English - Siegfried

English - Siegfried

English - Siegfried

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

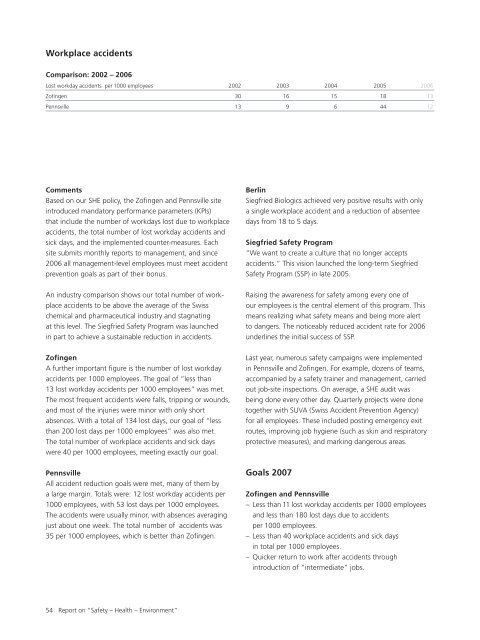

Workplace accidentsComparison: 2002 – 2006Lost workday accidents per 1000 employees 2002 2003 2004 2005 2006Zofingen 30 16 15 18 13Pennsville 13 9 6 44 12CommentsBased on our SHE policy, the Zofingen and Pennsville siteintroduced mandatory performance parameters (KPIs)that include the number of workdays lost due to workplaceaccidents, the total number of lost workday accidents andsick days, and the implemented counter-measures. Eachsite submits monthly reports to management, and since2006 all management-level employees must meet accidentprevention goals as part of their bonus.An industry comparison shows our total number of workplaceaccidents to be above the average of the Swisschemical and pharmaceutical industry and stagnatingat this level. The <strong>Siegfried</strong> Safety Program was launchedin part to achieve a sustainable reduction in accidents.ZofingenA further important figure is the number of lost workdayaccidents per 1000 employees. The goal of “less than13 lost workday accidents per 1000 employees” was met.The most frequent accidents were falls, tripping or wounds,and most of the injuries were minor with only shortabsences. With a total of 134 lost days, our goal of “lessthan 200 lost days per 1000 employees” was also met.The total number of workplace accidents and sick dayswere 40 per 1000 employees, meeting exactly our goal.PennsvilleAll accident reduction goals were met, many of them bya large margin. Totals were: 12 lost workday accidents per1000 employees, with 53 lost days per 1000 employees.The accidents were usually minor, with absences averagingjust about one week. The total number of accidents was35 per 1000 employees, which is better than Zofingen.Berlin<strong>Siegfried</strong> Biologics achieved very positive results with onlya single workplace accident and a reduction of absenteedays from 18 to 5 days.<strong>Siegfried</strong> Safety Program“We want to create a culture that no longer acceptsaccidents.” This vision launched the long-term <strong>Siegfried</strong>Safety Program (SSP) in late 2005.Raising the awareness for safety among every one ofour employees is the central element of this program. Thismeans realizing what safety means and being more alertto dangers. The noticeably reduced accident rate for 2006underlines the initial success of SSP.Last year, numerous safety campaigns were implementedin Pennsville and Zofingen. For example, dozens of teams,accompanied by a safety trainer and management, carriedout job-site inspections. On average, a SHE audit wasbeing done every other day. Quarterly projects were donetogether with SUVA (Swiss Accident Prevention Agency)for all employees. These included posting emergency exitroutes, improving job hygiene (such as skin and respiratoryprotective measures), and marking dangerous areas.Goals 2007Zofingen and Pennsville– Less than 11 lost workday accidents per 1000 employeesand less than 180 lost days due to accidentsper 1000 employees.– Less than 40 workplace accidents and sick daysin total per 1000 employees.– Quicker return to work after accidents throughintroduction of “intermediate” jobs.54 Report on “Safety – Health – Environment”