 M64EU25 128 7 13 M6 97 220 219 206 196 94 176 M64EU27 146 10 18 M8 114 250 255 235 280 101 200 M64EU30 155 10 18 M8 116 280 285 264 310 118 224 M64EU36 169 10 18 M8 180 335 345 314 360 138 264 M64EU39 174 12 18 M10 197 385 405 366 410 141 316 M64EU43 194 15 22 M12 212 435 458 416 460 155 356 M64EU45 221 15 22 M12 211 435 458 416 460 182 356 M64EU47 251 15 22 M12 231 435 458 416 460 212 356 M64EU50 195 12.5 12.5 M10 220 565 533 470 518 158 410 M124EU52 220 12.5 12.5 M10 242 565 533 470 518 183 410 M12Flat connector Rated current I Lna 1 a 2 a 3 a 4 a 5 a 6 a 7A mm Mm mm mm mm mm mma 545 to 80 30 20 3 10 9 - -81201316801totototo20031580010003540505025304040566812.515202011141414--------a 2a 4a 1a 3Siemens DA 64 – 1998/99 (04/99) 3/31

Technical InformationMICROMASTERMICROMASTER VectorMIDIMASTER Vector3.14 MICROMASTER Vector - BrakingResistors1 m 2-corescreened cablewith 6.3 mmfastonsThe braking resistors are for use with the MICROMASTERVector range of inverters. They enable high inertia loads to bedecelerated rapidly. During deceleration of the motor andload, excess energy is returned to the inverter and is stored inthe dc-link capacitors. This causes an increase in the dc-linkvoltage which, if too high, will trip the inverter. The inverterdissipates the excess energy to the externally-mountedbraking resistor.The resistor case is manufactured from extruded aluminiumto dissipate the heat generated during braking/deceleration.LDDepth1 m 2-corescreened cablewith 6.3 mmfastonsL1LDDepthL1W1W2W1WWFixing holes: 2 x 5.5 mmFixing holes: 4 x 5.5 mmThe resistors must be installed in a vertical position andsecured to a metal surface (> 0.5 m 2 area) using two/four M5screws. They are convection-cooled, so a free space of atleast 100 mm must be left above and below the componentsto allow an unimpeded air flow. The resistor must be mountedat least 50 mm from the side of the inverter to preventexcessive heating of the units.The thermal cut-out switch supplied with the braking resistorshould be installed directly onto the resistor body.ResistorOrder No.6SE3290-0CA87-2RA06SE3290-0CB87-2RA06SE3290-0CC87-2RA06SE3290-0DA87-2RA06SE3290-0DB87-2RA06SE3290-0DC87-2RA0ContinuousRatingPeak RatingResistance(Tol. ± 10%)Pk. volts Dimensions Weight InverterTypeW(5% dutycycle)W(Ω)DCVLmmL1mmWmmW1mmW2mmDmm kg40 800 200 200 190 57 28 - 54 1.3 MMV12 - MMV75MMV12/2 - MMV75/280 1600 100 450 280 271 57 28 - 54 1.7 MMV110 - MMV150MMV110/2 -MMV150/2200 4000 40 338 330 80 20 40 54 3.1 MMV220 - MMV300MMV220/2 -MMV400/280 1600 400 280 270 57 28 - 54 1.7 MMV37/3 -MMV150/3150 3000 200 900 280 271 83 23 40 54 2.5 MMV220/3 -MMV300/3400 7500 85 400 390 103 28 40 52 3.8 MMV400/3 -MMV750/3During braking, the inverter dissipates the braking energy of the motor and load to the externally mounted resistor. The lower thevalue of the external resistor the greater the braking power. The resistors are able to dissipate large amounts of energy for shortperiods but when used continuously, the rating is considerably less. To protect the resistor and the inverter from overload, theMICROMASTER Vector ‘chopper circuit’ (P070) limits the duty cycle (ratio of ‘time on’ to ‘time off’) to 5% (12 seconds in 4minutes). This reduces the maximum dissipation level of the resistor.The resistor must be adequately rated to withstand the resulting power dissipation.3/32 Siemens DA 64 – 1998/99 (04/99)

MICROMASTERMICROMASTER VectorMIDIMASTER VectorTechnical Information3.15 Electronic Braking Module (EBU) &Braking Resistors for MIDIMASTERVectorUsing the Electronic Brake Unit (EBU) and Brake Resistoroptions, the rotational kinetic energy of the motor and load isregenerated back into the inverter and is converted into heatwithin the external braking resistors, thus significantlyimproving the braking effect. The inverter DC link voltageincreases during this regenerative operation and its rise islimited by the EBU and the braking resistor.A reference voltage is established from the incoming mainsac supply. This is compared with the dc link voltage, derivedin the inverter. If the dc link voltage is excessively high (whichoccurs during regenerative braking) the power switch istriggered to reduce this voltage by dissipating energy to theexternal resistors. The continuous rated power of the brakingresistors is 10 % of their peak power. The minimumpermissible resistance value for maximum brake unit powerfor each EBU is specified in the tables below. The duty cycleof the power switch is limited to approximately 10% (typically5 seconds on, 45 seconds off) to protect the braking resistorsfrom excessive energy dissipation.The Electronic Brake Unit/s (EBU) should be mounted directlynext to the MIDIMASTER Vector unit, and connected to theinverter DC link and Braking Resistor using short-screenedfeeder cables.-+RES/WIDRES/WIDNCNOCDC-DC+}}To MIDIMASTERResistor connections}Fault circuit relay connections92197 250DToMIDIMASTERVector+-BABCDE104ACTerminal Rail X1 (see section 4.2)Cable entriesCable tiesInternal fuse 38 mm(100 mA time delay)ON/Fault LEDVOLTAGEREFERENCEANDCOMPARATORPOWER SWITCH CONTROLLERDUTYCYCLECONTROLPOWERSWITCHDRIVEREDepth: 146 mmFixing holes: 4 x 6.5 mm diameterWeight: 2.2 kgAll measurements in millimetres.RES/WIDRES/WIDPOWER SWITCHTRANSISTORNOEXTERNALRESISTORSANDTHERMALSWITCHPEL2L1Figure 1:}Mains power supplyTerminal Block Diagram of the ElectronicBrake Unit (EBU)ACINPUTL1L2POWERSUPPLYFigure 1: Block Diagram - Electronic Braking UnitFigure 2:FAULTMONITORLEDRELAYNote:NCCOMMON‘NO’ contact is closed when thesystem is OK; open for a ‘fault’.Block Diagram of the Electronic BrakeUnit with External Brake ResistorEBU Technical SpecificationsAmbient temperature:0 to 40 o CStorage/transport temperature: -30 to +85 o CDegree of protection:IP20,External braking resistors: IP20Humidity (non-condensing): 0 to 95%Siemens DA 64 – 1998/99 (04/99) 3/33

Technical informationMICROMASTERMICROMASTER VectorMIDIMASTER VectorTotalResistorIntermittentRating100%Figure 3:Timing Diagram for the Electronic BrakeUnit50%Total ResistorContinuousRating10%5 10 1520 25 30 35 40 45Time (secs)Resistor Type A B D EDimensions560 x 185 x 150 560 x 365 x 150 560 x 365 x 150 495 x 425 x 300L x W x H (mm)MIDIMASTER Vector208 -240 208 - 240 380 - 500 380 - 500Mains Supply VoltageResistance (Ω) 20 10 40 20Pulse Power (kW) 7.5 15 15 30Average Power (kW) 1.25 2.5 2.5 5Part Number(MLFB)6SE3213-6SP87-0RA0 6SE3221-4SP87-0RA0 6SE3214-0TP87-0RA0 6SE3222-4TP87-0RA0During braking, the EBU dissipates the braking energy of the motor and load to the external power resistors. The lower the value ofthe external resistor the greater the braking power. The resistors can dissipate large amounts of energy for short periods but whenused continuously, their dissipation is considerably less. In order to protect the resistors from overload, the EBU limits its dutycycle (ratio of time on to time off) to 10%. This reduces the maximum dissipation level to that shown in Figure 3.InverterModelEBUMin. TotalResistanceValue perEBUΩAssociated Resistor DataRes.PeakInstantaneousrating(5 sec)kW20%DutyRatingCont.RatingType EBU Model Order No.Resistor Order No. ΩkW kW VMD(V)550/2to 6SE3190-0CX87-2DA0 10 6SE3213-6SP87-0RA0 20 7.5 5 1.25 380MDV4500/2 6SE3221-4SP87-0RA0 10 15 10 2.5 380MD(V)750/3to 6SE3190-0DX87-2DA0 20 6SE3214-0TP87-0RA0 40 15 10 2.5 950MDV7500/3 6SE3222-4TP87-0RA0 20 30 20 5 950MDV220/4toMD(V)3700/4For EBU availability for these inverters,contact your local Siemens sales office.Peak.voltsDCBraking ResistorsResistorTypeOrder NumberContinuous RatingPeak Inst.RatingResistance(Ohms)NoteskWkWΩA 6SE3213-6SP87-0RA0 1.25 7.5 20 Only for mains suppliesB 6SE3221-4SP87-0RA0 2.5 15 10 208 V - 240 VD 6SE3214-0TP87-0RA0 2.5 15 40 Only for mains suppliesE 6SE3222-4TP87-0RA0 5 30 20 380 V - 500 VIf the EBU is to be used with high inertia loads (or very short ramp-down times), additional resistors may be required to beconnected in parallel or several EBUs to be connected in parallel.3/34 Siemens DA 64 – 1998/99 (04/99)

MICROMASTERMICROMASTER VectorMIDIMASTER VectorTechnical InformationBraking Power for 208 - 240 V InvertersInverterInverterRatingBrakingPower(minimum)TypekWMDV550/2 5.5 MediumHighMDV750/2 7.5 MediumHighMDV1100/2 11 MediumHighMDV1500/2 15 LowMediumHighMDV1850/2 18.5 LowMediumHighMDV2200/2 22 LowMediumHighMDV3000/2 30 LowMediumHighMDV3700/2 37 LowMediumHighMDV4500/2 45 LowMediumHighPeakBrakingPowerkW7.5157.5157.5157.515307.515307.51530151530153045153060Total Numberof ExternalBraking UnitsRequired111111112112112112123124Total Numberof Resistors Required111111112112112112123124Type ofResistor/sABABABABBABBABBBBBBBBBBBSiemens DA 64 – 1998/99 (04/99) 3/35