- Page 1: REGULATING PARTICLE MORPHOLOGY DURI

- Page 4 and 5: IIFür meinen Großvater

- Page 6 and 7: IVPetra Neubarth danke ich für die

- Page 8 and 9: VIParts of this thesis have already

- Page 10 and 11: IITABLE OF CONTENTS4 MATERIAL AND M

- Page 12 and 13: IVTABLE OF CONTENTS5.4 Lactate Dehy

- Page 14 and 15: VIABBREVIATIONSSmall lettersaacd pi

- Page 16 and 17: VIIIABBREVIATIONSSEMSFDSFLSLSSSAUVs

- Page 18 and 19: 2 INTRODUCTIONdrying (SFD) [Maa et

- Page 20 and 21: 4 INTRODUCTION TO SPRAY FREEZE‐DR

- Page 22 and 23: 6 INTRODUCTION TO SPRAY FREEZE‐DR

- Page 24 and 25: 8 INTRODUCTION TO SPRAY FREEZE‐DR

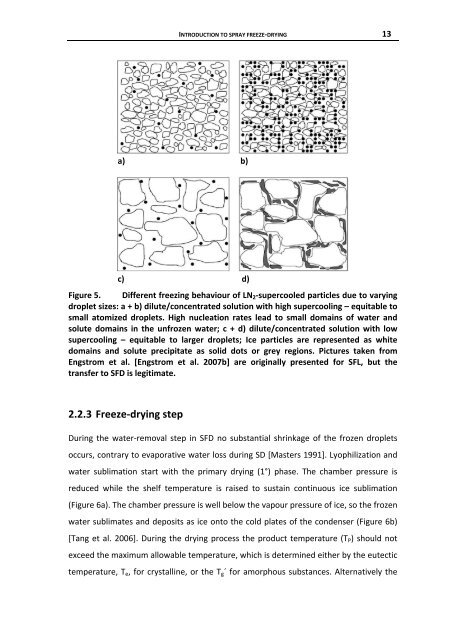

- Page 26 and 27: 10 INTRODUCTION TO SPRAY FREEZE‐D

- Page 30 and 31: 14 INTRODUCTION TO SPRAY FREEZE‐D

- Page 32 and 33: 16 INTRODUCTION TO SPRAY FREEZE‐D

- Page 34 and 35: 18 LIGHT‐SCATTERING3 Light‐scat

- Page 36 and 37: 20 LIGHT‐SCATTERINGWhen an electr

- Page 38 and 39: 22 LIGHT‐SCATTERINGThe dominant p

- Page 40 and 41: 24 LIGHT‐SCATTERING3.2.2 The spec

- Page 42 and 43: 26LIGHT‐SCATTERINGa)b)Figure 13.

- Page 44 and 45: 28 LIGHT‐SCATTERINGassure correct

- Page 46 and 47: 30 LIGHT‐SCATTERINGThe positions

- Page 48 and 49: 32LIGHT‐SCATTERING3.3.1Size exclu

- Page 50 and 51: 34 LIGHT‐SCATTERINGthe permeable

- Page 52 and 53: 36 MATERIAL AND METHODS4.1.1.1 Bovi

- Page 54 and 55: 38 MATERIAL AND METHODS[1983] defin

- Page 56 and 57: 40 MATERIAL AND METHODSthe molecule

- Page 58 and 59: 42MATERIAL AND METHODS4.2Methods4.2

- Page 60 and 61: 44 MATERIAL AND METHODS4.2.2 Spray

- Page 62 and 63: 46 MATERIAL AND METHODSupstream of

- Page 64 and 65: 48 MATERIAL AND METHODS348 nm at 25

- Page 66 and 67: 50 MATERIAL AND METHODSblank titrat

- Page 68 and 69: 52 MATERIAL AND METHODS50 mM trizma

- Page 70 and 71: 54 RESULTS AND DISCUSSIONAfter all

- Page 72 and 73: 56 RESULTS AND DISCUSSIONAs a small

- Page 74 and 75: 58 RESULTS AND DISCUSSIONWhen calcu

- Page 76 and 77: 60 RESULTS AND DISCUSSIONcalibratio

- Page 78 and 79:

62 RESULTS AND DISCUSSION5.1.3 UV

- Page 80 and 81:

64 RESULTS AND DISCUSSIONFigure 41.

- Page 82 and 83:

66 RESULTS AND DISCUSSIONAn advanta

- Page 84 and 85:

68 RESULTS AND DISCUSSION5.1.6 Dete

- Page 86 and 87:

70 RESULTS AND DISCUSSIONa)b)Figure

- Page 88 and 89:

72 RESULTS AND DISCUSSIONIn additio

- Page 90 and 91:

74 RESULTS AND DISCUSSIONa) b)Figur

- Page 92 and 93:

76 RESULTS AND DISCUSSION5.1.9 Solv

- Page 94 and 95:

78 RESULTS AND DISCUSSIONthat could

- Page 96 and 97:

80 RESULTS AND DISCUSSION5.1.10 Eva

- Page 98 and 99:

82 RESULTS AND DISCUSSION5.2 Bovine

- Page 100 and 101:

84 RESULTS AND DISCUSSIONFigure 57.

- Page 102 and 103:

486 RESULTS AND DISCUSSIONFigure 59

- Page 104 and 105:

88RESULTS AND DISCUSSIONFigure 62.

- Page 106 and 107:

90 RESULTS AND DISCUSSIONFigure 65.

- Page 108 and 109:

92 RESULTS AND DISCUSSIONa) b)Figur

- Page 110 and 111:

94 RESULTS AND DISCUSSION5.3 SFD/SD

- Page 112 and 113:

96 RESULTS AND DISCUSSIONactivity l

- Page 114 and 115:

98 RESULTS AND DISCUSSION[Maa and P

- Page 116 and 117:

100 RESULTS AND DISCUSSIONTo avoid

- Page 118 and 119:

102 RESULTS AND DISCUSSIONIn contra

- Page 120 and 121:

104RESULTS AND DISCUSSIONFigure 78.

- Page 122 and 123:

106 RESULTS AND DISCUSSIONFigure 80

- Page 124 and 125:

108 RESULTS AND DISCUSSIONDuring al

- Page 126 and 127:

110 RESULTS AND DISCUSSION(Table 21

- Page 128 and 129:

112 RESULTS AND DISCUSSIONa) b)500

- Page 130 and 131:

114 RESULTS AND DISCUSSIONFigure 88

- Page 132 and 133:

116 RESULTS AND DISCUSSIONof Sonner

- Page 134 and 135:

118 RESULTS AND DISCUSSION5.3.4 SFD

- Page 136 and 137:

120 RESULTS AND DISCUSSIONFigure 92

- Page 138 and 139:

122 RESULTS AND DISCUSSIONincreasin

- Page 140 and 141:

124 RESULTS AND DISCUSSIONa) b)20

- Page 142 and 143:

126 RESULTS AND DISCUSSIONLF of dif

- Page 144 and 145:

128 RESULTS AND DISCUSSIONa) b)200

- Page 146 and 147:

130 RESULTS AND DISCUSSIONFigure 10

- Page 148 and 149:

132 RESULTS AND DISCUSSIONmore than

- Page 150 and 151:

134 RESULTS AND DISCUSSIONNeverthel

- Page 152 and 153:

136 RESULTS AND DISCUSSIONMolar mas

- Page 154 and 155:

138 RESULTS AND DISCUSSIONa)b)500

- Page 156 and 157:

140 RESULTS AND DISCUSSIONFigure 11

- Page 158 and 159:

142 RESULTS AND DISCUSSION5.3.5.2 C

- Page 160 and 161:

144 RESULTS AND DISCUSSIONAF4 and S

- Page 162 and 163:

146 RESULTS AND DISCUSSIONa)b)Figur

- Page 164 and 165:

148 RESULTS AND DISCUSSIONFigure 11

- Page 166 and 167:

150 RESULTS AND DISCUSSIONUV‐meas

- Page 168 and 169:

152 RESULTS AND DISCUSSIONstable an

- Page 170 and 171:

154 RESULTS AND DISCUSSIONFigure 12

- Page 172 and 173:

156 RESULTS AND DISCUSSIONpartially

- Page 174 and 175:

158 RESULTS AND DISCUSSIONdrying ca

- Page 176 and 177:

160 RESULTS AND DISCUSSION5.5.2 Cha

- Page 178 and 179:

162 RESULTS AND DISCUSSIONSFD parti

- Page 180 and 181:

164 RESULTS AND DISCUSSIONsalt comp

- Page 182 and 183:

166 RESULTS AND DISCUSSIONadditiona

- Page 184 and 185:

168 RESULTS AND DISCUSSIONThe addit

- Page 186 and 187:

170 RESULTS AND DISCUSSIONwith Hg p

- Page 188 and 189:

172 RESULTS AND DISCUSSIONon their

- Page 190 and 191:

174 RESULTS AND DISCUSSIONA change

- Page 192 and 193:

176 CONCLUSIONSand an UV‐B lamp w

- Page 194 and 195:

178 CONCLUSIONSLactic dehydrogenase

- Page 196 and 197:

180 ZUSAMMENFASSUNGConducted modifi

- Page 198 and 199:

182 ZUSAMMENFASSUNGes beim Lösen h

- Page 200 and 201:

184 ZUSAMMENFASSUNGAggregation oder

- Page 202 and 203:

186 REFERENCES8 References[Adler 19

- Page 204 and 205:

188 REFERENCES[Carpenter et al. 199

- Page 206 and 207:

190 REFERENCES[Dawson et al. 1964]

- Page 208 and 209:

192 REFERENCESInternational Journal

- Page 210 and 211:

194 REFERENCES[Kok and Rudin 1981][

- Page 212 and 213:

196 REFERENCES[Masters 1991]Masters

- Page 214 and 215:

198 REFERENCES[Pikal et al. 1990][P

- Page 216 and 217:

200 REFERENCES[Serrien et al. 1992]

- Page 218 and 219:

202 REFERENCES[Wahlund and Caldwell

- Page 220 and 221:

204 REFERENCES[Wyatt 2006a] Wyatt,

- Page 222:

206 CURRICULUM VITAE9 Curriculum Vi