Heat-Tracing Systems for Hazardous Division 1 Locations

Heat-Tracing Systems for Hazardous Division 1 Locations

Heat-Tracing Systems for Hazardous Division 1 Locations

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

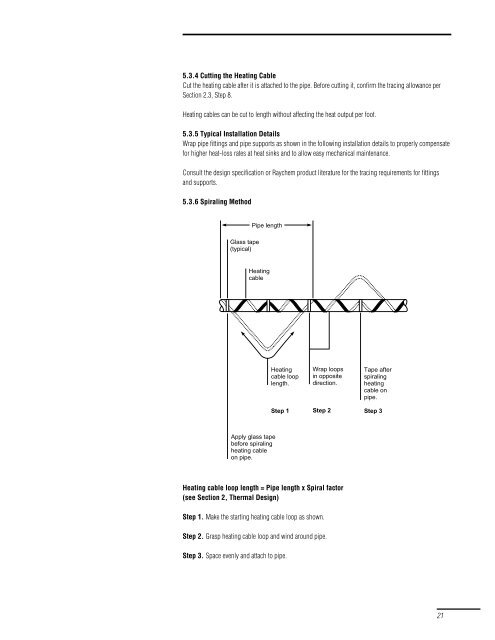

5.3.4 Cutting the <strong>Heat</strong>ing CableCut the heating cable after it is attached to the pipe. Be<strong>for</strong>e cutting it, confirm the tracing allowance perSection 2.3, Step 8.<strong>Heat</strong>ing cables can be cut to length without affecting the heat output per foot.5.3.5 Typical Installation DetailsWrap pipe fittings and pipe supports as shown in the following installation details to properly compensate<strong>for</strong> higher heat-loss rates at heat sinks and to allow easy mechanical maintenance.Consult the design specification or Raychem product literature <strong>for</strong> the tracing requirements <strong>for</strong> fittingsand supports.5.3.6 Spiraling MethodGlass tape(typical)Pipe length<strong>Heat</strong>ingcable<strong>Heat</strong>ingcable looplength.Step 1Wrap loopsin oppositedirection.Step 2Tape afterspiralingheatingcable onpipe.Step 3Apply glass tapebe<strong>for</strong>e spiralingheating cableon pipe.<strong>Heat</strong>ing cable loop length = Pipe length x Spiral factor(see Section 2, Thermal Design)Step 1. Make the starting heating cable loop as shown.Step 2. Grasp heating cable loop and wind around pipe.Step 3. Space evenly and attach to pipe.21